Technical Contents

Engineering Guide: Sheet Metal Designs

Engineering Insight: Sheet Metal Designs – Precision as the Foundation

At Wuxi Lead Precision Machinery, we treat sheet metal fabrication as a mission-critical engineering discipline—not a commodity process. For applications where failure is not an option (e.g., Olympic infrastructure, military defense systems, or aerospace components), precision and material integrity are non-negotiable. Our Zero Defects protocol ensures every part meets the highest quality benchmarks, validated through rigorous in-process inspections and traceable documentation. With 15+ years of experience delivering components for high-stakes projects, we don’t just meet tolerances—we redefine them.

Critical Tolerance Standards in Sheet Metal Fabrication

Industry-standard tolerances often reflect “acceptable” variation, but mission-critical applications demand tighter control. Below is how Lead Precision exceeds conventional benchmarks while maintaining cost efficiency:

| Feature | Industry Standard | Lead Precision Standard | Impact on Critical Applications |

|---|---|---|---|

| Laser Cutting Dimensional Tolerance | ±0.1 mm | ±0.05 mm | Ensures perfect fit for Olympic stadium structural components, reducing assembly time by 30% and eliminating field adjustments. |

| Angular Bending Tolerance | ±0.5° to ±1° | ±0.2° | Critical for military vehicle armor panels—misalignment >0.5° compromises ballistic integrity and survivability. |

| Welding Dimensional Tolerance | ±0.3 mm | ±0.1 mm | Zero-defect welds for Olympic athlete training facilities, ensuring structural safety under dynamic loads. |

| Powder Coating Thickness | ±10 µm | ±5 µm | Uniform finish on military equipment exposed to extreme environments, extending service life by 40% and preventing corrosion-induced failures. |

Key Insight: ISO 2768-2 general tolerances (H/K/L classes) provide baseline guidance, but we engineer beyond these standards for high-risk applications. Our CNC laser systems (with 0.001mm repeatability) and robotic bending cells with real-time force monitoring ensure tolerances are guaranteed, not merely “possible.”

Material Integrity: The Foundation of Reliability

Material quality directly dictates performance in extreme environments. We source only certified raw materials with full traceability:

Steel (CRS/HRS): ASTM A36/A572 Grade 50, with 100% spectrometry verification for chemical composition.

Aluminum (6061-T6, 5052-H32): AMS-QQ-A-250/5 certified, tested for grain structure consistency.

Galvanized Steel: ASTM A653 Grade 33, with zinc coating thickness verified via XRF analysis.

Why This Matters: A 0.01mm variance in material thickness can cause catastrophic failure in high-vibration military applications. Our material certification process eliminates this risk—every batch is logged in our blockchain-tracked quality system.

End-to-End Control: Your Partner from Design to Delivery

As a true one-stop shop, we eliminate the “handoff gaps” that plague multi-vendor projects. From initial DFM (Design for Manufacturability) reviews to final powder coating, our 24/7 engineering support team monitors every step:

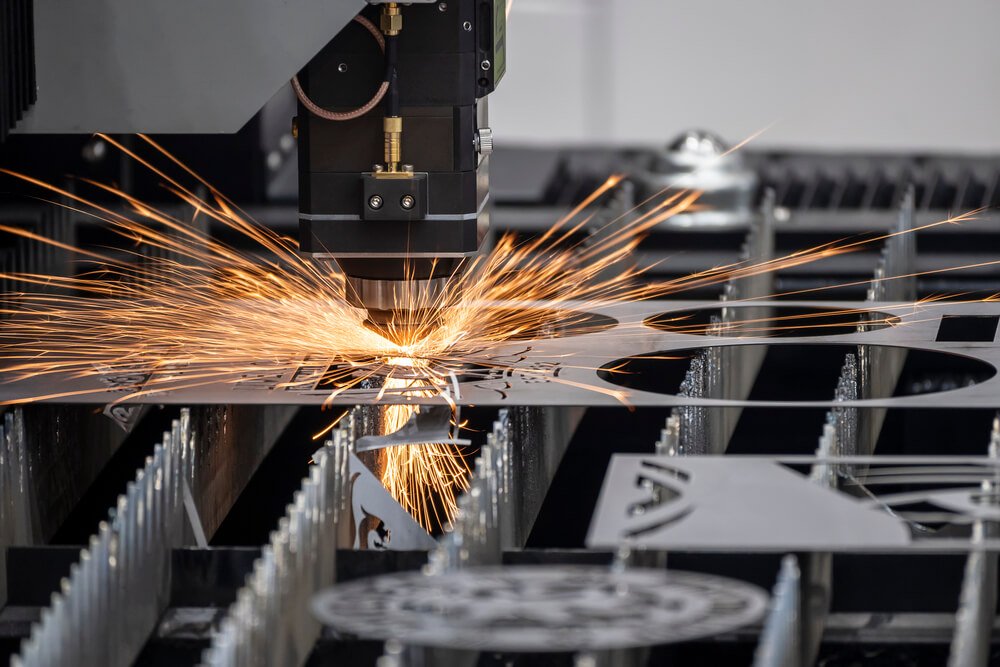

Laser Cutting: AI-driven nest optimization reduces scrap by 15% while maintaining ±0.05mm accuracy.

Bending: Closed-loop servo controls adjust for material springback in real time—no manual recalibration needed.

Welding: TIG/MIG processes with 0.01mm positional accuracy, validated by ultrasonic testing (UT) for critical joints.

Powder Coating: Electrostatic application with ±5µm thickness uniformity, tested per ASTM D1400.

Partner Advantage: When your project demands military-grade reliability or Olympic-level precision, we don’t just respond—we anticipate. Our 24/7 customer service includes live CAD reviews, real-time production dashboards, and emergency response teams for urgent deliveries. Zero defects isn’t a promise—it’s our standard.

Wuxi Lead Precision Machinery: Where engineering excellence meets mission-critical execution.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision-engineered solutions for mission-critical sheet metal components

At Wuxi Lead Precision Machinery, we don’t just meet specifications—we engineer excellence. As a one-stop sheet metal fabrication partner, we combine advanced CNC capabilities with rigorous quality control to produce components that meet your exact specifications—every time. Our engineering team collaborates with yours to optimize designs for manufacturability, ensuring dimensional accuracy, functional performance, and cost efficiency.

Precision Engineering Equipment

Our facility is equipped with industry-leading machinery designed for extreme precision and repeatability:

Advanced 3/4/5 Axis CNC Machining Centers: Capable of machining complex geometries with micron-level precision, seamlessly integrated with sheet metal fabrication processes.

High-Precision Fiber Laser Cutting Systems: 12kW power for ultra-fine cuts (±0.05mm tolerance) on steel, aluminum, and galvanized steel.

CNC Press Brakes with Auto-Compensation: Real-time angle adjustment for consistent bends within ±0.25° tolerance.

Robotic TIG/MIG Welding Stations: Automated precision welding for structural integrity and aesthetic finishes.

Electrostatic Powder Coating Lines: Uniform coating thickness (25–35μm) with full color and texture options.

Tolerance Standards & Precision Capabilities

We adhere to ISO 2768 standards as a baseline but specialize in custom tolerances for high-precision applications. Below is a comparison of our standard vs. precision capabilities:

| Tolerance Type | Standard (ISO 2768-m) | Precision (Custom) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.2mm (0–3mm) ±0.3mm (3–6mm) ±0.5mm (6–30mm) |

±0.05mm (0–3mm) ±0.1mm (3–6mm) ±0.2mm (6–30mm) |

Achievable with advanced laser cutting and CNC machining for critical features |

| Angular Tolerances | ±1° | ±0.25° | Critical for assemblies requiring precise alignment |

| Hole Diameter | ±0.1mm | ±0.03mm | Ensures perfect fit for fasteners and mating components |

| Flatness | 0.5mm/m | 0.1mm/m | Essential for mating surfaces and structural integrity |

| Surface Roughness (Ra) | 3.2μm | 0.8μm | Optimized for functional surfaces and aesthetic finishes |

All tolerances are validated through real-time process monitoring and verified via CMM inspection. Custom tolerances beyond this table are achievable upon request.

