Technical Contents

Engineering Guide: Round Corner Moulding

Engineering Insight: The Critical Role of Precision in Round Corner Moulding

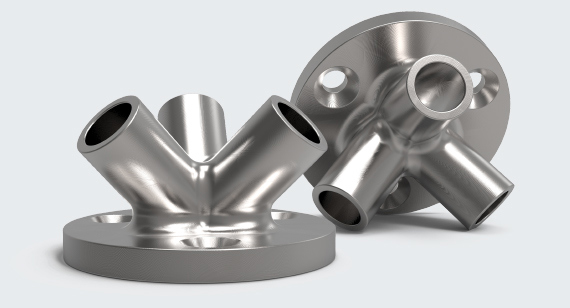

In high-end custom metal manufacturing, the execution of round corner moulding is far more than an aesthetic refinement—it is a testament to engineering rigor and dimensional accuracy. Round corner moulding, often utilized in structural components, architectural elements, and precision enclosures, demands exact control over curvature, material flow, and surface continuity. At Wuxi Lead Precision Machinery, we treat every radius not as a simple bend but as a calculated intersection of form, function, and structural integrity.

The challenge in round corner moulding lies in maintaining uniform wall thickness and stress distribution while achieving tight geometric tolerances. Even minor deviations—measured in microns—can compromise part performance, especially in applications subjected to dynamic loads or environmental stress. This is particularly critical in industries such as aerospace, defense, and high-performance architecture, where component failure is not an option.

Our approach integrates advanced CNC forming, precision die design, and real-time process monitoring to ensure repeatability and accuracy across production runs. Utilizing finite element analysis (FEA), we simulate material behavior during forming to anticipate springback, thinning, and residual stress, allowing for proactive compensation in tooling design. This predictive capability ensures that each round corner meets both geometric specifications and mechanical requirements.

Wuxi Lead Precision Machinery has applied this level of precision in mission-critical projects, including components for Olympic-standard sporting facilities and military-grade enclosures. These applications demanded not only flawless surface finish and dimensional stability but also compliance with stringent international material and testing standards. Our work on such high-profile projects underscores our capacity to deliver precision under exacting conditions, where reliability and consistency are non-negotiable.

Material selection further influences the success of round corner moulding. We specialize in processing aluminum alloys, stainless steel, and titanium—each presenting unique challenges in ductility, springback, and tool wear. Through proprietary forming techniques and custom tooling, we achieve radii as tight as 1.5× material thickness while preserving material properties and surface quality.

The following table outlines typical capabilities for round corner moulding at Wuxi Lead Precision Machinery:

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Minimum Bend Radius | 2.0 × material thickness | 1.5 × material thickness |

| Tolerance (radius) | ±0.2 mm | ±0.05 mm |

| Material Thickness Range | 0.8 mm – 12.0 mm | 0.8 mm – 8.0 mm |

| Surface Finish (Ra) | ≤1.6 µm | ≤0.4 µm |

| Angular Accuracy | ±0.5° | ±0.1° |

| Max Part Length | 6,000 mm | 4,000 mm |

At Lead Precision, we recognize that round corner moulding is not merely a fabrication step—it is a signature of engineering excellence. Our commitment to precision, backed by proven experience in elite industrial sectors, ensures that every component we produce meets the highest standards of performance and reliability.

Precision Specs & Tolerances

Advanced Technical Execution for Precision Round Corner Moulding

Wuxi Lead Precision Machinery delivers uncompromising accuracy in custom round corner moulding through integrated 5-axis CNC machining capabilities. Our HAAS UMC-750 and DMG MORI CTX beta 1250 platforms enable simultaneous multi-directional toolpath control, eliminating repositioning errors inherent in 3-axis systems. This is critical for complex radii transitions where compound angles and continuous curvature demand micron-level consistency. The 5-axis workflow reduces setup time by 40% while maintaining geometric integrity across intricate profiles, ensuring seamless blends between planar and curved surfaces without witness lines or micro-steps. Material utilization is optimized through dynamic tool orientation, minimizing waste in premium alloys like aerospace-grade 7075-T6 aluminum and medical stainless steels.

