Technical Contents

Engineering Guide: Real Cnc

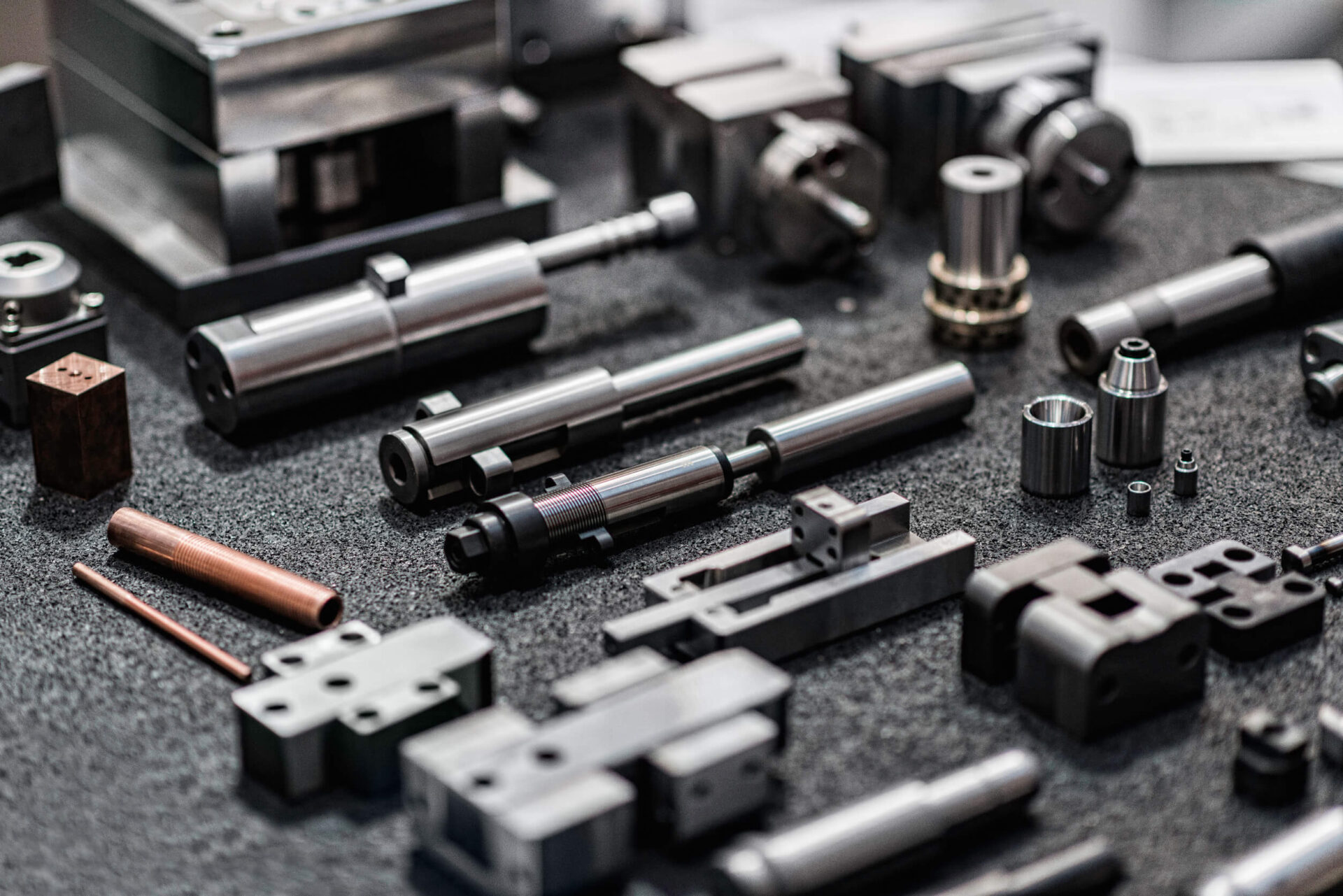

Engineering Insight: The True Meaning of Precision in CNC Machining

In high-end manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we define precision as the consistent ability to produce components within micron-level tolerances, across materials, volumes, and geometries, without compromise. This standard is not achieved through advanced machinery alone, but through a holistic integration of engineering expertise, process control, and unwavering attention to detail.

Precision CNC machining transcends the simple removal of material. It demands a deep understanding of material behavior, thermal dynamics, tool wear, and vibration management. Every micron deviation can impact the performance of a final assembly, particularly in mission-critical applications such as aerospace, defense systems, and high-performance sporting equipment. Our experience in delivering components for Olympic-grade athletic systems and military-grade hardware has reinforced a singular truth: consistency under extreme conditions separates true precision from mere accuracy.

At Lead Precision, our engineering team leverages over a decade of specialized CNC development to ensure that every machining cycle adheres to the most stringent quality benchmarks. We utilize high-rigidity machine platforms equipped with real-time thermal compensation and laser tool measurement systems. These technologies are essential, but they are only effective when guided by experienced process engineers who understand how to optimize cutting strategies, fixturing, and inspection protocols.

