Technical Contents

Engineering Guide: Sheet Metal Panel Fabrication

Engineering Insight: Precision in Sheet Metal Panel Fabrication

In high-end manufacturing, sheet metal panel fabrication is far more than a process—it is an engineering discipline where precision defines performance, reliability, and longevity. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise structural integrity, assembly compatibility, and end-product functionality. This is especially critical in sectors such as aerospace, defense, medical equipment, and advanced industrial systems, where our panels are routinely deployed.

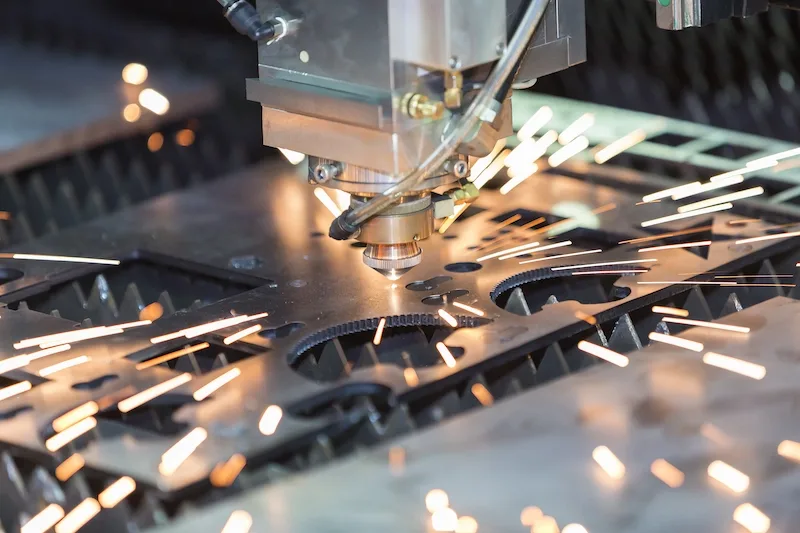

Precision in sheet metal fabrication begins with material selection and extends through every stage: laser cutting, bending, welding, surface treatment, and final inspection. Each operation demands tight tolerances, advanced tooling, and real-time quality control. For instance, laser cutting accuracy ensures clean edges and exact hole placement, while CNC press brakes achieve consistent bend angles within ±0.2 degrees. At Lead Precision, our integrated manufacturing cells are calibrated daily, and our processes are governed by ISO 9001-certified quality systems, ensuring repeatability across batches of any size.

Our experience fabricating panels for Olympic-standard sports infrastructure and mission-critical military applications has reinforced the non-negotiable nature of precision. In these environments, panels must withstand extreme mechanical stress, environmental exposure, and rigorous safety audits. A single misaligned mounting point or inconsistent weld could lead to cascading system failures. Our engineering team employs finite element analysis (FEA) and 3D metrology to simulate load behavior and validate dimensional accuracy before any component leaves the facility.

Beyond machinery, precision is sustained through expertise. Our engineers average over 12 years of hands-on experience in metal forming and assembly integration. This depth of knowledge allows us to anticipate challenges such as spring-back in high-strength alloys or thermal distortion during welding—issues that automated systems alone cannot resolve.

We also recognize that precision must be measurable and transparent. Below is a representative specification table reflecting the capabilities we deliver on standard production runs.

| Specification | Capability | Notes |

|---|---|---|

| Material Thickness Range | 0.5 – 6.0 mm | Cold-rolled steel, stainless steel, aluminum |

| Laser Cutting Tolerance | ±0.1 mm | Up to 4 kW fiber laser, kerf optimized |

| Bending Tolerance | ±0.2°, ±0.1 mm | CNC press brakes with automatic angle correction |

| Hole Position Accuracy | ±0.15 mm | Multi-hit forming and punch-laser combo |

| Surface Flatness | ≤0.3 mm per 1000 mm | Stress-relieved and roller leveled |

| Welding Standards | ISO 15614-1, AWS D1.1 | TIG, MIG, spot welding with post-weld machining |

| Coating Options | Powder coating, anodizing, zinc plating | Adhesion tested per ASTM D3359 |

At Wuxi Lead Precision Machinery, precision is not a claim—it is a documented outcome. Our panels are engineered to integrate seamlessly into complex assemblies, meeting the exacting demands of global OEMs. When performance cannot be compromised, our fabrication standards ensure confidence at every level.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication at Scale

Wuxi Lead Precision Machinery delivers uncompromising accuracy and repeatability in sheet metal panel fabrication, engineered for mission-critical industrial applications. Our integrated manufacturing ecosystem centers on advanced 5-axis CNC machining technology, specifically configured for complex sheet metal geometries. This capability transcends conventional 3-axis limitations, enabling the production of intricate 3D forms, compound angles, and precise cutouts within a single setup. The elimination of secondary operations significantly reduces cumulative error potential, part handling, and lead times while ensuring superior dimensional integrity across the entire component. Material utilization is optimized through intelligent nesting routines, minimizing waste without sacrificing structural requirements or surface finish quality. All machining processes are governed by rigorously validated programs, developed using industry-leading CAD/CAM software and executed on state-of-the-art equipment maintained to stringent OEM specifications.

