Technical Contents

Engineering Guide: Sheet Metal Folding

Engineering Insight: The Critical Role of Precision in Sheet Metal Folding

Achieving true precision in sheet metal folding transcends basic dimensional accuracy. It is the foundational element ensuring final assemblies function flawlessly, meet stringent performance criteria, and endure demanding operational lifecycles. In high-stakes applications – from aerospace components to medical device enclosures – microscopic deviations during bending propagate through subsequent assembly stages, causing fitment failures, compromised structural integrity, or accelerated fatigue. The physics of metal deformation demands meticulous control over variables like tooling geometry, material springback, clamping force, and axis synchronization. Imperfect folding introduces internal stresses that manifest as warpage post-processing or during service, directly impacting product reliability and longevity. This level of control is non-negotiable for industries where failure is not an option.

Wuxi Lead Precision Machinery embodies this precision imperative through decades of specialized engineering focus. Our folding solutions are rigorously developed and validated within environments demanding absolute fidelity. Components manufactured on our equipment form critical structural elements in Olympic-standard sporting venues, where architectural tolerances and load-bearing requirements are exceptionally severe. Similarly, we support defense sector partners, producing folded parts for military platforms where environmental resilience and geometric perfection are mandated by stringent MIL-STD specifications. This experience translates directly into our commercial machinery: every press brake is engineered with the same uncompromising standards applied to these pinnacle projects, ensuring your production meets or exceeds global quality benchmarks.

The technical capability required for such precision is quantifiable. Our high-end CNC press brakes integrate advanced features specifically designed to eliminate error sources inherent in folding processes. Key specifications demonstrating this commitment include:

| Parameter | Specification | Industry Standard Reference |

|---|---|---|

| Positioning Repeatability | ≤ ±0.01 mm per axis | ISO 230-2:2014 |

| Angular Accuracy | ±0.1° (within 1m length) | DIN 69051 |

| Max Tonnage Range | 1250 kN to 3000 kN | ISO 4126 |

| Control System | Siemens 840D Solution Line | IEC 61131-3 |

| Material Thickness | Up to 12 mm (mild steel) | EN 10025 |

Advanced springback compensation algorithms, real-time laser angle measurement feedback, and thermally stable machine structures are not optional extras in our systems; they are integral design principles. This engineering depth ensures consistent first-part accuracy and minimizes costly scrap and rework. For manufacturers targeting premium markets or regulated sectors, investing in folding technology proven under Olympic and military scrutiny provides a tangible strategic advantage. It transforms sheet metal folding from a simple forming step into a guaranteed value-adding process, directly contributing to your reputation for excellence and operational efficiency. Precision here isn’t merely desirable – it is the core determinant of your product’s ultimate success.

