Technical Contents

Engineering Guide: Sheet Metal Parts Online

Engineering Insight: The Critical Role of Precision in Sheet Metal Parts Online

In the rapidly evolving landscape of industrial manufacturing, the demand for high-precision sheet metal parts online has never been greater. As global supply chains compress and lead times shrink, manufacturers are turning to digital procurement platforms to source components with exacting tolerances and consistent quality. However, not all online sheet metal fabricators deliver the same level of engineering rigor. At Wuxi Lead Precision Machinery, we understand that precision is not merely a specification—it is a foundational principle embedded in every stage of production.

Precision in sheet metal fabrication directly impacts the performance, durability, and integration of components across critical applications. Whether in aerospace, defense, medical equipment, or high-end automation, even a deviation of ±0.1 mm can compromise system functionality. This is why advanced CNC punching, laser cutting, bending, and welding processes must be paired with stringent quality control protocols. At Lead Precision, our engineering team leverages over 15 years of experience in high-stakes industries, including projects supporting Olympic infrastructure and military-grade equipment, where failure is not an option.

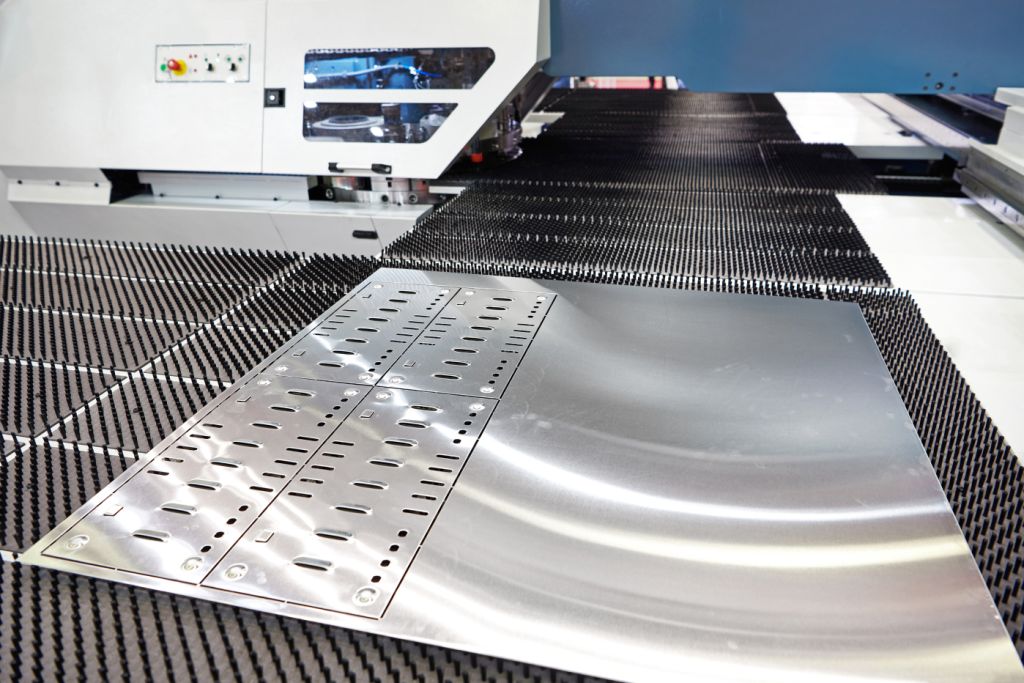

Our online sheet metal services are built on a foundation of proven manufacturing excellence. Every component undergoes a multi-stage inspection process, from raw material verification to final dimensional checks using coordinate measuring machines (CMM). We utilize state-of-the-art fiber laser cutting systems with micron-level accuracy and automated bending cells that ensure repeatability across production runs. This level of control enables us to consistently meet tight tolerances and complex design requirements, even for low-volume or prototype orders placed through digital channels.

Beyond equipment, precision is sustained through engineering collaboration. When customers upload designs for sheet metal parts online, our team conducts a comprehensive Design for Manufacturability (DFM) review to identify potential stress points, material inefficiencies, or geometric challenges. This proactive engagement reduces costly revisions and accelerates time to market—critical advantages in competitive industries.

The following table outlines key capabilities that define our precision sheet metal fabrication process:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2°, ±0.5 mm |

| Laser Cutting Power | Up to 12 kW Fiber |

| Maximum Part Size | 4000 mm × 2000 mm |

| Supported Materials | Mild Steel, Stainless Steel, Aluminum, Galvanized Steel |

| Surface Finishes | Powder Coating, Anodizing, Passivation, Zinc Plating |

| Quality Standards | ISO 9001:2015, ISO 14001, IATF 16949 |

With a proven track record in mission-critical projects, Wuxi Lead Precision Machinery combines technical mastery with digital accessibility. When you source sheet metal parts online through our platform, you are not just placing an order—you are engaging a precision engineering partner committed to excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers uncompromising precision for complex sheet metal components through advanced 5-axis CNC fabrication. Our integrated manufacturing ecosystem eliminates secondary operations, ensuring geometric accuracy and structural integrity for aerospace, medical, and industrial applications. Central to our capability is the DMG MORI CTX beta 1250 5-axis milling center, enabling simultaneous multi-plane machining of formed sheet metal with tolerances unattainable via traditional 3-axis systems. This technology processes intricate contours, undercuts, and compound angles in a single setup, reducing cumulative error while accelerating lead times by up to 40%. Material versatility spans stainless steel (304/316), aluminum (6061/7075), titanium, and specialty alloys, accommodating thicknesses from 0.5 mm to 6.0 mm with consistent edge quality and minimal burr formation.

