Technical Contents

Engineering Guide: Sheet Metal Fabrication Prototype

Engineering Insight: The Critical Role of Precision in Sheet Metal Fabrication Prototyping

In the realm of advanced manufacturing, the transition from concept to physical product begins with a single, pivotal step: prototyping. For sheet metal fabrication, this phase is not merely about creating a preliminary version of a component—it is about validating design integrity, ensuring functional performance, and de-risking full-scale production. At this stage, precision is not a luxury; it is a fundamental requirement. Even minor deviations in flat pattern layout, bend angles, or hole positioning can cascade into significant assembly failures, costly rework, or compromised product reliability.

At Wuxi Lead Precision Machinery, we approach sheet metal prototyping with the same rigor applied to final production runs. Our engineering team leverages state-of-the-art CNC punching, laser cutting, and press brake technologies to achieve tolerances as tight as ±0.05 mm. This level of accuracy ensures that prototypes mirror end-use parts in form, fit, and function—enabling clients to conduct meaningful testing, secure design approvals, and accelerate time-to-market with confidence.

Our commitment to precision is not theoretical. It has been tested and proven in high-stakes environments where failure is not an option. We have supported projects tied to Olympic infrastructure developments, where structural components demanded flawless dimensional consistency under extreme loads and environmental conditions. Similarly, our work with defense and military subcontractors has required adherence to strict quality protocols, including MIL-STD compliance and rigorous traceability standards. These experiences have honed our ability to manage complexity, maintain repeatability, and deliver prototypes that meet the most exacting engineering demands.

Beyond equipment and certifications, our engineering insight lies in proactive design for manufacturability (DFM). Before a single sheet is cut, our team collaborates with clients to assess material selection, grain direction, bend reliefs, and weld accessibility—factors that directly influence both prototype performance and scalability. This consultative approach minimizes iterations, reduces waste, and aligns the prototype phase seamlessly with future production strategies.

For industries such as aerospace, medical device manufacturing, and high-performance industrial equipment, the prototype is more than a model—it is a benchmark. At Wuxi Lead, we understand that every micron matters, and every bend radius carries engineering intent. Our mission is to transform designs into precision-engineered realities, ensuring that the first part is not just a prototype, but a promise of what’s to come.

Typical Prototype Fabrication Specifications at Wuxi Lead Precision Machinery

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 12 mm (steel, stainless, aluminum) |

| Cutting Tolerance | ±0.05 mm |

| Bend Angle Accuracy | ±0.5° |

| Hole Positioning Tolerance | ±0.1 mm |

| Minimum Bend Radius | 0.8x material thickness (varies by alloy) |

| Surface Finish Options | Deburred, anodized, powder-coated, passivated |

| Lead Time (Prototype Batch) | 5–10 working days (depending on complexity) |

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Prototyping

Wuxi Lead Precision Machinery delivers uncompromising accuracy for sheet metal fabrication prototypes through integrated 5-axis CNC technology. Our DMG MORI and TRUMPF systems handle complex geometries in a single setup, eliminating cumulative errors from multiple repositionings. This capability is critical for aerospace, medical, and robotics prototypes where angular features, compound curves, and tight internal radii demand sub-0.05mm positional fidelity. Material versatility spans stainless steel (304/316), aluminum (5052/6061), and specialty alloys up to 6mm thickness, with automated tool changers optimizing cycle times for low-volume prototype runs. Unlike conventional 3-axis systems, our 5-axis bending cells achieve undercuts and asymmetric flanges without secondary operations, preserving dimensional integrity across multi-stage forming sequences.

Quality assurance is anchored in Zeiss CONTURA CMM inspection, providing full-spectrum validation against CAD models. Every prototype undergoes first-article inspection with 100% critical feature reporting, including geometric dimensioning and tolerancing (GD&T) analysis per ASME Y14.5 standards. Our closed-loop process correlates CMM data directly to machine offsets, enabling real-time compensation for thermal drift or tool wear. Traceable calibration certificates accompany all inspection reports, meeting ISO 9001 and IATF 16949 requirements for regulated industries. This integrated metrology approach ensures prototypes function as true design validators, not just physical representations.

