Technical Contents

Engineering Guide: Runner Injection Moulding

Engineering Insight: Precision Runner Systems in High-End Metal Injection Moulding

In the demanding realm of custom metal manufacturing, particularly for aerospace, medical, and defense applications, the runner system within an injection mould is far more than a simple conduit. It is a critical engineering component dictating material flow, thermal management, and ultimately, the dimensional integrity and structural reliability of the final part. Precision in runner design and execution is non-negotiable; microscopic variations in flow dynamics or thermal gradients can propagate into significant defects – weld lines, sink marks, or inconsistent density – rendering high-value components unusable. For industries where failure is not an option, achieving sub-10μm tolerances consistently demands runner systems engineered with the same rigor as the primary cavities themselves.

At Wuxi Lead Precision Machinery, we understand that runner precision is the unsung hero of successful metal injection moulding (MIM). Our decades of experience focus intensely on optimizing runner geometry, gate design, and thermal control systems to ensure laminar, balanced flow of feedstock into every cavity. This prevents shear-induced particle alignment issues and minimizes internal stresses, directly contributing to the homogeneous microstructure required for critical load-bearing components. Our commitment to this level of control is proven through stringent quality programs developed for projects demanding absolute reliability. We have successfully delivered MIM components meeting the exacting sub-5μm tolerance requirements for precision timing systems used in international Olympic events, where毫秒 timing accuracy is paramount. Similarly, our runner systems consistently produce military-spec connectors and structural brackets operating under extreme vibration and thermal cycling, validated through rigorous MIL-STD testing protocols.

The foundation of this capability lies in our advanced mould-making infrastructure and deep process understanding. We leverage high-stability machine platforms and proprietary thermal simulation software to model and perfect runner performance before steel is cut. This proactive engineering approach minimizes trial-and-error, reduces material waste, and ensures first-article success for complex, low-volume production runs. The result is consistent part quality, maximized yield, and significantly reduced risk for our clients in the most challenging sectors.

Wuxi Lead Precision Machinery: Runner System Capability Specifications

| Parameter | Capability Range | Precision Level | Relevance to Runner Performance |

|---|---|---|---|

| Clamping Force | 50 – 2000 Tons | ±0.5% | Ensures mould stability during high-pressure injection, preventing flash at runner gates |

| Melt Temperature Control | ±0.5°C (Multi-Zone) | ±0.2°C (Critical Zones) | Critical for consistent feedstock viscosity through runner network, preventing premature solidification |

| Injection Speed Control | 1 – 1000 mm/s | ±0.1% repeatability | Enables precise shear rate management within runner to avoid particle segregation |

| Position Repeatability | < ±1μm (Closed-Loop Servo) | < ±0.5μm | Guarantees exact gate seal and consistent packing pressure transfer through runner |

| Thermal Simulation | Full 3D Flow & Thermal Analysis | Material-Specific Models | Predicts and optimizes runner filling patterns, weld line locations, and cooling efficiency |

This relentless focus on the entire injection pathway, from hopper to cavity, defines Wuxi Lead’s approach. We engineer runner systems not as afterthoughts, but as integral, precision components – because in high-stakes manufacturing, the path to perfection is meticulously controlled, one micron at a time. Partner with us to transform your most challenging metal injection moulding requirements into reality.

