Technical Contents

Engineering Guide: Rubber Injection Mold

Engineering Insight Precision as the Non-Negotiable Foundation of Rubber Injection Molding

Achieving flawless performance in rubber injection molded components demands uncompromising precision at every stage of mold creation. Unlike thermoplastics, rubber compounds exhibit complex viscoelastic behavior under heat and pressure, making minute dimensional variations in the mold cavity or core catastrophic for part functionality, sealing integrity, and longevity. Thermal expansion differentials between mold steel and the rubber during the curing cycle necessitate micro-level compensation in the design phase. Flow dynamics within intricate geometries require exact gate positioning and runner balancing, achievable only through advanced simulation and micron-accurate machining. Surface finish uniformity directly impacts part ejection and cosmetic quality, demanding consistent Ra values across all critical surfaces. In high-stakes applications like aerospace seals or medical device components, tolerances often reside in the single-digit micron range; failure to meet these specifications renders parts unusable, causing costly production delays and reputational damage. Precision is not merely desirable—it is the absolute prerequisite for functional, reliable rubber molded products.

Wuxi Lead Precision Machinery operates at this exacting threshold daily. Our engineering philosophy centers on treating every rubber injection mold as a critical precision instrument, not merely a production tool. This commitment is forged through rigorous application of advanced 5-axis CNC machining, high-precision EDM, and comprehensive metrology using Zeiss CMMs and optical comparators. Our process integrates deep material science understanding with computational fluid dynamics (CFD) analysis to predict and counteract rubber flow anomalies before metal is cut. This systematic approach ensures dimensional stability across the mold’s operational lifespan, even under the extreme thermal cycling inherent in rubber vulcanization.

Our capability to deliver this level of precision is validated by the most demanding global standards. We are a trusted supplier for mission-critical components supporting Olympic-grade athletic equipment requiring absolute consistency and military/aerospace systems where failure is not an option. These projects demand adherence to stringent AS9100 and ISO 13485 protocols, pushing our engineering and manufacturing processes to their zenith. The tolerances, material certifications, and validation documentation required for these sectors define our baseline operating standard for all clients.

The table below outlines the core precision specifications consistently achieved within our dedicated rubber injection mold manufacturing division:

| Specification Parameter | Typical Capability Range | Industry Standard Reference |

|---|---|---|

| Cavity/Core Dimensional Tolerance | ±0.005 mm to ±0.01 mm | ISO 2768-mK / Custom |

| Surface Roughness (Critical Areas) | Ra 0.05 µm to Ra 0.4 µm | ISO 10110-8 / ASME B46.1 |

| Parting Line Match | ≤ 0.003 mm | Internal Military Spec |

| Guide Pin/Bushing Clearance | 0.002 mm to 0.005 mm | DIN 172 fit class |

| Material Hardness (Pre-hard) | HRC 28-32 (Uniform) | AISI P20 / 1.2311 |

| Thermal Deformation Control | ≤ 0.015 mm @ 200°C | CFD Simulation Validated |

This precision mastery translates directly into client value: extended mold life exceeding 1 million cycles, reduced scrap rates below industry averages, and accelerated time-to-market for complex rubber components. At Wuxi Lead, we engineer certainty into every cavity, core, and cooling circuit, ensuring your rubber injection molding process delivers consistent, high-performance results from the first shot to the last. Precision is our material.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision rubber injection mold production. Our facility integrates cutting-edge 5-axis CNC machining technology to achieve complex geometries with exceptional accuracy and surface finish. This multi-axis capability allows simultaneous movement across five planes, enabling the machining of intricate mold features in a single setup. The result is reduced cycle time, minimized human error, and superior part consistency—critical factors in producing molds that meet the stringent demands of the automotive, aerospace, and medical industries.

Our 5-axis CNC systems are operated by certified engineers with over a decade of experience in mold design and manufacturing. Each machine is maintained to OEM standards and equipped with high-speed spindles and automated tool changers, ensuring optimal performance and throughput. We work with a wide range of tool steels and pre-hardened alloys commonly used in rubber molding applications, including P20, H13, 420 stainless, and S7. Advanced CAM software enables precise toolpath optimization, minimizing chatter and maximizing dimensional stability across production runs.

