Technical Contents

Engineering Guide: Rubber Injection Moulding Machine

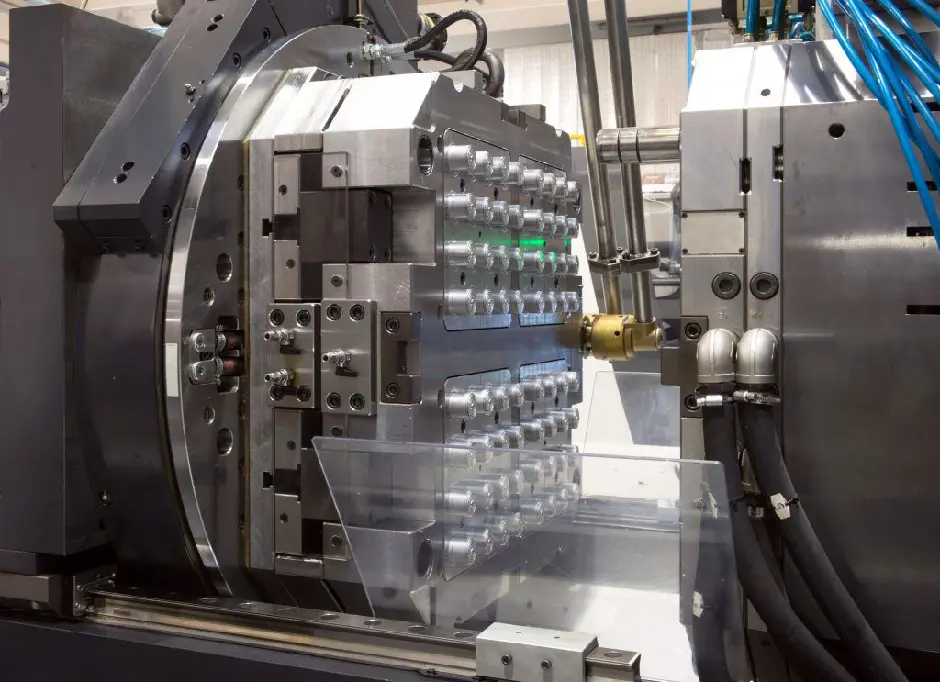

Engineering Insight: The Role of Precision in Rubber Injection Moulding Machines

In high-end custom metal manufacturing, the integration of rubber components demands exceptional dimensional accuracy, material consistency, and long-term reliability. This necessity elevates the importance of precision in rubber injection moulding machines—equipment that must perform under rigorous industrial standards while maintaining micron-level repeatability. At Wuxi Lead Precision Machinery, we recognize that precision is not a feature but a foundational requirement, especially when serving sectors such as aerospace, defense, and high-performance automotive, where failure is not an option.

