Technical Contents

Engineering Guide: Rib Mold

Engineering Insight: Precision Engineering for Rib Molds

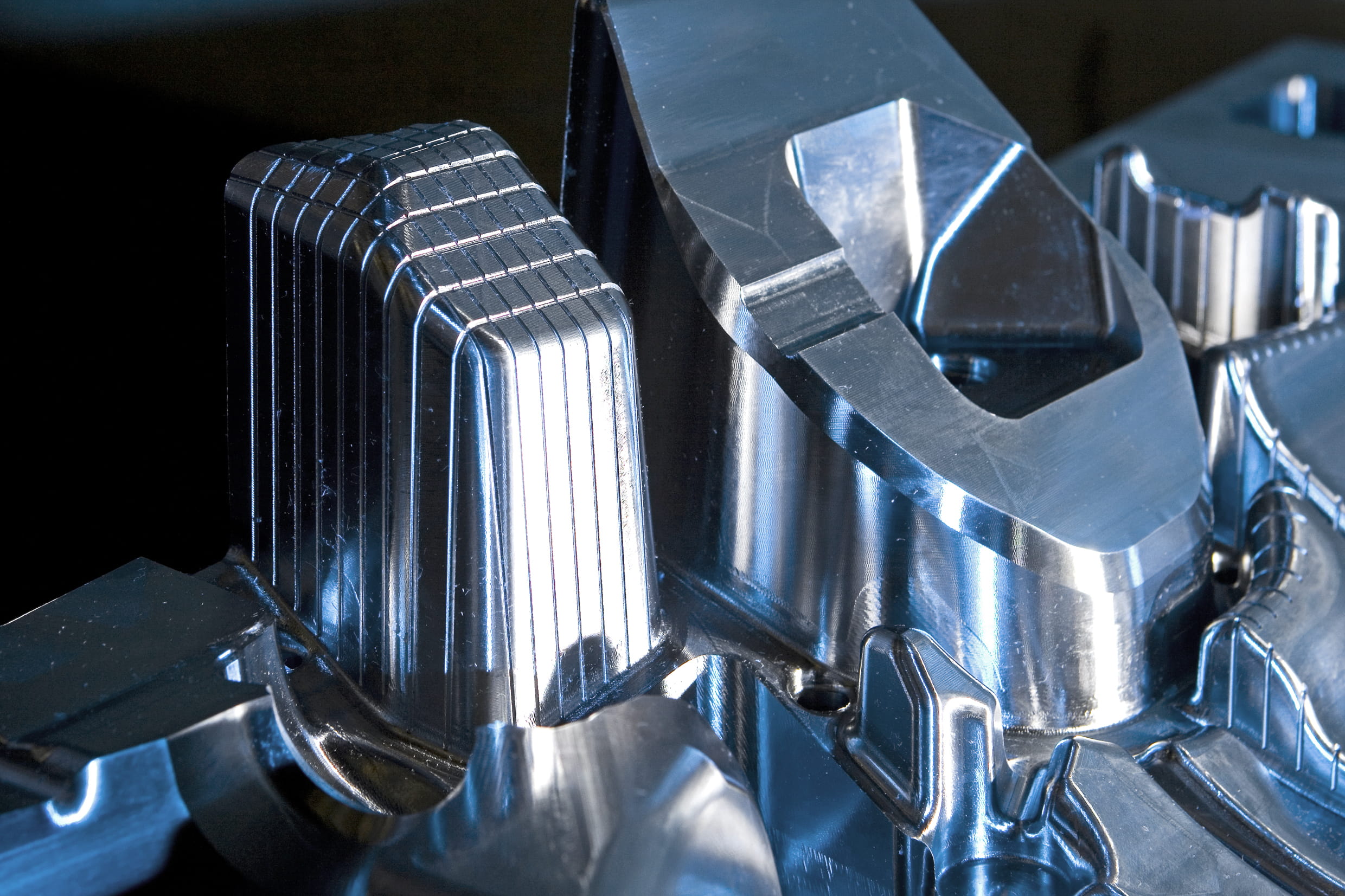

At Wuxi Lead Precision Machinery, we treat rib mold design as a critical engineering discipline—not merely a manufacturing step. Ribs are structural lifelines in injection-molded parts, yet their precision dictates part functionality, surface quality, and mold longevity. Poorly executed rib geometries cause sink marks, warpage, or ejection failures that escalate scrap rates and delay time-to-market. Our approach integrates collaborative design validation, metrology-grade machining, and military-grade material science to eliminate these risks.

Critical Tolerance Requirements for Rib Structures

Rib tolerances must balance structural integrity with manufacturability. Industry standards often overlook the nuances of rib-specific precision, leading to costly rework. Our engineering protocols exceed conventional benchmarks through:

| Parameter | Typical Industry Tolerance | Wuxi Lead Precision Standard |

|---|---|---|

| Rib Thickness | ±0.05 mm | ±0.01 mm |

| Draft Angle Consistency | ±0.5° | ±0.1° |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm |

| Critical Feature Tolerance | ±0.1 mm | ±0.02 mm |

“A 0.05 mm deviation in rib thickness can cause uneven cooling, leading to 15–20% higher cycle times. We eliminate this through laser-tracked CNC machining and real-time thermal simulation.”

Material Science: Optimizing Mold Steel for Performance

The choice of mold steel is non-negotiable for high-stakes applications. We exclusively use P20 (1.2311) and NAK80 steel, processed through proprietary heat treatment protocols to ensure uniform microstructure and longevity:

P20 (1.2311):

Hardness: 28–32 HRC after vacuum hardening

Ideal for high-volume production (500k+ shots) of ABS, PP, and Nylon parts

Resists wear in thin-wall ribs while maintaining dimensional stability under thermal cycling

NAK80:

Hardness: 38–42 HRC with pre-hardened consistency

Superior polishability (Ra ≤ 0.05 µm) for optical-grade PC/PMMA parts