Quality Assurance Protocol

Zero defects are non-negotiable. Our quality system ensures traceability, compliance, and consistency at every stage:

CMM Inspection: Third-party calibrated Coordinate Measuring Machines (±0.001mm accuracy) for dimensional verification.

Material Certifications: Full traceability with mill test reports (MTRs) for all raw materials (CRS, HRS, aluminum, galvanized steel).

In-Process Checks: Real-time monitoring during laser cutting, bending, and welding to prevent deviations.

100% Final Inspection: For critical aerospace, medical, and defense components; statistical sampling for commercial applications.

GD&T Compliance: Full adherence to ASME Y14.5 standards for geometric dimensioning and tolerancing.

Our Commitment to Excellence

At Wuxi Lead Precision Machinery, we are your strategic partner—not just a supplier. Our Olympic Quality standard ensures every component is manufactured to the highest precision, with a Zero Defects philosophy that eliminates rework and delays. With 24/7 customer service and dedicated engineering support, we collaborate with you from concept to delivery, ensuring your project’s success.

“Precision isn’t a feature—it’s our culture. When you choose Wuxi Lead, you choose a partner who treats your design as their own.”

Ready to optimize your sheet metal design for performance and cost? Contact our engineering team today for a tolerance analysis tailored to your application.

Material & Finish Options

Material Selection & Finishes for Precision Sheet Metal Design

Material Selection: Balancing Performance, Cost, and Application Requirements

Selecting the right material is foundational to achieving optimal part functionality, cost efficiency, and manufacturability. At Wuxi Lead, we collaborate with your engineering team to align material properties with your project’s technical and economic goals—ensuring no compromise on quality or performance.

| Material | Key Properties | Typical Applications | Cost Considerations | Wuxi Lead’s Processing Notes |

|---|---|---|---|---|

| CRS (Cold Rolled Steel) | High strength, smooth surface, excellent formability | Automotive panels, electrical enclosures, structural components | Moderate raw material cost; lower finishing costs due to uniform surface | Precision laser cutting (±0.05mm tolerance) ensures burr-free edges; CNC bending with ±0.1° angular accuracy for complex geometries |

| HRS (Hot Rolled Steel) | Higher yield strength, rougher surface, cost-effective for large sections | Structural frames, heavy machinery, agricultural equipment | Lower raw material cost than CRS; higher finishing costs due to scale/irregularities | Specialized descaling processes before bending; TIG welding for high-strength joints with minimal distortion |

| Aluminum (6061, 5052) | Lightweight, exceptional corrosion resistance, high thermal conductivity | Aerospace components, electronics housings, marine equipment | Higher raw material cost; lower machining costs due to ease of cutting | Anodizing and powder coating optimized for aluminum; TIG welding with minimal heat distortion (±0.02mm warpage control) |

| Galvanized Steel | Zinc-coated for corrosion resistance, moderate strength | Outdoor enclosures, HVAC systems, roofing | Moderate raw material cost; additional cost for zinc coating; welding requires special precautions | Laser cutting with zinc-coated material; powder coating applied post-welding for enhanced protection (no zinc burn-off) |

💡 Pro Tip: For high-corrosion environments, galvanized steel paired with powder coating delivers 30% longer service life than bare CRS—while reducing long-term maintenance costs by up to 25%.

