Technical Contents

Engineering Guide: Sheet Metal Custom Cages

Engineering Insight Precision in Sheet Metal Custom Cages

Achieving true precision in custom sheet metal cages transcends mere dimensional accuracy; it is the foundational element ensuring structural integrity, functional reliability, and long-term performance in demanding applications. In sectors like advanced electronics, aerospace instrumentation, and critical infrastructure, a cage is far more than a simple enclosure. It must provide exact electromagnetic interference (EMI) shielding, maintain precise alignment for sensitive internal components, withstand specific environmental stresses, and integrate seamlessly within complex assemblies. Even minor deviations in bend angles, hole placement, or overall flatness can compromise shielding effectiveness, induce mechanical stress on mounted equipment, or cause costly assembly failures downstream. The cost of imprecision manifests not just in rejected parts, but in field failures, warranty claims, and reputational damage – risks far exceeding the initial fabrication cost.

Wuxi Lead Precision Machinery understands these critical stakes intimately. Our engineering team approaches every custom cage project with the rigor honed through supplying mission-critical components for high-profile, zero-tolerance environments. We have engineered and manufactured precision sheet metal enclosures for major infrastructure projects supporting the Beijing Olympic venues, where structural stability and exact dimensional conformity under varying thermal loads were non-negotiable. Similarly, our adherence to stringent military specifications (MIL-STD) for electronic housings demanded absolute consistency in material properties, weld integrity, and surface finishes capable of withstanding extreme vibration and corrosion. This experience instills a culture where ±0.1mm tolerance isn’t an aspiration; it’s the baseline expectation we engineer and inspect against.

Translating this precision into your custom cage requires integrated expertise across the entire fabrication workflow. Material selection must account for springback characteristics during bending. Complex geometries demand sophisticated CNC turret punch programming or laser cutting paths optimized for minimal thermal distortion. Precision forming relies on advanced press brakes with real-time feedback systems and skilled operators who understand material behavior. Critical weld seams require controlled parameters and often post-weld stress relief to prevent warpage. Finally, comprehensive in-process and final inspection using coordinate measuring machines (CMMs) and optical comparators is non-optional. We do not merely manufacture to prints; we validate every critical feature against the functional requirements of the end application.

The table below outlines the core precision specifications consistently achieved and verified across our custom cage production:

| Specification Parameter | Standard Capability | Enhanced Capability (e.g., Military/Olympic Projects) |

|---|---|---|

| Linear Dimensional Tolerance | ±0.1 mm | ±0.05 mm |

| Hole Position Tolerance | ±0.15 mm | ±0.08 mm |

| Bend Angle Tolerance | ±0.5° | ±0.25° |

| Flatness Tolerance (per 300mm) | 0.2 mm | 0.1 mm |

| Critical Feature CMM Reporting | Full Report | Full Report + Statistical Process Control Data |

| Material Certification | Mill Cert Available | Full Traceability + 3rd Party Test Reports |

Precision in sheet metal cages is an engineered outcome, not a manufacturing accident. It demands proven processes, calibrated equipment, and an unwavering commitment to quality embedded in the company culture. At Wuxi Lead Precision Machinery, our legacy in supporting the most exacting projects globally is your assurance that your custom cage will perform flawlessly, exactly as designed, every time. We engineer precision you can deploy with confidence.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions for high-performance industrial applications, specializing in custom enclosures, chassis, and structural cages. Our technical capabilities are built on precision engineering, advanced machinery, and rigorous quality control, ensuring every component meets the exact functional and dimensional requirements of demanding sectors such as automation, energy, telecommunications, and transportation.

At the core of our manufacturing process is a suite of 5-axis CNC machining centers, which provide unparalleled flexibility and accuracy in shaping complex sheet metal components. Unlike conventional 3-axis systems, our 5-axis platforms enable simultaneous multi-directional cutting and forming, allowing us to produce intricate geometries with tight tolerances and superior surface finishes. This capability is particularly critical when fabricating custom cages that require precise mounting interfaces, integrated heat dissipation features, or non-orthogonal structural elements. The ability to machine from multiple angles in a single setup reduces cumulative error, improves repeatability, and shortens production cycles—delivering consistent quality and faster turnaround times.