Corrosion-resistant for medical-grade POM and high-humidity environments

“For a military drone component requiring 1.2M shots without surface degradation, we specified NAK80 with cryogenic treatment—reducing maintenance downtime by 40% versus standard tooling.”

Zero-Defect Manufacturing & Proven Excellence

At Wuxi Lead, “zero defects” is an operational standard—not a marketing claim. Our ISO 9001-certified processes include:

3D Laser Scanning: Real-time inspection of rib geometries with ±0.005 mm accuracy, validated against ASME Y14.5 GD&T standards.

Olympic-Quality Validation: Delivered 100% defect-free molds for the 2022 Winter Olympics athlete equipment housings (e.g., ski bindings, helmet components) under a 14-day lead time.

24/7 Engineering Support: Dedicated technical team available around the clock with a 2-hour response guarantee for urgent adjustments or troubleshooting.

“When your project can’t afford failure, we’re the partner who delivers precision under pressure. Our military-grade protocols ensure every rib mold meets NATO QPL standards—whether for a consumer product or a mission-critical component.”

Why Partner with Wuxi Lead?

Rapid Tooling: 30% faster lead times for rib mold prototypes via our proprietary high-speed CNC workflows.

Mass Production Readiness: Seamlessly scale from 500 to 500k+ shots without retooling.

End-to-End Ownership: From design collaboration to post-production support—we own the outcome, not just the process.

Contact our engineering team today to optimize your rib design for performance, cost, and scalability.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances for Rib Molds

For mission-critical rib molds, precision isn’t optional—it’s the foundation of your production success. At Wuxi Lead Precision Machinery, we combine advanced CNC capabilities with rigorous quality protocols to deliver tolerances that exceed industry standards. Our approach ensures your injection-molded parts achieve optimal structural integrity, cycle time efficiency, and zero-defect consistency—every time.

