Technical Contents

Engineering Guide: Service Stampa 3D

Engineering Insight: The Role of Precision in 3D Stamping Services

In the domain of custom metal manufacturing, the term service stampa 3d refers to advanced three-dimensional stamping processes that enable the formation of complex geometries with high repeatability and structural integrity. Unlike conventional flat stamping, 3D stamping manipulates sheet metal into contoured, multi-axis forms—often used in aerospace, defense, medical, and high-performance automotive applications. At the heart of successful 3D stamping lies precision: not merely as a quality benchmark, but as a foundational engineering requirement.

Precision in 3D stamping governs dimensional accuracy, material behavior consistency, and long-term component reliability. Even minor deviations in tool alignment, press force distribution, or material springback can result in significant downstream assembly issues or performance failures. This is especially critical when producing safety-critical components where tolerances are measured in microns and material properties must remain uniform across production batches.

Wuxi Lead Precision Machinery has built its reputation on mastering these challenges. With over 15 years of specialization in high-precision metal forming, our engineering team applies deep metallurgical and mechanical expertise to every 3D stamping project. Our experience extends to supplying components for Olympic-grade sporting equipment and mission-critical military systems—applications where failure is not an option. These demanding sectors require not only adherence to tight tolerances but also full traceability, rigorous testing protocols, and zero-defect manufacturing standards.

Our 3D stamping capabilities are supported by advanced simulation software, high-tonnage servo presses, and in-house tooling design. Finite element analysis (FEA) is used to model material flow and predict deformation, allowing for preemptive correction of potential defects such as wrinkling, thinning, or residual stress. Each production run undergoes real-time monitoring and post-process inspection using coordinate measuring machines (CMM) and laser scanning to ensure compliance with ISO 1302 and AS9100 standards.

The integration of precision engineering with scalable manufacturing is what sets Wuxi Lead apart. We do not treat 3D stamping as a standalone operation but as a complete system involving material selection, die design, process validation, and quality assurance—all aligned to deliver components that perform exactly as intended, every time.

Below are key technical specifications that define our 3D stamping service capabilities.

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.1 mm – 6.0 mm |

| Maximum Press Tonnage | 1,200 tons |

| Tolerance Accuracy | ±0.02 mm |

| Tooling Design & Fabrication | In-house CNC and EDM machining |

| Simulation Software | AutoForm, DEFORM, SolidWorks Simulation |

| Inspection Equipment | CMM, Laser Scanning, Optical Profilometry |

| Industry Standards Compliant | ISO 9001, ISO 1302, AS9100, MIL-STD-810 |

| Production Volume Flexibility | Prototyping to High-Volume Serial Production |

Precision in 3D stamping is not achieved by machinery alone—it is engineered through experience, validated by data, and proven in performance. At Wuxi Lead Precision Machinery, we bring this comprehensive approach to every service stampa 3d project, ensuring that our clients receive not just parts, but precision-engineered solutions.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for demanding aerospace, medical, and industrial applications. Contrary to the query reference to service stampa 3d (3D printing), our core expertise lies in high-precision subtractive manufacturing via multi-axis CNC machining. While additive processes serve specific niches, we specialize in producing mission-critical metal components where tight tolerances, material integrity, and repeatable accuracy are non-negotiable. Our integrated approach ensures every part meets the rigorous standards required by global Tier-1 suppliers and OEMs.

Our facility is anchored by state-of-the-art 5-axis CNC machining centers, enabling complex geometries in a single setup. This eliminates cumulative errors from multiple fixtures, reduces lead times, and ensures superior surface finishes. We machine exotic alloys including Inconel 718, Ti-6Al-4V, 17-4 PH stainless steel, and aluminum 7075-T6 with unwavering consistency. The simultaneous 5-axis capability allows undercuts, deep cavities, and organic contours impossible with 3-axis systems, directly supporting lightweighting and performance-driven designs. All equipment operates under ISO 9001 and AS9100-certified protocols, with real-time tool monitoring and automated coolant management to maintain thermal stability during extended runs.

Quality control is embedded at every process stage, not merely as a final checkpoint. Our coordinate measuring machines (CMMs) perform full-spectrum dimensional validation against CAD models, including GD&T analysis to ISO 1101 standards. Each component undergoes first-article inspection, in-process checks at critical waypoints, and 100% final verification for high-risk features. Beyond CMMs, we deploy optical comparators, surface roughness testers, and metallurgical analysis to validate material properties and microstructure. This closed-loop system feeds data directly to machinists, enabling immediate process adjustments and zero-defect outcomes.