Rigorous quality validation is embedded at every production stage. All round corner components undergo 100% post-machining inspection via Zeiss CONTURA G3 coordinate measuring machines (CMM). Our CMM protocols follow ISO 10360-2 standards, verifying radius conformity, edge continuity, and positional accuracy against CAD nominal data. Critical features are scanned using tactile probes with 0.5µm resolution, generating comprehensive deviation heatmaps for real-time process correction. This closed-loop system ensures first-pass yield rates exceed 98.5% even for tolerances approaching ±0.005mm. Surface integrity is further validated through profilometry testing to confirm Ra values meet stringent aesthetic and functional requirements.

The following table details achievable specifications for round corner moulding applications. Tolerances are validated under controlled thermal conditions (20°C ±0.5°C) and reflect our standard production capacity without secondary finishing.

| Feature Type | Tolerance Range | Surface Roughness (Ra) | Measurement Standard |

|---|---|---|---|

| Radius Conformity | ±0.005mm to ±0.02mm | 0.2µm to 0.8µm | ISO 12181 |

| Edge Continuity | ≤ 0.003mm G-max | 0.1µm to 0.4µm | ASME B46.1 |

| Positional Accuracy | ±0.008mm | N/A | ISO 5458 |

| Angular Transitions | ±0.05° | 0.4µm to 1.6µm | ISO 1101 |

Our technical infrastructure supports rapid prototyping through full production runs, with digital twin simulation validating toolpaths before material contact. This eliminates trial-and-error machining, reducing time-to-part by up to 60% versus conventional methods. Clients benefit from design freedom to specify aggressive radii blends or micro-contoured edges without manufacturability compromises. Every component is traceable via our MES system, with inspection reports archived for full lifecycle documentation. Partner with Wuxi Lead to transform demanding round corner specifications into flawless physical realities, backed by engineering expertise and uncompromised metrological rigor.

Material & Finish Options

Material Selection for High-Precision Round Corner Moulding

Selecting the appropriate material for round corner moulding is critical to ensuring long-term performance, dimensional accuracy, and resistance to operational stresses. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of industries such as aerospace, automotive, and high-end industrial equipment. For round corner moulding applications, three primary materials stand out: aluminum, steel, and titanium. Each offers distinct mechanical properties, weight characteristics, and compatibility with finishing processes such as anodizing.

Aluminum is a preferred choice for lightweight moulding components where strength-to-weight ratio is paramount. Its excellent machinability allows for precise contouring of round corners, ensuring smooth transitions and tight tolerances. Aluminum 6061-T6 and 7075-T6 are commonly used alloys, offering good corrosion resistance and weldability. When paired with anodizing, aluminum achieves enhanced surface hardness, wear resistance, and aesthetic consistency. Type II and Type III (hard coat) anodizing are frequently applied, with the latter providing superior durability for high-abrasion environments.

Steel, particularly tool steel and stainless steel variants, delivers exceptional strength and thermal stability. It is ideal for high-pressure or high-temperature moulding operations where deformation must be minimized. Materials such as H13, P20, and 420 stainless steel maintain structural integrity over prolonged cycles, making them suitable for long production runs. While steel cannot be anodized in the traditional sense, it benefits from alternative surface treatments like nitriding, chrome plating, or passivation to improve corrosion resistance and surface finish.

Titanium, though more costly and challenging to machine, offers an unmatched combination of high tensile strength, low density, and outstanding corrosion resistance. It is often selected for mission-critical applications in aerospace and medical fields. Titanium’s biocompatibility and performance under extreme conditions justify its use where reliability is non-negotiable. Surface finishing options for titanium include anodizing for color coding and mild surface enhancement, though it does not achieve the same hardness as anodized aluminum.