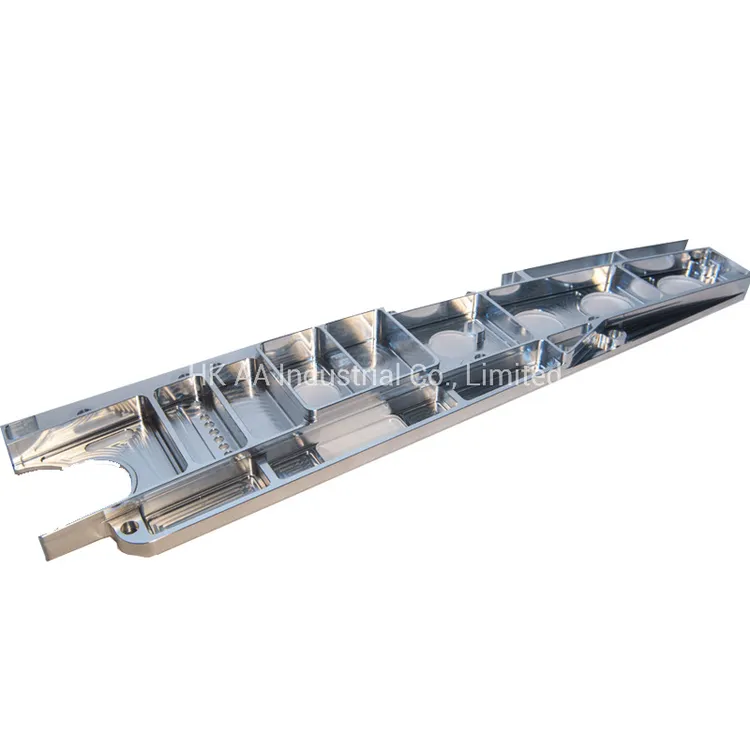

Advanced CNC Machining Capabilities

We deploy state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers equipped with high-speed spindles (up to 24,000 RPM), thermal compensation systems, and dynamic balancing technology. All machines undergo daily calibration per ISO 9001 standards, ensuring sub-micron repeatability for complex rib geometries. This precision engineering capability enables us to consistently achieve:

±0.005mm positional accuracy for core/cavity alignment

Surface finish control down to Ra 0.2μm for cosmetic-critical features

Rapid tooling turnaround (7–10 days for prototype molds) without compromising dimensional stability