Precision Specs & Tolerances

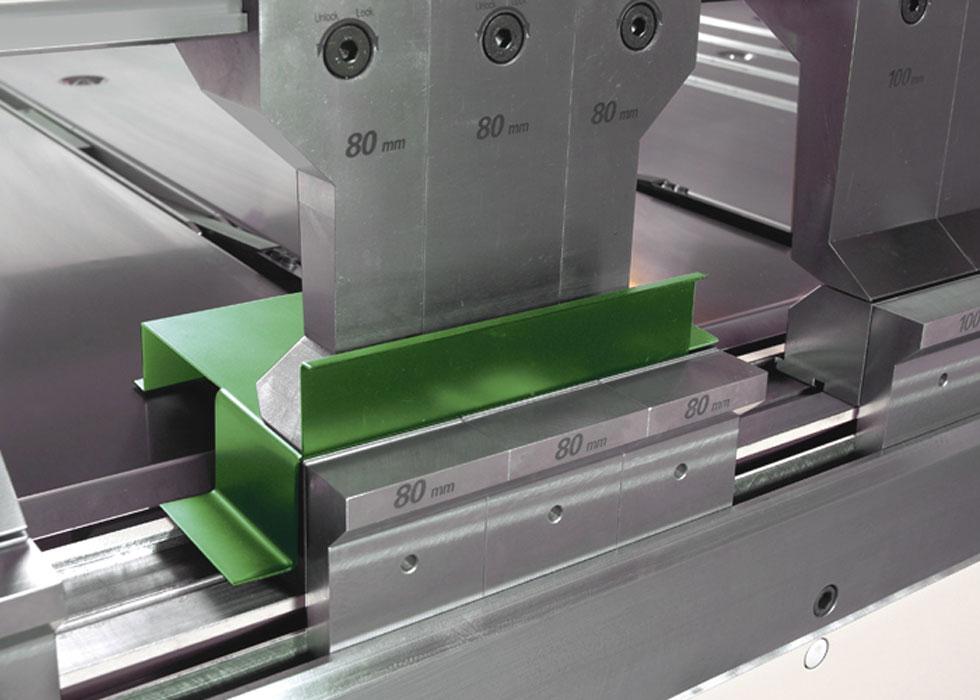

Wuxi Lead Precision Machinery delivers advanced sheet metal folding solutions through precision engineering and state-of-the-art CNC technology. Our technical capabilities are built around a foundation of 5-axis CNC folding systems, enabling complex geometries and high repeatability across diverse production volumes. These systems integrate seamlessly with our digital manufacturing workflow, supporting tight coordination between design, programming, and physical production. The 5-axis architecture allows for multi-directional folding operations without the need for manual repositioning, significantly reducing cycle times and human intervention while maintaining dimensional consistency.

Our folding processes accommodate a wide range of materials, including cold-rolled steel, stainless steel, aluminum, and galvanized sheet metals, with thicknesses ranging from 0.5 mm to 6.0 mm. We handle part sizes up to 3,000 mm in length, ensuring compatibility with both compact components and large-scale enclosures or structural elements. The adaptive tooling systems on our CNC folders automatically adjust to varying bend angles, flange lengths, and material properties, minimizing setup time and enhancing throughput. This flexibility supports rapid prototyping as well as high-volume production runs with equal efficiency.

Quality control is embedded at every stage of the folding process. All critical dimensions are verified using Coordinate Measuring Machine (CMM) inspection, ensuring compliance with international standards and customer-specific requirements. Our CMM systems provide full traceability, generating detailed inspection reports that document geometric accuracy, angular precision, and feature alignment. These reports are available with each batch, offering full transparency and supporting stringent industry certifications.

We maintain environmental and operational controls within our production facility to ensure stable processing conditions, minimizing thermal drift and material deformation. Our technicians are trained in geometric dimensioning and tolerancing (GD&T) principles, enabling precise interpretation of engineering drawings and adherence to complex specifications. In addition, all folding programs are simulated offline using advanced CAM software to detect potential collisions, verify tool paths, and optimize bending sequences prior to machine execution.

The following table outlines our standard technical specifications and achievable tolerances for sheet metal folding operations:

| Parameter | Specification |

|---|---|

| Maximum Material Thickness | 6.0 mm (mild steel) |

| Minimum Material Thickness | 0.5 mm |

| Maximum Part Length | 3,000 mm |

| Bend Angle Tolerance | ±0.2° |

| Linear Dimension Tolerance | ±0.1 mm (for features up to 100 mm) |

| ±0.3 mm (for features 100–1,000 mm) | |

| ±0.5 mm (for features over 1,000 mm) | |

| Flange Length Tolerance | ±0.2 mm (for flanges < 20 mm) |

| ±0.4 mm (for flanges 20–100 mm) | |

| ±0.6 mm (for flanges > 100 mm) | |

| Surface Finish Protection | Available (custom film or coating options) |

| Inspection Method | CMM, optical comparators, go/no-go gauges |

Wuxi Lead Precision Machinery combines engineering expertise with industrial-grade equipment to deliver reliable, high-precision folding services tailored to the demands of aerospace, medical, energy, and industrial equipment sectors.