Quality assurance is non-negotiable. Every critical dimension and geometric feature undergoes comprehensive verification via our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM). This metrology-grade system provides traceable, NIST-calibrated measurements with sub-0.02mm repeatability, validating conformance to even the most demanding engineering drawings. Our certified metrologists perform full First Article Inspections (FAI) per AS9102 standards and implement statistical process control (SPC) on high-volume runs, ensuring consistent output throughout production. This proactive inspection regime identifies and corrects potential deviations at the source, guaranteeing that every panel meets the specified tolerance stack-up requirements for seamless integration into final assemblies.

Achievable precision is fundamentally supported by our controlled process parameters and material science expertise. The following table details our standard guaranteed tolerance capabilities for common sheet metal fabrication processes, applicable to materials including stainless steel, aluminum alloys, and mild steel within specified thickness ranges. These values represent our baseline performance under optimal conditions; tighter tolerances are achievable through specialized process refinement upon engineering review.

| Parameter | Standard Tolerance | Conditions |

|---|---|---|

| Material Thickness Range | 0.5mm – 6.0mm | Steel, Stainless Steel, Aluminum Alloys |

| Bending Angle | ±0.5° | For bends > 3x material thickness |

| Bend Position (Linear) | ±0.10mm | Measured from defined datum |

| Hole Position (to Datum) | ±0.05mm | Holes > Ø3mm; within 100mm of primary datum |

| Hole Position (Relative) | ±0.10mm | Between features within same panel |

| Overall Panel Flatness | 0.10mm per 300mm | Measured on unclamped state |

| Edge Condition (Burrs) | < 0.05mm | Deburred edges per customer specification |

This level of dimensional control directly translates to reduced assembly scrap, faster time-to-market, and enhanced product reliability for our clients. Wuxi Lead’s technical capabilities are not merely specifications; they are the foundation of trust we build with global engineering teams requiring flawless sheet metal components for aerospace, medical, semiconductor, and advanced automation systems. We partner with your design and quality engineers to ensure manufacturability and exceed performance expectations.

Material & Finish Options

Material Selection in Sheet Metal Panel Fabrication

Selecting the appropriate material for sheet metal panel fabrication is critical to ensuring performance, durability, and cost-efficiency in high-end industrial applications. At Wuxi Lead Precision Machinery, we prioritize material integrity and process compatibility to deliver precision-engineered components tailored to client specifications. The most widely used materials in our fabrication processes are aluminum, steel, and titanium—each offering distinct mechanical, thermal, and chemical properties suited to specific operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, electronics enclosures, and transportation applications where weight reduction is essential. Grade 6061-T6 is commonly selected for structural components due to its weldability and moderate strength, while 5052-H32 is preferred in marine environments for superior corrosion resistance. Aluminum’s natural oxide layer provides inherent protection, but for enhanced surface durability and aesthetics, anodizing is frequently applied.

Steel remains the backbone of industrial sheet metal fabrication due to its high tensile strength, affordability, and versatility. Mild steel (A36) is widely used in general-purpose enclosures and chassis, while stainless steel grades such as 304 and 316 offer superior corrosion and heat resistance, making them suitable for food processing, medical equipment, and outdoor installations. Stainless steel requires no additional coating for corrosion protection, though surface finishes such as brushing or polishing are often applied for aesthetic and hygienic purposes.

Titanium, though more expensive and challenging to machine, is indispensable in extreme environments. Its exceptional strength-to-density ratio, resistance to high temperatures, and immunity to chloride-induced corrosion make it ideal for aerospace, defense, and chemical processing applications. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are the most commonly fabricated titanium alloys, with the latter offering enhanced strength through heat treatment.

Surface Finishing: The Role of Anodizing

Anodizing is a key electrochemical finishing process used primarily on aluminum components. It thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paint or primers. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, available in clear or dyed colors. Type III, or hardcoat anodizing, produces a thicker, harder surface suitable for high-wear industrial parts. Anodized finishes are non-conductive, which must be considered in electrical applications.

Material selection must account for environmental exposure, mechanical loads, thermal conditions, and lifecycle requirements. At Wuxi Lead Precision Machinery, our engineering team collaborates with clients to match material and finish choices with functional demands, ensuring optimal performance and longevity.

| Material | Common Grades | Tensile Strength (MPa) | Key Properties | Typical Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 290–320 | Lightweight, corrosion-resistant, conductive | Aerospace, electronics, transport |

| Steel | A36, 304, 316 | 400–700 | High strength, durable, cost-effective | Industrial enclosures, machinery |

| Titanium | Grade 2, Grade 5 | 345–900 | High strength-to-weight, heat-resistant | Aerospace, medical, defense |

Manufacturing Process & QC

Sheet Metal Panel Fabrication: Precision Production Process from Design to Zero Defects

At Wuxi Lead Precision Machinery, our sheet metal panel fabrication process is engineered for uncompromising quality and efficiency. We integrate advanced engineering with rigorous quality control across three critical phases: Design, Prototyping, and Mass Production. This structured approach ensures zero defects while optimizing cost and lead time for high-volume industrial applications.