Material selection is optimized for structural integrity and environmental resilience. We work with a broad range of sheet metals including cold-rolled steel, stainless steel (grades 304, 316), aluminum alloys (5052, 6061), and galvanized substrates. Each material is processed using laser cutting, precision bending, and CNC punching technologies, ensuring clean edges, accurate fold lines, and minimal deformation. Our in-house welding and finishing stations support MIG, TIG, and spot welding techniques, followed by surface treatments such as powder coating, anodizing, or passivation to enhance durability and corrosion resistance.

Quality assurance is integral to our production workflow. Every custom cage undergoes comprehensive dimensional verification using a Coordinate Measuring Machine (CMM), capable of sub-micron level inspection. This metrology-grade validation ensures that all critical features—mounting holes, alignment surfaces, and geometric profiles—conform precisely to engineering drawings and GD&T specifications. Our quality management system is ISO 9001-certified, with documented inspection reports provided for full traceability.

The following table outlines the standard technical tolerances we maintain across key fabrication processes:

| Process | Dimensional Tolerance | Angular Tolerance | Positional Tolerance | Surface Finish (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.1° | ±0.01 mm | 0.8 – 3.2 µm |

| Laser Cutting | ±0.1 mm | ±0.2° | ±0.15 mm | 6.3 – 12.5 µm |

| CNC Bending | ±0.2° | ±0.5° | ±0.2 mm | N/A |

| Welding (Post-Process) | ±0.3 mm | ±0.5° | ±0.3 mm | 12.5 – 25 µm |

These capabilities, combined with our engineering-first approach, position Wuxi Lead Precision Machinery as a trusted partner for high-precision sheet metal cages where reliability, accuracy, and repeatability are non-negotiable.

Material & Finish Options

Material Selection for Precision Sheet Metal Custom Cages

Selecting the optimal material for sheet metal custom cages is critical for performance, longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize engineering requirements over generic specifications. Aluminum alloys, particularly 6061-T6, dominate lightweight applications requiring EMI shielding and thermal management. Its high strength-to-weight ratio reduces structural load in aerospace and telecom enclosures, while natural corrosion resistance minimizes maintenance. However, aluminum lacks the rigidity needed for high-impact industrial environments, where steel becomes essential. Cold-rolled steel (CRS) and stainless steel 304 offer superior durability and weldability for heavy machinery housings. Stainless variants excel in corrosive settings like marine or chemical processing, though material costs rise 30-40% versus CRS. For extreme conditions—such as satellite components or medical implants—titanium Grade 2 provides unmatched strength at high temperatures and near-immunity to saltwater degradation. Its density is 45% lower than steel, but machining complexity increases lead times and costs by 200-300%. Always validate material choices against load requirements, environmental exposure, and lifecycle costs.

Anodizing remains the industry-standard finish for aluminum cages, transforming the surface into a hard, non-conductive oxide layer. Type II (sulfuric acid) anodizing delivers cost-effective corrosion resistance and paint adhesion for indoor electronics enclosures. Type III (hardcoat) anodizing achieves 50-70 μm thickness with 600-800 HV hardness, critical for outdoor telecom cabinets facing abrasive weather. Note: Anodizing cannot be applied to steel or titanium; these require powder coating or passivation instead. Incorrect finish selection risks galvanic corrosion—e.g., pairing untreated aluminum with copper components. We rigorously test adhesion per ASTM B577 and thickness per MIL-A-8625 to prevent field failures.

Below summarizes key material properties for cage fabrication:

| Material | Density (g/cm³) | Yield Strength (MPa) | Corrosion Resistance | Typical Cage Applications |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 276 | Moderate (enhanced with anodizing) | Telecom racks, server housings |

| Stainless 304 | 8.0 | 215 | Excellent | Marine equipment, food processing |

| Titanium Gr2 | 4.5 | 345 | Exceptional | Aerospace, medical implants |

Material decisions directly impact CNC machining parameters, weld integrity, and final part accuracy. Thin-walled cages (<1.5mm) in aluminum require specialized tooling to prevent warpage, while titanium demands slower feeds and rigid setups to avoid heat buildup. Wuxi Lead’s engineering team collaborates early in your design phase to align material specs with manufacturability—ensuring your cage meets IP ratings, vibration tolerance, and regulatory standards without over-engineering. We provide full material traceability (mill certificates) and in-house anodizing validation. Contact our precision engineering division for ASTM-certified material recommendations tailored to your operational environment.