Tolerance execution is governed by rigorous process controls, as demonstrated in the achievable specifications below:

| Feature Type | Standard Tolerance | Precision Capability | Process Control Method |

|---|---|---|---|

| Linear Dimensions | ±0.1mm | ±0.03mm | Laser-tracked machine calibration |

| Hole Position | ±0.15mm | ±0.05mm | CMM-verified tool offsets |

| Bend Angle | ±0.5° | ±0.2° | In-process angle sensors |

| Hole Diameter | ±0.05mm | ±0.02mm | Tool wear monitoring system |

| Surface Flatness | 0.1mm/m | 0.05mm/m | Post-forming CMM mapping |

These tolerances are consistently achieved across prototype batches of 1–50 units, leveraging our digital workflow from CAD to finished part. The elimination of fixture transitions in 5-axis processing reduces datum referencing errors by up to 70% compared to segmented manufacturing approaches. For prototypes requiring functional testing, this precision ensures seamless integration with mating components during validation phases.

Wuxi Lead’s technical infrastructure transforms prototyping from a risk-mitigation step into a strategic design acceleration tool. By converging advanced CNC forming with metrology-grade verification, we deliver prototypes that accurately predict production outcomes—reducing iteration cycles and accelerating time-to-market for your most demanding applications. All capabilities are executed within our 12,000m² ISO 14644 Class 8 clean facility, ensuring particulate-controlled environments for sensitive components.

Material & Finish Options

Material Selection in Sheet Metal Fabrication Prototyping

Selecting the appropriate material for sheet metal fabrication prototypes is critical to achieving optimal performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we prioritize material compatibility with design intent, environmental exposure, and functional requirements. The most widely used materials in high-precision prototyping are aluminum, steel, and titanium, each offering distinct mechanical and chemical properties suited to different industrial applications.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for aerospace, electronics, and transportation prototypes where weight reduction is essential. Grade 6061-T6 is among the most common aluminum alloys used due to its balanced mechanical properties and weldability. When enhanced surface protection and aesthetic finish are required, aluminum responds exceptionally well to anodizing, a process that increases surface hardness and wear resistance while allowing for color customization.

Steel remains the backbone of industrial prototyping, especially in structural and heavy-duty applications. Among steel variants, cold-rolled steel (CRS) and stainless steel (particularly 304 and 316 grades) are most prevalent. Cold-rolled steel offers high strength and dimensional accuracy, making it ideal for precision enclosures and frames. Stainless steel adds superior corrosion resistance and is preferred in medical, food processing, and marine environments. While steel does not anodize, it can be treated with powder coating, passivation, or plating to enhance durability and appearance.

Titanium, though more costly, delivers unmatched strength-to-density performance and exceptional resistance to extreme temperatures and corrosive environments. Grade 2 and Grade 5 (Ti-6Al-4V) titanium are commonly used in aerospace, defense, and high-performance automotive prototypes. Its low thermal expansion and biocompatibility also make it suitable for medical devices and precision instrumentation. Due to its reactivity during processing, titanium requires specialized tooling and expertise—capabilities Wuxi Lead Precision Machinery maintains in-house.

Surface finishing plays a pivotal role in both functionality and aesthetics. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that improves wear resistance and allows for dye integration. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat) anodizing is used in high-wear applications.

Below is a comparative overview of key material specifications relevant to prototyping:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Lightweight, corrosion resistant, anodizable | Aerospace, electronics, enclosures |

| Cold-Rolled Steel | 1018, 1020 | 440 | 7.85 | High strength, cost-effective, precise | Industrial frames, machinery |

| Stainless Steel | 304, 316 | 505–585 | 8.0 | Corrosion resistant, hygienic | Medical, food processing, marine |

| Titanium | Grade 2, Grade 5 | 345–1000 | 4.5 | High strength-to-weight, heat resistant | Aerospace, defense, medical |

Material selection directly influences prototype performance, scalability, and production readiness. At Wuxi Lead Precision Machinery, we support clients in aligning material properties with application demands to ensure rapid, accurate, and reliable prototyping outcomes.