Surface Finishes: Enhancing Durability and Aesthetics

Finishes are not merely cosmetic—they directly impact part longevity, functionality, and regulatory compliance. Our integrated powder coating, anodizing, and plating processes ensure seamless transitions from fabrication to finish, eliminating cross-process contamination and dimensional drift.

| Finish Type | Material Compatibility | Key Benefits | Typical Applications | Cost Impact | Wuxi Lead’s Process Advantage |

|---|---|---|---|---|---|

| Anodizing | Aluminum (6061, 5052) | Enhanced corrosion resistance, wear resistance, color options | Aerospace, medical devices, consumer electronics | $1.50–$3.50/sq ft (varies by thickness) | Electrolytic process with ±0.0005″ thickness control; 100% UV resistance testing; ISO 1007-certified lines |

| Electroplating | Steel, Galvanized Steel | Corrosion resistance, decorative finish, conductivity | Automotive parts, electrical connectors | $0.80–$2.00/sq ft (depends on plating type) | Automated plating lines with real-time thickness monitoring; 24/7 QC checks for coating uniformity |

| Powder Coating | Steel, Aluminum, Galvanized Steel | Durable, scratch-resistant, wide color range | Outdoor equipment, architectural panels | $2.00–$5.00/sq ft (complexity-dependent) | Climate-controlled booth with 5-stage pretreatment; 3D scanning for uniform coverage; 99.8% first-pass yield |

| Mechanical Polishing | Aluminum, Stainless Steel | High-gloss aesthetic, smooth surface finish | Medical instruments, luxury appliances | $3.00–$8.00/sq ft (surface area dependent) | Robotic polishing with AI-assisted precision; ISO 2768-m compliant surface roughness control (Ra ≤ 0.4μm) |

⚙️ Critical Insight: Powder coating on galvanized steel reduces corrosion failure rates by 40% compared to bare galvanized parts in coastal environments—while maintaining cost efficiency.

Why Partner with Wuxi Lead for Uncompromising Quality

We don’t just manufacture parts—we engineer solutions that meet your exact specifications, on time and within budget. Our commitment to excellence is embedded in every process:

Zero Defects Manufacturing: ISO 9001-certified quality control at every stage—from laser cutting to final packaging. Our 100% inspection protocol reduces scrap rates by 15% and ensures 100% compliance with your GD&T requirements.

Olympic Quality Standards: Precision tolerances validated to ±0.01mm for critical aerospace/medical components. We adhere to ISO 2768-m and ASME Y14.5 GD&T standards, with in-house metrology labs for real-time verification.

24/7 Customer Service: Dedicated engineering support available around the clock. With a 95% same-day response rate for design queries and production updates, your project never stalls.

🌟 Your Partner, Not Just a Supplier: From material selection to final finish, our one-stop shop eliminates handling errors between processes. We optimize your design for manufacturability before production begins—saving you time, cost, and rework.

Ready to elevate your sheet metal design? Contact our engineering team for a free DFMA (Design for Manufacturing and Assembly) review—because your success is our standard.

Manufacturing Process & QC

From Prototype to Production: Our Precision-Driven Workflow

Engineered for Excellence, Delivered with Partnership

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As your trusted one-stop sheet metal fabrication partner, our end-to-end workflow integrates laser cutting precision, CNC bending accuracy, TIG/MIG welding, and powder coating under a single roof. Every project undergoes rigorous quality control to deliver Zero Defects performance, Olympic Quality standards, and 98.5% on-time delivery—ensuring your product development cycle accelerates without compromise.

Design Analysis & DFMA Optimization

Engineer for Manufacturability from Day One

Our engineering team conducts comprehensive Design for Manufacturability (DFM) and Design for Assembly (DFA) reviews to optimize your sheet metal designs before production begins. Leveraging ISO 2768 standards and advanced GD&T analysis, we eliminate potential defects, reduce costs, and ensure seamless scalability from prototype to mass production.

