Technical Contents

Engineering Guide: Rib Parts

Engineering Insight: The Critical Role of Precision in Rib Part Manufacturing

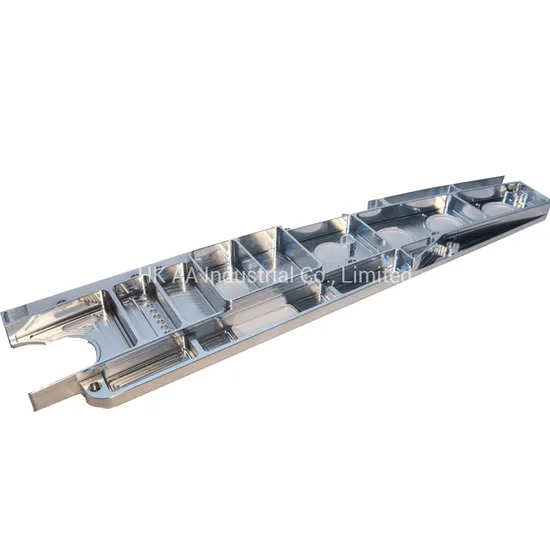

In high-performance industries such as aerospace, defense, and advanced robotics, rib parts serve as fundamental structural components that ensure rigidity, load distribution, and dimensional stability within complex assemblies. These parts, often characterized by thin walls, deep cavities, and intricate geometries, demand an exceptional level of precision during manufacturing. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise the integrity and performance of the final product. This understanding drives our commitment to excellence in every rib part we produce.

Rib parts are typically integrated into larger frameworks—such as aircraft fuselages or armored vehicle chassis—where they act as internal supports that maintain shape under extreme mechanical and thermal stress. The complexity of these components requires advanced CNC machining capabilities, including multi-axis milling, high-speed cutting, and precise toolpath optimization. Maintaining tight tolerances across large work envelopes is not merely a technical challenge; it is a necessity for ensuring safety, reliability, and compliance with stringent industry standards.

At Lead Precision, our engineering team leverages over a decade of experience in custom metal manufacturing, with a proven track record in mission-critical applications. We have contributed precision-machined components for infrastructure projects tied to Olympic venues and supplied parts meeting military-grade specifications. These experiences have refined our approach to quality control, material selection, and process validation, enabling us to deliver rib parts that consistently meet or exceed client expectations.

Our manufacturing process begins with detailed finite element analysis (FEA) and design for manufacturability (DFM) reviews, ensuring optimal performance and producibility. We utilize premium-grade aluminum alloys, titanium, and high-strength steels, all processed on state-of-the-art 5-axis CNC machines equipped with in-process probing and thermal compensation systems. This integration of advanced technology and engineering expertise allows us to achieve exceptional surface finishes, minimal residual stress, and superior geometric accuracy.

The table below outlines typical specifications achievable for custom rib parts at Wuxi Lead Precision Machinery:

| Parameter | Capability |

|---|---|

| Material Options | 7075-T6, 6061-T6, Ti-6Al-4V, 4140, 17-4PH |

| Tolerance (Linear) | ±0.005 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Maximum Part Size | 2000 mm × 1000 mm × 800 mm |

| Wall Thickness (Min) | 0.8 mm (with support structures) |

| Machining Axes | 3-axis, 4-axis, 5-axis simultaneous |

| Lead Time (Prototype) | 10–18 days |

| Quality Standards | ISO 9001:2015, MIL-STD-810, AS9100 (in progress) |

Precision in rib part manufacturing is not an incremental advantage—it is a foundational requirement. At Wuxi Lead Precision Machinery, we combine technical mastery with real-world experience in high-stakes environments to deliver components that perform under the most demanding conditions.

Precision Specs & Tolerances

Advanced Manufacturing Capabilities for Precision Rib Components

Wuxi Lead Precision Machinery delivers uncompromising precision for complex rib part geometries demanded by aerospace, medical, and defense sectors. Our integrated 5-axis CNC machining platform forms the cornerstone of this capability, enabling single-setup production of intricate contours, undercuts, and thin-wall features inherent to structural ribs. This eliminates cumulative error from multiple fixturing operations, ensuring geometric integrity across critical datums. All machining occurs within climate-controlled environments using high-rigidity DMG MORI and Makino platforms, maintaining thermal stability for micron-level repeatability. Advanced toolpath strategies dynamically adjust feed rates and spindle loads to prevent deflection in thin rib sections, preserving wall straightness and dimensional fidelity even in challenging materials like Inconel 718 and Ti-6Al-4V.

Rigorous quality control is non-negotiable in rib component production. Every part undergoes comprehensive inspection via Zeiss CONTURA CMM systems, programmed to ISO 10360-2 standards. Our inspection protocols validate not only dimensional accuracy but also critical form characteristics—flatness, parallelism, and profile tolerances—across all rib surfaces. Surface finish verification employs Mitutoyo SJ-410 profilometers to confirm Ra values meet stringent aerospace or medical requirements. Full first-article inspection reports (FAIR) and PPAP documentation are standard, providing traceable evidence of conformance to AS9100 and ISO 13485 quality management systems.

