Technical Contents

Engineering Guide: Rubber Injection Molding Equipment

Engineering Insight: Precision as the Non-Negotiable Core of Rubber Injection Molding

In the demanding realm of high-performance rubber components—where failure is not an option—precision in injection molding equipment transcends mere specification; it becomes the foundational requirement for success. For mission-critical applications in aerospace, defense, medical devices, and elite sporting goods, the dimensional stability, sealing integrity, and functional reliability of a rubber part are directly dictated by the micron-level accuracy and repeatability of the molding process. Standard equipment often falls short, introducing variables like inconsistent material flow, uneven curing, or part deformation that compromise performance under extreme pressure, temperature, or cyclic stress. True precision engineering ensures the mold cavity is filled uniformly, held with exact force, and cooled with thermal control that accounts for rubber’s complex viscoelastic behavior and inherent shrinkage characteristics. This level of control eliminates scrap, guarantees batch-to-batch consistency, and ultimately, delivers components that perform predictably in life-or-death scenarios. At Wuxi Lead Precision Machinery, we engineer this precision into every system, understanding that tolerances measured in microns define the boundary between function and catastrophic failure.

Our commitment to uncompromising precision is rigorously validated through real-world deployment in the most demanding environments. We engineered and supplied specialized rubber injection molding systems for critical components used in the Beijing 2022 Winter Olympic Games infrastructure, where performance under extreme cold and constant mechanical stress was paramount. Furthermore, our equipment meets stringent military-grade specifications for vibration resistance, thermal stability, and long-term operational reliability, trusted for sealing and damping solutions in defense applications where component integrity directly impacts mission success and personnel safety. This experience shapes our core philosophy: precision is not a feature, it is the essential baseline.

The technical execution of this precision is embedded in the fundamental architecture of our machines. It requires exceptional clamping force distribution to prevent flash, ultra-stable hydraulic or electric drive systems for shot consistency, and sophisticated thermal management that precisely controls both barrel zones and the mold itself, counteracting rubber’s thermal sensitivity. Material memory and flow dynamics demand closed-loop monitoring and adaptive control far beyond basic timers or pressure switches. The result is a process where every parameter is measurable, controllable, and repeatable.

Key technical parameters defining precision capability in our rubber injection molding systems include:

| Parameter | Standard Precision Range | High-End Capability (e.g., Olympic/Military) |

|---|---|---|

| Clamping Force Range | 50 – 3000 T | 50 – 3500 T (Custom) |

| Shot Weight Repeatability | ± 0.3% | ± 0.15% |

| Temperature Control | ± 1.0 °C | ± 0.5 °C |

| Injection Speed Control | ± 2% | ± 0.8% |

| Mold Parallelism | ≤ 0.05 mm/m | ≤ 0.02 mm/m |

Achieving this level of performance requires deep material science understanding fused with advanced mechanical and control engineering. Wuxi Lead Precision Machinery leverages over 15 years of focused expertise in custom metal manufacturing for ultra-precision tooling and machine components. We do not merely supply equipment; we deliver engineered solutions where every micron of tolerance is a promise of performance, forged in the crucible of Olympic and military demands. Partner with us to ensure your critical rubber components meet the exacting standards your application demands.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to support high-performance applications in rubber injection molding equipment. Our production infrastructure integrates precision engineering with advanced process control, ensuring components meet the rigorous demands of industrial molding environments. At the core of our machining capacity is a full suite of 5-axis CNC machining centers, enabling complex geometries, tight tolerances, and superior surface finishes on a wide range of metal substrates including hardened steels, stainless alloys, and tool-grade materials.

The 5-axis CNC systems allow simultaneous multi-directional cutting, reducing setup cycles and enhancing dimensional consistency across intricate mold bases, manifolds, platen components, and cavity inserts. This capability is essential for manufacturing non-symmetrical and deep-featured parts commonly found in high-pressure rubber molding systems. With Y-axis rotation and full articulation of the cutting tool, we achieve undercuts, compound angles, and contoured flow channels without secondary operations, significantly improving accuracy and reducing lead times.

All machined components undergo comprehensive quality verification through a structured inspection protocol. Our metrology lab is equipped with a high-precision Coordinate Measuring Machine (CMM), providing full 3D validation of critical dimensions, geometric tolerances, and positional accuracy. The CMM system operates with sub-micron resolution, ensuring compliance with ISO 10360 standards and enabling full traceability for every production batch. Inspection data is documented and archived, supporting quality audits and customer certification requirements.

To maintain consistency across production runs, we implement process capability studies (Cp/Cpk) on key features and utilize statistical process control (SPC) to monitor tool wear, thermal drift, and machine performance in real time. Our engineers work closely with client specifications to define critical-to-quality (CTQ) characteristics and establish control plans that ensure repeatability across both prototype and high-volume manufacturing.

