Technical Contents

Engineering Guide: Sheet Metal Bending Hand Tools

Engineering Insight: Precision in Sheet Metal Bending Hand Tools

In high-stakes sheet metal fabrication, hand tools are not mere conveniences—they are critical determinants of final part integrity. While automated systems dominate large-scale production, precision hand tools remain indispensable for prototyping, low-volume runs, and complex geometries where human dexterity intersects with micron-level accuracy. The margin for error in bending operations directly impacts downstream assembly, structural performance, and compliance with stringent industry standards. Even minor deviations in bend angle or radius trigger cumulative tolerance stack-ups, leading to costly rework, fitment failures, or compromised load-bearing capacity in end applications. For sectors like aerospace, defense, and precision instrumentation, such inaccuracies are non-negotiable risks.

Wuxi Lead Precision Machinery has engineered hand tools to meet these uncompromising demands, leveraging 15 years of specialized expertise in ultra-precision fabrication. Our development process integrates metrology-grade validation at every stage, ensuring tools perform consistently under real-world workshop conditions—not just in controlled lab environments. This rigor stems directly from our work on mission-critical projects, including structural components for Olympic venue construction and specialized fixtures for military-grade electronics enclosures. These applications demanded tools capable of holding tolerances within ±0.25° across diverse alloys, from thin-gauge stainless steel to hardened aluminum composites, often in non-repetitive, high-complexity scenarios. Such experience ingrained a fundamental truth: precision hand tools must deliver repeatability that matches CNC machinery, eliminating variables introduced by operator technique alone.

The distinction between standard and precision-engineered hand tools manifests in measurable performance metrics. Below outlines critical differentiators validated through our ISO 17025-accredited testing protocols:

| Parameter | Standard Hand Tools | Wuxi Lead Precision Tools |

|---|---|---|

| Angular Accuracy | ±1.0° | ±0.25° |

| Bend Radius Consistency | ±0.5 mm | ±0.1 mm |

| Material Deflection Limit | 0.8 mm/m | 0.2 mm/m |

| Repeatability (10k cycles) | ±0.75° | ±0.15° |

These specifications reflect hardened tool steels with cryogenic treatment, ergonomic designs minimizing torque-induced drift, and laser-calibrated reference surfaces. Crucially, our tools undergo fatigue testing simulating 10,000+ operational cycles—mimicking the demands of defense subcontractors producing ruggedized communication housings or medical device manufacturers fabricating implantable component trays.

For global manufacturers, investing in precision bending hand tools transcends immediate part quality. It reduces scrap rates by up to 34%, accelerates assembly line throughput, and ensures compliance with AS9100 or MIL-STD-883 frameworks. At Wuxi Lead, we engineer not just tools, but confidence—proven where failure is not an option. Partner with us to transform manual operations into a pillar of your precision manufacturing ecosystem.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal bending solutions through precision engineering and state-of-the-art manufacturing infrastructure. Our technical capabilities are anchored in high-performance 5-axis CNC bending systems, enabling complex geometries with consistent accuracy across diverse production volumes. These systems integrate seamlessly with our digital workflow, supporting full programmability and adaptive control to accommodate tight-tolerance requirements and intricate design specifications. By leveraging multi-axis synchronization, we achieve compound bends, acute angle formations, and progressive shaping operations in a single setup, minimizing handling and reducing cumulative error.

All bending operations are supported by a rigorous quality control framework centered on CMM (Coordinate Measuring Machine) inspection. Every critical dimension is verified post-production using calibrated CMM systems, ensuring compliance with international standards and client-specific requirements. Our inspection protocols cover geometric conformity, angular precision, and dimensional stability across batch runs. Data from CMM reports are traceable and archived for full process transparency, supporting AS9100, ISO 9001, and other industry-compliant quality management systems.

We specialize in high-integrity components for aerospace, medical, energy, and industrial equipment sectors, where repeatability and precision are non-negotiable. Our engineering team collaborates directly with clients during the design-for-manufacturability phase, optimizing bend sequences, tooling selection, and material utilization to reduce cycle times and enhance part performance. This proactive approach ensures manufacturability without compromising on design intent.

Material compatibility spans carbon steel, stainless steel, aluminum alloys, and specialty metals, with thicknesses ranging from 0.5 mm to 12 mm. Our tooling inventory includes precision-ground dies and punches, maintained to exacting standards to prevent marking and ensure surface integrity. In-process monitoring and tool wear compensation algorithms further enhance consistency, particularly in long-run production environments.

