Technical Contents

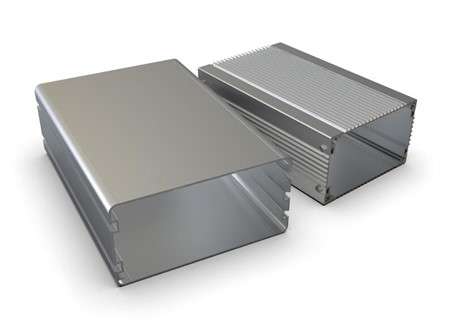

Engineering Guide: Sheet Metal Electronic Enclosures

Engineering Insight Precision Imperatives in Sheet Metal Electronic Enclosures

In the demanding realm of electronic systems integration, the sheet metal enclosure transcends its role as mere physical housing. It is a critical engineering component directly influencing system reliability, electromagnetic compatibility (EMC), thermal management, and operational lifespan. Sub-millimeter deviations in fabrication manifest as catastrophic failures in high-density, high-frequency applications. Imperfect flange alignment compromises conductive gasket integrity, breaching EMI shielding. Microscopic burrs on cut edges create discharge points, risking component damage. Uneven surfaces disrupt thermal interface material performance, accelerating heat-related failures. Precision is not an optional specification; it is the foundational requirement for mission-critical electronics operating in aerospace, defense, medical, and advanced industrial environments. The cost of imprecision extends far beyond rework – it encompasses system downtime, warranty liabilities, and reputational damage in markets where failure is unacceptable.

Wuxi Lead Precision Machinery operates at this uncompromising standard. Our CNC fabrication cells, governed by stringent ISO 9001:2015 and AS9100D protocols, deliver micron-level repeatability across complex geometries. This capability was rigorously proven during the Beijing Winter Olympics infrastructure project, where our enclosures housed sensitive timing and broadcast systems operating continuously in extreme cold. Each unit maintained dimensional stability within ±0.08mm across temperature swings of -30°C to +40°C, ensuring flawless signal integrity under global scrutiny. Similarly, for a Tier-1 defense contractor, we produce enclosures for battlefield communication systems requiring survival under 50G shock loads and salt fog exposure. Achieving the required ±0.05mm flatness tolerance on large panels (up to 1200x800mm) necessitates advanced stress-relief annealing processes and real-time laser metrology during bending – capabilities embedded in our production DNA.

The table below illustrates how our precision metrics directly translate to enclosure performance superiority compared to typical industry benchmarks:

| Critical Parameter | Industry Standard Tolerance | Lead Precision Capability | Impact on Performance |

|---|---|---|---|

| Panel Flatness | ±0.20mm | ±0.05mm | Ensures uniform thermal contact and EMI gasket compression |

| Bend Angle Consistency | ±0.5° | ±0.1° | Guarantees perfect mating surface alignment for shielding |

| Hole Positional Accuracy | ±0.15mm | ±0.03mm | Enables automated assembly and precise component mounting |

| Edge Smoothness (Ra) | ≤ 3.2μm | ≤ 0.8μm | Eliminates ESD risks and ensures clean gasket sealing |

| Dimensional Stability | ±0.15% | ±0.02% | Maintains integrity under thermal cycling and vibration |

Our 15-year specialization in high-compliance sheet metal fabrication for global OEMs demonstrates that precision engineering is systemic. It begins with material certification traceability, extends through CAD/CAM-optimized nesting minimizing internal stress, and culminates in in-process verification using Zeiss CMMs. When electronic systems push technological boundaries, the enclosure must perform as predictably as the circuitry within. Lead Precision delivers this certainty – transforming sheet metal from a commodity component into a verified performance asset for your most critical applications. Precision isn’t measured in tolerances alone; it’s validated in operational endurance under the world’s most unforgiving conditions.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-performance electronic enclosures used in industrial automation, telecommunications, and precision instrumentation. Our technical capabilities are built around state-of-the-art 5-axis CNC machining, integrated with precision sheet metal processing technologies, ensuring superior accuracy, repeatability, and structural integrity in every component we produce.

