Technical Contents

Engineering Guide: Send Cut Send Cnc

Engineering Insight: The Critical Role of Precision in send cut send cnc Manufacturing

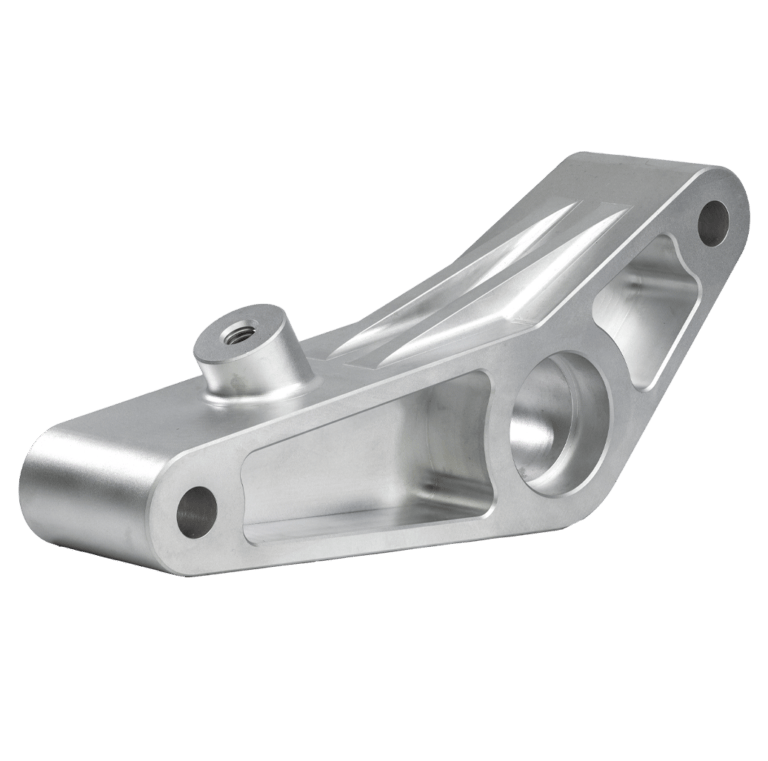

In the realm of modern manufacturing, the phrase send cut send cnc has evolved beyond a simple workflow description—it represents a paradigm of efficiency, accuracy, and repeatability. At Wuxi Lead Precision Machinery, we understand that the success of any CNC-based production cycle hinges on one non-negotiable factor: precision. Whether producing aerospace components, medical devices, or high-tolerance industrial parts, the margin for error is not measured in millimeters, but in microns.

Precision in CNC machining is not merely about tight tolerances; it encompasses thermal stability, toolpath optimization, material consistency, and real-time feedback systems. A deviation of even 5 microns can compromise the functionality of a part designed for high-stress environments. This is where our engineering philosophy at Lead Precision diverges from standard practices. We integrate multi-axis control systems with closed-loop monitoring, ensuring that every cut aligns exactly with the digital blueprint—regardless of batch size or material complexity.

Our expertise has been rigorously tested in applications where failure is not an option. We have contributed to components used in Olympic-grade timing systems, where split-second accuracy depends on flawless mechanical performance. Likewise, our machining processes meet stringent military-grade specifications, including MIL-STD-810 and ISO 2768-fine, ensuring durability under extreme conditions. These projects demand more than advanced machinery—they require a culture of precision that permeates every stage of production.

The send cut send cnc model benefits immensely from this culture. When clients transmit digital designs, our systems perform automated feasibility analysis, tool selection, and stress simulation before a single chip is removed. This pre-emptive engineering reduces iteration cycles and accelerates time-to-market without sacrificing quality. Moreover, our facility in Wuxi operates under ISO 9001 and IATF 16949 certifications, guaranteeing consistent output across global supply chains.

Material selection further underscores our commitment to precision. From aerospace-grade aluminum 7075-T6 to medical stainless steel 316L, we match material properties with cutting dynamics to minimize deformation and maximize surface integrity. Our 5-axis CNC centers, equipped with high-frequency spindles and automatic tool changers, maintain sub-10-micron repeatability across extended production runs.