Our process excellence extends beyond equipment to material science expertise. We optimize cutting parameters and coolant strategies for each alloy, minimizing residual stress in delicate rib structures post-machining. This proactive approach prevents distortion during secondary operations or in-service conditions, ensuring long-term component stability.

Precision Tolerance Specifications for Rib Components

| Material Category | Max. Part Size (mm) | Positional Tolerance (mm) | Profile Tolerance (mm) | Surface Finish (Ra µm) |

|---|---|---|---|---|

| Aluminum Alloys | 1200 x 800 x 600 | ±0.005 | 0.010 | 0.4 – 0.8 |

| Titanium Alloys | 900 x 600 x 450 | ±0.008 | 0.015 | 0.8 – 1.6 |

| Stainless Steels | 1000 x 700 x 500 | ±0.006 | 0.012 | 0.4 – 1.2 |

| Nickel Superalloys | 800 x 500 x 400 | ±0.010 | 0.020 | 0.8 – 2.0 |

This technical foundation ensures rib parts meet the most demanding functional requirements—maximizing strength-to-weight ratios while guaranteeing assembly compatibility. Wuxi Lead’s end-to-end process control from raw material certification through final inspection delivers components that consistently exceed OEM specifications, reducing scrap rates and accelerating time-to-market for your critical applications. Partner with us for rib components where precision directly translates to system performance and reliability.

Material & Finish Options

Material selection is a critical decision in the production of high-performance rib parts, where structural integrity, weight efficiency, and environmental resistance are paramount. At Wuxi Lead Precision Machinery, we specialize in precision-manufactured rib components used in aerospace, automotive, and industrial applications. The choice between aluminum, steel, and titanium depends on the operational demands of the final assembly, including load requirements, temperature exposure, and service environment.

Aluminum is often the preferred material for rib parts where weight reduction is essential without compromising strength. Its high strength-to-density ratio makes it ideal for aerospace structures and high-speed transportation systems. 6061-T6 and 7075-T6 are the most commonly used aluminum alloys due to their excellent machinability, weldability, and corrosion resistance. When combined with anodizing, aluminum achieves enhanced surface hardness and improved wear resistance, making it suitable for dynamic loading environments.

Steel, particularly alloy and stainless grades such as 4140 and 304/316, offers superior strength and durability under high-stress conditions. While heavier than aluminum, steel is selected when rigidity and fatigue resistance are non-negotiable—common in heavy machinery and structural support systems. Its inherent toughness allows rib parts to withstand impact and sustained mechanical loads. However, steel requires protective surface treatments to prevent oxidation, especially in humid or corrosive environments.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, low density, and outstanding corrosion resistance, particularly in extreme temperatures and saline environments. It is frequently used in aerospace and defense applications where performance under thermal stress and long-term reliability are critical. Although more expensive and challenging to machine, titanium’s longevity and performance justify its use in mission-critical rib components.

Anodizing is a key finishing process, primarily applied to aluminum rib parts. This electrochemical treatment grows a durable oxide layer on the surface, significantly improving wear resistance, corrosion protection, and aesthetic consistency. Type II (sulfuric acid) anodizing is standard for general applications, while Type III (hardcoat anodizing) is used when extreme surface hardness and abrasion resistance are required. Anodized layers are also electrically insulative and provide excellent adhesion for primers and paints.

Below is a comparative overview of key material properties relevant to rib part performance.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 570 | High (with anodizing) | Aerospace, UAVs | Anodizing (Type II/III) |

| Steel 4140 | 7.85 | 950 | Moderate (needs coating) | Industrial machinery | Zinc plating, painting |

| Stainless 316 | 8.00 | 700 | Very High | Marine, chemical | Passivation, polishing |

| Titanium Ti-6Al-4V | 4.43 | 900 | Excellent | Jet engines, space systems | As-machined, bead blast |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on functional requirements, lifecycle expectations, and cost targets. Our engineering team supports every stage—from prototyping to serial production—ensuring optimal performance of rib parts in the most demanding applications.

Manufacturing Process & QC

Precision Rib Part Manufacturing: From Concept to Flawless Volume Production

At Wuxi Lead Precision Machinery, producing critical rib components demands an uncompromising, integrated process engineered for zero defects. Our methodology rigorously bridges design intent with high-volume reality, ensuring structural integrity and dimensional perfection for aerospace, automotive, and energy applications. This disciplined sequence—Design, Prototyping, Mass Production—forms the backbone of our zero-defect commitment, leveraging China-based advanced manufacturing with global quality standards.

The Design phase is foundational. Our engineering team collaborates intensely with clients using advanced CAD/CAM suites (Siemens NX, SolidWorks) to translate functional requirements into manufacturable geometry. Finite Element Analysis (FEA) validates structural performance under load, while rigorous Geometric Dimensioning and Tolerancing (GD&T) studies define critical features. Material selection—typically aerospace-grade aluminum alloys (7075-T6, 2024-T3), titanium (Ti-6Al-4V), or high-strength steels—is optimized for fatigue resistance and machinability. Crucially, Design for Manufacturing (DFM) reviews occur concurrently, identifying potential production risks like thin-wall instability or complex fixturing needs before metal cutting begins. This proactive analysis prevents costly iterations later.

