Technical Contents

Engineering Guide: Rubber Injection Molding Machine

Engineering Insight: The Critical Role of Precision in Rubber Injection Molding Machines

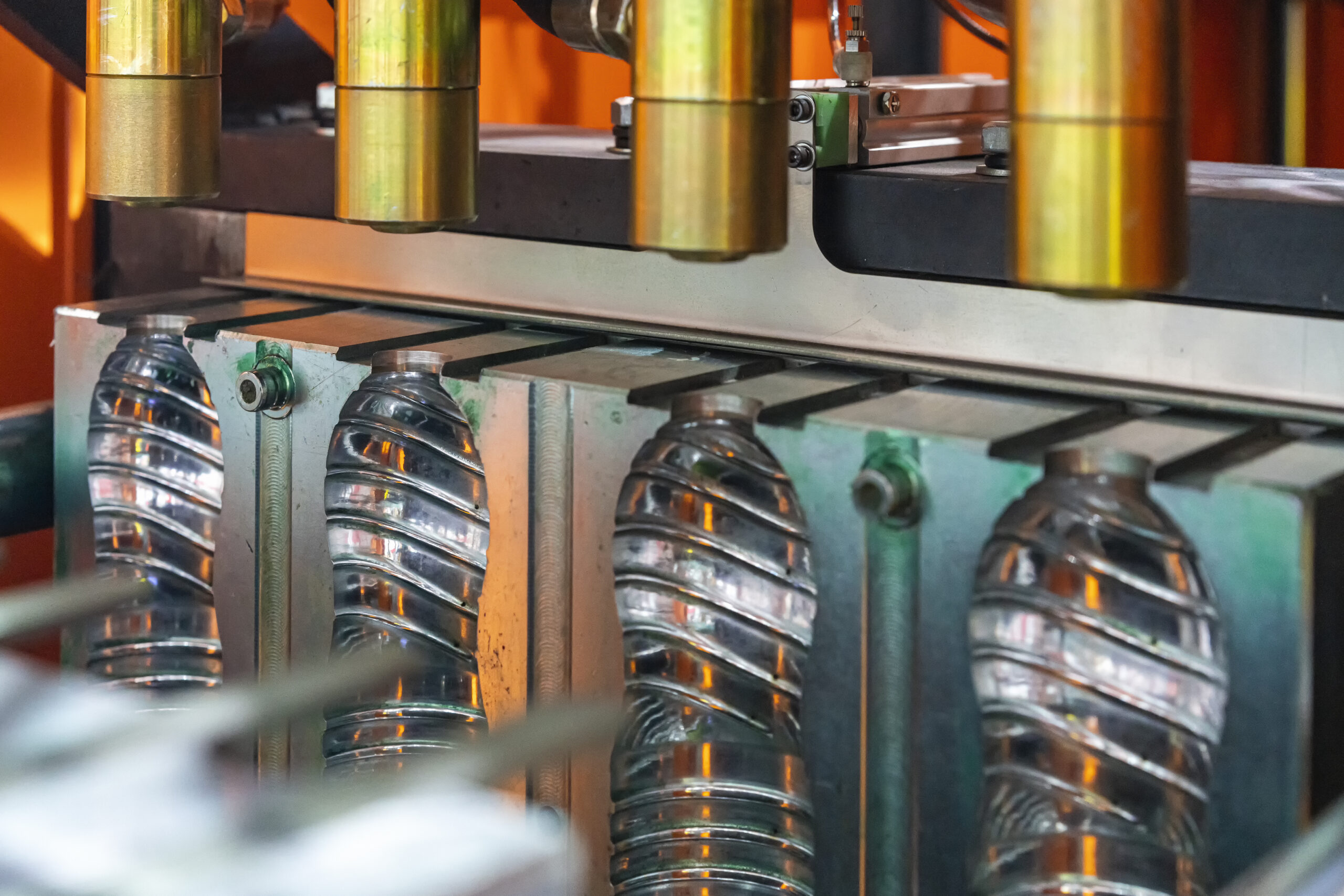

In the realm of high-performance manufacturing, rubber injection molding machines are pivotal for producing components that meet exacting standards across aerospace, defense, automotive, and medical sectors. At Wuxi Lead Precision Machinery, we recognize that the success of these applications hinges on one core principle: precision. Unlike conventional molding systems, advanced rubber injection molding demands micron-level control over temperature, pressure, and material flow to ensure consistency, durability, and repeatability in every cycle.