The following table outlines the standard technical specifications and achievable tolerances across our 5-axis CNC and inspection processes:

| Parameter | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Dimensional Tolerance | ±0.01 mm (standard), down to ±0.002 mm (tight) |

| Surface Roughness (Ra) | 0.4 µm (standard), down to 0.1 µm (polished) |

| Geometric Tolerance (GD&T) | ±0.008 mm (flatness, parallelism, runout) |

| Maximum Work Envelope | 1200 mm × 800 mm × 750 mm |

| Material Compatibility | Tool Steel, Stainless Steel, Aluminum, Brass |

| CMM Measurement Accuracy | ±1.5 + L/300 µm (L = length in mm) |

| Process Capability (Cpk) | ≥1.67 (standard production runs) |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for OEMs and mold builders requiring mission-critical components in rubber injection molding systems. Our integrated approach to precision manufacturing ensures durability, alignment integrity, and long-term performance under high-cycle operational stress.

Material & Finish Options

Material Selection for Rubber Injection Molding Equipment Components

Selecting the optimal material for rubber injection molding equipment components is a critical engineering decision directly impacting machine longevity, performance consistency, and total cost of ownership. At Wuxi Lead Precision Machinery, our decades of experience in custom metal manufacturing for demanding industrial applications inform a rigorous, application-specific approach. We prioritize material properties that withstand the unique stresses of rubber processing: high clamping forces, thermal cycling, potential chemical exposure from rubber compounds, and the need for precise dimensional stability over extended production runs. The choice between aluminum, steel, and titanium hinges on a detailed analysis of operating pressures, temperature profiles, production volume, and environmental factors, not merely initial cost.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer significant advantages for prototype tooling, low-volume production, or specific non-critical structural elements. Their high machinability reduces lead times and initial tooling costs substantially. Excellent thermal conductivity aids in faster cycle times during mold heating and cooling phases. However, aluminum’s lower hardness and wear resistance compared to steel make it unsuitable for high-volume production cores, cavities, or ejector systems subject to constant abrasive contact with rubber compounds and metal parts. Surface treatments like hard anodizing become essential to enhance wear resistance where aluminum is utilized.

Tool steels, especially pre-hardened grades like P20 and H13, are the dominant choice for production molds and critical wear components in rubber injection molding. These steels provide the necessary hardness (typically 28-40 HRC for P20, 44-52 HRC for H13 after heat treatment) and exceptional resistance to deformation under high clamping pressures. Their superior wear resistance ensures dimensional accuracy is maintained over hundreds of thousands of cycles. H13, with its excellent hot hardness and thermal fatigue resistance, is particularly favored for molds operating at elevated temperatures. While initial machining costs are higher than aluminum, the extended service life and reduced downtime for maintenance deliver superior long-term value for high-volume manufacturing.

Titanium alloys (e.g., Ti-6Al-4V) represent a specialized solution for extreme environments where exceptional corrosion resistance to specific aggressive rubber additives or cleaning agents is paramount, and weight reduction is critical. Its strength-to-weight ratio surpasses steel, but significantly higher material and machining costs limit its use to highly specific, niche applications within the equipment where its unique properties justify the investment. It is not a general-purpose material for standard molding equipment.

Material Property Comparison for Key Applications

| Property | Aluminum (7075-T6) | Tool Steel (P20) | Tool Steel (H13) | Titanium (Ti-6Al-4V) |

|---|---|---|---|---|

| Typical Hardness | 150 HB | 28-32 HRC | 44-52 HRC | 36 HRC |

| Thermal Conductivity (W/m·K) | 130 | 28-36 | 24-30 | 7.2 |

| Corrosion Resistance | Moderate | Good | Very Good | Excellent |

| Relative Cost | Low | Medium | Medium-High | Very High |

| Primary Use Case | Prototypes, Low Volume | Standard Production Molds | High Temp/High Wear Molds | Extreme Corrosion Environments |

Anodizing, specifically hard anodizing (Type III), is a vital surface enhancement for aluminum components. This electrochemical process creates a dense, hard, wear-resistant aluminum oxide layer integral to the base metal. It significantly improves surface hardness (up to 60 HRC equivalent), enhances corrosion resistance against moisture and mild chemicals encountered in molding environments, and provides excellent electrical insulation. While not a substitute for steel in high-wear areas, properly specified hard anodizing is crucial for extending the functional life of aluminum fixtures, housings, or guide plates within rubber injection molding systems.

