Technical Contents

Engineering Guide: Sheet Metal Products Inc

Engineering Insight Precision as the Non-Negotiable Foundation in Sheet Metal Fabrication

In the demanding realm of high-end sheet metal fabrication, precision transcends mere specification; it is the absolute cornerstone of functional integrity, assembly success, and long-term product reliability. For industries like aerospace, defense, medical technology, and advanced electronics, tolerances measured in thousandths of an inch directly dictate performance, safety, and lifecycle costs. A deviation of 0.1mm in a critical bracket can cascade into catastrophic assembly failures, compromised structural integrity, or electromagnetic interference in sensitive systems. Precision engineering ensures components fit seamlessly within complex assemblies, maintain required clearances for thermal expansion or movement, and consistently meet the stringent performance criteria demanded by end applications. It is not an optional premium but the fundamental requirement separating viable manufacturing from costly rework and field failures. The true measure of a fabrication partner lies not just in claiming precision, but in demonstrably achieving it under the most challenging conditions, consistently and verifiably.

Wuxi Lead Precision Machinery operates at this pinnacle of dimensional accuracy. Our engineering DNA is forged through direct involvement in projects where failure is not an option. We engineered and produced critical titanium components for the Beijing Winter Olympics infrastructure, demanding tolerances held to ±0.02mm under extreme environmental cycling. Similarly, our military-grade fabrication for radar housings and avionics enclosures adheres strictly to MIL-STD-810G vibration and thermal shock requirements, with geometric dimensioning and tolerancing (GD&T) rigorously maintained across complex multi-axis bends and weldments. This experience instills an uncompromising culture where every laser cut path, every press brake stroke, and every weld pass is executed with military-grade discipline. We understand that the cost of imprecision in your final product far exceeds the investment in achieving it correctly the first time.

Our commitment is quantifiable through advanced process control and metrology. The following specifications represent our standard operational capabilities for critical sheet metal processes, consistently validated across high-mix, low-volume production runs typical of engineered solutions:

| Capability | Specification | Application Impact |

|---|---|---|

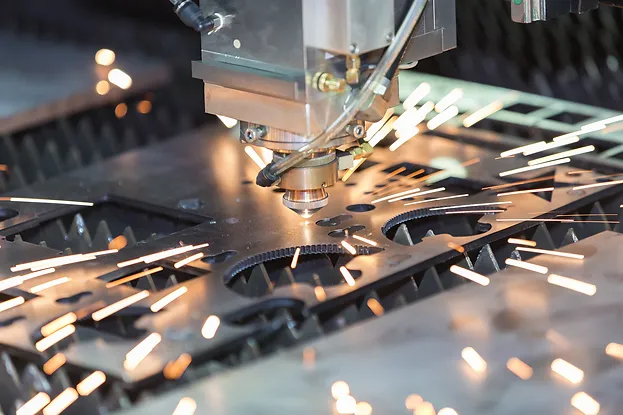

| Laser Cutting Accuracy | ±0.05 mm | Ensures perfect nesting, minimal kerf loss, critical feature alignment |

| CNC Bending Tolerance | ±0.1° angular / ±0.05 mm linear | Guarantees precise fit-up for welded assemblies and complex geometries |

| Forming Complexity | Up to 5 Axes Continuous | Enables single-setup production of intricate enclosures and brackets |

| Material Thickness Range | 0.5 mm – 6.0 mm Steel/SS/Al | Supports diverse structural and shielding requirements |

| In-Process Metrology | CMM, Vision Systems, Laser Trackers | Real-time verification against CAD models, full traceability |

Precision fabrication demands more than advanced machinery; it requires deep material science understanding, rigorous process validation, and an engineering mindset focused on the final application. At Wuxi Lead Precision Machinery, our Olympic and military heritage provides the proven framework to transform your most demanding sheet metal designs into reality, where every micron matters. Demand precision engineered, not merely promised.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities are engineered to meet the stringent demands of aerospace, medical, energy, and advanced automation sectors. At the core of our production floor is a fully integrated suite of 5-axis CNC machining centers, enabling complex geometries and tight-tolerance components from a single setup. This multi-axis capability significantly reduces part handling, minimizes cumulative error, and enhances repeatability across production runs.