Manufacturing Process & QC

Sheet Metal Fabrication Prototype Production Process: From Concept to Zero Defects Manufacturing

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for seamless transition from initial concept to flawless mass production, with Zero Defects as the non-negotiable cornerstone. This integrated workflow eliminates costly rework and delays inherent in fragmented supplier models. The journey begins with rigorous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the design phase, scrutinizing CAD models for material efficiency, geometric feasibility, and process optimization. We identify potential stress points, weld accessibility issues, and tolerance stack-ups before metal is cut, ensuring the design is intrinsically manufacturable to the highest precision standards. This proactive DFM review is critical for avoiding downstream failures and forms the foundation of our Zero Defects commitment.

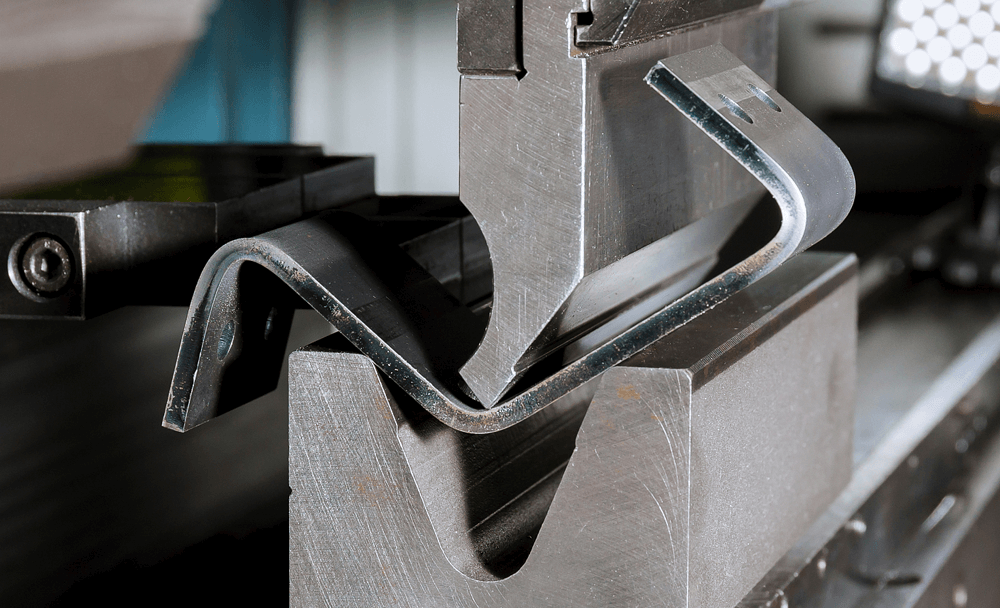

Prototyping is not merely a validation step; it is the critical proving ground for the entire production system. Utilizing the same state-of-the-art CNC equipment destined for mass production—including Amada laser cutters, Trumpf press brakes, and robotic welding cells—we fabricate functional prototypes under actual production conditions. This identical process environment is paramount. It allows us to validate tooling paths, fixture stability, material behavior, and final assembly fit with absolute accuracy. Every bend angle, hole location, and surface finish is measured against the original CAD data using Zeiss CMM technology. Any deviation triggers immediate root cause analysis and process correction. This prototype phase confirms not only the part’s functionality but also the robustness and repeatability of the manufacturing process itself, ensuring zero surprises during scale-up.

Transitioning to mass production leverages the validated process parameters and tooling from the prototype phase. Our integrated production floor, featuring automated material handling and real-time SPC (Statistical Process Control) monitoring, executes the approved workflow. Every component undergoes in-process inspection at critical control points, with data fed directly into our quality management system. This closed-loop system, combined with operator certification and stringent first-article inspection protocols, guarantees consistency. The result is mass production output that meets the exact specifications proven during prototyping, eliminating scrap, rework, and production line stoppages. Zero Defects is achieved through process discipline, not post-production sorting.