Below is a comparative overview of key material properties relevant to round corner moulding:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Corrosion Resistance | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 95 | Good | Excellent (Type II/III) |

| Steel H13 | 7.8 | 1,700 | 230 | Moderate | No (alternative finishes) |

| Steel 304 | 8.0 | 505 | 200 | High | No |

| Titanium Gr5 | 4.5 | 900 | 330 | Excellent | Limited (decorative/ID) |

Material selection must align with functional requirements, environmental exposure, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support clients in evaluating these factors to deliver optimized round corner moulding solutions with precision and reliability.

Manufacturing Process & QC

Round Corner Moulding Production: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our round corner moulding production process is engineered for uncompromising quality and repeatability, adhering strictly to the Zero Defects philosophy demanded by high-end industrial clients. This rigorous methodology spans three integrated phases, ensuring every component meets exacting global standards for form, function, and finish. We eliminate variability at its source, transforming complex design requirements into flawless metal components.

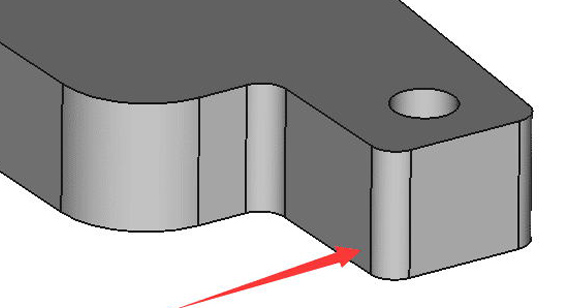

The process commences with collaborative engineering design. Our application engineers work directly with client specifications, utilizing advanced CAD/CAM software to model the precise radius geometry, material flow characteristics, and structural integrity requirements. Critical factors such as material grade (e.g., 6061-T6 aluminum, 304 stainless steel), wall thickness transitions, and secondary operation interfaces are rigorously simulated. Finite Element Analysis (FEA) validates stress distribution around the curved profile, preventing potential deformation during forming or in-service. This phase establishes the foundational blueprint where potential defects are proactively designed out, not merely inspected later.

Prototyping follows as the critical validation step. Using high-precision 5-axis CNC milling centers with sub-micron positioning accuracy, we produce functional prototypes directly from the validated digital model. Each prototype undergoes comprehensive metrology using calibrated CMMs and surface profilers to verify dimensional conformance, radius consistency, and surface texture against the original CAD data. Client feedback is integrated immediately, and the digital process parameters are refined. This iterative loop ensures the manufacturing sequence—toolpath optimization, fixture design, and in-process gauging—is perfected before volume commitment, guaranteeing the first production part is identical to the approved prototype.

Mass production leverages the validated process within a controlled environment focused on sustained zero defects. Components are manufactured on dedicated CNC cells equipped with in-process probing for real-time feature verification and automatic tool wear compensation. Every production run operates under closed-loop Statistical Process Control (SPC), continuously monitoring critical parameters like radius tolerance and surface finish. 100% automated optical inspection may supplement manual checks for high-criticality features. Material traceability is maintained from raw stock to finished part, with full documentation provided. This systematic execution, rooted in the前期 design and prototyping rigor, ensures batch-to-batch consistency and eliminates escapes, delivering components ready for immediate integration into client assemblies.

The following table details key precision specifications achievable for round corner moulding components:

| Parameter | Standard Tolerance | High-Precision Option | Measurement Method |

|---|---|---|---|

| Corner Radius | ±0.05 mm (±0.002″) | ±0.01 mm (±0.0004″) | CMM / Optical Comparator |

| Radius Consistency | ±0.03 mm (±0.0012″) | ±0.005 mm (±0.0002″) | Profile Projector |

| Surface Roughness | Ra 0.8 µm (32 µin) | Ra 0.2 µm (8 µin) | Surface Profilometer |

| Dimensional Accuracy | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) | CMM / Air Gaging |

| Form Deviation | 0.05 mm (0.002″) | 0.01 mm (0.0004″) | CMM / Laser Scanner |

Wuxi Lead Precision Machinery’s integrated Design-Prototyping-Production framework, underpinned by advanced metrology and relentless process control, delivers round corner mouldings that exceed the dimensional and functional demands of aerospace, medical, and premium automotive OEMs. We transform complex curvature requirements into defect-free reality, batch after batch.