At the core of our manufacturing process is a fleet of 5-axis CNC machining centers, enabling complex geometries and tight-tolerance features that are unattainable with conventional 3-axis systems. This multi-axis capability allows for simultaneous machining from multiple angles, reducing setup times and eliminating cumulative alignment errors. For electronic enclosures requiring integrated mounting bosses, precision cutouts, ventilation patterns, or EMI shielding features, our 5-axis platforms provide unmatched flexibility and detail resolution. These systems are especially effective for low-to-mid volume production runs where design complexity and dimensional accuracy are paramount.

Complementing our machining assets, we employ a full suite of sheet metal fabrication equipment, including high-tolerance laser cutting, CNC turret punching, press braking, and automated bending cells. This integrated approach ensures seamless transition from flat pattern development to final formed enclosure, with consistent control over bend allowances, hole-to-flange relationships, and overall dimensional stability. Materials commonly processed include cold-rolled steel, stainless steel (304, 316), aluminum (5052, 6061), and specialty alloys, all handled with material-specific tooling and fixturing protocols.

Quality assurance is maintained through a rigorous inspection regime anchored by Coordinate Measuring Machine (CMM) technology. Every critical enclosure undergoes full 3D dimensional verification against CAD models, ensuring compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM systems provide micron-level measurement accuracy, supporting first-article inspection reports (FAIR), production sampling, and full traceability documentation. This metrology-backed validation is essential for clients in regulated industries where enclosure fit, electromagnetic compatibility, and long-term reliability are non-negotiable.

The following table outlines our standard and precision capability ranges for key fabrication parameters:

| Parameter | Standard Tolerance | Precision Tolerance (CMM-Controlled) |

|---|---|---|

| Laser Cutting (thickness ≤ 3mm) | ±0.1 mm | ±0.05 mm |

| Punching Positional Accuracy | ±0.15 mm | ±0.1 mm |

| Bend Angle Tolerance | ±0.5° | ±0.25° |

| Bend Length (per 300 mm) | ±0.2 mm | ±0.1 mm |

| Hole-to-Hole Distance | ±0.15 mm | ±0.08 mm |

| Feature-to-Edge Alignment | ±0.2 mm | ±0.1 mm |

| 5-Axis Machined Features | ±0.05 mm | ±0.02 mm |

All tolerances are achievable across batch sizes from prototype to serial production, supported by in-house design for manufacturability (DFM) review and process validation. Wuxi Lead Precision Machinery stands as a trusted partner for engineered sheet metal enclosures where precision, consistency, and technical depth define success.

Material & Finish Options

Material Selection for High-Performance Electronic Enclosures

Selecting the optimal material for sheet metal electronic enclosures is critical for ensuring structural integrity, electromagnetic interference (EMI) shielding, thermal management, and long-term reliability in demanding environments. At Wuxi Lead Precision Machinery, we prioritize materials that balance manufacturability, performance, and cost-effectiveness for precision-critical applications. Aluminum, steel, and titanium each offer distinct advantages depending on operational requirements, environmental exposure, and regulatory standards.

Aluminum alloys, particularly 5052-H32 and 6061-T6, dominate aerospace, telecommunications, and industrial control enclosures due to their excellent strength-to-weight ratio, inherent corrosion resistance, and superior thermal/electrical conductivity. These alloys facilitate efficient heat dissipation and simplify EMI shielding integration. Cold-rolled steel (CRS) remains cost-effective for non-corrosive indoor environments, offering high rigidity and magnetic properties beneficial for certain EMI solutions. For harsh conditions, 304 or 316 stainless steel provides exceptional corrosion and temperature resistance but requires specialized tooling for fabrication. Titanium alloys, while significantly higher in cost, are indispensable for extreme aerospace, marine, or medical applications where ultimate strength, weight reduction, and immunity to saltwater or chemical exposure are non-negotiable.