Our 5-axis CNC systems are equipped with high-speed spindles, automated tool changers, and real-time adaptive control, ensuring optimal material removal rates and surface integrity across a range of metals including stainless steel, aluminum alloys, titanium, and specialty alloys. These machines support both prototyping and high-volume production, with dynamic work envelope management that accommodates large and intricate sheet metal assemblies. Advanced CAM programming ensures efficient toolpaths, minimizing cycle times while maintaining dimensional accuracy and edge quality.

Complementing our machining strength is a comprehensive quality assurance infrastructure anchored by Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMM systems provide full 3D metrology with sub-micron resolution, enabling complete first-article inspection reports (FAIR), production sampling, and process validation. All inspections are traceable to international standards (ISO 17025), and data is integrated into our digital quality management system for full part traceability and continuous process improvement.

In addition to CMM, we deploy laser scanning, optical comparators, and surface roughness testers to verify form, fit, and finish. Every component undergoes stage-specific quality checks—from raw material verification to final assembly—ensuring compliance with ASME Y14.5 and ISO 2768 standards. Our quality engineers work in parallel with production teams, enabling real-time corrections and reducing non-conformance rates to below 0.1%.

The following table outlines our standard and precision tolerance capabilities across key fabrication processes:

| Process | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| 5-Axis CNC Machining | ±0.025 mm | ±0.005 mm | Achieved with thermal compensation and in-process probing |

| Laser Cutting | ±0.1 mm | ±0.05 mm | For sheet thickness up to 25 mm |

| Press Brake Forming | ±0.2° angular | ±0.1° angular | With CNC-controlled backgauging |

| Hole Positioning | ±0.15 mm | ±0.08 mm | Relative to datum, per ISO 2768-mK |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achievable with fine finishing passes |

All technical workflows are supported by integrated CAD/CAM/CAQ systems, ensuring seamless data transfer from customer models to final inspection documentation. Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality protocols, and deep engineering expertise to deliver sheet metal components that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is critical for achieving performance, longevity, and cost efficiency in sheet metal components. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, environmental, and aesthetic demands. Below, we detail key considerations for aluminum, steel, and titanium, alongside anodizing as a premier finish solution.

Aluminum dominates aerospace, electronics, and automotive sectors due to its exceptional strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 offers balanced weldability and structural integrity, while 5052-H32 excels in marine environments. Its natural oxide layer provides baseline protection, but anodizing significantly enhances surface hardness and wear resistance—essential for precision enclosures or heat sinks.

Carbon and stainless steel remain indispensable for structural and high-stress applications. Mild steel (e.g., A36) delivers affordability and weldability for brackets or chassis, whereas stainless grades 304 and 316 provide superior corrosion resistance in medical or food-processing equipment. Note that 316’s molybdenum content combats pitting in chloride-rich settings. Steel’s higher density suits load-bearing components but requires coatings like powder painting for harsh environments.

Titanium, though premium-priced, is unmatched for extreme conditions. Grade 2 titanium offers excellent biocompatibility and resistance to acids, saltwater, and temperatures exceeding 600°F. It is ideal for aerospace actuators, chemical valves, or medical implants where failure is not an option. Its low thermal conductivity demands specialized CNC tooling—a capability we engineer into every Wuxi Lead production run.

Anodizing transforms aluminum surfaces through electrolytic passivation, creating a porous oxide layer that accepts dyes and sealants. Type II (sulfuric acid) anodizing achieves 15–25 µm thickness for standard durability, while Type III (hard coat) reaches 50+ µm for abrasion-heavy applications like hydraulic manifolds. This finish ensures dimensional stability—critical for tight-tolerance parts—without compromising conductivity when specified.