Quality control is embedded at every stage of the manufacturing process. All rubber injection molds undergo comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This high-accuracy system verifies critical dimensions, geometric tolerances, and surface profiles in three-dimensional space, ensuring compliance with customer specifications and international standards such as ISO 2768 and ASME Y14.5. Our CMM inspection reports are fully traceable and provided with every mold delivery, offering complete documentation for audit and validation purposes.

We maintain strict environmental controls within our metrology lab to eliminate thermal distortion during measurement, with temperature stabilized at 20°C ±0.5°C. In addition to CMM inspection, we perform surface roughness testing, hardness verification, and first-article inspection for full process validation. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and zero-defect manufacturing.

The following table outlines the standard technical tolerances we consistently achieve in rubber injection mold components:

| Specification | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Tolerance | ±0.01 mm | ±0.005 mm |

| Geometric Tolerance (Position, Flatness) | ±0.01 mm | ±0.003 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Hole Diameter Tolerance | H7 | H6 |

| Angular Tolerance | ±0.05° | ±0.02° |

| Feature Repeatability | ±0.008 mm | ±0.002 mm |

These capabilities ensure that every rubber injection mold produced at Wuxi Lead meets the highest standards of precision, durability, and performance. By combining advanced equipment, rigorous quality control, and expert engineering, we deliver molds that support efficient, high-yield rubber molding operations for our global clients.

Material & Finish Options

Material Selection for High-Performance Rubber Injection Molds

Selecting the optimal material for rubber injection molds is critical to achieving precision, longevity, and cost efficiency in high-volume production. At Wuxi Lead Precision Machinery, we prioritize material properties that directly impact thermal management, wear resistance, and dimensional stability under repeated compression and high-temperature cycles. Rubber processing imposes unique demands—such as resistance to thermal shock from rapid heating/cooling and compatibility with aggressive elastomer compounds—making informed material selection non-negotiable for mold performance.

Aluminum alloys (e.g., 7075-T6) excel in prototyping and low-to-medium production runs due to superior thermal conductivity (130–150 W/m·K), enabling faster cycle times and reduced rubber scorch risk. However, their lower hardness (150 HB) limits use in abrasive compounds or extended production. For high-volume applications, tool steels like H13 or S7 dominate. These offer exceptional hardness (48–52 HRC after heat treatment), wear resistance, and thermal fatigue strength, ensuring cavity integrity beyond 500,000 cycles. Pre-hardened P20 steel provides a cost-effective balance for moderate runs. Titanium alloys (e.g., Ti-6Al-4V) are reserved for extreme scenarios requiring ultra-high corrosion resistance against fluorosilicone or peroxide-cured rubbers, though their high cost and machining complexity necessitate rigorous ROI analysis.

Anodizing remains the gold-standard surface finish for aluminum molds, forming a hard, non-conductive oxide layer that prevents galvanic corrosion and improves release properties. Type III (hardcoat) anodizing at 25–50 μm thickness delivers optimal abrasion resistance for rubber molding, while maintaining precise tolerances. For steel molds, nitriding or PVD coatings (e.g., TiN) are preferred to enhance surface hardness beyond 60 HRC without compromising dimensional accuracy.

The following table summarizes key material specifications for rubber injection molding applications:

| Material | Hardness Range | Thermal Conductivity (W/m·K) | Typical Production Life | Key Application Context |

|---|---|---|---|---|

| Aluminum 7075-T6 | 130–150 HB | 130–150 | 10,000–50,000 cycles | Prototyping, low-volume runs |

| Tool Steel H13 | 48–52 HRC | 25–30 | 500,000+ cycles | High-volume production |

| Pre-hard P20 | 28–32 HRC | 28–32 | 100,000–300,000 cycles | Medium-volume, cost-sensitive |

| Titanium Ti-6Al-4V | 36 HRC | 7–8 | 1M+ cycles (corrosive) | Extreme chemical resistance |

Material choice directly dictates total cost of ownership. While aluminum reduces upfront tooling costs by 30–40%, steel molds often prove economical beyond 100,000 parts due to extended service life. Titanium’s niche viability hinges on specific chemical exposure risks. Our engineering team conducts rigorous application audits—including rubber compound chemistry, cycle parameters, and volume requirements—to eliminate material-related failures. Partner with Wuxi Lead to transform material science into production certainty, ensuring your mold investment delivers uncompromised part quality from first shot to end-of-life. Contact our technical sales division for a tailored material feasibility assessment.

