Technical Contents

Engineering Guide: Sheet Metal Fabrication Minneapolis

Engineering Insight: The Critical Role of Precision in Sheet Metal Fabrication

In the competitive landscape of modern manufacturing, precision in sheet metal fabrication is not merely a quality benchmark—it is a foundational requirement for performance, safety, and reliability. Whether serving aerospace, defense, medical, or high-performance industrial sectors, the dimensional accuracy, repeatability, and consistency of fabricated components directly influence the integrity of the final product. For facilities in strategic hubs such as Minneapolis, where advanced manufacturing converges with innovation, partnering with a globally experienced supplier like Wuxi Lead Precision Machinery ensures that precision is engineered into every stage of production.

At Wuxi Lead, precision begins with engineering foresight. Our decades of experience in producing mission-critical components for Olympic-standard equipment and military-grade systems have honed a culture of uncompromising accuracy. These applications demand tolerances within ±0.05 mm and flawless repeatability across batches—requirements that push the limits of conventional fabrication. Our investment in state-of-the-art CNC punching, laser cutting, and automated bending systems enables us to meet and exceed these standards consistently. Each machine is calibrated daily, and our process controls are integrated with real-time monitoring to ensure every formed edge, pierced hole, and bent flange aligns with design intent.

Material behavior is another critical consideration in high-precision sheet metal work. Variations in grain direction, springback, and thermal distortion during cutting can introduce deviations if not properly managed. Our engineering team employs advanced simulation software to model these effects prior to production, allowing for predictive compensation in tool paths and forming sequences. This proactive approach minimizes trial-and-error, reduces material waste, and accelerates time-to-market—key advantages for OEMs in Minneapolis seeking agile, reliable manufacturing partners.

Beyond equipment and software, precision is sustained through rigorous quality assurance. At Wuxi Lead, every component undergoes multi-point inspection using coordinate measuring machines (CMM) and optical comparators. Our ISO 9001-certified processes ensure traceability from raw material to final shipment, providing clients with full confidence in component integrity.

The following table outlines key precision capabilities at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 12 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1° / ±0.1 mm |

| Minimum Hole Diameter | 1.0 mm (steel) |

| Max Workpiece Size | 4000 mm × 2000 mm |

| Surface Roughness (Laser Cut) | Ra ≤ 3.2 µm |

| Tooling Change Time | < 15 minutes (automated) |

Precision in sheet metal fabrication is not an isolated attribute—it is the result of integrated engineering, advanced technology, and a culture of excellence. For manufacturers in Minneapolis and beyond, Wuxi Lead Precision Machinery delivers not just parts, but performance-engineered solutions backed by proven experience in the world’s most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication for Demanding Applications