Below is a summary of our core machining capabilities:

| Specification | Detail |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on material and geometry) |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (polished) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin |

| Certifications | ISO 9001, IATF 16949, MIL-STD-810 compliant processes |

At Wuxi Lead Precision Machinery, we do not simply fulfill CNC orders—we engineer trust through precision. In the send cut send cnc ecosystem, reliability is the ultimate currency. Our legacy in Olympic and defense applications proves that we deliver not just parts, but performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

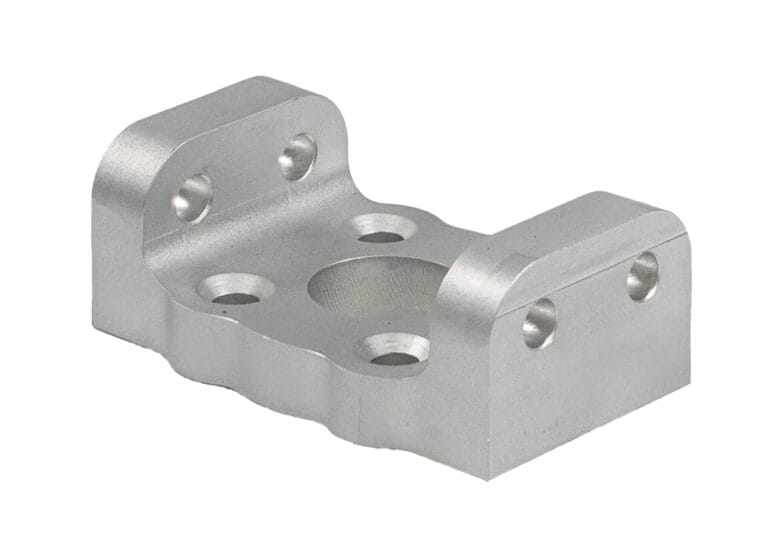

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical components through advanced multi-axis CNC machining and rigorous quality validation. Our core strength lies in simultaneous 5-axis machining, which eliminates manual repositioning and secondary operations. This capability enables the production of intricate geometries—including organic contours, deep cavities, and compound angled features—in a single setup. The result is superior part integrity, reduced lead times, and elimination of cumulative alignment errors inherent in 3-axis processes. For industries like aerospace, medical device manufacturing, and energy systems, where component failure is not an option, this precision directly translates to enhanced product performance and reliability.

Our production floor integrates 12 state-of-the-art 5-axis CNC machining centers, featuring Haas UMC-750 and DMG MORI CTX beta 1250 models. These systems support work envelopes up to 1,250 x 800 x 750 mm with rapid traverse rates of 60 m/min and spindle speeds to 15,000 RPM. High-torque spindles (80 Nm continuous) ensure stability during heavy cutting of titanium, Inconel, and hardened steels, while integrated probing systems enable real-time in-process verification. All machines operate under strict environmental controls (20±1°C) to mitigate thermal drift, a critical factor for maintaining micron-level consistency across production runs.

Quality assurance is non-negotiable. Every critical dimension undergoes validation via our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM), equipped with VAST XT gold sensor technology and Calypso software. This system provides traceable, NIST-certified measurements with a maximum permissible error of MPE E₀,XY,Z = (2.3 + L/300) μm. Full first-article inspection reports (FAIRs) are standard, documenting GD&T compliance, surface roughness (Ra 0.4 μm achievable), and material certification. Statistical process control (SPC) data is actively monitored to preempt deviations, ensuring batch-to-batch repeatability.

