Technical Contents

Engineering Guide: Sheet Metal Fabrication Online

Precision: The Non-Negotiable Core of Sheet Metal Fabrication Online

In the competitive landscape of online sheet metal fabrication, precision transcends mere specification; it is the absolute foundation of functional integrity, assembly success, and long-term product viability. When components are sourced remotely through digital platforms, the margin for dimensional error vanishes. A tolerance deviation of mere tenths of a millimeter can cascade into catastrophic assembly failures, compromised structural performance, or accelerated wear in the final product. This reality is magnified in high-stakes industries where online procurement is increasingly common but demands uncompromising accuracy. The digital interface of online ordering cannot compensate for inadequate process control on the shop floor. True precision requires deep engineering integration – from initial material selection and laser cutting paths to sophisticated press brake forming sequences and rigorous in-process inspection protocols. It demands machinery maintained to micron-level standards and operators possessing not just skill, but an ingrained understanding of how each process step impacts the final geometry. For the discerning buyer, online convenience must never equate to precision compromise.

Wuxi Lead Precision Machinery operates at this critical intersection of digital accessibility and uncompromised engineering rigor. Our facility is engineered specifically to deliver the precision demanded by the most challenging online fabrication requests. This capability is not theoretical; it is forged through direct experience supplying mission-critical components where failure is not an option. We have consistently met the exacting dimensional and material integrity requirements for structural elements within Olympic venue infrastructure, where public safety and architectural perfection were paramount. Similarly, our processes adhere to the stringent standards mandated for specialized military hardware components, subject to rigorous third-party validation. This heritage instills a culture where tolerances are treated as absolute limits, not targets, and every bend, cut, and weld undergoes multi-stage verification. It is this proven discipline, applied systematically to every online order regardless of volume, that transforms digital convenience into genuine manufacturing excellence.

The table below outlines key precision parameters achievable across our standard online fabrication services, reflecting the capability level honed through high-profile projects:

| Parameter | Standard Specification | High-Precision Option |

|---|---|---|

| Material Thickness Range | 0.5mm – 6.0mm | 0.3mm – 8.0mm |

| Laser Cutting Tolerance | ±0.10mm | ±0.05mm |

| CNC Punching Tolerance | ±0.15mm | ±0.10mm |

| Press Brake Bending Tolerance | ±0.2° / ±0.1mm | ±0.1° / ±0.05mm |

| Hole Positional Tolerance | ±0.15mm | ±0.08mm |

| Surface Flatness (per m²) | 0.3mm | 0.15mm |

Selecting an online fabrication partner demands scrutiny beyond user interface ease. Verify their demonstrable engineering depth, process control systems, and proven track record in applications where precision is non-negotiable. At Wuxi Lead Precision Machinery, our Olympic and military project legacy is not a badge; it is the daily standard we apply to ensure your online-sourced components perform flawlessly, on time, and within the tightest tolerances your application requires. Precision is our promise, engineered into every part.