Comparative Material Specifications

| Material | Key Properties | Common Grades | Primary Applications |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, conductive | 6061-T6, 5052-H32 | Aerospace panels, heat sinks, enclosures |

| Stainless Steel | High strength, weldable, corrosion-resistant | 304, 316 | Medical devices, food processing, structural frames |

| Titanium | Extreme corrosion resistance, biocompatible, high-temperature stability | Grade 2, Grade 5 | Aerospace components, chemical valves, medical implants |

Material choice directly impacts fabrication complexity, tooling requirements, and lifecycle costs. Wuxi Lead Precision Machinery leverages 15+ years of CNC expertise to match your project’s exact needs—from prototyping to high-volume production. Our engineers provide material certification, DFMA analysis, and finish validation to ensure zero compromise on performance. Contact us for a tailored material recommendation backed by ISO 9001-certified manufacturing.

Manufacturing Process & QC

Design: Precision Engineering from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless sheet metal production begins with meticulous design engineering. Our process integrates client specifications with advanced 3D CAD modeling to ensure dimensional accuracy, structural integrity, and manufacturability. Engineers collaborate closely with clients to refine concepts, validate material selection, and optimize designs for performance and cost-efficiency. Using SolidWorks, AutoCAD, and PTC Creo, we simulate real-world conditions including thermal stress, load distribution, and assembly compatibility. This proactive approach eliminates design-related defects before physical production begins. All designs undergo internal DFM (Design for Manufacturability) reviews to confirm compliance with tight tolerance requirements and production scalability.

Prototyping: Validating Performance Before Scale

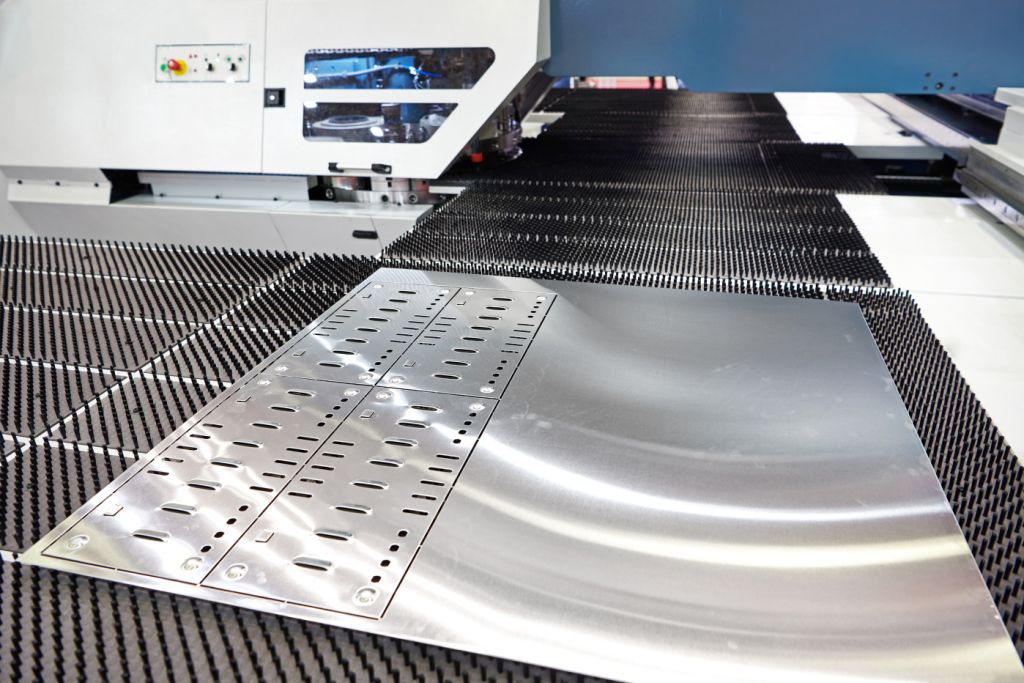

Once the design is finalized, Wuxi Lead initiates low-volume prototyping to verify functionality and precision. Utilizing laser cutting, CNC punching, and precision bending technologies, we produce functional prototypes that mirror final production quality. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to validate geometric dimensions and surface finish. Clients receive detailed inspection reports and sample units for field testing. This phase is critical for identifying potential assembly issues, material behavior under stress, or minor design deviations. Feedback is incorporated rapidly, ensuring the final design is fully optimized for mass production. Our prototyping cycle typically completes within 7–10 days, accelerating time-to-market without compromising quality.