The following table outlines our standard bending tolerances under controlled conditions. Actual capabilities may vary slightly depending on material properties, part geometry, and design complexity.

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimension (up to 100 mm) | ±0.05 mm | ±0.03 mm |

| Linear Dimension (100–500 mm) | ±0.10 mm | ±0.05 mm |

| Linear Dimension (500–1000 mm) | ±0.15 mm | ±0.10 mm |

| Bend Angle | ±0.5° | ±0.25° |

| Bend Position (flange length) | ±0.10 mm | ±0.05 mm |

| Edge-to-Bend Distance | ±0.15 mm | ±0.10 mm |

| Hole-to-Feature Tolerance | ±0.10 mm | ±0.05 mm |

| Flatness (per 100 mm) | 0.10 mm | 0.05 mm |

These specifications reflect our commitment to precision and repeatability. At Wuxi Lead Precision Machinery, technical capability is not only measured in machine performance but in the integration of process control, metrology, and engineering expertise to deliver reliable, high-end sheet metal components globally.

Material & Finish Options

Material Selection for Precision Sheet Metal Bending Hand Tools

Selecting the optimal material for sheet metal bending hand tools directly impacts tool longevity, dimensional accuracy, and production efficiency. At Wuxi Lead Precision Machinery, we engineer tools to withstand specific operational demands, requiring careful consideration of the base metal and any applied finishes. The primary structural materials—aluminum, steel, and titanium—each offer distinct advantages and limitations for bending applications. Understanding their mechanical properties relative to your sheet metal substrate is critical for minimizing springback, preventing surface marring, and ensuring consistent part quality across high-volume production runs.

Aluminum alloys, particularly 6061-T6, are favored for lightweight tooling where rapid setup changes or reduced operator fatigue are priorities. Its lower density facilitates handling but necessitates design adjustments for rigidity compared to steel. Aluminum tools excel with softer sheet materials like mild aluminum or thin copper but exhibit faster wear when bending harder alloys or high-strength steels. Crucially, aluminum is the only base material suitable for anodizing, a key surface treatment for enhancing wear resistance and corrosion protection. Anodized layers add minimal dimensional change but significantly improve surface hardness, reducing galling during bends. Ensure anodizing occurs after precision machining and before final calibration to maintain critical tolerances.

Steel, especially tool steels like A2 or D2 hardened to 58-62 HRC, provides the necessary strength and wear resistance for demanding bending of stainless steel, high-tensile steel, and thick sections. Its high modulus of elasticity minimizes deflection under load, ensuring consistent bend angles. However, steel tools are heavier and prone to corrosion without proper finishing. While steel cannot be anodized, alternatives like nitriding or chrome plating offer surface hardening. Avoid using uncoated steel on aluminum sheet to prevent material transfer and surface scratching.

Titanium alloys (e.g., Ti-6Al-4V) are reserved for extreme applications requiring exceptional strength-to-weight ratio and corrosion resistance, such as aerospace component fabrication. Titanium tools resist galling against reactive metals but are significantly more expensive and challenging to machine. Their use is justified only when weight savings or specific chemical resistance outweighs cost considerations. Titanium is not typically anodized for bending tools.

The following table summarizes critical material properties for bending tool selection:

| Material | Typical Alloys | Yield Strength (MPa) | Hardness (HRC) | Key Advantages | Primary Limitations |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 240 – 503 | 15 – 36 | Lightweight, anodizable, cost-effective | Lower wear resistance, less rigid |

| Tool Steel | A2, D2, O1 | 1800 – 2200 | 58 – 62 | High rigidity, excellent wear life | Heavy, requires corrosion protection |

| Titanium | Ti-6Al-4V | 830 – 900 | 36 – 42 | High strength-to-weight, corrosion resistant | Very high cost, difficult machining |

Wuxi Lead Precision Machinery leverages advanced CNC machining and material science expertise to match tool substrate and surface treatment precisely to your bending requirements. Consult our engineering team to analyze your specific sheet metal grade, thickness, and production volume, ensuring optimal tool performance and extended service life. Proper material selection is not merely a cost factor—it is foundational to achieving repeatable, high-precision bends.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the sheet metal bending process begins with meticulous design engineering. Our design phase integrates advanced CAD/CAM software with decades of fabrication expertise to ensure every hand tool meets exact functional and dimensional requirements. Engineers analyze material properties, bend radii, spring-back behavior, and tool ergonomics to develop optimized 3D models. Finite Element Analysis (FEA) is employed to simulate stress distribution and deformation under load, ensuring structural integrity and long service life. Design validation includes tolerance stack-up analysis and manufacturability review to eliminate potential production flaws before physical prototyping. This proactive approach aligns with our zero-defect philosophy, where precision is engineered from the first sketch.