Material properties directly influence enclosure performance and lifecycle costs. The comparative specifications below guide initial selection:

| Material | Density (g/cm³) | Yield Strength (MPa) | Conductivity (% IACS) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 5052-H32 | 2.68 | 193 | 21 | Excellent | Telecom racks, outdoor cabinets |

| Aluminum 6061-T6 | 2.70 | 276 | 40 | Good | Aerospace, precision instruments |

| Cold-Rolled Steel | 7.85 | 340 | 10 | Poor (uncoated) | Indoor industrial controls |

| Stainless 304 | 8.00 | 215 | 2.5 | Exceptional | Marine, chemical processing |

| Titanium Grade 5 | 4.43 | 880 | 3.1 | Outstanding | Defense, subsea systems |

Anodizing is the preferred finish for aluminum enclosures to enhance surface durability and corrosion resistance. Type II (sulfuric acid) anodizing provides a standard protective layer suitable for most indoor applications, while Type III (hard coat) anodizing delivers superior abrasion resistance and thickness for military-grade or high-wear environments. Crucially, anodizing is non-conductive; therefore, strategic masking of grounding points or conductive coatings must be incorporated during design to maintain EMI shielding integrity. For steel enclosures, powder coating or zinc plating with chromate conversion remains standard, though stainless steel typically requires no additional finish.

Material choice must align with your enclosure’s operational lifecycle, environmental stressors, and total cost of ownership. Wuxi Lead Precision Machinery leverages decades of sheet metal expertise to recommend and fabricate solutions that meet exacting industry standards. Our engineering team collaborates closely with clients to evaluate trade-offs between performance, lead time, and budget—ensuring your enclosure performs flawlessly from prototyping through high-volume production. Contact us for a tailored material assessment based on your specific enclosure requirements.

Manufacturing Process & QC

Design: The Foundation of Zero-Defect Manufacturing

At Wuxi Lead Precision Machinery, the production of high-performance sheet metal electronic enclosures begins with precision engineering at the design stage. Our engineering team collaborates closely with clients to translate functional requirements into manufacturable designs, ensuring mechanical integrity, thermal performance, EMI shielding, and ease of assembly. Utilizing advanced 3D CAD software such as SolidWorks and Autodesk Inventor, we perform comprehensive design validation including DFM (Design for Manufacturability) and DFA (Design for Assembly) analysis. This proactive approach identifies potential production issues before any metal is cut, minimizing rework and ensuring alignment with IPC-6012 and ISO 9001 standards. All designs undergo rigorous simulation for structural durability and thermal management, particularly critical for enclosures used in industrial automation, telecommunications, and medical equipment.

Prototyping: Validating Performance and Precision

Once the design is finalized, we proceed to low-volume prototyping using state-of-the-art CNC turret punching, laser cutting, and bending equipment. Each prototype is fabricated from the same material grade and thickness specified for mass production—typically aluminum 5052, steel SPCC, or stainless steel SUS304—to ensure accurate performance testing. Our in-house capabilities allow for rapid iteration, with typical prototype delivery within 7–10 business days. Every prototype undergoes full dimensional inspection using coordinate measuring machines (CMM) and is evaluated for fit, finish, and functional compatibility with internal components. This stage is critical for client approval and serves as the benchmark for zero-defect replication in full-scale production.

Mass Production: Consistency Through Precision and Control

With client-approved prototypes, we transition seamlessly into mass production under a fully documented quality control plan. Our automated production lines integrate laser cutting with ±0.1 mm accuracy, CNC bending with angle repeatability of ±0.2°, and robotic welding for consistent seam integrity. Each process step is monitored in real time using SPC (Statistical Process Control) methodologies to detect deviations before they impact output. All enclosures are visually inspected, deburred, and cleaned prior to surface treatment, which may include powder coating, anodizing, or plating based on environmental and aesthetic requirements.