Mass Production: Zero Defects Through Integrated Quality Control

With approved prototypes, Wuxi Lead transitions seamlessly into high-volume manufacturing. Our automated production lines integrate laser cutting, turret punching, robotic bending, and precision welding systems to maintain consistency across thousands of parts. The zero-defect philosophy is enforced through an embedded quality management system compliant with ISO 9001:2015. Every production batch is monitored in real time using SPC (Statistical Process Control), with inspections conducted at critical stages: raw material intake, post-cutting, post-forming, and final assembly. In-process checks ensure dimensional stability, while final products undergo 100% visual and functional inspection. Non-conforming parts are immediately quarantined and analyzed via root cause failure analysis (RCFA) to prevent recurrence.

Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Standard) | ±0.1 mm (critical features: ±0.05 mm) |

| Max Part Size | 3000 mm × 1500 mm |

| Surface Roughness (Ra) | ≤1.6 µm (machined areas) |

| Tooling Setup Time | < 2 hours (average) |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days (after prototype approval) |

| Quality Standard | ISO 9001:2015, First Article Inspection (FAI) |

Through seamless integration of design validation, rapid prototyping, and disciplined mass production, Wuxi Lead ensures every sheet metal component meets the highest standards of precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Excellence

In the demanding landscape of precision sheet metal fabrication, your choice of manufacturing partner directly impacts product integrity, time-to-market, and total cost of ownership. Wuxi Lead Precision Machinery stands as your strategic ally for mission-critical components where dimensional accuracy, material consistency, and process reliability are non-negotiable. We engineer solutions for global OEMs in aerospace, medical technology, and advanced industrial equipment—sectors where a single micron of deviation can cascade into system failure. Our vertically integrated facility in Wuxi, China, merges 18 years of deep-sheet metal expertise with Industry 4.0 automation, ensuring your designs transition from CAD model to certified production without compromise.

Our technical capabilities are engineered to exceed Tier-1 supplier standards. We deploy state-of-the-art Amada CNC punch presses, laser cutters, and robotic bending cells calibrated to maintain sub-0.05mm tolerances across high-mix production runs. Critical process parameters are monitored in real-time via integrated MES systems, eliminating variability in forming, welding, and finishing operations. The table below details our core production envelope for rapid feasibility assessment.

| Parameter | Capability Range | Application Impact |

|---|---|---|

| Tolerance | ±0.05mm to ±0.1mm | Precision assemblies for medical imaging |

| Material Thickness | 0.5mm to 6.0mm | Structural integrity in aerospace brackets |

| Max Part Size | 3000mm x 1500mm | Large-scale enclosures for energy systems |

| Materials | SS 304/316, AL 5052/6061, Cu, Ti | Corrosion-resistant marine components |

| Finishing | Anodizing, powder coating, passivation | EMI shielding compliance for defense systems |

Quality is not inspected but built into every process stage. Our ISO 9001 and IATF 16949-certified workflows include first-article inspection with Zeiss CMMs, in-process SPC tracking, and full material traceability from certified mills. Unlike commodity fabricators, we implement Design for Manufacturability (DFM) collaboration at the quotation phase—reducing your prototyping costs by up to 30% while optimizing tooling longevity. When your project demands zero-defect delivery under tight regulatory scrutiny, our documented change control protocols and 99.2% on-time shipment rate become your competitive advantage.

The volatility of global supply chains necessitates a partner who anticipates disruption. We mitigate risk through dual-sourced raw material channels, 120-day strategic inventory buffers for critical alloys, and agile reconfiguration of production cells for urgent ramp-ups. Our engineering team engages as an extension of your R&D department—providing GD&T validation, cost-reduction simulations, and rapid iteration for complex geometries that challenge conventional fabrication.

Do not let substandard sheet metal components undermine your product’s performance or reputation. Contact Wuxi Lead Precision Machinery today to initiate a technical consultation. Email [email protected] with your design specifications and volume requirements. Our applications engineers will respond within 4 business hours with a detailed DFM analysis and timeline-optimized production plan. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.