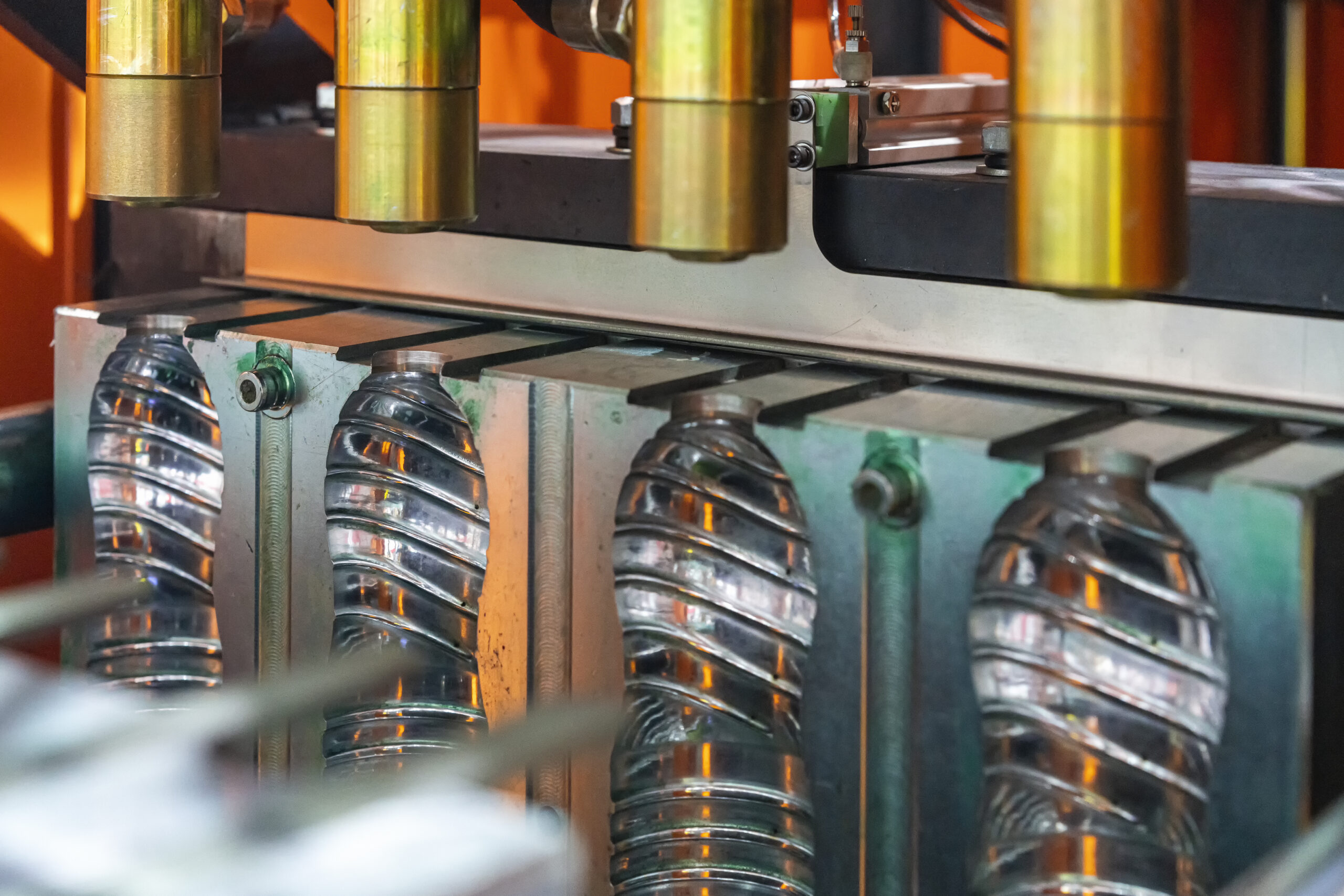

Rubber injection moulding differs significantly from plastic injection due to the viscoelastic nature of elastomers. These materials exhibit time- and temperature-dependent flow behavior, requiring tightly controlled injection profiles, clamping forces, and curing times. Even minor deviations in pressure or temperature can result in flash, incomplete filling, or inconsistent cross-linking—defects that compromise both function and safety. Therefore, the machine’s control system, hydraulic or electric drive mechanism, and mould alignment must operate in perfect synchrony.

Our engineering philosophy centers on deterministic precision. Every rubber injection moulding machine we design incorporates high-rigidity steel frames, servo-optimized drive systems, and closed-loop feedback controls that monitor injection velocity, pressure, and screw position in real time. This enables consistent shot-to-shot repeatability, critical when producing seals, gaskets, or dampers for military-grade equipment or Olympic-standard timing systems—applications where Wuxi Lead has delivered mission-critical components.

Precision also extends to thermal management. Our machines feature multi-zone barrel heating with PID control and advanced cooling circuits to maintain optimal melt temperature. This ensures uniform material viscosity and minimizes cure cycle variation, directly impacting part integrity and production efficiency.

Furthermore, our custom integration capabilities allow for automation compatibility, in-line inspection systems, and IoT-enabled monitoring—ensuring full traceability and process optimization for high-mix, low-volume manufacturing environments.

With over 15 years of specialized experience in precision engineering, Wuxi Lead has supported projects that demand the utmost in reliability and accuracy. Our involvement in supplying components for Olympic timing systems and military communication units underscores our commitment to performance under extreme conditions. This same rigor is applied to every rubber injection moulding solution we engineer.