The following table details our standard tolerance capabilities for critical features. Note that tighter tolerances are achievable through process-specific optimization and are common in aerospace and medical applications:

| Feature Type | Standard Tolerance (mm) | Tight Tolerance Option (mm) |

|---|---|---|

| Linear Dimensions | ±0.010 | ±0.005 |

| Bore Diameters | +0.010 / -0.000 | +0.005 / -0.000 |

| Positional Accuracy | ±0.015 | ±0.008 |

| Flatness | 0.020 | 0.008 |

| Profile of a Surface | 0.030 | 0.015 |

| Surface Roughness (Ra) | 1.6 | 0.4 |

These specifications represent as-machined results without secondary finishing. By harmonizing cutting-edge 5-axis technology with metrology-grade validation, Wuxi Lead ensures every component meets the exacting demands of high-stakes engineering. Our process eliminates the hidden costs of supplier fragmentation—delivering precision that integrates seamlessly into your assembly, reducing scrap rates and accelerating time-to-market. Partner with us for components where tolerance is not a specification, but a guarantee.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of advanced engineering materials, with extensive expertise in aluminum, steel, and titanium alloys. Each material offers distinct mechanical and thermal properties, making them suitable for specific industrial applications ranging from aerospace and medical devices to automotive and energy systems.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly popular in structural and enclosure applications due to its weldability and moderate strength. For high-performance environments, 7075-T6 offers superior strength, often used in aerospace components. Aluminum’s lightweight nature reduces transportation and assembly costs, making it ideal for mass-produced or portable systems.

Steel remains the backbone of industrial machinery due to its high tensile strength, wear resistance, and thermal stability. We commonly machine alloy steels such as 4140 and 1045, which are heat-treatable and provide excellent mechanical properties under heavy loads. Stainless steel grades like 304 and 316 are selected when corrosion resistance and hygiene are paramount, such as in medical or food processing equipment. While heavier than aluminum, steel delivers unmatched durability in high-stress applications.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosive media make it indispensable in aerospace, defense, and medical implant manufacturing. Though more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced CNC toolpaths and cooling strategies ensure tight tolerances and superior surface integrity.

Surface finishing further enhances material performance. Anodizing is a key post-processing technique for aluminum components, providing improved wear and corrosion resistance while allowing for color coding and aesthetic customization. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hard anodizing) delivers a thicker, harder coating suitable for high-wear applications. Our anodizing process is tightly controlled to ensure uniform coating thickness and adherence to MIL-A-8625 standards.

Below is a comparative overview of key material properties for common alloys used in precision CNC machining.

| Material | Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Enclosures, brackets | Excellent |

| Aluminum | 7075-T6 | 572 | 2.8 | Aerospace, defense | Good |

| Steel | 4140 | 655 | 7.85 | Shafts, tooling | Moderate |

| Stainless Steel | 316 | 580 | 8.0 | Medical, marine | Fair |

| Titanium | Ti-6Al-4V | 900 | 4.43 | Aircraft, implants | Poor |

Selecting the right material and finish requires a deep understanding of operational demands. Wuxi Lead Precision Machinery supports clients in making informed decisions by combining material science expertise with precision manufacturing capabilities.

Manufacturing Process & QC

Precision CNC Production Process: Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and repeatability, transforming conceptual designs into flawless high-volume components. We adhere to a rigorously controlled three-stage workflow: Design Validation, Precision Prototyping, and Statistical Mass Production. This integrated approach ensures zero defects are not an aspiration but a measurable outcome.

The foundation is meticulous Design Validation. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis, scrutinizing CAD models for geometric feasibility, material suitability, and optimal toolpath generation. We collaborate closely with clients to resolve potential stress points, tolerance stack-ups, or complex feature challenges before metal cutting begins. Material certification is verified against international standards, and fixture strategies are simulated to guarantee stability and minimal distortion. This phase eliminates over 90% of potential defects at the source, preventing costly errors downstream.

Precision Prototyping follows, serving as the critical physical validation step. Utilizing the same HAAS and DMG MORI machining centers intended for mass production, we manufacture initial samples under identical process parameters. Each prototype undergoes exhaustive First Article Inspection (FAI) per AS9102 or client-specific requirements. Dimensional accuracy is verified using calibrated CMMs, surface finishes are measured via profilometry, and critical functional interfaces are tested. Client feedback on these prototypes is incorporated iteratively, refining the process until all specifications are met consistently. This stage validates the DFM conclusions and locks the final, defect-proofed manufacturing procedure.