Precision in rubber injection molding is not merely a performance metric—it is a necessity. Elastomeric materials exhibit nonlinear behavior under heat and pressure, making them particularly sensitive to variations in processing conditions. Even minor deviations in mold cavity filling or curing time can result in flash, incomplete vulcanization, or dimensional instability—defects that are unacceptable in mission-critical applications. Our engineering approach integrates closed-loop control systems, high-resolution sensors, and adaptive algorithms to maintain process integrity across thousands of cycles, ensuring that each molded part conforms to the tightest tolerances.

Wuxi Lead Precision Machinery brings decades of specialized expertise to the design and manufacture of custom rubber injection molding solutions. Our experience extends to supplying precision-engineered systems for projects tied to Olympic-standard facilities and military-grade equipment, where failure is not an option. These high-stakes environments demand machines capable of sustained performance under extreme conditions, and our systems are built to deliver. From servo-driven screw designs to advanced thermal management in mold platens, every component is optimized for accuracy, longevity, and energy efficiency.

Our machines are engineered with modular flexibility, allowing customization for specific elastomers—including silicone, EPDM, nitrile, and fluororubber—while maintaining strict compliance with international quality standards such as ISO 9001 and CE. This adaptability, combined with precision engineering, enables clients to achieve superior part quality with reduced cycle times and minimal waste.

Below are key technical specifications representative of our high-precision rubber injection molding platforms:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 500 kN – 30,000 kN |

| Injection Weight (Max) | 500 g – 5,000 g |

| Screw Diameter | Ø30 mm – Ø120 mm |

| Injection Pressure | Up to 200 MPa |

| Temperature Control Accuracy | ±1°C across all heating zones |

| Position Repeatability | ±0.01 mm |

| Control System | Siemens S7-1500 with HMI interface |

| Cycle Time Optimization | Adaptive cooling & servo energy recovery |

At Wuxi Lead Precision Machinery, we do not simply build machines—we engineer reliability. Our commitment to precision ensures that every rubber injection molding system we deliver supports the highest standards of industrial performance, reflecting our legacy in custom metal manufacturing and advanced automation.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Rubber Injection Molding Systems