Manufacturing Process & QC

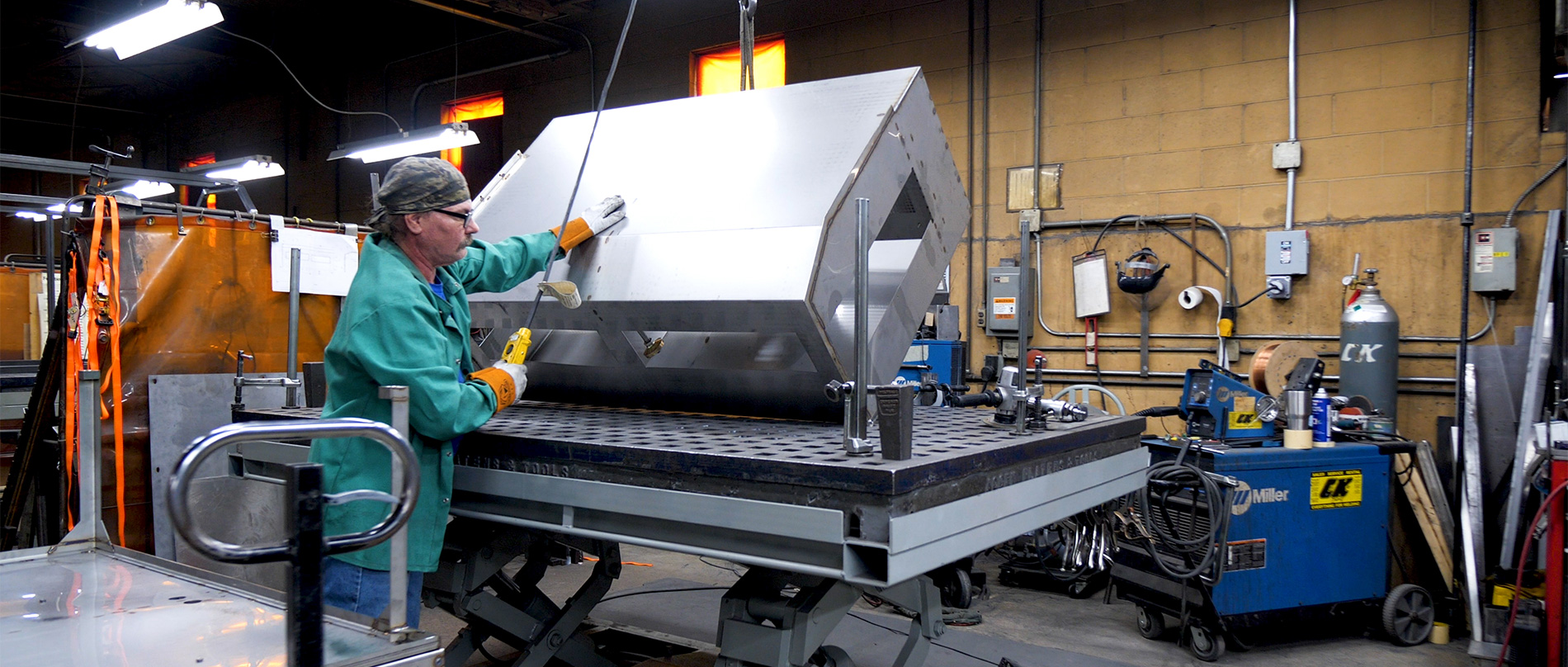

From Concept to Completion: The Sheet Metal Custom Cage Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, the production of custom sheet metal cages follows a rigorously defined workflow designed to ensure precision, repeatability, and zero defects. Every stage—from initial design to mass production—is engineered for maximum efficiency and uncompromising quality. This structured process ensures that our clients receive fully compliant, high-performance enclosures tailored to exact specifications.

The journey begins with design engineering, where our technical team collaborates closely with the client to interpret functional requirements, environmental conditions, and integration needs. Using advanced CAD software such as SolidWorks and AutoCAD, we develop 3D models and 2D fabrication drawings, incorporating precise bend allowances, weld zones, and tolerance stacks. Design for Manufacturability (DFM) analysis is conducted at this stage to eliminate potential production issues, optimize material usage, and ensure structural integrity. All designs undergo internal review and client approval before proceeding.

Next, we move into prototyping. A small batch of 1–5 units is fabricated using the same equipment and materials intended for full-scale production. This phase validates the design under real-world conditions, allowing for dimensional inspection, fit testing, and functional evaluation. We employ laser cutting, CNC punching, precision bending, and MIG/TIG welding as required, all performed by certified technicians. Any deviations identified during inspection are addressed through rapid design iteration. Only after the prototype passes all quality checkpoints—dimensional accuracy, surface finish, and mechanical performance—is the design released for mass production.

