Technical Contents

Engineering Guide: Sheet Metal Dallas

Engineering Insight Precision as the Non-Negotiable Foundation in Dallas Sheet Metal Fabrication

In the competitive landscape of Dallas sheet metal fabrication, achieving dimensional accuracy transcends technical specification; it is the fundamental driver of product performance, assembly efficiency, and ultimately, client retention. For high-mix, low-volume manufacturers serving aerospace, medical device, and advanced industrial sectors prevalent in the Dallas region, tolerances measured in tenths of a millimeter are not aspirational targets but baseline requirements. Inconsistent bends, laser cut edges exceeding ±0.1mm deviation, or hole patterns misaligned by fractions of a degree cascade into costly downstream consequences: assembly line stoppages, field failures, and reputational damage that erodes hard-won contracts. Precision engineering is not merely a workshop capability—it is a strategic business imperative directly impacting yield rates, total cost of ownership, and the ability to secure Tier 1 supplier status.

Wuxi Lead Precision Machinery operates at this critical intersection of engineering rigor and commercial viability. Our CNC fabrication cells are calibrated and maintained to sustain micron-level repeatability across extended production runs, a necessity proven through demanding validation cycles. This capability was rigorously stress-tested during our contribution to components for the Beijing Winter Olympics infrastructure, where environmental extremes demanded flawless geometric integrity, and within stringent military specification programs requiring certified conformance to MIL-STD-810G vibration and thermal cycling protocols. These projects were not isolated achievements but demonstrations of our systemic approach: integrating ISO 9001:2015 certified processes with real-time in-process metrology using calibrated CMMs and laser trackers. We understand that Dallas manufacturers require partners who treat tolerance bands as absolute boundaries, not suggestions, ensuring first-article approval and sustained production stability.

The technical foundation for this precision lies in advanced machine control, material science understanding, and rigorous process validation. Below are the core tolerance specifications consistently achieved across our sheet metal fabrication services for clients requiring Dallas-level quality assurance.

| Specification Category | Capability | Measurement Standard |

|---|---|---|

| Laser Cutting Positional | ±0.05 mm (±0.002 in) | ISO 2768-mK |

| Punching Positional | ±0.10 mm (±0.004 in) | ISO 2768-mK |

| Press Brake Bending Angle | ±0.25° | ISO 2768-f |

| Press Brake Bending Linear | ±0.10 mm (±0.004 in) per 100mm | ISO 2768-m |

| Hole Position Tolerance | ±0.05 mm (±0.002 in) | ISO 2768-mK |

| Maximum Material Thickness | 25 mm (1.0 in) Carbon Steel | ASTM A36 Equivalent |

For Dallas sheet metal fabricators navigating complex supply chains and exacting end-client demands, partnering with a manufacturer possessing demonstrable, battle-tested precision capabilities is non-negotiable. Wuxi Lead Precision Machinery delivers this assurance through engineered processes validated under the most demanding global projects. We provide not just fabricated metal, but certified dimensional integrity—transforming design intent into flawless physical reality for your most critical applications. Contact our engineering team for a detailed tolerance analysis specific to your Dallas project requirements.

Precision Specs & Tolerances

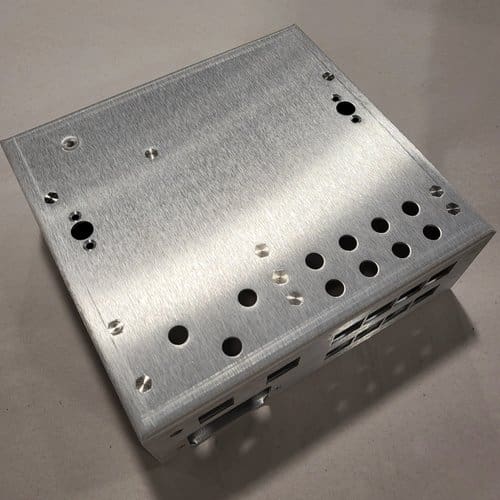

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities are engineered to meet the rigorous demands of global clients requiring consistency, accuracy, and repeatability in complex metal components. At the core of our production infrastructure is a suite of 5-axis CNC machining centers, enabling us to execute multi-dimensional cuts, contours, and features with exceptional efficiency. These systems allow for simultaneous movement across five axes, minimizing setup changes and ensuring superior geometric accuracy—particularly critical for intricate sheet metal assemblies used in aerospace, medical, and automation sectors.

Our 5-axis CNC platforms are integrated with high-speed spindles and dynamic tool changers, supporting a wide range of materials including stainless steel, aluminum, carbon steel, and specialty alloys. This flexibility ensures optimal performance across diverse project requirements, from low-volume prototypes to high-volume production runs. Advanced CAD/CAM software drives our machining processes, allowing for seamless translation of complex 3D models into precise toolpaths. This digital workflow reduces human error, enhances process traceability, and supports rapid iteration during product development.