Below are key technical specifications representative of our high-precision rubber injection moulding machines:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 500 kN – 30,000 kN |

| Injection Weight (Max) | 500 g – 5,000 g (depending on model) |

| Screw Diameter | Φ30 mm – Φ120 mm |

| Injection Pressure | Up to 200 MPa |

| Control System | Siemens PLC with HMI interface |

| Repeatability of Injection | ±0.3% |

| Heating Zones | 4 – 7 zones with ±1°C temperature control |

| Cycle Time Optimization | Adaptive curing with sensor feedback |

| Frame Construction | Monoblock high-tensile steel with anti-deflection design |

At Wuxi Lead Precision Machinery, precision is engineered into every component, every process, and every machine. When reliability defines success, our rubber injection moulding systems deliver without compromise.

Precision Specs & Tolerances

Technical Capabilities for Precision Mold Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical metal components for rubber injection molding machines through advanced manufacturing processes. Our expertise centers on producing mold bases, cavities, cores, and precision inserts where dimensional stability and surface integrity directly impact rubber part consistency, cycle times, and tool longevity. We understand that sub-micron deviations in mold geometry translate to flash, short shots, or premature wear in high-pressure rubber molding environments. Consequently, our capabilities are engineered to exceed the stringent demands of modern elastomer processing.

Our foundation is a dedicated fleet of 5-axis CNC machining centers, enabling single-setup fabrication of complex 3D contours, undercuts, and cooling channels essential for efficient heat transfer in rubber molds. This eliminates cumulative alignment errors inherent in multi-axis repositioning, ensuring critical features like parting lines, ejector pin bores, and runner systems maintain absolute positional fidelity. High-speed machining with rigid toolholding systems achieves superior surface finishes down to Ra 0.4 µm on hardened tool steels (e.g., H13, S136), minimizing post-machining labor and enhancing rubber release properties. Material removal strategies are optimized for thermal stability, preventing micro-distortion in large mold plates during extended operations.

Every component undergoes rigorous validation via coordinate measuring machine (CMM) inspection, utilizing calibrated Zeiss and Hexagon systems with sub-micron repeatability. Full 3D scanning captures as-built geometry against CAD nominal data, generating comprehensive deviation maps for critical functional zones. This metrology-driven approach verifies not only linear dimensions but also complex form tolerances—flatness of parting surfaces, concentricity of bushings, and parallelism of guide pillars—where rubber flow dynamics are most sensitive. Inspection reports are integrated into our traceability system, providing customers with certified evidence of conformance before shipment.

The following table details our standard achievable geometric tolerances for mold components, validated under controlled environmental conditions per ISO 2768-mK and customer-specific requirements:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | CMM / High-Precision Micrometer |

| Flatness (Parting Surfaces) | 0.015 mm/m² | 0.005 mm/m² | CMM / Optical Flat |

| Parallelism | 0.010 mm | 0.004 mm | CMM / Granite Surface Plate |

| Perpendicularity | 0.012 mm | 0.005 mm | CMM / Precision Square |

| Positional Accuracy | ±0.015 mm | ±0.006 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

This disciplined integration of 5-axis CNC machining and CMM metrology ensures molds perform predictably across thousands of cycles. Reduced trial runs, minimized scrap rates, and extended tool life are direct outcomes for our partners in the rubber molding industry. Wuxi Lead Precision Machinery treats every tolerance band as a commitment to your production efficiency—not merely a specification. Contact our engineering team to discuss how these capabilities solve your most challenging mold performance requirements.

Material & Finish Options

Material Selection for Rubber Injection Moulding Machines: Precision Engineering for Demanding Applications

Selecting the appropriate materials for rubber injection moulding machine components is critical to ensuring durability, precision, and long-term performance under high-pressure and high-temperature conditions. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the rigorous demands of industrial automation and precision tooling. Our expertise enables clients to choose optimal materials—aluminum, steel, and titanium—based on application-specific requirements such as strength, thermal conductivity, weight, and corrosion resistance.