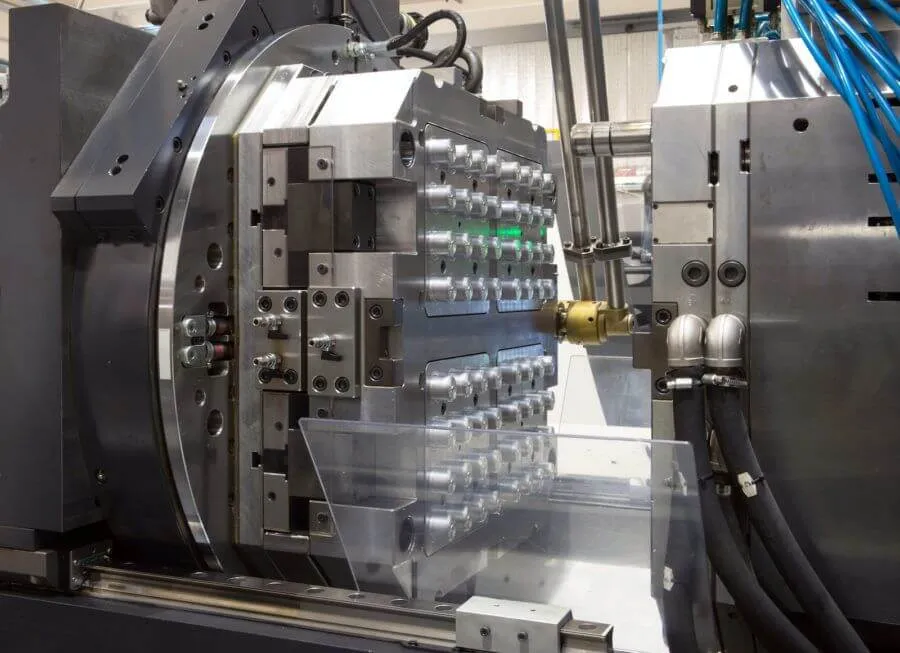

At Wuxi Lead Precision Machinery, our core competency in custom metal manufacturing directly addresses the stringent demands of high-performance rubber injection molding machine production. We specialize in fabricating critical structural and functional components where micron-level precision directly translates to machine longevity, part consistency, and operational efficiency. Our integrated technical capabilities ensure every machined element meets the exacting standards required for reliable molding processes under high pressure and thermal cycling.

Our advanced 5-axis CNC machining centers form the foundation of this precision capability. These systems enable the simultaneous multi-directional machining of complex geometries inherent in molding machine platens, tie bars, clamping units, and intricate mold bases. The elimination of multiple setups inherent in 5-axis processing is critical for maintaining absolute dimensional coherence across large, monolithic components. This capability is essential for achieving the precise alignment of mounting surfaces, hydraulic cylinder bores, and cooling channel networks within a single machining cycle. The result is superior part integrity, reduced assembly time for machine builders, and the elimination of cumulative tolerance stack-up that compromises machine performance and mold registration accuracy. Material removal strategies are optimized for the specific alloys used in molding machinery, ensuring optimal surface finishes and structural integrity without inducing thermal stress.

Complementing our machining prowess is our rigorous quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Every critical component undergoes comprehensive dimensional verification against the original CAD model and engineering specifications. Our CMM systems, operating within a climate-controlled metrology lab, provide traceable, NIST-certified measurements of geometric features, positional tolerances, and complex surface profiles. This goes beyond simple dimensional checks; we validate critical parameters such as platen parallelism, bore concentricity across extended lengths, and the true geometric form of parting surfaces. This systematic verification guarantees that components will assemble correctly and function as intended within the final molding machine, minimizing downtime and ensuring consistent clamping force distribution essential for high-quality rubber part production.

The achievable precision for key molding machine components is consistently demonstrated through our production processes. The following table outlines representative tolerance capabilities for typical features:

| Feature Type | Dimensional Tolerance | Geometric Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| Critical Bore Diameters | ±0.005 mm | Cylindricity 0.003 mm | 0.4 – 0.8 µm |

| Large Platen Surfaces | ±0.01 mm | Flatness 0.015 mm/m² | 1.6 – 3.2 µm |

| Complex Contours | ±0.01 mm | Profile 0.01 mm | 0.8 – 1.6 µm |

| Positional Features | ±0.008 mm | True Position 0.015 mm | As required |

This combination of advanced 5-axis CNC machining and comprehensive CMM validation ensures Wuxi Lead delivers components that form the reliable, high-precision backbone of modern rubber injection molding systems. We understand that the performance of the final machine is intrinsically linked to the quality of its foundational metal components, and our technical capabilities are structured to meet this exacting requirement.

Material & Finish Options

Material Selection for Rubber Injection Molding Machine Components

In the precision-driven domain of rubber injection molding machinery, material selection is a decisive factor in ensuring durability, performance, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, leveraging advanced CNC capabilities to produce high-integrity components from aluminum, steel, and titanium. Each material offers distinct mechanical and thermal properties, making it suitable for specific applications within the machine structure, mold frames, platen systems, and auxiliary units.