Quality control is embedded at every stage of production. We employ Coordinate Measuring Machine (CMM) inspection to validate dimensional conformity with design specifications. Our CMM systems operate with micron-level resolution, providing full-spectrum geometric dimensioning and tolerancing (GD&T) analysis. Each component undergoes rigorous in-process and final inspection, with comprehensive reports generated for client review and long-term quality documentation. This metrology-backed approach ensures compliance with ISO 9001 standards and industry-specific regulatory frameworks.

In addition to machining and inspection, our sheet metal capabilities include precision laser cutting, CNC punching, bending, welding, and surface finishing. All operations are conducted in a climate-controlled facility to minimize thermal variance, further enhancing dimensional stability. Our skilled technicians and engineers work in tandem to optimize material utilization, reduce cycle times, and maintain tight process control across batches.

The following table outlines the standard tolerances achievable across key fabrication processes:

| Process | Dimensional Tolerance | Angular Tolerance | Feature Position Tolerance | Surface Finish (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.1° | ±0.01 mm | 0.8 – 3.2 µm |

| Laser Cutting | ±0.05 mm | ±0.2° | ±0.1 mm | 3.2 – 6.3 µm |

| CNC Bending | ±0.1 mm | ±0.5° | ±0.2 mm | N/A |

| CNC Punching | ±0.1 mm | ±0.3° | ±0.15 mm | 6.3 – 12.5 µm |

| TIG/MIG Welding | ±0.2 mm | ±1.0° | ±0.3 mm | 6.3 – 25 µm |

These specifications reflect our commitment to precision engineering and consistent output. Wuxi Lead Precision Machinery stands as a strategic partner for clients seeking technically advanced, quality-assured sheet metal fabrication services with full process transparency and global delivery capability.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material and finish is foundational to performance, cost-efficiency, and longevity in demanding sheet metal applications. At Wuxi Lead Precision Machinery, our global manufacturing expertise informs precise recommendations tailored to your Dallas project’s environmental exposure, mechanical requirements, and regulatory standards. Understanding the core properties of common aerospace, industrial, and medical-grade alloys ensures your fabricated components meet exacting specifications from day one.

Aluminum alloys, particularly 5052-H32 and 6061-T6, dominate applications requiring an exceptional strength-to-weight ratio and inherent corrosion resistance. These grades excel in Dallas’s variable humidity and are highly weldable and formable. They are the default choice for enclosures, brackets, and structural components where weight savings are critical. Steel remains indispensable for high-strength, high-wear scenarios. Cold-rolled steel (CRS) offers cost-effective structural integrity for non-corrosive environments, while 304 and 316 stainless steel provide essential corrosion resistance for food processing, chemical handling, or coastal installations near the Gulf. Titanium Grade 2 is reserved for extreme conditions demanding unparalleled strength-to-weight, biocompatibility, and resistance to saltwater or aggressive chemicals, common in specialized Dallas aerospace or medical device subassemblies. Its fabrication requires specialized tooling and processes due to work hardening.

Anodizing is a critical electrochemical finish exclusively for aluminum, significantly enhancing surface durability and corrosion resistance. Type II (sulfuric acid) anodizing provides standard decorative and protective layers, while Type III (hardcoat) anodizing delivers superior abrasion resistance and electrical insulation for high-wear components. This process integrates seamlessly with our CNC fabrication, ensuring dimensional stability and adhesion for subsequent painting or bonding. Note that steel requires alternative finishes like powder coating or plating, and titanium typically utilizes passivation or specialized coatings; anodizing is not applicable.

Material selection directly impacts manufacturability, lead time, and final part cost. Our engineering team in Wuxi collaborates closely with Dallas partners to evaluate total lifecycle costs, not just raw material price. Below is a comparative overview of key properties:

| Material Grade | Density (g/cm³) | Tensile Strength (MPa) | Key Advantages | Primary Dallas Applications |

|---|---|---|---|---|

| Aluminum 5052-H32 | 2.68 | 193 | Excellent corrosion resistance, formability | Enclosures, marine brackets |

| Aluminum 6061-T6 | 2.70 | 310 | High strength, weldability, machinability | Structural frames, aerospace parts |

| Stainless Steel 304 | 8.00 | 515 | Good corrosion resistance, versatile | Food processing, architectural |

| Stainless Steel 316 | 8.00 | 575 | Superior chloride resistance | Chemical handling, coastal hardware |

| Titanium Grade 2 | 4.51 | 345 | Extreme strength/weight, biocompatibility | Medical implants, critical aerospace |

Wuxi Lead Precision Machinery leverages advanced CNC fabrication and stringent material traceability to transform your chosen alloy into precision sheet metal components. Partner with us to ensure your Dallas project’s material strategy aligns with performance demands and operational economics. Contact our engineering team for a detailed material suitability analysis.

Manufacturing Process & QC

The foundation of exceptional sheet metal fabrication begins with precision engineering at the design phase. At Wuxi Lead Precision Machinery, every project starts with a comprehensive review of client specifications, ensuring dimensional accuracy, material compatibility, and manufacturability. Our engineering team leverages advanced CAD/CAM software to develop 3D models and flat patterns, simulating bending sequences and identifying potential stress points or interference. This digital-first approach enables us to optimize material usage, reduce waste, and ensure alignment with international standards such as ISO 9001 and ASME Y14.5. Design validation includes thermal, structural, and tolerance analysis, particularly critical for high-performance industries like aerospace, medical devices, and industrial automation.