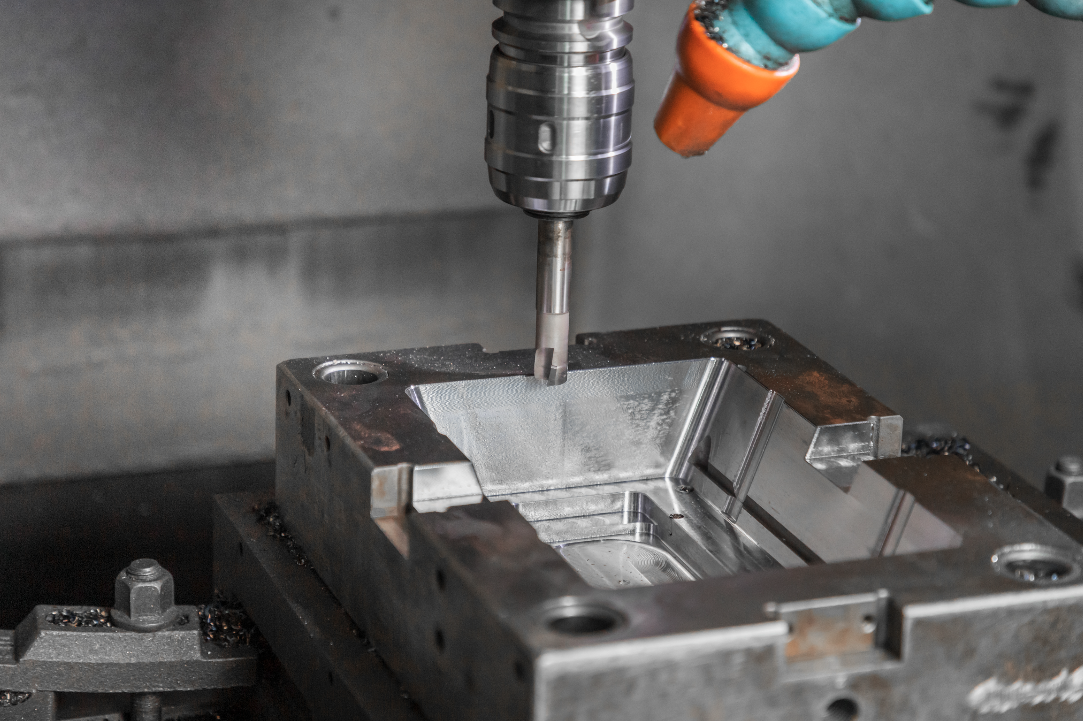

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for high-complexity runner injection moulding systems, engineered to meet the exacting demands of the automotive, aerospace, and medical industries. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce intricate runner geometries with superior surface finishes and dimensional accuracy. These multi-axis systems allow simultaneous machining from multiple angles, eliminating the need for multiple setups and significantly reducing cumulative tolerances. This results in highly consistent, precision-engineered components that ensure optimal flow dynamics and thermal distribution in injection moulding applications.

Our machining processes are supported by a rigorous quality control framework, anchored by comprehensive CMM (Coordinate Measuring Machine) inspection protocols. Every component undergoes full dimensional validation against CAD-based inspection plans, ensuring conformity to design specifications. The CMM systems are integrated with automated reporting software, allowing traceability and real-time feedback for process optimization. This closed-loop quality system ensures that all runner components meet international standards, including ISO 9001 and IATF 16949, critical for high-reliability sectors.

Material selection is tailored to application requirements, with expertise in machining hardened tool steels such as H13, P20, and S136, as well as high-thermal-conductivity alloys like beryllium copper. Our technical team collaborates closely with clients during the design phase to optimize runner profiles for minimal pressure drop, reduced cycle times, and improved part quality. Advanced simulation tools are employed to model melt flow and cooling behavior, ensuring the final machined runner system performs as intended under real production conditions.

All runner injection moulding components are manufactured in-house, from initial blank to final inspection, ensuring complete control over quality, lead time, and process consistency. Our facility operates under strict environmental and process controls, maintaining stable conditions for precision machining. With over 15 years of experience in custom metal manufacturing, Wuxi Lead Precision Machinery has established a reputation for delivering technically superior solutions that enhance mould performance and longevity.

The following table outlines our standard machining capabilities and achievable tolerances for runner injection moulding components:

| Parameter | Specification |

|---|---|

| Machining Technology | 5-Axis CNC Milling |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.2 µm (polished finishes available) |

| Minimum Feature Size | 0.3 mm radius |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Standard Tolerances (Milling) | ±0.01 mm (standard), ±0.005 mm (tight) |

| Geometric Tolerances | ±0.01 mm (flatness, cylindricity) |

| Material Compatibility | Tool steels, stainless steels, copper alloys, aluminum |

| Inspection Method | CMM, Optical Comparator, Surface Profilometer |

These capabilities, combined with our engineering expertise, position Wuxi Lead Precision Machinery as a trusted partner for high-performance runner injection moulding solutions in the global precision manufacturing sector.

Material & Finish Options

Material Selection for High-Performance Runner Injection Moulding Systems

Selecting the optimal material for runner systems in precision injection moulding is critical for achieving consistent part quality, maximizing mould longevity, and ensuring production efficiency. At Wuxi Lead Precision Machinery, our CNC expertise ensures runners are manufactured to exacting tolerances, but the base material fundamentally dictates performance under high-pressure, high-temperature cycling. Key considerations include thermal conductivity for rapid cooling, mechanical strength to resist deformation, wear resistance against abrasive resins, and compatibility with required surface finishes. Aluminum, tool steel, and titanium represent the primary high-performance options, each suited to specific production demands and resin types.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer exceptional thermal conductivity. This enables significantly faster cooling cycles compared to steel, directly boosting throughput for high-volume production of commodity plastics like PP or PE. Their lower density also reduces overall mould weight, easing handling. However, aluminum’s lower hardness makes it less suitable for highly abrasive engineering resins or ultra-high-cavitation moulds where wear resistance is paramount. It remains the economical choice for prototyping and medium-run production where cycle time reduction is the priority.