The Design phase begins with collaborative engineering using 3D CAD/CAM software to validate manufacturability. Our team conducts comprehensive Design for Manufacturability (DFM) analysis, focusing on material utilization, bend sequencing, and tooling compatibility. Finite Element Analysis (FEA) simulates stress points and deformation risks, while laser-cut flat pattern nesting achieves 95% material yield. This phase eliminates 80% of potential defects before metal touches machinery, ensuring designs align with our CNC press brakes, fiber laser cutters, and turret punch capabilities.

Prototyping transforms validated designs into physical first articles. We produce 1–5 units using the exact tooling and parameters planned for mass production. Each prototype undergoes full dimensional inspection via CMM (Coordinate Measuring Machine) against the original 3D model, with critical features measured to ±0.05 mm. Surface finish, burr levels, and assembly fit are verified through functional testing. This step confirms process stability and provides clients with tangible validation before committing to volume runs, reducing time-to-market by up to 30%.

Mass Production leverages our automated production cells with real-time statistical process control (SPC). CNC machines operate under closed-loop feedback systems, monitoring tonnage, angle consistency, and positional accuracy every 5 seconds. Automated optical inspection (AOI) scans 100% of parts for dimensional deviations, while in-process gauging checks critical features at 15-minute intervals. All data feeds into our centralized quality dashboard, triggering immediate process corrections if trends approach tolerance limits. This system sustains Cp/Cpk values above 1.67, ensuring zero-defect delivery across runs from 100 to 100,000+ units.

Key Production Specifications

| Parameter | Capability Range | Quality Standard | Inspection Frequency |

|————————-|——————————|————————|———————-|

| Material Thickness | 0.5 mm – 6.0 mm | ISO 9001 | Per batch |

| Dimensional Tolerance | ±0.05 mm (critical features) | ISO 2768-mK | 100% via AOI |

| Bend Angle Accuracy | ±0.5° | DIN 6930 | Continuous SPC |

| Surface Roughness | Ra ≤ 1.6 μm (laser cut) | ISO 1302 | Random sampling |

| Hole Position Tolerance | ±0.1 mm | ASME Y14.5 | Per 50 parts |

Our end-to-end process guarantees that every sheet metal panel meets exacting aerospace, medical, and industrial equipment standards. By embedding zero-defect discipline from design through delivery, Wuxi Lead eliminates rework costs and supply chain disruptions—delivering precision you can measure, not just promise. Partner with us to transform your sheet metal requirements into flawless, high-volume reality.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Sheet Metal Panel Fabrication

When precision, scalability, and reliability define your manufacturing success, partnering with a trusted expert in sheet metal panel fabrication becomes a strategic imperative. At Wuxi Lead Precision Machinery, we specialize in delivering high-end, custom-engineered sheet metal solutions that meet the exacting demands of industries ranging from industrial equipment and automation to energy infrastructure and advanced electronics. Our vertically integrated manufacturing capabilities, combined with decades of engineering excellence, position us as a preferred partner for global OEMs and tier-one suppliers.

Our advanced production floor is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding systems, enabling us to produce complex sheet metal panels with tolerances as tight as ±0.05 mm. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing model ensures rapid turnaround without compromising quality. Every component undergoes rigorous in-process inspection and final QA checks, supported by our ISO 9001-certified quality management system.

We understand that every client brings unique technical and logistical challenges. That’s why we adopt a collaborative engineering approach—our team works closely with your design and procurement departments from concept to delivery, offering design for manufacturability (DFM) feedback, material optimization, and assembly integration support. This proactive engagement reduces time-to-market, lowers total cost of ownership, and enhances product performance.

Our facility in Wuxi, China, is strategically positioned to serve global supply chains with seamless logistics, export compliance, and on-time delivery performance exceeding 98%. We support a wide range of materials, including cold-rolled steel, stainless steel, aluminum, and specialty alloys, with surface treatments such as powder coating, anodizing, plating, and passivation to meet environmental and aesthetic requirements.

Below are key technical capabilities that define our sheet metal fabrication services:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Max. Processing Size | 3000 mm × 1500 mm |

| Laser Cutting Accuracy | ±0.05 mm |

| Punching Tolerance | ±0.1 mm |

| Bending Tolerance | ±0.2° |

| Welding Processes | MIG, TIG, Spot, Robotic Welding |

| Finishing Options | Powder Coating, Anodizing, Zinc Plating, Passivation |

| Quality Standards | ISO 9001:2015, RoHS Compliant |

Choosing the right manufacturing partner is more than a procurement decision—it’s a commitment to operational excellence. At Wuxi Lead Precision Machinery, we are committed to being an extension of your engineering team, ensuring every sheet metal panel we produce reflects your brand’s standards for quality and innovation.

Contact us today at [email protected] to discuss your next project. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.