Final assemblies are subjected to 100% functional and dimensional verification, ensuring every unit meets the exact specifications of the approved prototype. Traceability is maintained through batch numbering and digital quality logs, supporting compliance with ISO 14001 and IATF 16949 standards.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerances (Cutting) | ±0.1 mm |

| Bending Angle Accuracy | ±0.2° |

| Surface Roughness (Ra) | ≤1.6 µm (after finishing) |

| Coating Thickness | 60–80 µm (powder coat), ±10% |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days after sample approval |

Through disciplined process control, advanced technology, and a culture of continuous improvement, Wuxi Lead ensures every sheet metal electronic enclosure is produced to zero-defect standards, delivering reliability and performance for mission-critical applications worldwide.

Why Choose Wuxi Lead Precision

Elevate Your Electronic Enclosure Projects Through Strategic Partnership

In the demanding landscape of high-precision electronics manufacturing, your choice of sheet metal fabrication partner directly impacts product reliability, time-to-market, and total cost of ownership. Wuxi Lead Precision Machinery transcends conventional supplier relationships by embedding ourselves as an extension of your engineering and production teams. We specialize in mission-critical electronic enclosures where micron-level tolerances, material integrity, and adherence to stringent industry standards are non-negotiable. Our integrated approach—combining advanced CNC punching, laser cutting, bending, and finishing under one roof—eliminates the coordination delays and quality inconsistencies inherent in fragmented supply chains. For aerospace, medical device, and industrial automation clients, this translates to enclosures that consistently meet IP67, NEMA 4X, and EMI/RFI shielding requirements without costly rework or production bottlenecks.

Our technical capabilities are rigorously validated through ISO 9001:2015 and IATF 16949 certified processes, ensuring every enclosure batch delivers repeatability you can audit. Below are core specifications defining our production envelope for electronic enclosures:

| Specification Category | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm | ASTM A36, AISI 304/316, AL 5052, SPCC |

| Dimensional Tolerance | ±0.05mm (critical features) | ISO 2768-mK, GD&T per drawing |

| Max. Part Dimensions | 1500mm x 3000mm | Customizable per project |

| Surface Finish Options | Anodizing, Powder Coating (RAL), Passivation | MIL-STD-810G, RoHS 3 |

| Production Volume | 1 – 50,000+ units/month | JIT/Lean manufacturing support |

Beyond technical execution, we mitigate your supply chain vulnerability through dual-sourcing strategies for critical raw materials and dedicated project managers fluent in English and technical documentation. Our in-house tooling department reduces new enclosure ramp-up time by 30% compared to industry averages, while real-time production tracking portals provide full transparency from blanking to final assembly. When your engineering team faces last-minute design iterations or urgent prototyping needs, our 72-hour rapid turnaround service for qualified projects prevents costly program delays. This operational agility has enabled clients like Siemens Energy and Yokogawa to accelerate product launches without compromising on the structural integrity or electromagnetic compatibility of their enclosures.

The true measure of partnership lies in shared outcomes. At Wuxi Lead Precision Machinery, we align our success with your ability to deliver flawless end products to market. We invest in understanding your thermal management requirements, regulatory constraints, and assembly line workflows to propose optimizations you may not have considered—such as strategic bend sequencing to eliminate secondary fixturing or material substitutions that reduce weight while maintaining shielding effectiveness.

Initiate a technical dialogue to transform your electronic enclosure strategy. Contact our engineering sales team at [email protected] with your next project specifications. We will provide a comprehensive manufacturability analysis, competitive quotation, and sample timeline within 48 business hours—demonstrating precisely how Lead Precision becomes your decisive advantage in high-stakes fabrication. Your commitment to excellence demands a partner equally uncompromising in precision and accountability. Let us prove that standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.