Prototyping transitions validated designs into physical reality under controlled conditions. Utilizing our 5-axis milling centers and wire EDM capabilities, we produce 1-5 first-article parts mirroring final production methods. Each prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 standards, with full CMM reporting against all critical dimensions. Non-conformances trigger immediate engineering review and rapid design or process adjustment. This phase validates toolpaths, fixturing, and inspection protocols, ensuring the production process blueprint is statistically capable before scaling. Client sign-off on prototype performance and documentation is mandatory.

Mass Production executes the perfected process with relentless quality vigilance. Our Wuxi facility employs automated pallet systems for continuous 24/7 machining, minimizing human intervention. Real-time in-process metrology—using on-machine probes and automated optical inspection—monitors critical dimensions after each operation. Statistical Process Control (SPC) charts track key parameters like tool wear and thermal drift, enabling closed-loop correction before deviations occur. Every part receives 100% verification of critical features via CMM, with full traceability from raw material batch to final shipment. This integrated approach, combining advanced automation with human expertise, guarantees consistent conformance and eliminates escape defects.

Wuxi Lead’s integrated facility and process discipline deliver rib parts meeting the most stringent industry demands. The table below summarizes our core production capabilities for these high-precision components.

| Parameter | Capability Range | Standard Tolerance | Typical Lead Time (Prototype) |

|---|---|---|---|

| Material Options | Al 7075-T6, 2024-T3; Ti-6Al-4V; 4340 Steel | ±0.005 mm | 10-15 working days |

| Tolerance Range | Critical Features: ±0.002 mm | Surface Finish: | Ra 0.4 µm (machined) |

| Max Part Size | 1200 x 800 x 500 mm | Inspection: | Full CMM + FAI Report |

| Production Volume | 1 to 10,000+ units | Certifications: | ISO 9001, AS9100 Rev D |

This seamless workflow—anchored in collaborative design, validated prototyping, and statistically controlled mass production—is how Wuxi Lead achieves true zero defects. We transform complex rib part requirements into reliable, high-performance components, mitigating your supply chain risk through precision engineering executed in China.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Rib Part Manufacturing

When it comes to high-precision rib parts for aerospace, automotive, energy, and advanced industrial applications, engineering integrity and manufacturing consistency are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in the end-to-end production of complex rib structures—components that demand exceptional geometric accuracy, material integrity, and structural performance under extreme conditions. Our advanced CNC milling, 5-axis machining, and precision forming capabilities are backed by decades of experience in custom metal manufacturing for global OEMs and Tier-1 suppliers.

Rib parts present unique challenges due to their thin walls, deep cavities, and tight tolerance requirements. Standard manufacturing approaches often fail to maintain dimensional stability or surface quality across production runs. At Lead Precision, we apply a process-driven methodology that begins with material selection and extends through heat treatment, stress relieving, high-speed machining, and final inspection. Our facility is equipped with state-of-the-art HAAS, DMG MORI, and Makino machining centers, enabling us to produce rib components from aluminum alloys, titanium, stainless steel, and high-strength alloys with repeatability down to ±0.005 mm.

We understand that rib part performance directly impacts the structural efficiency and safety of the final assembly. That’s why every component we manufacture undergoes rigorous quality control, including CMM inspection, optical scanning, and first-article reporting per AS9102 or customer-specific requirements. Our AS9100 and ISO 9001 certifications reflect our commitment to traceability, process validation, and continuous improvement.

Our engineering team collaborates closely with your design and manufacturing departments to optimize part geometry, reduce weight, improve tool access, and minimize cycle times—without compromising strength or compliance. Whether you require low-volume prototypes or high-volume production, Lead Precision delivers on-time, high-yield results with full documentation and supply chain transparency.

Below are key technical specifications we support for rib part manufacturing:

| Specification | Capability |

|---|---|

| Maximum Part Size | 2000 mm × 1200 mm × 800 mm |

| Minimum Wall Thickness | 0.8 mm (aluminum), 1.2 mm (titanium) |

| Tolerance | ±0.005 mm typical |

| Surface Finish | Ra 0.8 µm standard, down to Ra 0.4 µm |

| Materials | 7075, 6061, 2024 Aluminum; Ti-6Al-4V; 316L, 17-4PH Stainless Steel |

| Machining Axes | 3-axis, 4-axis, 5-axis simultaneous |

| Quality Standards | AS9100D, ISO 9001:2015, PPAP, FAI, CMM Reports |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally that combines technical depth with operational agility. We are committed to becoming an extension of your engineering team, ensuring your rib parts meet the highest standards of precision and reliability.

For project inquiries, technical collaboration, or to request a quote, contact us today at [email protected]. Let’s build performance-critical components—right the first time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.