Wuxi Lead Precision Machinery leverages this deep materials science understanding during the collaborative engineering review phase for every custom project. We do not default to generic solutions; instead, we analyze your specific rubber compound, process parameters, and production targets to recommend and precision-machine the optimal material and finish combination, ensuring peak equipment performance and maximizing your operational ROI. Our ISO 9001-certified processes guarantee material traceability and consistent quality execution.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the rubber injection molding process begins with a meticulously engineered design phase. This foundational step integrates advanced CAD/CAM software with finite element analysis (FEA) to simulate material flow, thermal distribution, and mold stress under operational conditions. Our engineering team collaborates directly with clients to interpret technical requirements, part geometry, and performance specifications. This ensures the mold design accommodates complex geometries, tight tolerances, and material-specific behaviors such as shrinkage and compression set. Every design is validated for manufacturability, minimizing risk before physical production begins. We emphasize Design for Manufacturing (DFM) principles to optimize cycle time, reduce waste, and ensure repeatability—critical factors in achieving zero-defect outcomes.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, we proceed to prototype development using high-precision CNC-machined molds or rapid tooling solutions, depending on client timelines and volume needs. Prototyping serves as a critical validation phase where physical samples are produced under near-production conditions. These prototypes undergo rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), material hardness verification, and functional performance under simulated operating environments. Feedback from this stage informs any necessary design refinements, ensuring that mold venting, gating, and ejection systems are optimized. Our closed-loop quality system captures all deviations, enabling immediate correction. This iterative process guarantees that the transition to mass production occurs only when all performance metrics are consistently met.