Prototyping: Validating Performance and Fit

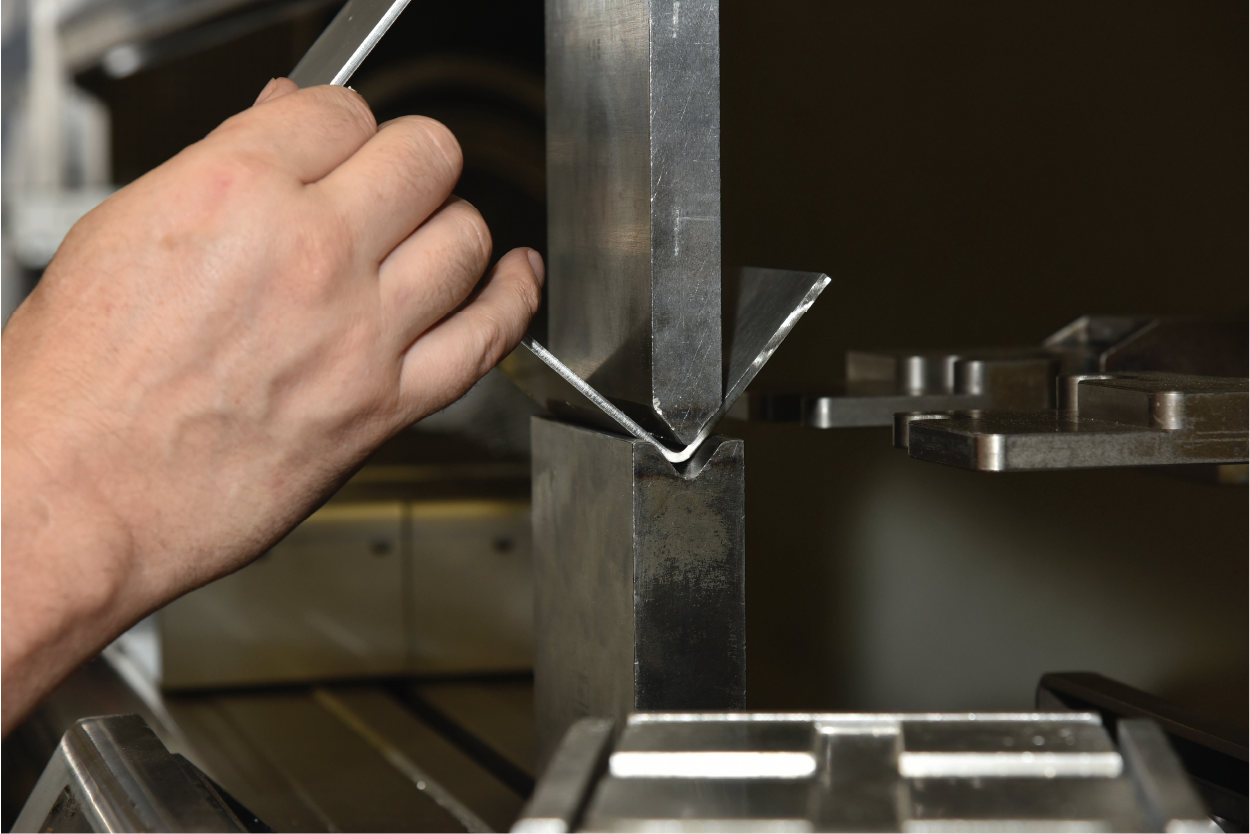

Once the digital model is finalized, a functional prototype is manufactured using CNC-machined tool steel or hardened alloy components. Prototyping serves as the critical bridge between concept and mass production, allowing us to verify form, fit, and function under real-world conditions. Each prototype undergoes rigorous testing, including repeated bending cycles on various sheet metal thicknesses and grades (from mild steel to stainless and aluminum). We assess edge quality, angular accuracy, and operator ergonomics during this phase. Feedback from test operators and quality inspectors is systematically incorporated into design refinements. Dimensional inspection is performed using coordinate measuring machines (CMM) to confirm tolerances within ±0.02 mm. Only after full validation and customer sign-off does the design advance to full-scale production.