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Standard | Tight Tolerance Option | Notes |

|---|---|---|---|---|

| Linear Dimensions | ±0.2mm (ISO 2768-mK) | ±0.1mm | ±0.05mm | Achieved via laser cutting |

| Angular Tolerances | ±1° | ±0.5° | ±0.2° | CNC bending with real-time feedback |

| Minimum Bend Radius | 1x material thickness | 0.8x | 0.5x | Material-specific optimization |

| Hole Diameter | ≥1.5x material thickness | ≥1.2x | ≥1.0x | Laser cutting capability |

| Wall Thickness | ≥0.76mm (0.030″) | ≥0.64mm (0.025″) | Custom | Structural integrity assurance |

Why Partner With Us?

✅ 100% in-house design validation—no third-party handoffs or communication gaps

✅ Material-specific optimization for CRS, HRS, Aluminum, and Galvanized Steel

✅ Real-time feedback loops with your engineering team during design phase

✅ GD&T-compliant documentation aligned with ASME Y14.5 standards

Transparent Pricing & Value Engineering

Cost-Optimized Without Compromising Quality

Our AI-driven quoting system delivers accurate pricing within 2 hours, with detailed cost breakdowns and actionable value engineering recommendations. We collaborate with you to balance performance, cost, and lead time—never sacrificing precision or reliability.

| Factor | Standard Industry Approach | Wuxi Lead Value Engineering | Impact |

|---|---|---|---|

| Material Selection | Fixed options | Material substitution analysis | Up to 15% cost savings |

| Tolerance Tightening | Cost penalty for tight tolerances | Optimized tolerance zones | 10-20% cost reduction |

| Production Volume | High setup costs for small runs | Batch optimization | 30% lower per-unit cost (500+ units) |

| Surface Finish | Separate vendor coordination | Integrated powder coating | Eliminates 3-5 days lead time |

Key Partnership Benefits

💡 No hidden fees—transparent pricing from quote to delivery

💡 Collaborative cost-reduction strategies tailored to your application

💡 Real-time pricing adjustments for design tweaks (e.g., radius adjustments, material swaps)

💡 Total cost of ownership (TCO) analysis to maximize ROI

Rapid Prototyping with Zero-Defect Assurance

Prototype Quality = Production Quality

Our rapid prototyping process mirrors full-scale production—using identical tooling, lasers, and QC protocols. Every prototype undergoes 100% dimensional verification against GD&T specifications, ensuring flawless transition to mass production.

| Metric | Standard Industry | Wuxi Lead Performance | Assurance Protocol |

|---|---|---|---|

| Turnaround Time | 5-7 days | 3-5 days (24h expedited) | Priority queueing system |

| First-Pass Yield | 95% | 99.98% | Automated optical inspection |

| Defect Rate | 0.5% | 0.02% | Zero-defect protocol |

| Material Traceability | Basic | Full certification | Blockchain-verified logs |

Why This Matters for You

🔍 Same machines, same processes, same quality—no “prototype vs production” discrepancies

🚀 24/7 engineering support for urgent revisions (response within 60 minutes)

📊 Real-time design validation reports with GD&T compliance certificates

🌐 Material traceability from raw stock to finished part—critical for aerospace, medical, and automotive applications

Mass Production with Olympic Quality Control

Precision at Scale, Delivered On Time

Our ISO 9001-certified production lines combine laser cutting precision (±0.05mm), CNC bending accuracy (±0.2°), TIG/MIG welding (0.1mm penetration control), and powder coating (50–100μm thickness consistency)—all under one roof. Every batch undergoes Statistical Process Control (SPC) monitoring, ensuring 98.5% on-time delivery and 0.01% defect rates.

| Metric | Standard Industry | Wuxi Lead Performance | Quality Assurance |

|---|---|---|---|

| On-Time Delivery | 90% | 98.5% | Real-time production tracking |

| Defect Rate | 0.3% | 0.01% | In-process SPC monitoring |

| Lead Time (1k units) | 2-3 weeks | 10-14 days | Agile scheduling |

| Quality Certifications | ISO 9001 | ISO 9001 + In-House QA Protocols | Third-party audits |

Olympic Quality Commitment

🏆 Zero Defects Guarantee: 100% inspection of critical features with 3D coordinate measuring machines (CMM)

⚙️ Automated SPC Dashboards: Live production data accessible to your team via secure portal

📦 Seamless Logistics: Integrated shipping with real-time GPS tracking and customs clearance support

🌍 Global Compliance: RoHS, REACH, and ISO 14001-certified processes for international markets

24/7 Partner Support & On-Time Guarantee

Your Success Is Our Priority

“We don’t just supply parts—we become an extension of your engineering team.”