Aluminum is widely used in mould bases and non-critical structural components due to its excellent machinability, lightweight nature, and good thermal conductivity. It allows for faster cooling cycles, improving production efficiency. While not as hard as steel or titanium, high-grade aluminum alloys such as 7075-T6 offer sufficient strength for many moulding applications, especially where weight reduction is a priority. Aluminum is also cost-effective for prototyping and low-to-medium volume production runs.

Steel remains the dominant material for core and cavity inserts in rubber injection moulds. Its high hardness, wear resistance, and ability to withstand repeated thermal cycling make it ideal for high-volume manufacturing. Tool steels such as H13, P20, and S136 are commonly selected for their balance of toughness, polishability, and resistance to thermal fatigue. These properties ensure dimensional stability and surface integrity over thousands of cycles, directly impacting part quality and tool life.

Titanium is employed in specialized, high-performance applications where extreme strength-to-density ratio and corrosion resistance are paramount. Though more expensive and challenging to machine, titanium components excel in environments with aggressive chemicals or elevated temperatures. Its low thermal expansion coefficient contributes to dimensional stability, making it suitable for precision-critical mould elements where minimal deformation is required.

Surface finishing plays a vital role in enhancing material performance. Anodizing, particularly for aluminum components, significantly improves surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with the latter offering superior durability for industrial tooling. Anodized layers are electrically insulating and can be dyed for identification, adding functional and aesthetic value.

The following table summarizes key mechanical and thermal properties of the primary materials used in rubber injection moulding machine construction:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 570 | 15–20 (HB) | 130 | 2.81 | Mould bases, housings, frames |

| H13 Tool Steel | 1,500 | 48–52 | 35 | 7.80 | Cores, cavities, inserts |

| P20 Steel | 1,100 | 28–32 | 30 | 7.85 | Mould plates, structural parts |

| Titanium Grade 5 | 900 | 36–40 | 7.2 | 4.43 | High-stress, corrosion-prone parts |

At Wuxi Lead Precision Machinery, we integrate advanced CNC machining with material science expertise to deliver components that meet exacting industrial standards. Our engineering team collaborates closely with clients to select the optimal material and surface treatment combination, ensuring reliability, efficiency, and cost-effectiveness in rubber injection moulding operations.

Manufacturing Process & QC

Precision Rubber Injection Moulding: The Zero-Defect Production Pathway

At Wuxi Lead Precision Machinery, achieving zero defects in rubber injection moulding machine production is not an aspiration; it is the engineered outcome of our rigorously controlled three-phase process. This methodology ensures every machine delivered meets the exacting demands of high-performance industrial applications, safeguarding your operational continuity and product integrity.

The process commences with Integrated Design Engineering. Our senior engineers collaborate directly with your technical team to translate functional requirements into precise machine specifications. Utilizing advanced CAD/CAM systems and finite element analysis (FEA), we simulate material flow, thermal dynamics, and structural stresses under real-world operating conditions. Critical tolerances for platen flatness, tie-bar alignment, and barrel concentricity are defined within micron-level bands, eliminating potential failure points before metal is cut. This phase incorporates Design for Manufacturability (DFM) principles, ensuring complex components like manifolds and screw assemblies are optimized for both performance and our multi-axis CNC machining capabilities, inherently preventing geometric deviations.

Validated Prototyping follows, transforming digital models into physical proof. We manufacture and assemble a fully functional prototype unit using the same hardened tool steels and precision machining processes destined for series production. This prototype undergoes exhaustive performance validation against the initial design parameters. Material compatibility tests, cycle time verification, and critical pressure/temperature profile mapping occur under controlled conditions. Any micro-variance detected triggers immediate design refinement. This phase is non-negotiable; it confirms process capability and validates that all subsystems interact flawlessly, ensuring the production blueprint is defect-free.

Zero-Defect Mass Production leverages the perfected blueprint. Every machine is built on a dedicated line with strict adherence to documented work instructions. Our quality management system employs real-time in-process inspection at critical control points: laser metrology verifies platen parallelism to ≤ 0.02mm/m, pressure transducers monitor hydraulic stability within ±1%, and thermal sensors ensure barrel zone control at ±0.5°C. Component traceability is maintained from raw material certification through final assembly. Final testing subjects each machine to 72-hour continuous runtime under maximum rated load, simulating years of operation. Only units passing all 127 validation checkpoints receive our Zero-Defect certification.