Mass Production leverages the validated process through Statistical Process Control (SPC) and automated in-process monitoring. Every machine cell operates under strict environmental controls, with real-time tool wear compensation and thermal drift correction. Our integrated quality management system continuously analyzes data from in-line sensors and periodic CMM checks, maintaining process capability indices (Cpk) consistently above 1.67. Final inspection employs multi-sensor metrology systems for 100% critical feature verification on all batches. This systematic execution ensures every component meets the stringent requirements defined during prototyping.

The following table details our core production specifications and control methodologies for critical parameters:

| Parameter | Specification | Control Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (Standard) ±0.001 mm (Precision) |

Real-time SPC charts CMM verification per ISO 2768 |

| Surface Roughness | Ra 0.8 µm (Standard) Ra 0.2 µm (Precision) |

In-process profilometer checks Final batch sampling |

| Geometric Accuracy | ±0.01 mm (Form/Position) | Laser interferometer calibration FAI on first/last piece |

| Material Integrity | Per ASTM/EN/GB Standards | Mill test reports Spectrographic verification |

| Process Stability | Cpk ≥ 1.67 | Automated SPC dashboards Hourly operator checks |

This closed-loop production system, rooted in proactive design validation and proven through rigorous prototyping, delivers true zero-defect manufacturing. Wuxi Lead’s commitment to process discipline ensures your high-volume CNC components arrive with absolute dimensional integrity and functional reliability, batch after batch.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as aerospace, medical device manufacturing, automotive engineering, and advanced robotics, precision is not an option—it is a requirement. As a globally recognized leader in CNC machining based in Wuxi, China, we specialize in delivering complex, high-tolerance components with consistency, speed, and technical mastery. When you choose to partner with Lead Precision, you are not simply outsourcing production—you are aligning with a team of engineers and manufacturing specialists committed to elevating your product to the highest standard.

Our facility integrates state-of-the-art 3-, 4-, and 5-axis CNC machining centers with advanced quality control systems, including CMM (Coordinate Measuring Machine) inspection, optical comparators, and real-time process monitoring. Every part is manufactured under ISO 9001:2015-certified processes, ensuring repeatability, traceability, and compliance with international standards. From prototype development to high-volume production runs, we offer scalable solutions tailored to your project’s unique demands.

What sets us apart is our engineering-first approach. Our team collaborates directly with your design and R&D departments to optimize manufacturability, reduce lead times, and minimize material waste—without compromising on precision. Whether you’re working with aluminum alloys, stainless steel, titanium, or high-performance plastics, our machining expertise ensures tight tolerances down to ±0.005 mm and superior surface finishes that meet or exceed industry benchmarks.

We support global clients with seamless digital workflows. Upload your CAD files, receive detailed DFM (Design for Manufacturability) feedback within 12 hours, and get a precise quote with no hidden costs. Our logistics network ensures on-time delivery to North America, Europe, and Asia, backed by real-time order tracking and dedicated account management.

Partnering with Lead Precision means gaining a manufacturing ally built on transparency, technical excellence, and long-term reliability. We don’t just meet expectations—we redefine them.

| Specification | Capability |

|---|---|

| Machining Types | 3-Axis, 4-Axis, 5-Axis CNC Milling; CNC Turning; Multi-Spindle Machining |

| Tolerances | ±0.005 mm (±0.0002″) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 5), Brass, Copper, Plastics (PEEK, Delrin, Nylon) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Powder Coating, Passivation, Bead Blasting |

| Quality Standards | ISO 9001:2015, Full First-Article Inspection Reports (FAIR), PPAP, APQP Support |

| Lead Times | Prototypes: 5–7 days; Production: 10–18 days (varies by complexity) |

Begin your partnership with precision. Contact us today at [email protected] to discuss your next project with a Lead Precision engineer. Let us deliver the accuracy, reliability, and scalability your business demands.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.