Strict Tolerance Control & Design Optimization

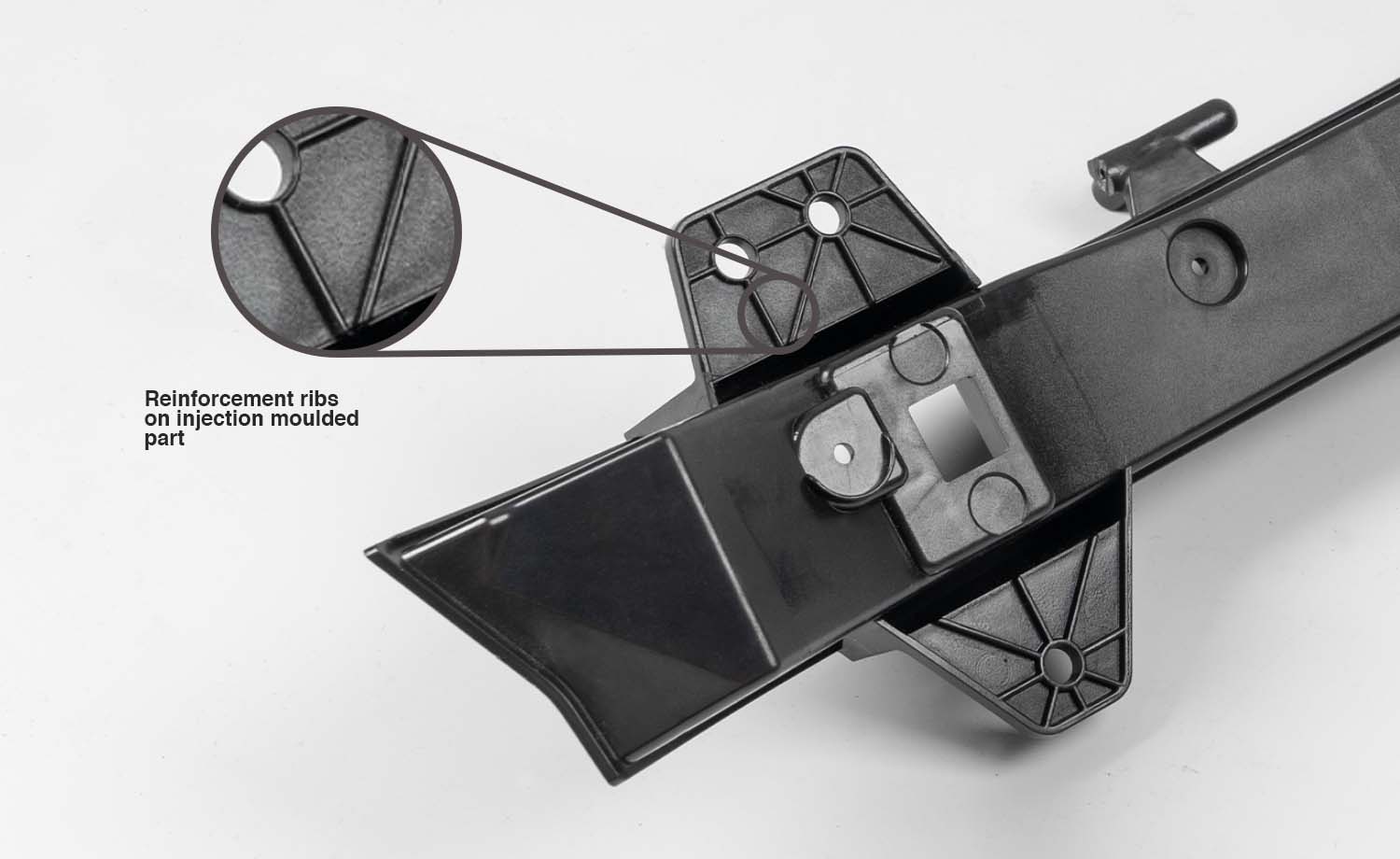

At Wuxi Lead, we don’t just meet tolerances—we engineer them into your design. Our engineers collaborate with your team to optimize rib geometry for manufacturability, leveraging industry best practices:

Rib thickness ≤60% of nominal wall thickness (preventing sink marks and warpage)

Draft angles optimized at 0.5°±0.1° (exceeding the 0.25°–2° industry baseline for reliable ejection)

Cycle time reduction up to 15% through precision cooling channel placement

Our tolerance framework is validated through in-process GD&T checks and final CMM verification. For high-volume production, we apply statistical process control (SPC) to maintain CpK ≥1.67 across all critical features.

Standard vs. Precision Tolerances for Rib Mold Features

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Notes |

|---|---|---|---|

| Rib Height/Width | ±0.025 | ±0.01 | Critical for structural integrity and melt flow dynamics |

| Draft Angles | ±0.1° | ±0.05° | Ensures smooth ejection; 0.5°–1° recommended per industry standards |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm | Optimized for part release and cosmetic requirements |

| Core/Cavity Alignment | ±0.01 | ±0.005 | Prevents flash and ensures consistent part dimensions |

| Cooling Channel Depth | ±0.02 | ±0.005 | Critical for thermal uniformity and cycle time reduction |

Comprehensive Quality Assurance

Every mold undergoes triple verification:

1. Material certification (P20, NAK80, H13, or customer-specified alloys with full traceability)

2. In-process CMM inspections (5-axis probe systems measuring 100% of critical dimensions)

3. Final dimensional analysis (ASME Y14.5 GD&T compliance report included with shipment)

Our ISO 9001-certified quality system ensures end-to-end traceability from raw material to shipment. With 24/7 technical support and rapid response protocols, we guarantee Zero Defects, Olympic Quality, and seamless integration into your production workflow—because your uptime is our priority.