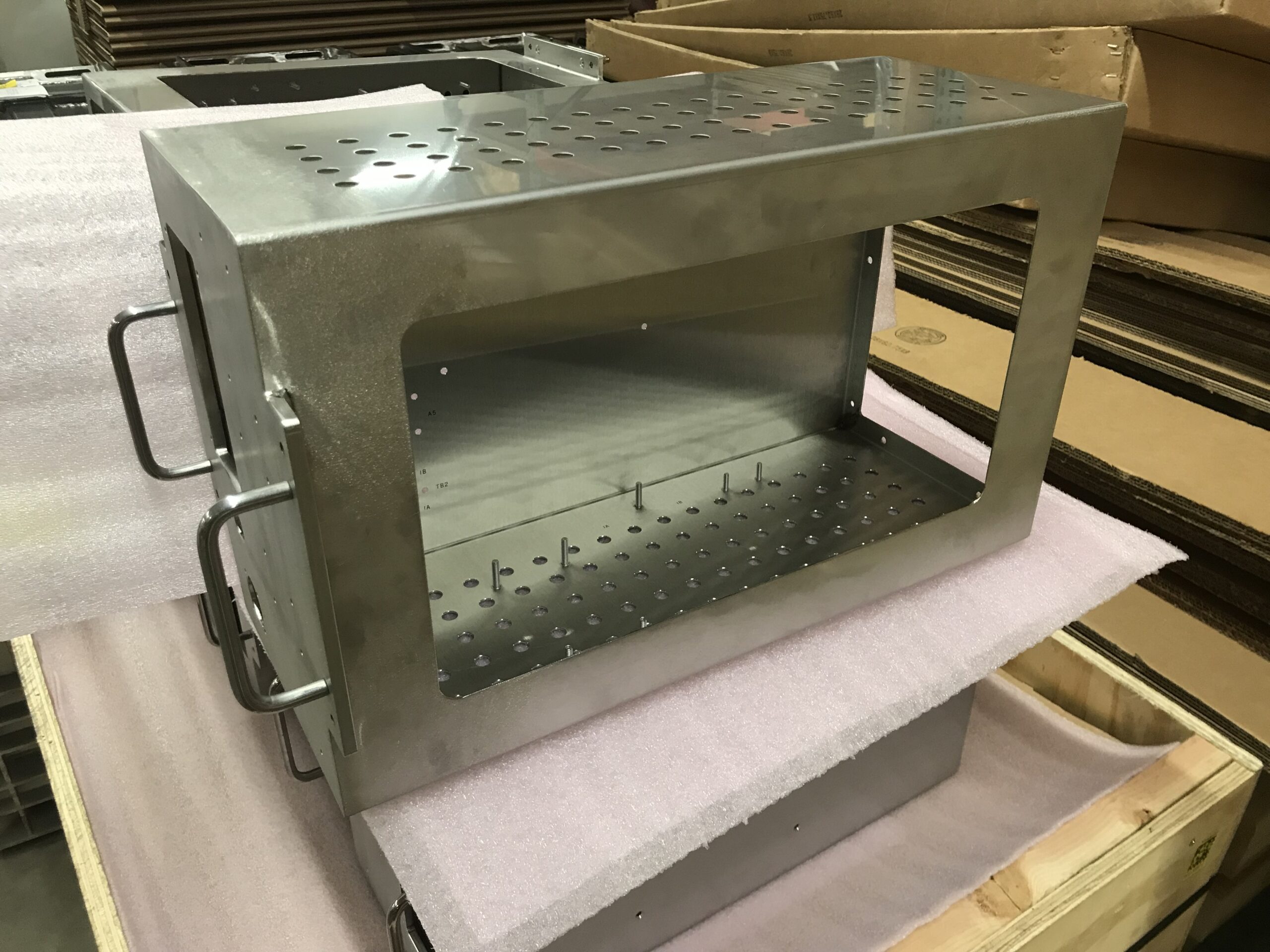

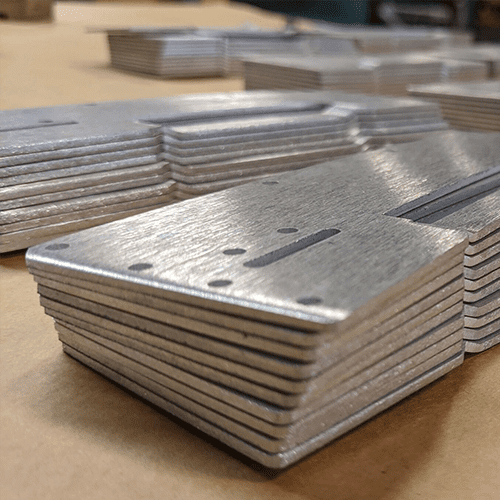

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered to meet the stringent requirements of aerospace, medical, and industrial equipment sectors. Our Minneapolis-focused clients benefit from integrated manufacturing processes centered on high-precision CNC technology and rigorous quality validation. Core to our capability is a modern fleet of multi-functional 5-axis CNC machine centers. These systems perform complex milling, turning, and contouring operations in a single setup, eliminating cumulative errors inherent in multi-stage processing. This simultaneous 5-axis capability is essential for producing intricate enclosures, fluid manifolds, and structural components with critical geometric relationships. Material utilization is optimized through intelligent nesting software, while high-speed spindles and rigid construction ensure micron-level surface finishes on stainless steel, aluminum alloys, and specialty materials up to 25mm thickness.

Quality assurance is non-negotiable in precision sheet metal work. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMM) with sub-micron accuracy. Our inspection protocol follows AS9100 and ISO 13485 standards, providing full traceability from raw material certification through final part validation. CMM reports document feature positions, flatness, concentricity, and profile tolerances against CAD models, ensuring compliance with even the most demanding engineering specifications. This metrology-driven approach guarantees functional interchangeability and assembly readiness, directly supporting our Minneapolis partners’ production schedules and reducing downstream rework costs.