Mass production leverages fully automated workflows on state-of-the-art machinery, including Amada CNC press brakes, Bystronic laser cutters, and robotic welding cells. Each工序 (process step) is governed by standardized work instructions and real-time process monitoring. In-line inspection stations verify critical dimensions at key intervals, while final assemblies undergo 100% functional and visual inspection. Our ISO 9001-certified quality management system enforces traceability through batch numbering and digital inspection records.

To ensure zero defects, we implement Statistical Process Control (SPC) and First Article Inspection (FAI) protocols. Any non-conformance triggers immediate root cause analysis and corrective action. This closed-loop quality approach minimizes variability and ensures every custom cage meets the highest standards of performance and reliability.

Below are key technical specifications supported in our production process:

| Parameter | Capability |

|---|---|

| Material Thickness | 0.5 mm – 6.0 mm (steel, stainless, aluminum) |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2° / ±0.5 mm |

| Maximum Part Size | 3000 mm × 1500 mm |

| Surface Finishes | Powder coating, anodizing, passivation, galvanizing |

| Welding Standards | ISO 3834, AWS D1.1 |

| Production Capacity | Up to 50,000 units/month |

Through disciplined process control and engineering excellence, Wuxi Lead delivers custom sheet metal cages that combine precision, durability, and flawless consistency—every time.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Cage Projects with Engineering Precision

Selecting a fabrication partner for custom sheet metal enclosures demands more than basic manufacturing capability. It requires an engineering ally who understands how structural integrity, electromagnetic shielding, thermal management, and assembly efficiency directly impact your product’s performance and lifecycle cost. At Wuxi Lead Precision Machinery, we operate at the intersection of advanced CNC technology and deep application expertise. Our dedicated team collaborates from initial concept through volume production, ensuring your custom cages meet exact functional and regulatory requirements while optimizing material utilization and manufacturability. We transform complex designs into flawless physical assets using industry-leading processes validated across aerospace, medical device, and industrial automation sectors.

Our technical capabilities are engineered for uncompromising quality in demanding applications. The following specifications define our production envelope and precision standards:

| Specification Category | Capability | Tolerance/Detail |

|---|---|---|

| Material Range | Cold Rolled Steel, Stainless Steel (304/316), Aluminum (5052/6061), Galvanized Steel | Up to 6mm thickness |

| Forming Precision | CNC Turret Punching, Laser Cutting, Press Brake Forming | ±0.02mm linear, ±0.1° angular |

| Maximum Work Envelope | 3000mm x 1500mm x 3mm (Laser), 2500mm x 1250mm (Punch) | Full 3D nesting optimization |

| Secondary Operations | Welding (TIG/MIG), Deburring, Anodizing, Powder Coating | In-house quality-controlled finishing |

| Quality Assurance | CMM Inspection, First Article Reporting, SPC Monitoring | ISO 9001:2015 certified processes |

This technical foundation enables us to solve challenges others cannot. Our engineers proactively engage in Design for Manufacturability (DFM) reviews, identifying potential assembly conflicts or material waste before cutting begins. Rapid prototyping with identical production tooling ensures seamless transition to volume runs, while our real-time production tracking system provides transparency into every stage of your order. For enclosures requiring EMI/RFI shielding or thermal dissipation, we implement material-specific bending strategies and joint treatments that maintain critical performance metrics without costly rework.

Partnering with Lead Precision means eliminating the risk of dimensional drift in high-tolerance cage assemblies and avoiding the hidden costs of supplier requalification. We assign a single project engineer to your account from RFQ to delivery, ensuring consistent technical oversight and accountability. Our facility in Wuxi operates under strict environmental controls to maintain dimensional stability during fabrication, a critical factor for enclosures integrating sensitive electronics or precision mechanisms.

Do not compromise your product’s reliability on substandard enclosure fabrication. Contact our engineering team today to discuss how our precision sheet metal capabilities can enhance your next custom cage project. Send your detailed requirements, 3D models, or target specifications to [email protected]. We will provide a comprehensive technical and commercial proposal within 48 hours, including DFM feedback and a production timeline. Let Lead Precision become your trusted partner for enclosures that perform as engineered. Your project’s success begins with an email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.