Precision Specs & Tolerances

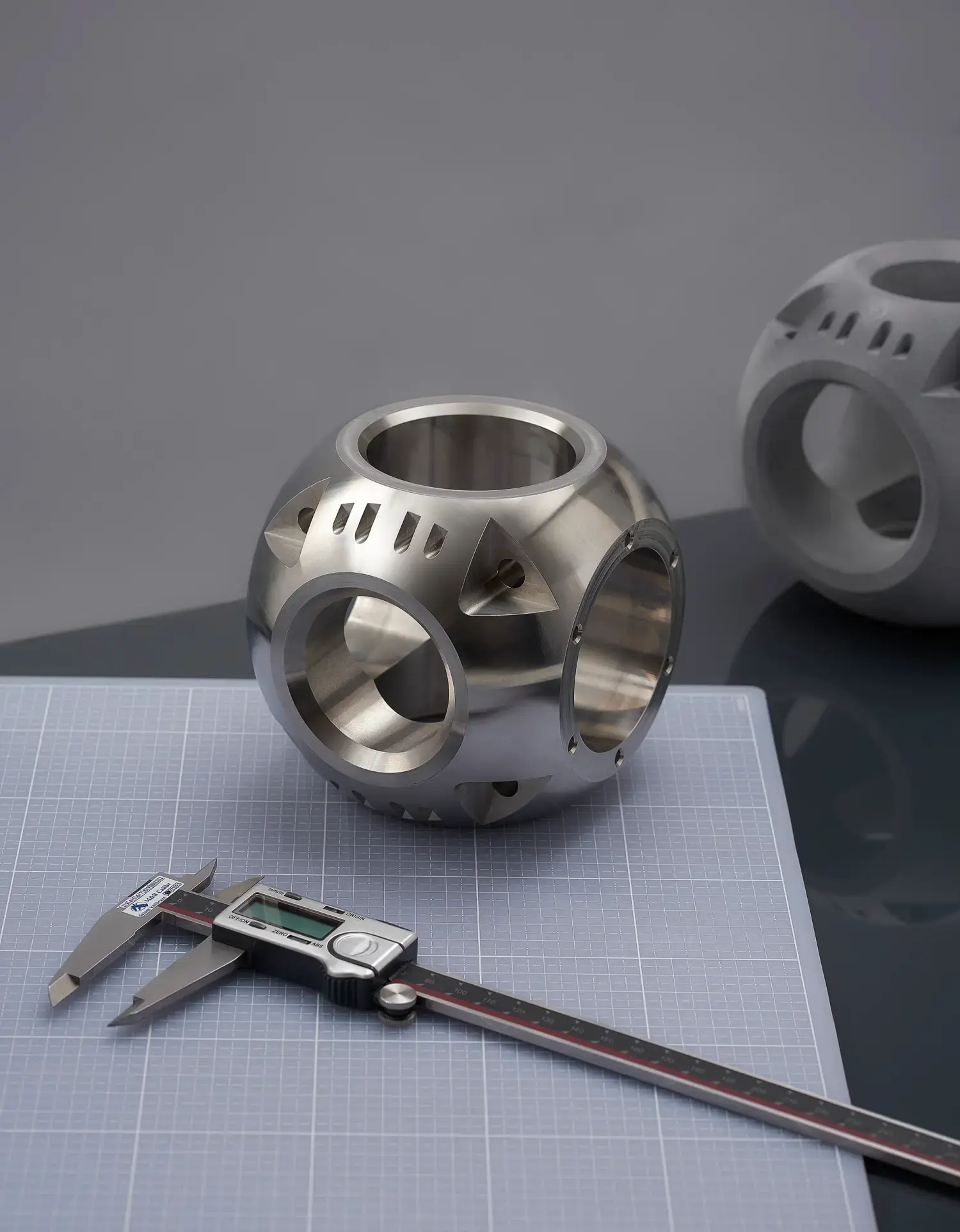

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and compliance with global industrial standards. Our technical capabilities are built around a modern, fully integrated manufacturing ecosystem that supports complex geometries, tight tolerances, and high-volume production runs with consistent quality. At the core of our fabrication process is a suite of 5-axis CNC machining centers, enabling multi-directional cutting, drilling, and forming operations in a single setup. This reduces cumulative error, improves part accuracy, and significantly enhances throughput for intricate components used in aerospace, medical devices, and high-end automation systems.

Our 5-axis CNC systems are programmed using industry-leading CAM software, allowing for optimized toolpaths and efficient material utilization. These machines operate with sub-micron positional accuracy and are maintained under strict environmental controls to ensure thermal stability. Coupled with automated tool changers and high-speed spindles, our equipment handles a wide range of materials—from aluminum alloys and stainless steel to titanium and specialty composites—without compromising dimensional integrity or surface finish.

Quality assurance is embedded into every stage of production. All critical components undergo comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), which provides full 3D geometric dimensioning and tolerance (GD&T) verification. The CMM system is calibrated monthly per ISO 10360 standards and operated by certified metrology technicians. Data from inspections is documented and traceable, supporting full compliance with ISO 9001, AS9100, and customer-specific quality requirements. In addition to CMM inspection, we employ first-article inspection (FAI) reporting, in-process checks, and final quality audits to ensure consistency across production batches.

Our sheet metal fabrication services include laser cutting, precision bending, welding, and assembly, all supported by digital work instructions and real-time process monitoring. We maintain tight control over material traceability, with barcoded lot tracking from receipt through final shipment. This integrated approach ensures that every fabricated part meets the exacting demands of high-performance applications.