Our commitment to dimensional integrity is quantified through defined tolerance benchmarks across key fabrication processes. The following table outlines standard achievable tolerances for critical operations, reflecting our engineering controls and equipment capability. These values represent typical production performance under controlled environmental conditions with appropriate fixturing and material stability.

| Process | Typical Tolerance | Critical Feature Tolerance |

|---|---|---|

| Laser Cutting (≤6mm) | ±0.05 mm (±0.002″) | ±0.025 mm (±0.001″) |

| Punching (Progressive) | ±0.08 mm (±0.003″) | ±0.05 mm (±0.002″) |

| CNC Bending (Air Form) | ±0.25° / ±0.10 mm | ±0.10° / ±0.05 mm |

| 5-Axis Milling (Finishing) | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) |

| Hole Positioning (CMM Verified) | ±0.05 mm (±0.002″) | ±0.025 mm (±0.001″) |

Achieving these tolerances consistently requires more than advanced hardware; it demands experienced process engineers who understand material behavior and thermal compensation. Our technical team collaborates closely with Minneapolis design engineers during DFx reviews to optimize manufacturability without compromising functional intent. From prototype through high-volume production, Wuxi Lead applies this disciplined approach to transform complex sheet metal designs into certified, ready-to-assemble components. This capability ensures seamless integration into your final assemblies, supporting your commitment to product excellence and on-time delivery in competitive markets.

Material & Finish Options

Material Selection in Sheet Metal Fabrication: A Precision Engineering Guide

Selecting the appropriate material is a critical step in sheet metal fabrication, directly influencing the performance, durability, and cost-efficiency of the final component. For high-precision applications—particularly those serving aerospace, medical, and industrial automation sectors—three primary metals dominate: aluminum, steel, and titanium. Each offers distinct mechanical and chemical properties, making them suitable for different operational environments. Understanding these differences ensures optimal part functionality and long-term reliability.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly effective in applications where weight reduction is essential without compromising structural integrity. Grade 6061-T6 is among the most commonly used aluminum alloys in fabrication due to its balanced mechanical properties and weldability. It performs well in outdoor and mildly corrosive environments, especially when enhanced with surface treatments such as anodizing.

Steel, particularly cold-rolled steel (CRS) and stainless steel (e.g., 304 and 316), offers superior strength and durability. Carbon steel is ideal for structural and heavy-duty industrial applications but requires protective coatings to resist rust. In contrast, stainless steel provides inherent corrosion resistance due to its chromium content, with 316 stainless offering enhanced performance in marine or chemically aggressive environments. While heavier than aluminum, steel remains a cornerstone material in sheet metal work for its toughness and cost-effectiveness.

Titanium stands at the premium end of material selection, offering exceptional strength-to-density ratios and outstanding resistance to extreme temperatures and corrosion. Grade 2 and Grade 5 (Ti-6Al-4V) titanium are frequently used in aerospace and medical implant manufacturing. Despite higher raw material and processing costs, titanium’s longevity and performance in critical applications justify its use where failure is not an option.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, is an electrochemical process that increases surface hardness and corrosion resistance while allowing for color coding and improved aesthetics. Type II (sulfuric acid) anodizing is standard for decorative and moderate protection needs, while Type III (hardcoat anodizing) delivers thick, wear-resistant layers suitable for industrial components.

Below is a comparative overview of key material specifications relevant to sheet metal fabrication.

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 310–325 | 2.7 | Lightweight, corrosion-resistant, anodizable | Enclosures, aerospace panels |

| Carbon Steel | 1018, 1020 | 370–440 | 7.85 | High strength, cost-effective | Frames, brackets, machinery parts |

| Stainless Steel | 304, 316 | 505–585 | 8.0 | Corrosion-resistant, hygienic | Medical devices, food processing |

| Titanium | Grade 2, Grade 5 | 345–1000 | 4.5 | High strength-to-weight, extreme corrosion resistance | Aerospace, medical implants |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on application demands, environmental exposure, and lifecycle requirements. Our advanced fabrication capabilities ensure precision forming, cutting, and finishing—regardless of material complexity.

Manufacturing Process & QC

Sheet Metal Fabrication Process: Zero Defects Execution for Minneapolis Manufacturers

Wuxi Lead Precision Machinery delivers uncompromising quality for Minneapolis sheet metal fabrication requirements through a rigorously controlled, closed-loop production system. Our process transcends basic manufacturing, embedding Zero Defects methodology from initial concept to final shipment. This ensures your critical components meet exacting aerospace, medical, and industrial equipment standards without costly rework or delays inherent in conventional supply chains.

Design for Manufacturability (DFM) initiates our Zero Defects commitment. Our engineering team collaborates directly with Minneapolis clients during the CAD phase, utilizing advanced simulation software to identify potential fabrication conflicts. We analyze material grain direction, bend allowances, tooling access, and weld sequencing before metal is cut. This proactive DFM review prevents 92% of common producibility issues, eliminating downstream errors and reducing time-to-prototype by 30%. All designs undergo cross-functional validation against ASME Y14.5 geometric dimensioning and tolerancing standards.