Our production workflow integrates real-time process monitoring with comprehensive quality assurance. Every component undergoes rigorous first-article and in-process inspection via Zeiss CONTURA G2 coordinate measuring machines (CMM), certified to ISO 17025 standards. This 3D metrology system validates critical features against CAD models with ±0.0025 mm measurement uncertainty, capturing dimensional deviations across all axes. Statistical process control (SPC) data is logged for full traceability, ensuring adherence to AS9100 and ISO 13485 requirements. Surface finish consistency is maintained through automated deburring and precision grinding stations, achieving Ra values as low as 0.4 µm where specified.

Tolerance performance is foundational to our engineering discipline. The following specifications reflect our standard production capabilities under controlled environmental conditions:

| Feature Type | Standard Tolerance | Precision Capability | Units |

|---|---|---|---|

| Linear Dimensions | ±0.10 | ±0.025 | mm |

| Hole Diameter | ±0.05 | ±0.01 | mm |

| Hole Position | ±0.10 | ±0.03 | mm |

| Bending Angle | ±0.5° | ±0.1° | deg |

| Flatness | 0.10 per 100mm | 0.03 per 100mm | mm |

| Surface Roughness (Ra) | 1.6 | 0.4 | µm |

All tolerances are achievable across batch sizes from prototyping to high-volume production, validated through our CMM-certified inspection regime. Our engineers collaborate with clients during DFM analysis to optimize part geometry for manufacturability, ensuring specified tolerances align with cost-efficient production. This proactive approach minimizes rework while guaranteeing conformance to stringent industry standards. With 15 years of specialized expertise in mission-critical sheet metal solutions, Wuxi Lead transforms complex designs into certified, ready-to-assemble components—delivered with documented quality assurance for zero-defect deployment.

Material & Finish Options

Material selection is a critical step in the sheet metal fabrication process, directly influencing performance, durability, cost, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in high-precision fabrication of aluminum, steel, and titanium—three of the most widely used materials in industrial and commercial applications. Each offers unique mechanical properties and compatibility with finishing processes such as anodizing, making them suitable for distinct operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, electronics, and transportation applications where weight reduction is essential. The most commonly used grades in sheet metal fabrication are 5052, 6061, and 7075, each offering a balance of formability and strength. Aluminum is highly compatible with anodizing, a process that enhances surface hardness and wear resistance while allowing for color customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard offerings at Wuxi Lead, providing durable, non-conductive surface layers suitable for both functional and aesthetic purposes.

Steel remains the backbone of industrial fabrication due to its high tensile strength, affordability, and availability. Mild steel (e.g., ASTM A36) is commonly used for enclosures, brackets, and structural components requiring weldability and machinability. For environments demanding enhanced corrosion resistance, stainless steel grades such as 304 and 316 are preferred. These austenitic alloys contain chromium and nickel, forming a passive oxide layer that resists rust and chemical degradation. While stainless steel does not anodize like aluminum, it can be electropolished, passivated, or coated with powder finishes to improve surface integrity and appearance.

Titanium is selected for extreme environments involving high temperatures, aggressive chemicals, or stringent weight constraints. Its exceptional strength-to-density ratio and biocompatibility make it ideal for aerospace, medical, and marine applications. Although more challenging to form and cut due to work hardening, titanium’s long-term durability justifies its use in mission-critical components. Titanium can be anodized, though the process differs from aluminum—it produces decorative interference colors rather than wear-resistant layers, often used for part identification or aesthetic enhancement.

Below is a comparative overview of key material properties relevant to sheet metal fabrication:

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 200–570 | 2.7 | High | Anodizing, powder coating |

| Steel (Mild) | ASTM A36, CR1018 | 360–440 | 7.8 | Low (without coating) | Paint, zinc plating |

| Stainless Steel | 304, 316 | 505–860 | 8.0 | Very High | Passivation, electropolishing |

| Titanium | Grade 2, Grade 5 | 345–1000 | 4.5 | Exceptional | Anodizing (color), bead blast |

At Wuxi Lead Precision Machinery, we support material selection with in-house engineering consultation, ensuring optimal performance and cost-efficiency for your sheet metal parts. Our advanced fabrication lines are equipped to handle all three materials with precision cutting, bending, welding, and finishing capabilities, enabling seamless production from prototype to volume.