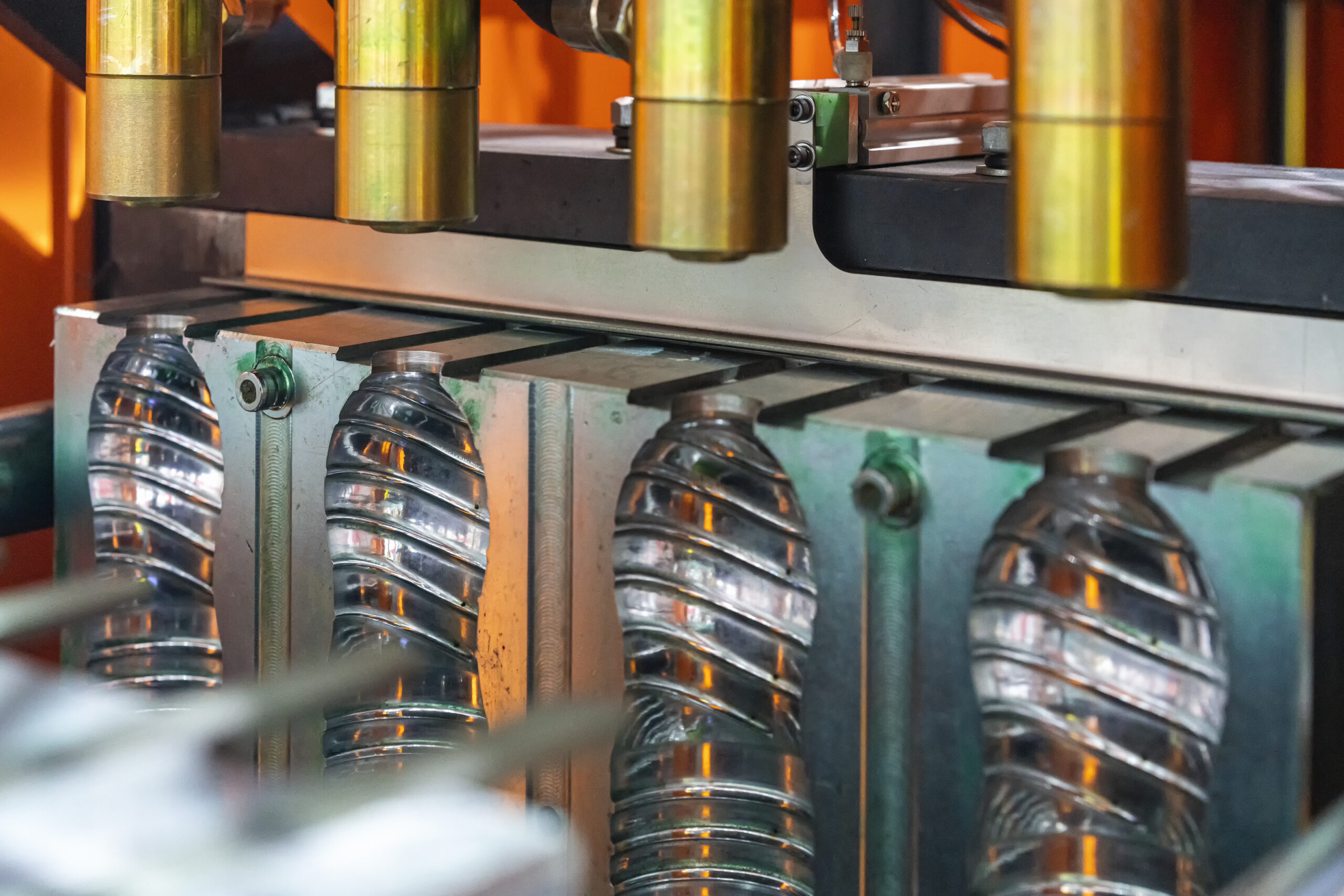

Mass Production: Consistency, Control, and Zero Defects

With design and prototyping successfully completed, Wuxi Lead initiates full-scale production using state-of-the-art rubber injection molding equipment. Our hydraulic and electric servo-driven presses offer precise control over injection pressure, temperature, and curing time, ensuring uniform part quality across batches. Each production run is monitored in real time using integrated sensors and Statistical Process Control (SPC) systems that detect anomalies before they affect output. Automated vision inspection systems and 100% in-line dimensional checks further enforce zero-defect standards. All molds are maintained under a preventive maintenance schedule, and process parameters are locked into our Manufacturing Execution System (MES) to ensure traceability and repeatability.

Technical Specifications of Our Rubber Injection Molding Systems

| Parameter | Specification |

|---|---|

| Clamping Force Range | 50 to 2,500 tons |

| Injection Weight (Max) | Up to 3,000 grams |

| Temperature Control Accuracy | ±1°C |

| Repeatability (Shot Weight) | ±0.3% |

| Cycle Time Optimization | Adjustable, down to 15 seconds (typical) |

| Materials Supported | NBR, EPDM, silicone, FKM, HNBR, CR, and blends |

| Automation Integration | Full robotic demolding and inspection ready |

| Compliance Standards | ISO 9001, IATF 16949, CE |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers rubber components with uncompromised quality, built for mission-critical applications in automotive, aerospace, and industrial sectors.

Why Choose Wuxi Lead Precision

Elevate Your Rubber Component Production Through Engineered Partnership

In the demanding landscape of precision rubber molding, component failure is not an option. Automotive seals, aerospace gaskets, and medical device elements require uncompromising dimensional stability and material integrity. Generic machinery often falls short under real-world production pressures, leading to scrap, downtime, and compromised product lifecycles. Wuxi Lead Precision Machinery exists to eliminate these risks through deep engineering collaboration—not transactional equipment supply. We integrate our expertise in custom metal fabrication with advanced motion control systems to deliver rubber injection molding platforms engineered for your specific material science and tolerance requirements.

Our partnership model begins with rigorous application analysis. Our engineering team dissects your polymer formulation, part geometry, and production volume to configure machine parameters at the foundational level. This includes optimizing platen flatness tolerances to ±0.01mm, hydraulic response times under 25ms, and barrel temperature uniformity within ±0.5°C—specifications proven to reduce flash and cure inconsistencies in critical elastomer applications. Unlike standardized solutions, we calibrate screw designs, nozzle interfaces, and mold mounting systems to your exact operational envelope, ensuring seamless integration into existing production cells while maximizing energy efficiency.

Validation occurs through iterative prototyping on our in-house demonstration cells, where we simulate your production environment to verify cycle times, part repeatability, and maintenance accessibility. This collaborative phase transforms theoretical specifications into quantifiable process improvements before equipment leaves our facility. The result is not merely a machine purchase but a risk-mitigated production asset designed for 20,000+ hour operational lifecycles with minimal total cost of ownership.

Technical Capabilities for Mission-Critical Applications

| Parameter | Specification Range | Engineering Significance |

|---|---|---|

| Clamping Force | 150–3,500 Tons | Supports large multi-cavity molds for automotive seals |

| Shot Weight (PSR) | 50–8,500 cm³ | Accommodates micro-parts to industrial gaskets |

| Platen Flatness | ≤ 0.01 mm/m² | Prevents flash in precision aerospace components |

| Position Repeatability | ± 0.02 mm | Ensures consistent wall thickness in medical tubing |

| Material Compatibility | NBR, FKM, EPDM, Liquid Silicone | Validated for aggressive chemical environments |

Choosing Wuxi Lead Precision Machinery means selecting a partner invested in your long-term operational success. Our engineering team remains engaged post-installation through remote diagnostics, scheduled performance audits, and continuous process optimization—transforming reactive maintenance into predictive asset management. This commitment to sustained partnership has driven 92% client retention across Fortune 500 manufacturers in demanding sectors where component failure carries severe consequences.

The next evolution of your rubber molding capability starts with a technical dialogue. Contact our application engineering team at [email protected] to initiate a confidential production assessment. Specify your target material, part dimensions, and annual volume requirements to receive a tailored capability analysis within 72 business hours. Let us demonstrate how precision-engineered machinery, backed by proactive engineering support, delivers measurable ROI through reduced scrap, extended mold life, and accelerated time-to-market. Your most demanding rubber components deserve an equipment partner as exacting as your quality standards.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.