Key process capabilities enabling this seamless transition are detailed below:

| Parameter | Prototype Capability | Mass Production Capability | Measurement Standard |

|---|---|---|---|

| Material Thickness | 0.5mm – 6.0mm Steel/Al/St | 0.5mm – 6.0mm Steel/Al/St | ISO 9013 |

| Cutting Tolerance | ±0.05mm | ±0.05mm | ISO 2768-mK |

| Bend Tolerance | ±0.1° / ±0.1mm | ±0.1° / ±0.1mm | ISO 2768-fine |

| Hole Position | ±0.05mm | ±0.05mm | ISO 2768-mK |

| Surface Finish | Ra 0.8μm (as-machined) | Ra 0.8μm (as-machined) | ISO 1302 |

| Lead Time (Proto) | 5-7 Working Days | N/A | From Approved CAD |

This unified approach—where design insight, prototype validation under production conditions, and rigorously controlled mass manufacturing converge—ensures your sheet metal components arrive on time, within specification, and ready for immediate integration. Wuxi Lead Precision Machinery delivers not just parts, but guaranteed production readiness.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Prototyping

When precision, speed, and reliability define your engineering standards, partnering with Wuxi Lead Precision Machinery ensures your sheet metal fabrication prototypes meet the highest industrial benchmarks. Based in Wuxi, China, we specialize in delivering high-accuracy, low-volume prototyping solutions tailored to the demanding needs of global OEMs, automation integrators, and advanced equipment manufacturers. Our advanced manufacturing ecosystem combines state-of-the-art CNC technology with expert engineering oversight, enabling us to transform complex designs into fully functional prototypes in record time.

At Lead Precision, we understand that prototyping is not just about creating a physical model—it’s about validating design integrity, testing functionality, and accelerating time-to-market. Our end-to-end prototyping workflow integrates laser cutting, precision bending, robotic welding, and surface finishing under one roof, ensuring consistent quality and tight tolerance control across every production stage. Whether you’re developing enclosures, brackets, chassis, or custom assemblies, our team applies material science expertise and geometric dimensioning practices to ensure your prototype performs exactly as intended.

We work with a wide range of sheet metals, including stainless steel, aluminum, carbon steel, and galvanized alloys, supporting thicknesses from 0.5 mm to 6.0 mm. Our CNC-driven processes maintain tolerances as tight as ±0.1 mm, guaranteeing repeatability and dimensional accuracy critical for downstream testing and validation. Every prototype undergoes rigorous in-process inspection using CMM and optical measurement systems, ensuring compliance with ISO 9001 standards and your specific technical requirements.

Our engineering team collaborates directly with your design staff to conduct Design for Manufacturability (DFM) reviews, identifying potential production challenges early and recommending optimizations that reduce cost and improve performance. This proactive approach minimizes iterations, reduces development cycles, and enhances overall project efficiency.

Below are key technical specifications for our sheet metal prototyping services:

| Parameter | Capability |

|---|---|

| Material Types | Stainless Steel, Aluminum, Carbon Steel, Galvanized Steel |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance | ±0.1 mm (standard), tighter on request |

| Max Part Size | 1500 mm × 3000 mm |

| Laser Cutting Accuracy | ±0.05 mm |

| Bending Tolerance | ±0.2° angular, ±0.1 mm linear |

| Finishing Options | Powder Coating, Anodizing, Passivation, Brushing, Painting |

| Lead Time (Prototype) | 5–10 working days (based on complexity) |

Choosing the right manufacturing partner is a strategic decision that impacts innovation velocity and product quality. At Wuxi Lead Precision Machinery, we are committed to being an extension of your engineering team—delivering precision, transparency, and technical excellence at every step.

Contact us today at [email protected] to discuss your next sheet metal fabrication prototype. Let Lead Precision turn your concept into a high-performance reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.