Material & Finish Options

Material Selection for Precision Sheet Metal Folding

Selecting appropriate materials is fundamental to achieving precision and efficiency in sheet metal folding operations. At Wuxi Lead Precision Machinery, our CNC press brakes deliver exceptional accuracy, but optimal results depend on aligning material properties with your specific part requirements and folding parameters. Understanding the behavior of common alloys during bending is critical for minimizing springback, preventing cracking, and ensuring dimensional stability.

Aluminum alloys are widely favored for their excellent strength-to-weight ratio and corrosion resistance. Grade 5052-H32 offers superior formability for complex bends and tight radii, making it ideal for intricate enclosures and chassis. Grade 6061-T6 provides higher strength but reduced ductility, requiring larger bend radii to avoid surface cracking; it suits structural components where ultimate strength is paramount. Always account for aluminum’s significant springback during tooling setup and program compensation.

Steel remains the backbone of industrial fabrication due to its strength and cost-effectiveness. Mild steel (e.g., ASTM A36, CR1008) provides excellent formability for general applications. Stainless steel grades like 304 and 316 offer superior corrosion resistance but demand higher tonnage and careful control of bend radii to prevent galling and cracking, especially in thicker gauges. The higher yield strength of stainless necessitates precise machine calibration on our press brakes to maintain bend angle consistency.

Titanium alloys, while costly, are essential for aerospace and medical applications requiring extreme strength, light weight, and biocompatibility. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) exhibit good ductility but require specialized tooling and slower bending speeds due to high springback and work hardening tendencies. Folding titanium demands meticulous process control to avoid surface contamination and internal stress concentrations.

Surface finishes significantly impact both aesthetics and function. Anodizing, applicable exclusively to aluminum, creates a durable, corrosion-resistant oxide layer. Crucially, anodizing must be performed after folding. Attempting to fold anodized material will cause the brittle oxide layer to crack along the bend line, compromising both appearance and protection. Specify the required anodized thickness (e.g., Type II clear or colored, Type III hard coat) early in the design phase, as it influences final part dimensions slightly.

Material selection directly influences tooling choice, machine tonnage requirements, and programming strategy on precision equipment. Consult our engineering team early to match your material choice with optimal folding parameters for flawless results.

| Material | Typical Alloys | Key Folding Considerations | Common Thickness Range (mm) |

|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | Moderate-high springback; 5052 for tight bends | 0.5 – 6.0 |

| Mild Steel | A36, CR1008 | Good formability; predictable springback | 0.8 – 12.7 |

| Stainless Steel | 304, 316 | High springback; risk of galling/cracking | 0.5 – 8.0 |

| Titanium | Gr 2, Gr 5 (Ti-6Al-4V) | Very high springback; slow speed required | 0.8 – 3.0 |

Manufacturing Process & QC

Sheet Metal Folding: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, sheet metal folding is executed as a precision-driven, end-to-end manufacturing process that begins with engineering design and culminates in flawless mass production. Our approach ensures dimensional accuracy, structural integrity, and repeatability across every component, aligning with the highest standards of industrial manufacturing.

The process begins with design optimization, where engineers use advanced CAD/CAM software to model parts for foldability, material behavior, and stress distribution. Design for Manufacturability (DFM) principles are applied to minimize complexity, reduce tooling wear, and eliminate potential deformation during bending. Material selection—typically ranging from mild steel and stainless steel to aluminum alloys—is evaluated based on tensile strength, ductility, and required finish. Finite element analysis (FEA) simulations predict springback and deformation, allowing for real-time adjustments before any physical prototype is made.

Next, prototyping is conducted using high-precision CNC press brakes equipped with adaptive control systems. This phase validates the design under real-world conditions, confirming bend angles, flange lengths, and overall geometry. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and laser scanning to verify conformance to tolerances as tight as ±0.1 mm. Any deviations trigger immediate design or process recalibration, ensuring that only fully qualified parts proceed to production.