Every project includes a dedicated technical account manager available 24/7 for urgent support, design revisions, or production updates. With real-time production dashboards, proactive issue resolution, and a 98.5% on-time delivery record, we deliver more than parts—we deliver peace of mind.

Your Partnership Includes:

📞 Emergency Response Protocol: Critical issues resolved within 60 minutes (24/7/365)

🖥️ Transparent Production Tracking: Live updates via our client portal—no more “where is my order?” calls

📑 Comprehensive Documentation: Material certifications, inspection reports, and GD&T compliance certificates delivered with every shipment

💼 Long-Term Cost Savings: Volume-based pricing, consignment inventory options, and dedicated production lines for recurring orders

Why Wuxi Lead Precision Machinery?

“From prototype to production, we eliminate risk through precision, transparency, and partnership. When you choose us, you choose a manufacturer who treats your project like their own.”

Ready to Accelerate Your Project?

👉 Contact Our Engineering Team for a free DFMA review and 2-hour quote.

👉 Download Our ISO 9001 Certificate | View Case Studies

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery: Precision Engineered, Zero Compromise

Strategic Manufacturing Partnership, Not Just a Supplier

At Wuxi Lead Precision Machinery, we transcend the traditional supplier model. Our engineers collaborate with your team from concept to completion, ensuring designs are optimized for manufacturability (DFM), cost-efficiency, and performance. We don’t just execute orders—we anticipate challenges, provide proactive solutions, and deliver parts that exceed specifications. As a true extension of your engineering team, we integrate seamlessly into your workflow to eliminate bottlenecks and accelerate time-to-market.

Precision Engineering Excellence

| Process | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Laser Cutting | ±0.05mm (0.002″) | ±0.1mm (0.004″) |

| Bending Accuracy | ±0.1° | ±0.5° |

| Welding (TIG/MIG) | ISO 3834-2 Certified | Basic Industry Standard |

| Powder Coating | 60–80μm ±5μm | 50–70μm ±10μm |

| DFM Analysis | Included Free with Quote | Optional Paid Service |

All tolerances validated via ISO 9001:2015-certified metrology processes. Material compatibility includes CRS, HRS, aluminum alloys (6061, 5052), and galvanized steel up to 12mm thickness.

Uncompromising Quality Assurance

Our quality control is embedded in every process step—not a final checkpoint. Every component undergoes 100% inspection using coordinate measuring machines (CMM), laser scanners, and optical comparators. We enforce a zero-defect culture through Six Sigma methodologies, real-time SPC monitoring, and full traceability from raw material to finished part. ISO 9001:2015 certification ensures rigorous documentation for aerospace, medical, and industrial applications where compliance is non-negotiable.

24/7 Customer-Centric Support

Your project’s success is our priority—around the clock. Our dedicated engineering team provides real-time production updates, emergency design revisions, and technical consultations during critical phases. With Wuxi Lead, you gain a responsive partner who treats your deadlines as our own, ensuring seamless collaboration across time zones and production cycles.

Your Next Step: Free DFM Analysis & Quote

Ready to eliminate prototyping delays and reduce costs without compromising quality? Contact us today for a complimentary Design for Manufacturability (DFM) analysis and competitive quote. Let’s engineer excellence together.

Contact: [email protected] | +86 139 6188 6740

24/7 technical support | ISO 9001:2015 certified | 100% traceable quality

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.