The following table outlines our standard machining and fabrication tolerances:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (machined) | ±0.05 mm | ±0.01 mm | Up to 500 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed/precision bored |

| Angular Tolerance | ±0.1° | ±0.05° | 5-axis controlled |

| Positional Tolerance (GD&T) | ±0.05 mm | ±0.02 mm | Verified via CMM |

| Surface Roughness (machined) | Ra 3.2 µm | Ra 0.8 µm | As required |

| Sheet Metal Bend | ±0.2° | ±0.1° | Air bending, coining |

| Sheet Metal Linear | ±0.1 mm | ±0.05 mm | Laser cut, post-formed |

These capabilities are supported by a continuous improvement framework, ensuring that Wuxi Lead remains at the forefront of precision sheet metal fabrication for demanding international markets.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally determines the performance, longevity, and cost-effectiveness of sheet metal components. At Wuxi Lead Precision Machinery, we emphasize that selecting the optimal base material and finish is not merely a procurement decision but a critical engineering step integrated into the design-for-manufacturing process. Understanding the specific demands of the application—environmental exposure, mechanical loads, weight constraints, and regulatory requirements—is paramount before finalizing material specifications. Our precision fabrication capabilities are engineered to maximize the inherent properties of each material through advanced CNC forming, laser cutting, and welding processes.

Aluminum alloys, particularly 5052 and 6061, offer an exceptional strength-to-weight ratio and natural corrosion resistance, making them ideal for aerospace, transportation, and electronic enclosures where weight reduction is critical. Aluminum readily accepts anodizing, significantly enhancing surface hardness and wear resistance while providing excellent adhesion for paints and adhesives. Mild steel, such as ASTM A36 or CRCA, provides high strength and excellent formability at a lower cost, dominating structural applications, chassis, and brackets. Its susceptibility to rust necessitates protective finishes like powder coating or galvanization for outdoor use. Stainless steel grades 304 and 316 deliver superior corrosion and heat resistance, essential for medical devices, food processing equipment, and marine environments, though they present greater challenges in forming and welding. Titanium alloys, while significantly higher in cost, are unmatched for extreme strength-to-weight ratio, biocompatibility, and resistance to highly corrosive environments, finding critical use in aerospace, defense, and medical implants. Processing titanium demands specialized tooling and expertise due to its low thermal conductivity and tendency to gall.

Surface finishing, particularly anodizing for aluminum, is not merely cosmetic. Type II (Sulfuric Acid) anodizing creates a durable, corrosion-resistant oxide layer that can be dyed various colors, while Type III (Hardcoat) anodizing produces a much thicker, extremely hard surface suitable for high-wear applications like hydraulic components or military hardware. Proper anodizing thickness and sealing are crucial for meeting stringent performance standards.

The following table summarizes key comparative properties for common sheet metal fabrication materials:

| Material Type | Common Grades | Tensile Strength (MPa) | Key Advantages | Primary Limitations | Typical Cost Index |

|---|---|---|---|---|---|

| Aluminum Alloy | 5052, 6061 | 170 – 310 | Lightweight, corrosion resistant, excellent thermal/electrical conductivity, easily anodized | Lower strength vs steel, can gall | Medium |

| Mild Steel | A36, CRCA | 360 – 510 | High strength, excellent formability, low cost, readily welded | Prone to rust without coating | Low |

| Stainless Steel | 304, 316 | 505 – 860 | Superior corrosion/heat resistance, hygienic, strong | Higher cost, harder to form/weld | High |

| Titanium Alloy | Gr 2, Gr 5 (6Al-4V) | 345 – 895 | Exceptional strength-to-weight, biocompatible, extreme corrosion resistance | Very high cost, difficult processing | Very High |

Partnering with Wuxi Lead ensures your material and finish selection leverages our deep metallurgical understanding and state-of-the-art fabrication infrastructure. We provide comprehensive material certification and collaborate closely during the design phase to recommend optimal solutions that balance performance, manufacturability, and total project cost, guaranteeing components meet the most rigorous global industry standards. Our multi-axis CNC systems and stringent quality control protocols are calibrated for precision across this entire material spectrum.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful sheet metal fabrication project begins with meticulous design engineering. Our team collaborates closely with clients to transform conceptual ideas into manufacturable designs using advanced CAD software such as SolidWorks, AutoCAD, and Siemens NX. This stage is critical in ensuring dimensional accuracy, material efficiency, and compliance with functional requirements. We conduct comprehensive Design for Manufacturability (DFM) reviews to identify potential issues early—such as improper bend radii, inadequate flange lengths, or weld accessibility—before any metal is cut. Our engineers assess material selection, surface finish options, and tolerance specifications to align the design with both performance demands and production feasibility. All designs are validated through 3D simulations and interference checks, minimizing downstream risks and ensuring seamless progression to prototyping.