This seamless Design-Prototyping-Production continuum, underpinned by Wuxi Lead’s metallurgical expertise and closed-loop monitoring, guarantees machines that deliver consistent, flawless output. The result is minimized downtime, eliminated scrap costs, and absolute reliability for your rubber component manufacturing.

Key Production Validation Specifications

| Parameter | Target Specification | Measurement Method | Acceptance Criterion |

|---|---|---|---|

| Platen Parallelism | ≤ 0.02 mm/m | Laser Interferometry | 100% within tolerance |

| Hydraulic Pressure Stability | ±1% of setpoint | High-Frequency Transducer | Max deviation ≤ 0.8% |

| Barrel Temperature Control | ±0.5°C | Calibrated RTD Probes | All zones compliant |

| Clamping Force Accuracy | ±0.5% of nominal | Load Cell Calibration | Within 0.4% |

| Shot Weight Repeatability | ≤ ±0.15% | Gravimetric Measurement | Max variation 0.12% |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery to elevate your rubber injection molding capabilities with engineered precision, unmatched reliability, and tailored manufacturing solutions. As a leading innovator in custom metal manufacturing, we specialize in high-performance rubber injection molding machines designed for demanding industrial applications. Our engineering expertise ensures every machine meets exacting standards for durability, efficiency, and repeatability—critical for industries such as automotive, aerospace, medical devices, and advanced industrial components.

At Wuxi Lead Precision Machinery, we understand that off-the-shelf solutions often fall short in high-precision environments. That’s why we offer fully customized rubber injection molding systems built to your exact specifications. From hydraulic and electric configurations to hybrid models with advanced control systems, our machines integrate seamlessly into your production workflow. Our in-house design, machining, and assembly processes guarantee quality control at every stage, ensuring optimal performance and long-term operational stability.

Our engineering team collaborates closely with clients throughout the development cycle, from initial concept and feasibility analysis to final commissioning and technical support. We prioritize innovation, material science, and energy efficiency in every machine we build, incorporating intelligent monitoring systems, precision temperature control, and robust clamping mechanisms. Whether you require high-tonnage models for large components or compact, high-speed units for intricate parts, we deliver solutions engineered for maximum uptime and minimal maintenance.

We serve global partners who demand more than just equipment—they seek a long-term manufacturing ally. Wuxi Lead Precision Machinery stands apart through our commitment to technical excellence, responsive service, and deep domain knowledge in rubber processing technologies. Our machines are built using premium-grade alloy steels and hardened components to resist wear, corrosion, and thermal fatigue—ensuring years of reliable service even under continuous operation.

For clients evaluating next-generation rubber injection molding systems, we provide comprehensive technical documentation, 3D modeling support, and remote diagnostics integration. Our after-sales network includes on-site installation guidance, operator training, and ongoing maintenance support to keep your operations running smoothly.

Below are key specifications representative of our standard high-end rubber injection molding machines. All parameters are customizable based on client requirements.

| Specification | Value |

|---|---|

| Clamping Force Range | 800 kN – 6,500 kN |

| Injection Weight (Max) | 1,200 g – 8,500 g |

| Screw Diameter | 50 mm – 120 mm |

| Injection Pressure | Up to 200 MPa |

| Control System | Siemens PLC with HMI Touch Interface |

| Heating Zones | 5 – 8 (PID Controlled) |

| Repeat Accuracy | ±0.3% |

| Power Supply | 380V / 50Hz (Custom Voltages Available) |

| Machine Frame Material | High-Strength Alloy Steel, Tempered |

| Automation Interface | Standard (Robotic Integration Ready) |

Partnering with Wuxi Lead Precision Machinery means investing in performance-built solutions backed by engineering integrity. Contact us today to discuss your application requirements and discover how our custom rubber injection molding machines can drive efficiency, consistency, and growth in your manufacturing operations.

Email us at [email protected] to schedule a technical consultation or request a detailed project quote.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.