Aluminum is widely used for non-load-bearing and lightweight components due to its excellent strength-to-weight ratio and thermal conductivity. It is particularly effective in heat dissipation applications such as mold cooling plates and support housings. While not as wear-resistant as steel, aluminum’s machinability allows for complex geometries and tight tolerances, reducing production lead times. When enhanced with anodizing, aluminum gains improved surface hardness, corrosion resistance, and aesthetic consistency—critical for long-term operational reliability in humid or chemically active environments.

Steel remains the dominant choice for high-stress components such as mold bases, tie bars, and clamping units. Its superior tensile strength, hardness, and resistance to deformation under thermal cycling make it ideal for enduring the repetitive mechanical loads inherent in rubber molding processes. Tool steels like P20 and H13 are commonly selected for their balance of toughness and machinability, often undergoing heat treatment to optimize performance. For environments demanding extreme wear resistance, case-hardened or nitrided steel variants are recommended to extend service life.

Titanium, though less common due to cost, is employed in specialized applications requiring exceptional strength-to-density ratios and corrosion resistance. Its use is typically limited to high-performance fasteners, sensor mounts, or components exposed to aggressive chemical environments. Titanium’s low thermal expansion coefficient also makes it suitable for precision alignment fixtures where dimensional stability is paramount.

Surface finishes further define component longevity and functionality. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), is the preferred finish for aluminum parts. It creates a durable oxide layer that resists abrasion and corrosion while allowing for color coding and branding. Hard anodizing can achieve surface hardness values exceeding 60 HRC, rivaling some steels.

The table below summarizes key properties of selected materials used in rubber injection molding machine manufacturing.

| Material | Tensile Strength (MPa) | Hardness (HB) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | 2.7 | 167 | Housings, cooling plates, brackets |

| Steel P20 | 950 | 290 | 7.8 | 28 | Mold bases, platens, structural frames |

| Steel H13 | 1,600 | 450 | 7.8 | 25 | Hot runner systems, high-wear inserts |

| Titanium Gr5 | 1,000 | 360 | 4.5 | 7.2 | Fasteners, sensor mounts, fixtures |

Material and finish selection must be aligned with operational demands, lifecycle expectations, and environmental conditions. At Wuxi Lead Precision Machinery, we work closely with engineering teams to optimize material specifications, ensuring peak performance and reliability in every rubber injection molding system we support.

Manufacturing Process & QC

Rubber Injection Molding Machine Production Process: Achieving Zero Defects

At Wuxi Lead Precision Machinery, our production process for custom rubber injection molding machines integrates rigorous engineering discipline with advanced manufacturing to deliver zero-defect outcomes. This begins with the Design phase, where our engineers utilize 3D CAD/CAM systems to model machine frames, platens, and injection units. Finite Element Analysis (FEA) validates structural integrity under 2000-ton clamp forces, while computational fluid dynamics optimizes melt flow paths. Material selection focuses on high-grade alloy steels (H13, 42CrMo4) for critical components, ensuring thermal stability and wear resistance. Tolerances are held to ±0.01mm during design to prevent future flash or bonding failures in rubber molding.

Prototyping transforms validated designs into physical units for exhaustive testing. We fabricate molds and machine subassemblies using 5-axis CNC machining centers with sub-micron repeatability. Each prototype undergoes 72-hour continuous cycle testing under simulated production loads, measuring clamp force consistency, injection pressure stability, and thermal uniformity. Real-time data loggers capture 200+ parameters per cycle, identifying micro-variances in platen parallelism or nozzle temperature. Non-conformities trigger immediate root-cause analysis; for instance, a 0.05°C thermal deviation in barrel zones prompts recalibration of PID controllers before progression. Only prototypes achieving 99.98% process capability indices (Cpk ≥ 1.67) advance to mass production.

Mass Production executes at scale with embedded quality gates. Our ISO 13485-certified facility employs automated guided vehicles (AGVs) for component traceability, while IoT sensors monitor torque values during platen assembly to ±2 Nm accuracy. Every machine undergoes a 100% functional test mimicking client-specific rubber compounds (EPDM, silicone, NBR), verifying shot weight repeatability within ±0.15g and clamp force accuracy to ±0.5%. Statistical Process Control (SPC) charts track critical dimensions hourly, with automatic line stoppages if trends approach specification limits. This closed-loop system—combining predictive maintenance, operator certifications, and end-of-line validation—ensures zero-defect delivery, reducing client scrap rates by up to 90% versus industry averages.