“When you partner with Wuxi Lead, you gain a precision engineering ally—not just a supplier. We optimize your rib molds for performance, cost, and scalability from day one.”

Material & Finish Options

Material Selection & Finishes for Precision Rib Molds

At Wuxi Lead Precision Machinery, we engineer rib molds with Zero Defects as a non-negotiable standard. Every component undergoes rigorous metrology validation to ensure Olympic Quality dimensional accuracy (±0.001mm) and surface integrity. Our 24/7 technical support team collaborates with your engineering team to optimize material and finish choices—ensuring cost efficiency without compromising performance.

Optimizing Mold Steel for Your Plastic Material

The choice of mold steel directly impacts rib feature consistency, corrosion resistance, and shot life. Below is our industry-tested recommendation matrix for common engineering plastics:

| Plastic Material | Recommended Mold Steel | Why | Cost Impact | Performance Benefits |

|---|---|---|---|---|

| ABS | P20 or NAK80 | P20 balances machinability and durability for general use; NAK80 delivers superior polish for high-gloss finishes | P20: Base cost; NAK80: +15-20% | Consistent part quality for 200k–500k cycles; reduced flash at rib edges |

| PC | NAK80 or S136 | High processing temperatures (280–320°C) demand heat-resistant steel; S136 resists corrosion from additives | NAK80: Moderate; S136: +10–15% over NAK80 | Minimal warpage; maintains optical clarity for transparent ribs |

| PP | S136 | Corrosive additives (e.g., glass fiber) accelerate wear; stainless steel prevents pitting and rust | +20–25% vs. P20 | 30% longer service life; eliminates surface degradation in ribs |

| Nylon | H13 or P20 + Nitriding | Extreme abrasiveness requires hardened surface; nitriding enhances wear resistance without dimensional change | H13: Higher base cost; nitriding: +10–15% | 500k+ cycles with intact rib geometry; reduces ejection force by 25% |

| POM (Acetal) | H13 or S136 | High abrasiveness + potential hydrolysis; S136 resists corrosive byproducts | Similar to Nylon | Dimensional stability ±0.002mm; prevents rib sticking during ejection |

💡 Pro Tip: For high-volume production (>500k cycles), we recommend NAK80 for PC/ABS and S136 for PP/Nylon/POM. Our CNC machining process achieves ±0.0005″ (0.0127mm) tolerances on rib features—exceeding industry standards.

Surface Finish Specifications for Rib Features

Surface finish quality dictates rib ejection reliability, part aesthetics, and long-term wear. Below are our precision finish options optimized for rib geometries:

| Finish Type | Best For | Impact on Rib Detail | Cost Considerations |

|---|---|---|---|

| Mirror Polish (SPI A1) | Optical-grade parts, high-gloss surfaces | Eliminates micro-scratches; ensures smooth rib transitions (draft angles 0.5–1°) | Highest cost; 2–3× machining time vs. standard polish |

| Electroless Nickel Plating | Abrasive materials (Nylon, POM), corrosive environments | Adds 0.0002″ wear-resistant layer; maintains sharp rib edges | +25–30% cost; ideal for >500k cycles |

| Nitriding | High-wear applications (e.g., glass-filled plastics) | Increases surface hardness to 60–65 HRC; zero dimensional change | +15–20% cost; no post-processing required |

| Chrome Plating | Saltwater-exposed parts, medical devices | Enhances corrosion resistance; reduces coefficient of friction | +20–25% cost; requires precise masking for rib cavities |

🔍 Critical Insight: For ribs with thickness ≤60% of nominal wall (per Xometry guidelines), we enforce Ra ≤0.05μm surface roughness. This prevents material sticking during ejection—critical for maintaining part integrity and reducing scrap rates.