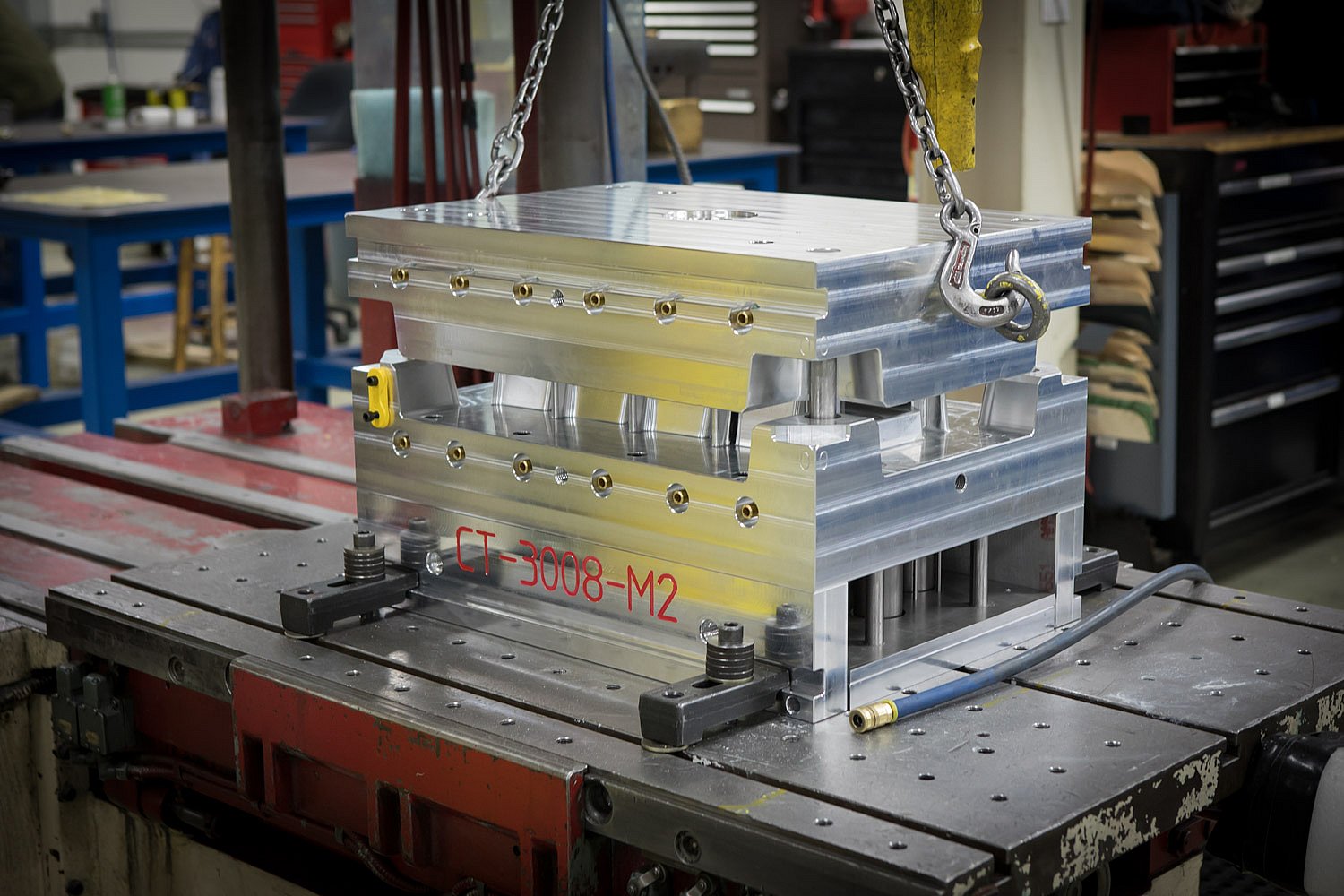

Manufacturing Process & QC

The production process for rubber injection molds at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects and optimal performance in high-volume industrial applications. Our methodology integrates precision engineering, advanced simulation, and continuous quality verification across three core phases: Design, Prototyping, and Mass Production.