Tool steels, especially pre-hardened grades like P20 and H13, provide superior hardness, wear resistance, and dimensional stability. These properties are essential for long production runs involving glass-filled nylons, PEEK, or other abrasive materials, as well as for complex multi-cavity moulds demanding extreme precision over millions of cycles. While thermal conductivity is lower than aluminum, requiring potentially longer cooling times, the extended service life and resistance to galling or erosion often justify the higher initial material and machining cost for demanding applications.

Titanium alloys, primarily Ti-6Al-4V, deliver a unique combination of very high strength-to-weight ratio, exceptional corrosion resistance, and moderate thermal conductivity. They excel in highly corrosive environments, such as processing PVC or certain medical-grade resins, where steel might degrade. Titanium’s non-galling properties are also advantageous for intricate runner geometries. The significantly higher material cost and challenging machinability necessitate its use only where its specific properties solve critical production problems unaddressed by aluminum or steel.

Anodizing is the predominant surface finish for aluminum runner components. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness and abrasion resistance, extending runner life in abrasive resin applications. It also improves corrosion resistance and reduces friction, aiding resin flow. Standard anodizing (Type II) offers basic corrosion protection and aesthetic consistency. Properly specified anodizing thickness and sealing are crucial; insufficient thickness compromises wear protection, while excessive thickness can affect critical dimensional tolerances achieved through our precision CNC processes.

Material properties directly impact runner system performance and lifespan. The following table summarizes key characteristics for informed selection.

| Material Grade | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Runner Application |

|---|---|---|---|---|

| Aluminum 6061-T6 | 15-20 | 167 | Moderate | Prototyping, Medium runs, Commodity resins (PP, PE, ABS) |

| Tool Steel P20 | 28-32 | 28-36 | Good | Long runs, Abrasive resins (GF-PA, PBT), Multi-cavity |

| Tool Steel H13 | 48-52 | 24-30 | Very Good | High-temp resins (PEEK, PEI), Critical wear areas |

| Titanium Ti-6Al-4V | 36-41 | 7.2 | Excellent | Corrosive resins (PVC, Medical), Weight-sensitive moulds |

Choosing the correct material and finish requires balancing production volume, resin characteristics, part complexity, and total cost of ownership. Wuxi Lead Precision Machinery’s engineering team collaborates closely with clients to analyze these factors and manufacture runner systems that deliver optimal performance and reliability. Contact our specialists for application-specific material recommendations.

Manufacturing Process & QC

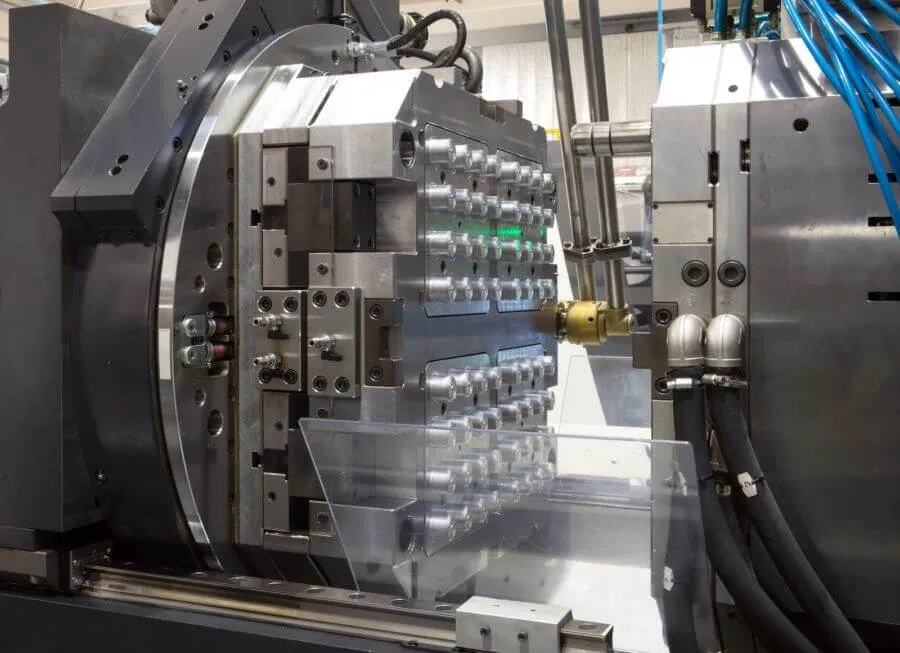

Runner Injection Moulding: Precision Engineering from Design to Mass Production

At Wuxi Lead Precision Machinery, runner injection moulding is executed as a fully integrated manufacturing solution, engineered for zero-defect output in high-performance metal components. This advanced process begins with precision-driven design, transitions through validated prototyping, and culminates in scalable, defect-free mass production. Each phase adheres to ISO 9001 standards and leverages cutting-edge simulation and metrology tools to ensure dimensional accuracy, material integrity, and long-term reliability.