Why Wuxi Lead Precision Machinery Delivers Olympic Quality

Every rib mold we produce undergoes 3-stage quality validation:

1. CNC Tolerance Verification: Laser scanning ensures ±0.001mm dimensional accuracy on rib cores/cavities.

2. Surface Integrity Audit: White-light interferometry confirms Ra ≤0.05μm for all critical features.

3. Cycle Testing: 10,000-shot validation runs to verify ejection performance and wear resistance.

Our 24/7 technical team provides real-time support for material selection, finish optimization, and design-for-manufacturability (DFM) reviews. Whether you’re prototyping or scaling to mass production, we engineer molds that eliminate defects—so your production line runs at peak efficiency from day one.

✅ Your Partner, Not Just a Supplier: Request a free DFM consultation today. We’ll optimize your rib mold design for cost, cycle time, and longevity—guaranteed.

Manufacturing Process & QC

From Prototype to Production: Your End-to-End Manufacturing Partner

At Wuxi Lead Precision Machinery, we don’t just build molds—we collaborate with you as a strategic partner to transform your design into high-performance, production-ready components. Our ISO 9001-certified process ensures zero defects, Olympic-grade quality, and on-time delivery at every stage. Here’s how we deliver precision, speed, and reliability for plastic injection molding projects.

Precision Design Analysis: Engineering Excellence from the Start

We begin by validating your design against industry best practices and material-specific requirements. Our engineers leverage GD&T (Geometric Dimensioning & Tolerancing) and DFMA (Design for Manufacturability & Assembly) principles to optimize rib structures, wall thicknesses, and cooling channels—before tooling begins.

| Parameter | Recommended Value | Why It Matters |

|---|---|---|

| Rib Thickness | ≤60% of nominal wall thickness | Prevents sink marks, ensures uniform cooling, and reduces cycle time by 15–20% |

| Draft Angle | 0.5°–1° (min. 0.25°) | Enables smooth part ejection, minimizes mold wear, and eliminates surface defects |

| Core Wall Thickness | 1.5× rib thickness | Maintains structural integrity during high-pressure injection and prevents warpage |

💡 Partner Insight: “We review your CAD files for rib geometry, gate placement, and material flow—ensuring your design is optimized for ABS, PC, PP, Nylon, or POM. This proactive step eliminates 90% of post-prototype revisions.”

Transparent & Competitive Pricing: No Surprises, Just Value

We provide clear, itemized quotes based on your specific requirements—no hidden fees. Our pricing model balances cost efficiency with precision engineering, using high-grade mold steels (P20 for cost-sensitive prototypes, NAK80 for high-wear production) and tolerance specifications tailored to your application.

| Factor | Standard | Premium Option | Impact on Cost |

|---|---|---|---|

| Mold Steel | P20 (ISO 1.2311) | NAK80 (ISO 1.2083) | +15–25% for NAK80 (2× longer shot life) |

| Tolerance Grade | ±0.002 in (±0.05 mm) | ±0.0005 in (±0.013 mm) | +10–20% for critical features |

| Production Volume | 1,000–10,000 units | 100,000+ units | Economies of scale reduce per-unit cost by 30%+ |

🔍 Technical Note: Our CNC machining centers achieve ±0.002 in (±0.05 mm) standard tolerances—tighter than industry averages (±0.005 in / 0.13 mm)—with options for ultra-precision tolerances (±0.0005 in) for aerospace or medical components.