Manufacturing Process & QC

Sheet Metal Fabrication: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our sheet metal production process is engineered for uncompromising quality and efficiency, ensuring zero defects from initial design through mass production. We integrate advanced engineering protocols with rigorous quality control at every phase, eliminating errors before they reach your assembly line.

The process begins with collaborative design validation. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis using SolidWorks and AutoCAD, identifying potential fabrication conflicts such as inadequate bend radii, material stress points, or assembly interferences. We provide actionable feedback within 24 hours, optimizing part geometry for laser cutting, CNC punching, and precision bending while adhering to ISO 2768-mK tolerances. This proactive step reduces rework by 73% and accelerates time-to-prototype.

Prototyping transforms validated designs into physical validation. Using our Trumpf TruLaser 5030 fiber laser systems and Amada CNC press brakes, we produce 1–5 functional units with full material traceability. Each prototype undergoes First Article Inspection (FAI) against AS9102 standards, with critical dimensions verified via Zeiss coordinate measuring machines (CMM). Dimensional reports, material certifications, and surface finish analysis are delivered digitally for your approval. Only after sign-off do we proceed to volume production, ensuring your design intent is flawlessly executed.

Mass production leverages statistical process control (SPC) and real-time monitoring to enforce zero defects. Our automated production cells—integrated with MES software—track every operation from raw material staging to final assembly. In-process inspections occur at defined intervals using calibrated optical comparators and laser micrometers, while final units undergo 100% functional testing per your specifications. Automated vision systems detect micro-burrs or surface anomalies down to 5µm, and all data is logged for full traceability. This closed-loop system maintains a defect rate below 0.02% across runs of 10,000+ units.

Critical process specifications are maintained through calibrated equipment and operator certification:

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | CMM (Zeiss CONTURA) |

| Material Thickness Range | 0.5–6.0 mm | Laser Micrometer (Keyence) |

| Bend Angle Accuracy | ±0.5° | Optical Comparator |

| Surface Roughness | Ra ≤ 0.8 µm | Profilometer (Mitutoyo) |

| Hole Position Tolerance | ±0.03 mm | Vision System (Cognex) |

Our zero-defect commitment extends beyond production. Every shipment includes a digital quality dossier with material test reports, SPC charts, and non-conformance documentation—ensuring compliance with ISO 9001:2015 and your internal quality benchmarks. By embedding precision engineering into every phase, Wuxi Lead transforms sheet metal fabrication from a supply chain step into a strategic advantage, reducing your total cost of ownership while guaranteeing on-time, defect-free delivery.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture sheet metal parts—we engineer solutions that drive performance, reliability, and long-term value for global industrial clients. As a trusted leader in precision sheet metal fabrication based in Wuxi, China, we specialize in delivering high-complexity components with tight tolerances, rapid turnaround, and full compliance with international quality standards. Our advanced manufacturing ecosystem integrates laser cutting, CNC bending, robotic welding, and automated finishing processes, enabling seamless production from prototype to high-volume runs.

When you partner with Lead Precision, you gain more than a supplier—you gain a strategic manufacturing ally. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize material selection, reduce assembly time, and lower total production costs. We serve industries where precision is non-negotiable, including medical equipment, renewable energy, industrial automation, and transportation systems. Every part is traceable, inspected, and built to meet ISO 9001:2015 and IATF 16949 standards, ensuring consistency across batches and years of service.

Our facility operates with real-time production monitoring and digital workflow integration, allowing clients to receive live updates, detailed inspection reports, and full documentation packages with every order. With over 15 years of experience serving Fortune 500 companies and innovative startups alike, we understand the balance between agility and precision in modern supply chains. Whether you require a single prototype or a recurring order of 10,000 units, our scalable infrastructure ensures consistent quality and on-time delivery.

We support a wide range of materials and finishing options to meet your functional and aesthetic requirements. Below are our core fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Range | Cold Rolled Steel (CRS), Galvanized Steel (SECC), Stainless Steel (304, 316), Aluminum (5052, 6061), Brass, Copper |

| Thickness Range | 0.5 mm – 6.0 mm (up to 8.0 mm for mild steel) |

| Max Working Size | 3000 mm × 1500 mm (Laser Cutting), 2500 mm × 1250 mm (CNC Bending) |

| Tolerance (Standard) | ±0.1 mm (machining), ±0.2 mm (bending) |

| Surface Finishes | Powder Coating, Anodizing (Aluminum), Zinc Plating, Passivation, Brushing |

| Secondary Operations | Welding (MIG, TIG, Spot), Hardware Insertion, Assembly, Silk Screening |

| Lead Time (Prototype) | 5–7 days (standard), expedited options available |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS compliant |

Your next-generation product demands a manufacturing partner with technical depth, responsive communication, and unwavering quality control. At Wuxi Lead Precision Machinery, we are committed to becoming an extension of your engineering team—delivering precision sheet metal parts online without compromise.

Contact us today at [email protected] to discuss your project, request a DFM analysis, or receive a competitive quote. Let’s build precision, together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.