Why Choose Wuxi Lead Precision

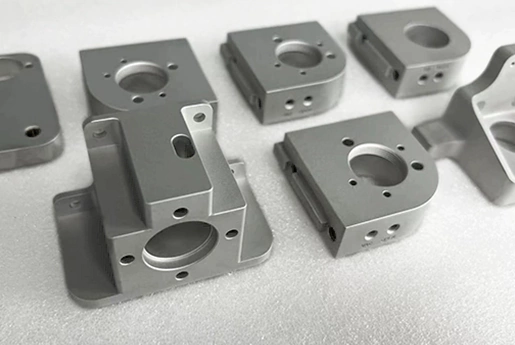

When it comes to precision-engineered round corner moulding for high-performance industrial applications, Wuxi Lead Precision Machinery stands as a trusted leader in custom metal manufacturing. With over 15 years of expertise in CNC machining, sheet metal fabrication, and precision tooling, we deliver tailored solutions that meet the exacting demands of global industries—from automotive and aerospace to architecture and advanced equipment manufacturing.

Partnering with Lead Precision means gaining access to a fully integrated production ecosystem backed by cutting-edge technology and a relentless commitment to quality. Our facility in Wuxi, China, spans over 10,000 square meters and operates under ISO 9001 and IATF 16949 certifications, ensuring every component we produce adheres to international standards for precision, durability, and consistency. Our engineering team works closely with clients from concept to completion, offering design optimization, material selection guidance, and rapid prototyping to accelerate time-to-market.

Round corner moulding requires not only advanced forming techniques but also precise control over tolerances, surface finish, and structural integrity. At Lead Precision, we utilize state-of-the-art CNC press brakes with automated angle measurement systems, multi-axis laser cutting machines, and custom die sets engineered for complex radius profiles. Whether you require tight radii on stainless steel enclosures, soft-formed aluminum trims for architectural facades, or high-strength carbon steel corner guards for industrial machinery, our process ensures repeatability and flawless aesthetics.

We understand that every client’s application is unique. That’s why we offer fully customizable solutions—from material thickness and bend radius to surface treatments such as powder coating, anodizing, or brushed finishes. Our in-house tooling department allows us to design and manufacture dedicated forming dies quickly, reducing setup time and enhancing long-term production efficiency.

Below are the key technical specifications we support for round corner moulding and related metal forming processes:

| Specification | Capability |

|---|---|

| Material Types | Stainless Steel (304, 316), Aluminum (5052, 6061, 7075), Carbon Steel (Q235, Q345), Galvanized Steel, Copper, Brass |

| Thickness Range | 0.5 mm – 12.0 mm |

| Bend Length | Up to 6,000 mm |

| Minimum Bend Radius | As low as 0.5 mm (material-dependent) |

| Tolerance | ±0.1 mm for linear dimensions, ±0.5° for angles |

| Surface Finishes | Brushed, Polished, Powder Coated, Anodized, Galvanized, Passivated |

| Secondary Operations | Welding (TIG, MIG, Spot), Drilling, Tapping, Hardware Insertion, Laser Marking |

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we build long-term partnerships based on reliability, transparency, and technical excellence. Our global client base trusts us to deliver complex metal components on time, every time, with full traceability and comprehensive quality reporting.

For your next project requiring precision round corner moulding or custom metal solutions, contact us today. Our engineering team is ready to review your drawings, provide DFM feedback, and deliver competitive pricing with clear lead times.

Email us at [email protected] and discover how Lead Precision can become your strategic manufacturing partner in China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.