Key Machine Specifications for Zero-Defect Performance

| Parameter | Specification | Quality Impact |

|———–|—————|—————-|

| Clamp Force Range | 800–2000 tons | Eliminates flash defects at high-viscosity rubber pressures |

| Injection Pressure | 2500 bar max | Ensures complete cavity fill for complex geometries |

| Shot Weight Accuracy | ±0.15g | Prevents material waste and weight variance in molded parts |

| Barrel Temperature Control | ±0.5°C stability | Critical for rubber vulcanization consistency |

| Platen Parallelism | ≤0.02mm/m | Avoids uneven part thickness and mold damage |

This end-to-end methodology—where design precision, prototype validation, and production controls converge—guarantees machines that sustain zero-defect operation for 20,000+ cycles. Wuxi Lead’s commitment transforms theoretical tolerances into field-proven reliability, directly enhancing your rubber molding efficiency and product integrity.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Rubber Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance rubber injection molding machines engineered for precision, durability, and seamless integration into advanced manufacturing environments. As a trusted name in custom metal manufacturing, we understand the critical demands of industries ranging from automotive and aerospace to medical devices and industrial components. Our rubber injection molding systems are not just machines—they are engineered solutions designed to elevate your production efficiency, reduce cycle times, and ensure consistent part quality.

When you partner with Lead Precision, you gain access to a team of seasoned engineers and technicians who work closely with your operations to develop fully customized systems. Whether you require high-tonnage clamping force, multi-cavity molds, or integration with automated production lines, our machines are built to meet exact specifications. We combine robust construction with intelligent control systems, ensuring optimal pressure regulation, temperature stability, and material consistency across every production run.

Our commitment to precision begins with the design phase and extends through fabrication, assembly, and on-site support. Each rubber injection molding machine is manufactured using premium-grade alloys and components, ensuring long-term reliability even under continuous operation. We also offer comprehensive after-sales service, including remote diagnostics, operator training, and preventive maintenance programs to maximize uptime and return on investment.

We understand that in high-end manufacturing, off-the-shelf solutions rarely suffice. That’s why every machine we deliver is tailored—not only to your technical requirements but also to your production environment and throughput goals. From hydraulic and hybrid models to fully electric servo-driven systems, we provide scalable solutions that grow with your business.

To ensure transparency and informed decision-making, we provide detailed technical specifications for all our standard configurations. Below is an overview of our most widely deployed rubber injection molding machine series.

| Model | Clamping Force (kN) | Injection Weight (g) | Screw Diameter (mm) | Max. Injection Pressure (MPa) | Machine Dimensions (L×W×H, m) | Power Supply |

|---|---|---|---|---|---|---|

| LP-RIM-800 | 800 | 800 | 50 | 180 | 4.2 × 1.8 × 2.1 | 380V, 50Hz, 3-phase |

| LP-RIM-1200 | 1200 | 1200 | 60 | 180 | 4.8 × 2.0 × 2.3 | 380V, 50Hz, 3-phase |

| LP-RIM-2000 | 2000 | 2000 | 75 | 175 | 6.0 × 2.5 × 2.5 | 380V, 50Hz, 3-phase |

| LP-RIM-3500 | 3500 | 3500 | 90 | 170 | 7.5 × 3.0 × 2.8 | 380V, 50Hz, 3-phase |

These machines are engineered for global compatibility and can be adapted to meet regional electrical and safety standards, including CE and ISO certifications.

Take the next step toward manufacturing excellence. Contact us today at [email protected] to discuss your application, request a technical consultation, or schedule a virtual factory tour. At Wuxi Lead Precision Machinery, we don’t just supply equipment—we build long-term partnerships rooted in performance, precision, and trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.