Design begins with a comprehensive analysis of the client’s technical specifications, including part geometry, material properties, operating environment, and production volume. Our engineering team utilizes 3D CAD software—such as Siemens NX and SolidWorks—to develop mold layouts that optimize flow dynamics, minimize flash, and ensure uniform curing. Finite Element Analysis (FEA) is applied to simulate thermal distribution and pressure behavior during injection, allowing preemptive correction of potential weaknesses. All designs adhere to ISO 1302 surface finish standards and are reviewed through a cross-functional gate approval system before progression.

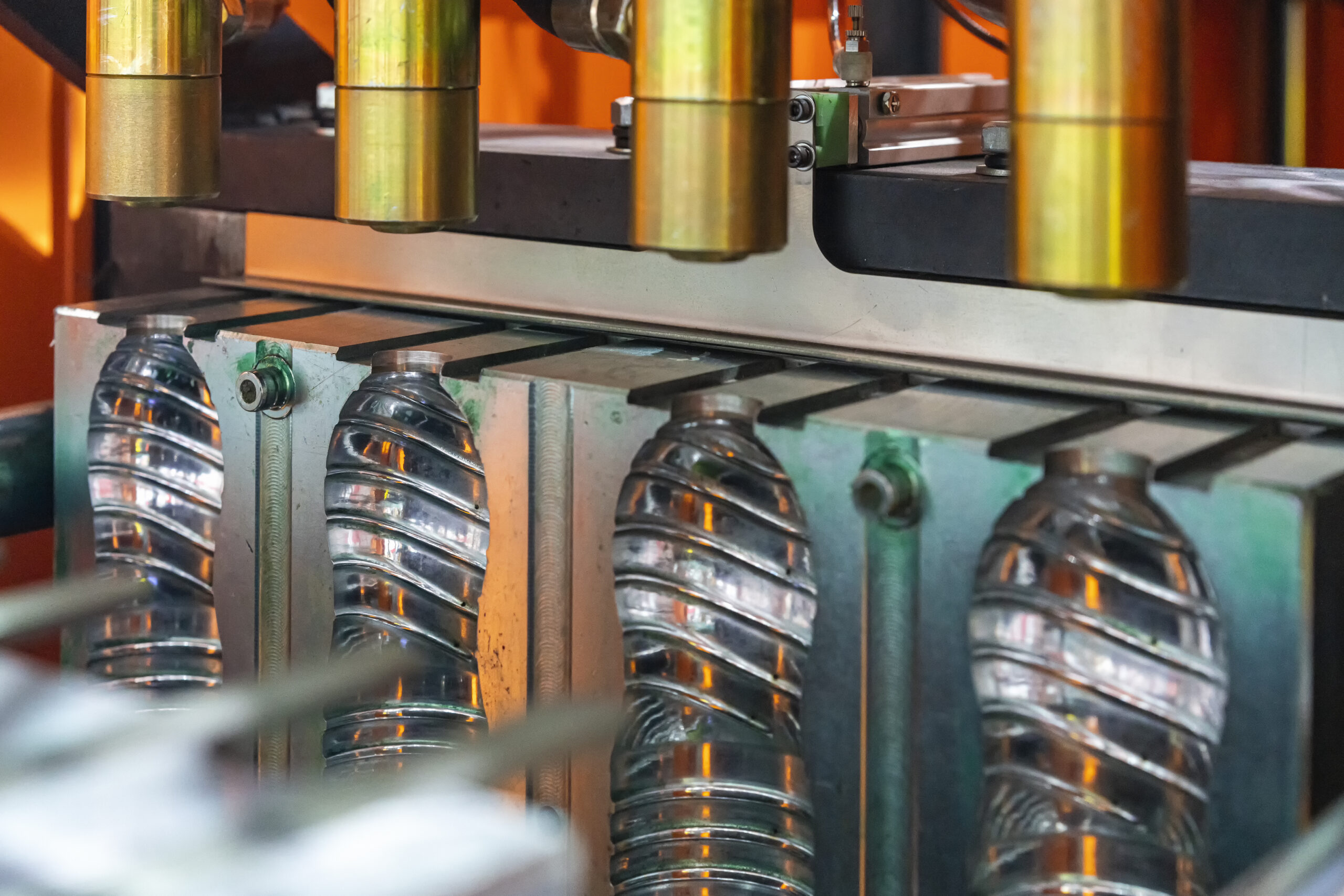

Prototyping follows design validation and serves as a functional test of the mold under real production conditions. A single-cavity prototype mold is fabricated using hardened tool steels such as H13 or 420 stainless, machined via CNC milling and wire EDM to tolerances of ±0.005 mm. The prototype undergoes a trial run on our in-house rubber injection presses, where material fill patterns, cure cycle, ejection efficiency, and part dimensional stability are evaluated. First Article Inspection (FAI) reports are generated, referencing ASME Y14.5 GD&T standards, and any deviations trigger immediate design or process adjustments. This iterative phase ensures the final mold design is fully optimized before scale-up.

Mass Production commences only after prototype approval and process capability validation. Multi-cavity molds are manufactured using the same hardened steels and surface treatments—such as PVD coating or nitriding—for maximum wear resistance and longevity. Each mold is built on synchronized machining platforms with real-time tool wear monitoring to maintain dimensional consistency. Production molds are tested for 10,000+ cycles to confirm durability and defect-free output. Throughout manufacturing, we implement Six Sigma quality controls, including in-process CMM inspections and 100% visual surface checks. All molds are delivered with a complete documentation package, including 3D models, maintenance manuals, and process validation data.

This end-to-end process ensures that every rubber injection mold meets the highest standards of precision, reliability, and repeatability required by automotive, medical, and aerospace industries.

| Specification | Value |

|---|---|

| Material Options | H13, 420SS, P20, SKD61 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2–0.8 µm (polished or textured) |

| Cavity Configuration | Single to 16 cavities |

| Hardness | 48–52 HRC (standard), up to 58 HRC (coated) |

| Process Standards | ISO 9001, ASME Y14.5, ISO 1302 |

| Quality Control | FAI, CMM, 100% visual inspection |

| Production Validation | 10,000+ cycle testing |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Rubber Injection Molding Excellence