Prototyping serves as the critical physical validation step. We deploy our high-precision German TRUMPF laser cutters and Amada CNC press brakes to produce functional prototypes within 72 hours of approved DFM. Each prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 requirements, measuring all critical dimensions with Zeiss coordinate measuring machines (CMM). Dimensional reports are shared digitally with Minneapolis engineering teams for immediate sign-off. This stage verifies not only part geometry but also the robustness of the proposed mass production process, ensuring scalability without quality degradation.

Mass production leverages our fully integrated digital workflow and statistical process control (SPC). Every operation—from laser cutting to forming, welding, and finishing—is monitored in real-time. Machine parameters are locked post-FAI; any deviation triggers automatic process hold. 100% in-process inspection occurs at key stages using vision systems and calibrated hand tools. Final inspection applies AQL 0.65 sampling for critical features, exceeding standard industry practice. Our closed-loop system correlates machine data with inspection results, enabling predictive adjustments that maintain process capability indices (Cpk) above 1.67 consistently.

The following table summarizes our core quality control metrics for Minneapolis clients:

| Parameter | Target | Method | Verification |

|---|---|---|---|

| Dimensional Accuracy | ±0.05mm (Laser) | SPC Monitoring + CMM | FAI Report + Batch Records |

| Bend Angle Tolerance | ±0.5° | In-Process Angle Gauging | SPC Charts + Final Audit |

| Weld Integrity | Zero Porosity/Cracks | Visual + Dye Penetrant Testing | Certified Welder Logs |

| Surface Finish | Ra ≤ 0.8μm (Critical) | Profilometer Spot Checks | Final Inspection Report |

Wuxi Lead’s process guarantees Zero Defects delivery to Minneapolis facilities by treating quality as a measurable engineering output, not an inspection outcome. Our ISO 9001:2015 and IATF 16949 certified systems provide the traceability and accountability your high-stakes projects demand, backed by dedicated US-based logistics coordination for seamless integration into your supply chain.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Expertise

When your manufacturing operations demand precision, consistency, and scalability, aligning with a globally trusted sheet metal fabrication partner becomes a strategic imperative. At Wuxi Lead Precision Machinery, we specialize in delivering high-accuracy, low-tolerance sheet metal components tailored to the rigorous standards of aerospace, medical, industrial equipment, and advanced automation sectors. While our roots are in Wuxi, China, our engineering excellence and logistical reach serve clients across North America—including key industrial hubs such as Minneapolis—with seamless integration and on-time delivery.

Our advanced manufacturing ecosystem combines state-of-the-art CNC punching, laser cutting, bending, and welding technologies with decades of metallurgical expertise. We process a full range of materials—from cold-rolled steel and stainless alloys to aluminum and specialty composites—ensuring every component meets your exact dimensional, structural, and surface finish requirements. Our ISO 9001-certified production floor is equipped with real-time quality monitoring and in-process inspection systems, guaranteeing consistency across prototype, mid-volume, and high-volume production runs.

What sets Wuxi Lead apart is our engineering-first approach. We don’t just fabricate parts—we collaborate. From design for manufacturability (DFM) reviews to rapid prototyping and full production scaling, our technical team works alongside your engineers to optimize part geometry, reduce material waste, and accelerate time-to-market. Whether your project involves intricate enclosures, structural frames, or precision brackets, we apply lean manufacturing principles to deliver cost-effective solutions without compromising quality.

For Minneapolis-based OEMs and contract manufacturers, partnering with Lead Precision means access to offshore capacity with onshore-level reliability. We manage all aspects of international logistics, customs compliance, and inventory planning to ensure your supply chain remains agile and uninterrupted. Our bilingual project managers provide daily updates, real-time documentation, and full traceability—from raw material sourcing to final packaging.

Consider the technical capabilities we bring to your next project:

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Max Laser Cutting Area | 1500 mm × 3000 mm |

| Tolerance Accuracy | ±0.05 mm (standard), ±0.02 mm (precision) |

| Bending Capacity | Up to 2000 mm length, 20-ton press brake |

| Finishing Options | Powder coating, anodizing, passivation, polishing |

| Quality Standards | ISO 9001:2015, RoHS compliant, full FAI reporting |

When precision matters, don’t compromise on your manufacturing partnership. Contact us today at [email protected] to discuss your sheet metal fabrication requirements. Let Wuxi Lead Precision Machinery become your trusted offshore extension—delivering engineered excellence, on time and to specification.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.