The process initiates with collaborative design engineering. Our technical team works closely with clients to analyze part geometry, material requirements, and functional demands. Using 3D CAD systems and mold flow simulation software, we optimize gate location, runner layout, and cooling channels to minimize material waste and prevent defects such as warpage, sink marks, or porosity. Finite element analysis (FEA) is applied to predict stress distribution and ensure structural performance under operational loads. This digital validation phase reduces physical trial iterations and accelerates time-to-market.

Prototyping follows design finalization, utilizing high-precision CNC-machined molds or rapid tooling to produce functional samples. These prototypes undergo rigorous evaluation, including first article inspection (FAI), mechanical testing, and fit/function validation in real-world assemblies. Any deviations are corrected through closed-loop feedback to the design model, ensuring the final mold design meets all technical and quality benchmarks before full-scale production.

Mass production is executed on state-of-the-art hydraulic and electric injection molding machines, equipped with real-time monitoring systems for pressure, temperature, and cycle time. Automated robotic handling ensures consistent part placement and reduces human error. In-process quality checks are conducted at defined intervals using coordinate measuring machines (CMM), optical comparators, and X-ray inspection for internal void detection. Statistical process control (SPC) is implemented to maintain process stability and enable immediate corrective action if trends deviate from set parameters.

Our zero-defect philosophy is reinforced through full traceability. Each batch is logged with material certifications, process parameters, and inspection reports, ensuring complete audit readiness. Preventive maintenance schedules and operator training programs further support sustained production excellence.

The table below outlines key technical specifications of our runner injection moulding capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | Aluminum Alloys (A380, A360, ADC12), Zinc Alloys (ZA-8, ZA-12) |

| Tolerance Range | ±0.05 mm (standard), ±0.02 mm (tight) |

| Part Weight Range | 10 g – 2,500 g |

| Machine Clamping Force | 150–2,500 Tons |

| Cycle Time | 15–120 seconds (depending on part size) |

| Surface Finish | As-cast, Polished, Textured, Anodized |

| Production Capacity | Up to 5 million parts/year per mold set |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive) |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures every runner injection moulded component meets the highest standards of performance, consistency, and quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered Excellence for Runner Injection Moulding

In the demanding landscape of precision metal manufacturing, runner injection moulding demands uncompromising accuracy and process stability. Substandard tooling or inconsistent production directly impacts part integrity, material waste, and time-to-market—critical vulnerabilities in aerospace, medical, and automotive supply chains. Wuxi Lead Precision Machinery eliminates these risks through integrated engineering mastery and vertically controlled manufacturing. We transform complex runner system specifications into repeatable, high-yield production, ensuring your components meet the strictest functional and regulatory requirements.

Our approach begins with collaborative design validation. Our engineering team dissects thermal dynamics, flow analysis, and ejection mechanics to optimize runner geometry for minimal material degradation and maximal cavity balance. This is executed within our ISO 9001 and IATF 16949 certified facility, leveraging Swiss and German-engineered CNC machining centers, wire EDM, and micro-milling systems. Every mould undergoes rigorous metrology validation using Zeiss CMMs and optical comparators, guaranteeing dimensional stability down to ±0.005mm. Unlike commodity suppliers, we treat your project as an extension of your engineering capability—providing real-time process data, material traceability, and proactive tolerance management from prototype to volume production.

The following specifications reflect our baseline capabilities for runner injection moulding tooling. All parameters are adjustable to your exact material science and performance criteria:

| Specification Category | Performance Standard |

|---|---|

| Maximum Mould Size | 1200 x 800 x 900 mm |

| Cavity Count Range | 1 to 32 cavities |

| Material Compatibility | P20, H13, S136, 420SS, Custom Alloys |

| Standard Tolerance | ±0.005 mm (critical features) |

| Surface Finish | Ra 0.05 µm to 0.8 µm (mirror to textured) |

| Lead Time (Prototype) | 25-35 days |

| Production Validation | 100% First-Article Inspection + SPC data |

This precision is meaningless without responsive partnership. We integrate seamlessly with your NPI workflows, offering concurrent engineering support and transparent project dashboards. Our technical account managers—engineers with 15+ years’ field experience—resolve bottlenecks before they escalate, whether material viscosity shifts or cooling channel inefficiencies. The result is 30% faster ramp-up cycles and scrap rates consistently below 0.8%, verified across 200+ active client programs.

Do not compromise on the core system driving your injection process. Contact our engineering team directly to discuss your runner moulding challenges. Email [email protected] with your part drawings, material specifications, and volume requirements. We will provide a detailed capability assessment within 24 hours, including feasibility analysis, DFM recommendations, and a fixed-cost quotation. Let Lead Precision become your strategic partner in achieving zero-defect production—where metallurgical expertise meets manufacturing discipline. Schedule your technical consultation today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.