In the demanding realm of high-performance rubber components, precision engineering is non-negotiable. Substandard molds lead to part defects, production delays, and unsustainable scrap rates—directly eroding your profitability and market reputation. Generic solutions fail to address the thermal stability, material flow dynamics, and micron-level tolerances required for aerospace seals, medical diaphragms, or automotive gaskets. At Wuxi Lead Precision Machinery, we engineer rubber injection molds as mission-critical systems, not disposable tools. Our integrated approach merges German-engineered CNC machining with decades of material science expertise to deliver molds that consistently produce flawless parts across 500,000+ cycles.

As your strategic manufacturing partner, we eliminate the guesswork in rubber molding. Our engineers collaborate with you from initial CAD analysis through DFM optimization, ensuring cavity design, runner systems, and cooling channels are calibrated for your specific elastomer compound and production environment. We deploy Makino 5-axis machining centers and coordinate with material specialists to select hardened H13 or S136H steel grades, guaranteeing dimensional stability under repeated thermal cycling. This precision-first methodology reduces your time-to-market by 30% while extending mold service life beyond industry averages.

Critical performance specifications define our capability threshold. The table below outlines the baseline standards we exceed for every custom project:

| Specification | Standard Capability | Premium Option |

|---|---|---|

| Cavity Count | 1-16 cavities | Up to 48 cavities |

| Tolerance | ±0.015 mm | ±0.005 mm |

| Steel Grade | H13 (Hardened 52 HRC) | S136H (Mirror Polish) |

| Surface Finish (Cavity) | Ra 0.8 μm | Ra 0.05 μm (Optical) |

| Lead Time (Prototype) | 25-35 days | 18-25 days |

Your competitive edge hinges on partners who treat mold integrity as foundational to product performance. We subject every mold to rigorous validation protocols—including pressure mapping and thermal imaging—before shipment, ensuring seamless integration into your production line. This commitment has made us the trusted supplier for Tier-1 automotive OEMs and ISO 13485-certified medical device manufacturers across Europe and North America.

Initiate your precision molding project with engineering certainty. Contact our technical sales team at [email protected] to submit your RFQ or request a DFM consultation. Include your part drawings, material specifications, and annual volume requirements for a tailored capability assessment within 24 business hours. Let Lead Precision become your technical extension—where CNC mastery meets rubber molding science. Your next-generation components demand nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.