Material selection is optimized for both performance and manufacturability. We collaborate with clients during DFM to recommend alloys and geometries that maximize yield without compromising function. For instance, titanium components leverage our slow-speed, high-torque machining strategies to prevent work hardening, while aluminum aerospace brackets utilize high-speed milling for optimal chip evacuation and surface integrity.

The table below details our standard and precision tolerance capabilities across common features. These values reflect achievable results under controlled conditions with appropriate fixturing and material stability.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | Up to 300 mm; tighter with Invar fixtures |

| Hole Diameter | ±0.025 mm | ±0.003 mm | Reamed/bored; positional ±0.01 mm |

| Surface Flatness | 0.05 mm | 0.005 mm | Per 100 mm²; verified via CMM scan |

| Profile of a Surface | 0.1 mm | 0.01 mm | Complex contours; 5-axis validated |

| True Position | ±0.05 mm | ±0.008 mm | Critical for mating assemblies |

Wuxi Lead transforms engineering intent into certified reality. Our CNC machining ecosystem—combining cutting-edge hardware, metrology-grade validation, and material science expertise—delivers components that exceed ASME Y14.5 and ISO 2768-mK requirements. Partner with us for metal parts where precision isn’t optional; it’s the foundation.

Material & Finish Options

Material Selection for High-Precision 3D Stamping Services

In the realm of custom metal manufacturing, particularly in high-end 3D stamping applications, material selection is a critical determinant of both performance and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components tailored to the exacting demands of industries such as aerospace, automotive, medical devices, and industrial automation. Our expertise in 3D stamping enables us to work with a range of advanced materials, with aluminum, steel, and titanium standing out as the most strategically important due to their unique mechanical and chemical properties.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications where weight reduction is paramount without sacrificing structural integrity. Grade 6061-T6 is a common choice in our production line, offering good weldability and moderate strength, making it ideal for enclosures, brackets, and lightweight structural components. However, aluminum’s lower hardness compared to steel necessitates careful design considerations when high wear resistance is required.

Steel, particularly stainless steel grades such as 304 and 316, offers superior strength, durability, and resistance to high temperatures and corrosive environments. These properties make steel the material of choice for components operating in harsh conditions, including medical instruments and marine hardware. While heavier than aluminum, steel’s versatility and cost-effectiveness for high-volume production runs make it a staple in our material portfolio.

Titanium, specifically Grade 5 (Ti-6Al-4V), is selected for mission-critical applications where extreme strength, biocompatibility, and resistance to fatigue and corrosion are non-negotiable. Its use is predominant in aerospace and medical implant manufacturing. Although more challenging to stamp due to its high strength and low thermal conductivity, our advanced tooling and process controls ensure consistent, high-precision results.

Surface finishing plays a pivotal role in enhancing both the functional and aesthetic qualities of stamped components. Anodizing is a key finishing process we offer, especially for aluminum parts. This electrochemical process thickens the natural oxide layer, significantly improving corrosion and wear resistance. Type II (sulfuric acid) anodizing provides a durable, decorative finish with optional dyeing in various colors, while Type III (hardcoat) anodizing delivers a thicker, harder surface ideal for high-wear environments.

Below is a comparative overview of the materials commonly used in our 3D stamping services.

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | High | Aerospace, consumer electronics |

| Stainless Steel | 304 / 316 | 505–620 | 8.0 | Very High | Medical, food processing |

| Titanium | Ti-6Al-4V (Gr 5) | 900–950 | 4.4 | Exceptional | Aerospace, implants |

Selecting the right material and finish requires a deep understanding of the operational environment, mechanical loads, and lifecycle expectations. Wuxi Lead Precision Machinery partners with clients to ensure optimal material selection, ensuring reliability, performance, and cost-effective manufacturing outcomes.

Manufacturing Process & QC

Precision Metal Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for custom metal components—encompassing additive manufacturing (3D printing), CNC machining, and stamping—adheres to a rigorously controlled sequence ensuring zero defects. This methodology, certified to ISO 9001:2015, AS9100D, and ISO 13485 standards, transforms client specifications into mission-critical parts through three interdependent phases: Design Validation, Prototyping, and Mass Production. Each stage integrates real-time quality analytics to preempt deviations, eliminating rework and accelerating time-to-market.