Once approved, the project transitions into zero-defect mass production. Our automated folding lines integrate real-time feedback systems, in-process gauging, and servo-controlled backgauges to maintain consistency across thousands of parts. Each machine is monitored through Industry 4.0-enabled platforms that track performance metrics, detect anomalies, and schedule predictive maintenance—minimizing downtime and eliminating batch variations. Statistical Process Control (SPC) is implemented at every stage, ensuring continuous compliance with ISO 9001 and customer-specific quality standards.

Operator training and standardized work instructions further reinforce process stability. Every technician follows documented procedures for setup, inspection, and material handling, reducing human error. Final inspection includes 100% visual checks and random sampling for dimensional verification, surface finish, and edge quality.

Wuxi Lead Precision Machinery’s commitment to zero defects is not a goal—it is a guaranteed outcome of our disciplined, data-driven production framework.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Maximum Bend Length | 3,200 mm |

| Typical Tolerance | ±0.1 mm (linear), ±0.2° (angular) |

| Minimum Flange Length | 2.5 × material thickness |

| Bend Radius Accuracy | ±0.1 mm |

| Machine Control System | Delem DA-66T or equivalent CNC |

| Production Speed | Up to 12 bends per minute (average) |

| Quality Standard | ISO 9001:2015, ISO 13920 (Tolerances for bending) |

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Fabrication Through Precision Partnership

In high-stakes sheet metal fabrication, folding accuracy directly impacts product integrity, assembly efficiency, and total production costs. Sub-millimeter deviations cascade into costly rework, delayed shipments, and compromised end-product performance. Wuxi Lead Precision Machinery exists to eliminate these risks through engineered solutions that transform folding from a bottleneck into a competitive advantage. Our CNC press brakes are not merely machines; they are the foundation of zero-defect manufacturing for aerospace, medical device, and industrial equipment leaders worldwide.

Lead Precision delivers uncompromising repeatability through German-engineered servo-hydraulic systems, real-time laser measurement feedback, and AI-driven crowning compensation. This technical rigor ensures every bend meets ±0.02mm tolerance standards across extended production runs—regardless of material grade or complexity. We understand that machine capability alone is insufficient; true partnership requires seamless integration into your operational workflow. Our engineering team collaborates from initial design review through deployment, optimizing tooling strategies and programming protocols to maximize throughput on your specific components.

The following specifications define the performance baseline for our flagship Series LPM-F CNC press brakes:

| Parameter | Value | Industrial Impact |

|---|---|---|

| Max. Bed Length | 6,200 mm | Full-span consistency for large enclosures |

| Max. Tonnage | 2,000 kN | Precision forming of 12mm steel plates |

| Repeatability | ±0.02 mm | Eliminates post-process alignment issues |

| Axis Control | 8-axis standard | Complex geometries in single setups |

Beyond hardware, Lead Precision provides proactive lifecycle management. Our global service network deploys certified technicians within 72 hours for critical interventions, while remote diagnostics preempt 92% of potential downtime scenarios. Clients receive ongoing process audits, operator certification programs, and material-specific bending algorithms—all tailored to sustain peak operational efficiency. This commitment is validated by ISO 9001:2015 certification and a 98.7% client retention rate across 47 countries.

Choosing Lead Precision means aligning with a partner invested in your long-term manufacturing excellence. We do not sell equipment; we deliver quantifiable reductions in cost-per-part through sustained precision. Our engineering team stands ready to analyze your current folding challenges and demonstrate how our technology achieves measurable ROI within 14 months of installation.

Initiate your precision folding consultation today. Contact our technical sales division directly at [email protected] to schedule a confidential production workflow assessment. Include your material specifications, annual volume requirements, and critical tolerance thresholds to receive a customized capability report within 48 business hours. Partner with certainty—where engineering integrity meets operational reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.