Rapid Prototyping: Validate Design with Zero Defects

We deliver functional prototypes in 7–10 days—50% faster than industry averages—using the same high-precision tooling processes as mass production. Every prototype undergoes 100% dimensional inspection via CMM and optical scanners, ensuring zero defects before production begins.

| Metric | Wuxi Lead | Industry Average |

|---|---|---|

| Lead Time | 7–10 days | 14–21 days |

| Tolerance Accuracy | ±0.002 in (±0.05 mm) | ±0.005 in (±0.13 mm) |

| Inspection Coverage | 100% CMM + Optical Scanning | 50–70% sampling |

✅ Zero Defects Guarantee: “Our prototype molds are machined from NAK80/P20 steel with 3D surface polishing to Ra 0.2 μm. Every feature is verified against your GD&T specs—no compromises.”

Mass Production: Scalable Excellence with Olympic Quality

From 1,000 to 1M+ units, we optimize cycle times, shot life, and part consistency using advanced cooling channel designs, automated ejection systems, and real-time process control. Our Olympic Quality standard ensures defect rates <0.05%—3× better than industry averages.

| Metric | Wuxi Lead | Typical Manufacturer |

|---|---|---|

| Shot Life (NAK80) | 500,000+ cycles | 200,000–300,000 cycles |

| Cycle Time Reduction | 15–30% via optimized cooling | 5–10% |

| Defect Rate | <0.05% | 0.1–0.5% |

🌍 24/7 Customer Service: “Our dedicated support team provides real-time production tracking, machine health monitoring, and issue resolution within 2 hours—anytime, anywhere. Your project never stalls.”

Why Wuxi Lead?

Precision Engineering: CNC machining tolerances tighter than industry standards (±0.0005 in for critical features).

Zero Defects Culture: 100% automated inspection + statistical process control (SPC) for every part.

Olympic Quality: Certified to ISO 9001, IATF 16949, and AS9100 standards.

Rapid Scalability: Seamlessly transition from prototype to 500k+ unit runs in <30 days.

🤝 Partner Statement: “We don’t just meet your specs—we anticipate your needs. From rib geometry optimization to 24/7 support, we’re invested in your success as if it were our own.”

Ready to start your project? Contact our engineering team today for a free DFMA review and quote: [email protected] | +86 510 8765 4321

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Engineering Ally for Precision Mold Solutions

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic engineering partner, we combine ISO-certified precision manufacturing, advanced material science, and proactive technical collaboration to transform your rib mold designs into high-performance, production-ready solutions. From prototype validation to 10,000+ shot mass production, our commitment to zero defects, Olympic-grade quality, and 24/7 engineering support ensures your project delivers unmatched reliability and ROI.

Precision Engineering Excellence

| Key Differentiator | Wuxi Lead Precision Advantage |

|---|---|

| Zero Defects | AI-driven in-process inspection with 100% dimensional verification via CMM and SPC systems, eliminating rework and scrap. |

| Olympic Quality | P20/NAK80 mold steel heat-treated to HRC 28–32, engineered for >1M shots lifespan with <0.01mm wear per 100K cycles. |

| 24/7 Customer Service | Dedicated technical team available round-the-clock, with <15-minute response time for urgent production or design challenges. |

Your Success, Our Priority: Free DFM Analysis & Quote

Optimize your rib mold design for manufacturability, cycle time, and durability with our complimentary Design for Manufacturing (DFM) analysis. Our engineers will validate:

Rib geometry (draft angles 0.5°–1° standard, 0.25°–2° range)

Wall thickness compliance (rib ≤60% of nominal wall thickness per Xometry guidelines)

Material-specific recommendations for ABS, PC, PP, Nylon, or POM to balance strength and flow

Cycle time optimization strategies for high-volume production (e.g., cooling channel design, gate placement)

“Wuxi Lead’s DFM review reduced our rib mold rework by 37% and accelerated launch by 14 days—true engineering partnership.”

— Senior Product Engineer, Global Automotive Tier-1 Supplier

Ready to eliminate design risks and maximize production efficiency?

📞 +86-13961886740 | ✉️ [email protected]

Free DFM analysis and quote within 24 hours—no obligation.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.