Prototyping: Validating Performance and Fit

Once the design is finalized, we proceed to prototype development. Prototyping serves as a physical validation step, allowing clients to evaluate form, fit, and function under real-world conditions. At Wuxi Lead, prototypes are produced using the same high-precision equipment intended for mass production—ensuring consistency and reliability. We utilize CNC punching, laser cutting, bending, and welding technologies to fabricate prototypes with exact material and process fidelity. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to verify geometric accuracy against the original CAD model. Feedback from prototype testing is integrated swiftly, enabling rapid design refinements. This iterative yet disciplined approach ensures that only fully validated designs advance to full-scale production, significantly reducing the risk of defects in later stages.

Mass Production: Scalable Excellence with Zero Defects

With design and prototype approval, we transition to mass production—executed with an uncompromising commitment to quality and consistency. Our automated production lines integrate state-of-the-art fiber laser cutting systems, CNC turret presses, and robotic bending cells to ensure repeatability and throughput. Every stage of fabrication is governed by documented quality control procedures aligned with ISO 9001 standards. In-process inspections, first-article checks, and statistical process control (SPC) monitoring are employed to maintain tight tolerances and detect deviations in real time. Final assemblies undergo comprehensive functional and visual inspections before packaging and shipment.

Our Zero Defects philosophy is embedded in every operation. From raw material sourcing to final delivery, traceability, continuous improvement, and preventive quality planning ensure that each component meets the highest standards of reliability and performance.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerances (Standard) | ±0.1 mm (cutting), ±0.2° (bending) |

| Maximum Part Size | 4000 mm × 2000 mm |

| Laser Cutting Power | Up to 12 kW (fiber) |

| Available Materials | Mild steel, stainless steel, aluminum, copper, brass |

| Surface Finishes | Anodizing, powder coating, plating, passivation |

| Production Capacity | Up to 50,000 units/month (automated lines) |

Why Choose Wuxi Lead Precision

Elevate Your Supply Chain with Wuxi Lead Precision Machinery

Securing a sheet metal fabrication partner capable of meeting exacting engineering standards and global delivery demands is critical for OEMs and tier-one suppliers. Wuxi Lead Precision Machinery delivers this assurance through integrated precision manufacturing, stringent quality control, and engineering collaboration. We transform complex designs into certified components for aerospace, medical, and industrial automation sectors, operating under ISO 9001:2015 and IATF 16949 frameworks. Our facility in Wuxi, China, combines advanced automation with decades of metallurgical expertise to ensure zero-defect production at scale. Partnering with us mitigates supply chain volatility while accelerating time-to-market for mission-critical hardware.

Core Sheet Metal Capabilities

| Process | Capability Range | Standard Tolerance | Material Types Supported |

|---|---|---|---|

| Fiber Laser Cutting | 0.5mm – 30mm thickness | ±0.1mm | Mild Steel, Stainless, Aluminum, Copper |

| CNC Punching | Up to 6mm thickness | ±0.05mm | Steel, Galvanized, Aluminum |

| Press Brake Forming | 0.5m – 6m length | ±0.5° angular | All standard sheet metals |

| Welding & Assembly | Robotic MIG/TIG | Per AWS D1.1 | Dissimilar metals, sub-assemblies |

Why Global Leaders Choose Lead Precision

Our engineering team engages during the design phase to optimize manufacturability, reducing material waste by up to 22% through intelligent nesting and process sequencing. Real-time SPC monitoring on all production lines ensures dimensional stability across batches, while our ERP system provides transparent order tracking from raw material to shipment. Unlike commodity suppliers, we prioritize technical partnership—offering DFM analysis, first-article inspection reports, and rapid prototyping to validate functionality before full production. This proactive approach eliminates costly rework and aligns output with your engineering intent.

Initiate Your Precision Partnership

Contact our technical sales team to discuss how Wuxi Lead Precision Machinery can resolve your most demanding fabrication challenges. Share your CAD files, material specifications, and volume requirements for a tailored capability assessment and competitive quotation within 48 hours. Our engineers are available for direct consultation to address tolerances, surface finishes, or compliance needs specific to your industry.

Email [email protected] with subject line “Precision Fabrication Inquiry – [Your Company Name]” to activate immediate support. Include project timelines and technical documentation for expedited review. We respond to all qualified inquiries within one business day, providing clear pathways to reduce your per-part cost while exceeding quality expectations. Trust Wuxi Lead to become your single-source solution for precision sheet metal components—where engineering rigor meets global delivery reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.