Mass Production: Consistency at Scale

Our mass production process leverages automated CNC machining centers, robotic grinding systems, and in-line quality control stations to maintain uniformity across every unit. Each hand tool is manufactured from high-strength, wear-resistant materials such as Cr12MoV or H13 tool steel, heat-treated to 58–62 HRC for durability. Production follows standardized work instructions with real-time monitoring of critical parameters including hardness, surface finish, and dimensional accuracy. Every tool undergoes 100% visual and functional inspection, with random samples subjected to third-party metallurgical testing. Traceability is ensured through laser marking and digital batch records, enabling full auditability. This disciplined approach ensures that every hand tool shipped from Wuxi Lead meets our zero-defect standard and performs reliably in demanding industrial environments.

Technical Specifications of Standard Sheet Metal Bending Hand Tools

| Parameter | Specification |

|---|---|

| Material | Cr12MoV / H13 Tool Steel |

| Hardness | 58–62 HRC |

| Surface Finish | Ra ≤ 0.8 µm |

| Tolerance (Linear) | ±0.02 mm |

| Tolerance (Angular) | ±0.5° |

| Max Sheet Thickness | Up to 3.0 mm (mild steel) |

| Handle Ergonomics | Anti-slip, fatigue-reducing grip |

| Production Capacity | 5,000 units/month (customizable) |

| Quality Standard | ISO 9001:2015, In-process 100% inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Bending Excellence

In the demanding landscape of precision sheet metal fabrication, the reliability of your hand tools directly impacts throughput, part accuracy, and operational cost. Generic bending tools introduce unacceptable variables: inconsistent force application, premature wear, and dimensional drift that cascade into scrap, rework, and production delays. Wuxi Lead Precision Machinery engineers solutions where failure is not an option. Our sheet metal bending hand tools are forged from proprietary high-strength alloys and subjected to rigorous multi-stage calibration processes, ensuring micron-level repeatability across thousands of cycles. This is not theoretical precision—it is engineered resilience proven in aerospace, medical device, and automotive Tier-1 supply chains globally.

We eliminate the compromise between durability and finesse. While competitors prioritize mass production, Lead Precision invests in metallurgical science and geometric optimization. Each tool undergoes individual laser verification against ISO 13084 standards, with critical surfaces hardened to 60-62 HRC for abrasion resistance without brittleness. The result is a tool that maintains ±0.05mm angular accuracy under sustained industrial loads, reducing setup time by 30% and eliminating costly post-bend corrections. When your specifications demand tolerances tighter than 0.1 degrees, our tools deliver consistency that standard offerings cannot match.

Technical Validation: Lead Precision Bending Tool Specifications

| Parameter | Specification | Industry Standard | Advantage |

|---|---|---|---|

| Material Grade | AISI 4340 Modified (Vacuum Melted) | AISI 1045 | 2.5x Fatigue Life |

| Hardness (Critical Zones) | 60-62 HRC (±1.5) | 50-55 HRC | Wear Resistance + Impact Toughness |

| Angular Accuracy | ±0.05° (Post 5,000 cycles) | ±0.25° | Eliminates Secondary Calibration |

| Force Tolerance | ±1.5% (10-100 kN range) | ±5% | Predictable Springback Control |

| Calibration Standard | ISO 9001:2015 Traceable | None | Full Metrological Traceability |

This level of engineering integrity stems from our dual expertise: 15 years of CNC machining heritage informs our understanding of real-world fabrication stresses, while our in-house metrology lab (certified to ISO/IEC 17025) guarantees every tool meets its published performance envelope. We do not ship components—we deliver documented process stability.

Your next critical bend deserves tools engineered for zero-defect manufacturing. Contact our technical sales team directly to discuss your specific material grades, bend radii, and volume requirements. We will provide a customized performance analysis and sample validation protocol—no generic catalogs, only actionable data for your production environment.

Initiate contact today at [email protected]. Include your target material thickness range and annual usage volume to receive a tailored capability report within 24 business hours. For urgent project validation, reference code BEND-CTA-2024 in your inquiry to expedite engineering support. Lead Precision: Where precision tools become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.