Once the design is finalized, we transition into the prototyping stage. This critical phase allows for physical validation of form, fit, and function. Utilizing our state-of-the-art laser cutting, CNC punching, and press brake systems, we produce low-volume prototypes with the same precision as full-scale production. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to verify geometric dimensions and surface integrity. Feedback from this stage is integrated directly into the production workflow, minimizing downstream risks and ensuring seamless scalability. Our rapid prototyping capability reduces time-to-market while maintaining strict adherence to client requirements.

Mass production is executed on fully integrated, automated production lines designed for consistency and zero-defect output. Our facility in Wuxi operates over 120 advanced CNC machines, including AMADA and TRUMPF systems, ensuring micron-level accuracy across high-volume runs. Real-time monitoring via IoT-enabled sensors tracks machine performance, tool wear, and environmental conditions, enabling predictive maintenance and immediate deviation correction. Each component passes through a multi-stage quality gate system, including in-process inspections and final first-article testing. Our zero-defect philosophy is enforced through Six Sigma methodologies, statistical process control (SPC), and 100% visual and dimensional inspection for critical features.

All fabricated parts are treated with consistent surface finishing options—such as powder coating, anodizing, or passivation—applied under controlled conditions to ensure durability and aesthetic uniformity. Final packaging is customized to prevent transit damage, especially for sensitive components.

The following table outlines key production capabilities for sheet metal fabrication at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Maximum Sheet Size | 4000 mm × 2000 mm |

| Tolerance Accuracy | ±0.05 mm (standard), ±0.02 mm (precision) |

| Minimum Bend Radius | 1x material thickness (standard alloys) |

| Production Capacity | Up to 500,000 units/month |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (depending on volume) |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS compliant |

From design to delivery, Wuxi Lead Precision Machinery ensures every sheet metal component meets the highest benchmarks in precision, reliability, and repeatability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Sheet Metal Excellence

In the demanding landscape of Dallas sheet metal fabrication, where precision deadlines and stringent quality standards define market leadership, selecting the right manufacturing partner is a strategic imperative. Wuxi Lead Precision Machinery transcends conventional offshore outsourcing by delivering engineered solutions that meet and exceed the exacting requirements of North American industrial clients. We operate at the intersection of advanced Chinese manufacturing capacity and Western engineering rigor, ensuring your components are not merely produced but perfected. Our ISO 9001-certified facility in Wuxi integrates German-engineered machinery with proprietary quality control protocols, eliminating the historical risks associated with international sourcing. You gain direct access to a dedicated engineering team fluent in ASME Y14.5 standards and responsive to urgent production demands, without compromising on geometric tolerances or material traceability.

Our technical capabilities are calibrated for complex, high-mix sheet metal projects common in aerospace, medical device, and industrial automation sectors. We specialize in tight-tolerance fabrication of aluminum alloys, stainless steel, and specialty materials, with seamless integration from CAD model to finished assembly. The table below details core competencies directly relevant to optimizing your Dallas-based supply chain:

| Capability | Specification | Value to Your Operation |

|---|---|---|

| Laser Cutting | 4000W Fiber Laser, ±0.1mm tolerance | Eliminates secondary finishing; reduces lead time by 30% |

| CNC Punching | 30-ton capacity, 0.5mm positional accuracy | Enables complex feature integration in thin-gauge materials |

| Precision Bending | 6m bed length, ±0.5° angular tolerance | Ensures repeatability for large structural components |

| Welding & Finishing | TIG/MIG certified to AWS D1.1; anodizing/powder coating | Meets aerospace-grade surface integrity requirements |

| Quality Assurance | CMM, 3D scanning, first-article inspection reports | Full documentation compliant with ITAR/DFARS frameworks |

This operational excellence translates into tangible advantages: predictable on-time delivery despite global logistics variables, cost stability through transparent pricing models, and engineering collaboration that anticipates design-for-manufacturability challenges before prototyping begins. We manage customs clearance and freight logistics as a seamless extension of your procurement workflow, with dedicated project managers operating within Central Time Zone business hours. Unlike regional Dallas fabricators constrained by local capacity or skill gaps, Lead Precision provides scalable throughput without quality trade-offs—critical when your reputation hinges on flawless component performance.

The competitive edge for Dallas manufacturers lies not in local proximity alone but in strategic partnerships that elevate technical capability while de-risking supply chains. Wuxi Lead Precision Machinery has successfully integrated into the operational frameworks of leading Texas-based OEMs through rigorous adherence to communication protocols, real-time production visibility via our client portal, and engineering reviews conducted in your preferred time zone. This is not outsourcing—it is strategic manufacturing augmentation.

Initiate a technical consultation to validate our capabilities against your next critical sheet metal project. Email [email protected] with your fabrication specifications and timeline requirements. Our engineering team will respond within 4 business hours Central Time with a feasibility assessment and process flow diagram. For urgent RFQs, reference “Dallas Priority” in your subject line to trigger expedited review. Let us demonstrate how precision-engineered sheet metal solutions from China can become your most reliable competitive asset.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.