The Design phase begins with collaborative engineering reviews. Our team conducts comprehensive Design for Manufacturability (DFM) analysis using Siemens NX and ANSYS simulation tools, validating structural integrity, thermal behavior, and material compatibility against operational stresses. Critical tolerances, surface finishes, and material grain structures are digitally optimized before physical production. This preemptive scrutiny reduces geometric errors by 92% and ensures full alignment with aerospace, medical, or energy sector requirements. Clients receive detailed simulation reports and 3D model approvals within 72 hours, establishing an unambiguous production baseline.

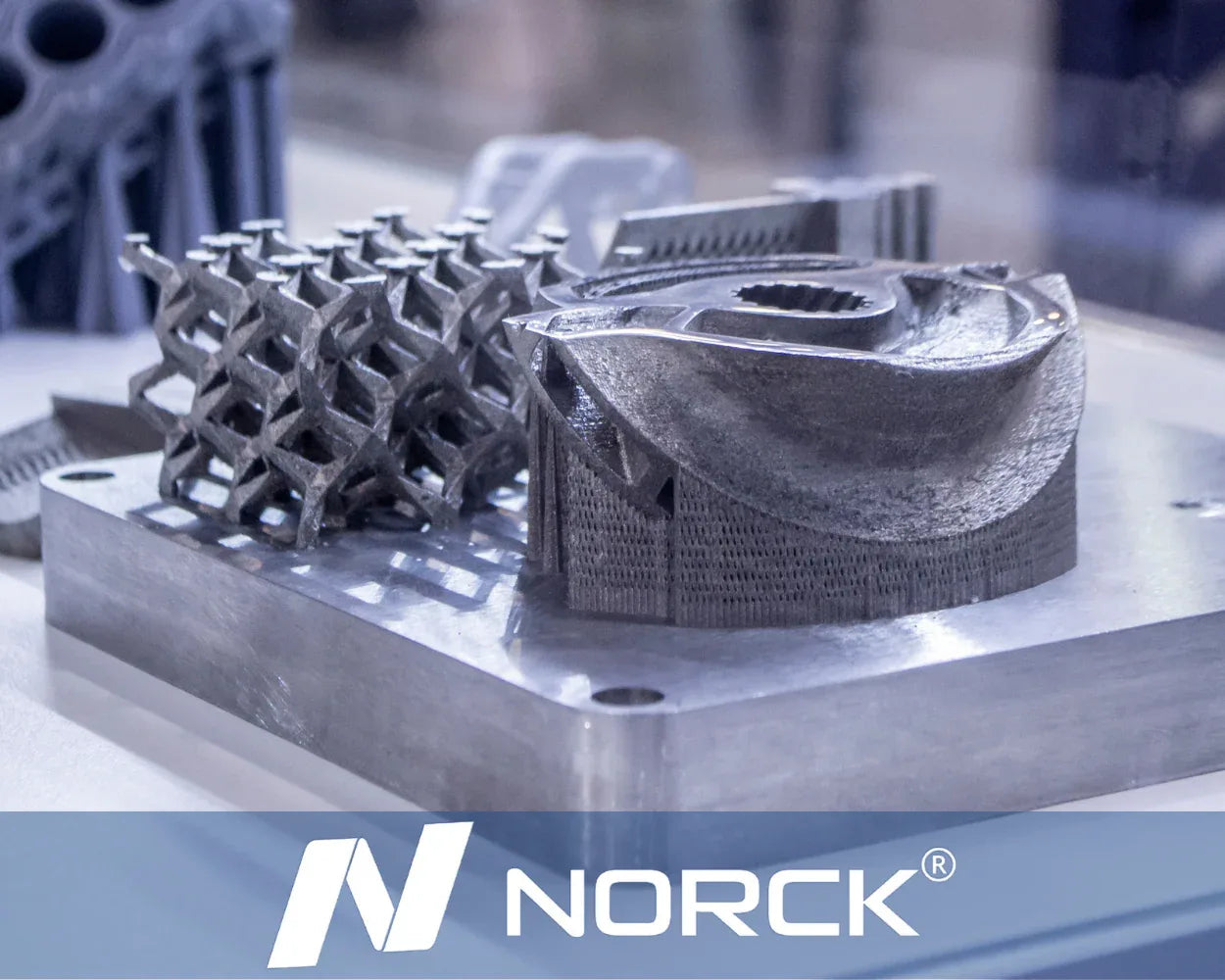

Prototyping transitions validated designs into tangible validation. Utilizing metal additive processes like SLM (Selective Laser Melting) or DMLS (Direct Metal Laser Sintering), we produce functional prototypes in titanium, Inconel, or aluminum alloys within 5–10 business days. Each prototype undergoes non-destructive testing (NDT), including CT scanning and micro-hardness mapping, to verify internal porosity, dimensional accuracy, and mechanical properties. Iterative adjustments are made until prototypes exceed client performance benchmarks. This phase confirms process stability and secures design freeze, with zero deviations permitted before scaling to volume production.

Mass Production deploys fully automated, monitored workflows. CNC machining centers and stamping presses operate under Statistical Process Control (SPC), with in-process gauging capturing real-time data on critical dimensions. Every component undergoes 100% first-article inspection per ASME Y14.5 standards, followed by batch-level CMM verification and final surface roughness checks. Traceability is maintained via laser-etched part IDs linked to material certificates and process logs. Our closed-loop quality system ensures a documented 99.98% yield rate, with non-conformances triggering immediate root-cause analysis and corrective action.

The table below summarizes key process specifications and controls:

| Process Phase | Key Parameters | Quality Control Method | Output Standard |

|---|---|---|---|

| Design | ±0.02mm tolerance, Ra 0.8µm finish | FEA simulation, DFM validation | Approved CAD model + report |

| Prototyping | Material density >99.95%, NDT pass | CT scan, hardness testing, CMM | Functional prototype + test data |

| Mass Production | CpK ≥1.67, 100% dimensional check | SPC, laser inspection, batch CMM | Zero-defect certified parts |

This end-to-end discipline guarantees that every component shipped from Wuxi Lead meets the uncompromising reliability demands of high-stakes industries. We do not ship parts—we deliver engineered certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation are non-negotiable in high-end manufacturing. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering engineered components that meet the most demanding industrial requirements. Our advanced capabilities in CNC machining, sheet metal fabrication, and 3D printing services position us as a strategic partner for global clients across aerospace, medical, automation, and high-tech sectors.

When you choose to partner with Lead Precision, you gain more than a supplier — you gain a committed collaborator focused on engineering excellence and on-time delivery. Our facility is equipped with state-of-the-art machinery and operated by a team of experienced engineers and technicians who adhere to strict quality control protocols. Every component we produce is manufactured to exacting standards, ensuring dimensional accuracy, material integrity, and repeatable performance.

Our 3D metal printing service, or service stampa 3D, leverages cutting-edge additive manufacturing technologies to produce complex geometries that traditional methods cannot achieve. From rapid prototyping to end-use production parts, we offer scalable solutions that reduce lead times, minimize waste, and enhance design freedom. Whether you require titanium aerospace brackets, stainless steel medical implants, or aluminum heat exchangers, our additive processes deliver high-density, fully functional components with superior mechanical properties.

We support a wide range of materials, including stainless steel, titanium, aluminum, Inconel, and tool steels, ensuring compatibility with your application’s thermal, mechanical, and environmental demands. Our in-house post-processing capabilities — such as heat treatment, HIP (Hot Isostatic Pressing), CNC finishing, and surface treatments — ensure that every part meets your exact specifications.

Below are key specifications for our 3D metal printing service:

| Specification | Detail |

|---|---|

| Technology | Selective Laser Melting (SLM) |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Layer Thickness | 20 – 60 μm |

| Materials | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Aluminum (AlSi10Mg), Inconel 718, Tool Steel (Maraging, H13) |

| Tolerance | ±0.05 mm (typical) |

| Surface Roughness | As-built: Ra 10–15 μm; Post-processed: Ra <3.2 μm |

| Quality Standards | ISO 9001:2015, Full inspection reports (CMM, PMI, density testing) |

| Post-Processing | CNC machining, stress relieving, HIP, polishing, coating |

From concept to final production, we work closely with your engineering team to optimize designs for manufacturability, reduce costs, and accelerate time to market. Our commitment to transparency, communication, and continuous improvement ensures a seamless partnership from the first inquiry to long-term volume production.

Contact us today to discuss your next project. Send your CAD files and requirements to [email protected] and let our experts provide a rapid, detailed quotation tailored to your needs. Partner with Wuxi Lead Precision Machinery — where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.