Our facility maintains ISO 9001 and IATF 16949 certifications, with in-house metrology including coordinate measuring machines (CMM), optical comparators, and surface roughness testers. This infrastructure allows us to validate precision at every stage—from first article inspection to full production runs.

The following table outlines the core precision capabilities maintained across our CNC machining platforms:

| Specification | Performance Level |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Standard Tolerances | ±0.005 mm (typical) |

| Tight Tolerance Capability | ±0.001 mm (on request) |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Spindle Runout | < 0.003 mm (at full speed) |

| In-Process Measurement | Available (laser and touch probe) |

These figures represent more than technical benchmarks—they reflect our commitment to delivering components that perform exactly as designed, every time. Whether supporting the development of next-generation defense systems or enabling Olympic athletes to break records, Wuxi Lead Precision Machinery operates at the leading edge of what is physically possible in CNC manufacturing.

Precision, in the real sense, is not accidental. It is engineered.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery: Advanced Technical Capabilities for Mission-Critical Components

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding aerospace, medical, and energy sector applications. Our core strength lies in integrating cutting-edge multi-axis machining with rigorous, data-driven quality assurance, ensuring every component meets or exceeds stringent global specifications. We operate a modern fleet of 5-axis CNC machining centers from industry leaders including DMG MORI and Makino. These platforms enable simultaneous 5-axis contouring, eliminating costly secondary operations and fixture setups while achieving complex geometries impossible with 3-axis systems. Our machining centers feature high-torque spindles, thermal compensation systems, and FANUC or Siemens controls optimized for stability during extended production runs. Material versatility is fundamental to our service; we routinely machine difficult alloys including Inconel 718, Ti-6Al-4V, Waspaloy, and high-performance engineering plastics with consistent repeatability. Process optimization is performed in-house by our senior CNC programming team using Mastercam and Siemens NX CAM, focusing on cycle time reduction, tool life maximization, and surface integrity critical for fatigue-sensitive components.

Quality verification is not a final step but an integrated process throughout production. Every critical feature undergoes non-destructive validation using state-of-the-art Coordinate Measuring Machines (CMMs) from Zeiss and Hexagon. Our CMM cells operate under strict ISO 17025 accredited environmental controls, ensuring measurement uncertainty is consistently maintained below 1.5 microns. Full first-article inspection reports (FAIRs) with comprehensive GD&T analysis are standard, providing complete dimensional traceability. Statistical Process Control (SPC) data is actively monitored during production runs, allowing immediate corrective action to maintain capability indices (Cp/Cpk) above 1.67 for critical features. Surface roughness is verified using Mitutoyo profilometers, and material certification documentation is fully traceable to mill test reports. This systematic approach to quality assurance minimizes client risk and ensures zero defects reach final assembly.

Our precision capabilities are quantifiable across diverse component types. The following table details our standard achievable tolerances under controlled production conditions, reflecting our commitment to engineering excellence:

| Feature Category | Typical Capability | Application Example |

|---|---|---|

| Linear Dimensions | ±0.005 mm (0.0002″) | Bearing bores, shaft diameters |

| Angular Features | ±0.001° (2 arc seconds) | Turbine blade root profiles |

| Positional Tolerance | ±0.010 mm (0.0004″) | Multi-hole patterns in fuel system parts |

| Surface Roughness (Ra) | 0.4 μm (16 μin) | Hydraulic sealing surfaces, optical mounts |

Partner with Wuxi Lead Precision Machinery for components where dimensional integrity directly impacts system performance and safety. Our technical team collaborates closely with client engineering departments during DFx stages to optimize manufacturability without compromising functional requirements. We transform complex design intent into physically verifiable precision, backed by transparent process data and unwavering commitment to on-time delivery of mission-critical hardware. Contact our engineering sales group to discuss your most challenging precision machining requirements.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the right material is critical in precision CNC machining, where performance, durability, and application environment dictate component success. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of three core metals: aluminum, steel, and titanium. Each offers unique mechanical properties and responds differently to finishing processes such as anodizing, enabling tailored solutions across aerospace, medical, automotive, and industrial automation sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly common in structural and enclosure applications due to its weldability and corrosion resistance. When enhanced with anodizing—especially Type II or Type III (hard coat)—aluminum gains a durable, non-conductive oxide layer that improves wear resistance and allows for color coding or branding. This makes it ideal for both functional and aesthetic components.

Steel, particularly alloy and stainless variants such as 4140, 17-4 PH, and 304/316, offers superior strength, hardness, and temperature resistance. These grades are essential in high-stress environments such as hydraulic systems, tooling, and medical instruments. While steel cannot be anodized, it responds well to alternative surface treatments like passivation, plating, and powder coating. Its higher density and abrasiveness require optimized toolpaths and tooling, which our advanced CNC centers are engineered to handle with precision.

Titanium, especially Grade 5 (Ti-6Al-4V), delivers exceptional performance in extreme conditions. With a strength-to-density ratio surpassing steel and outstanding corrosion resistance—even in saltwater and high-temperature environments—titanium is the material of choice for aerospace components, implants, and marine hardware. However, its low thermal conductivity and high reactivity demand careful machining strategies, including controlled feed rates and specialized coolants. Titanium does support anodizing, primarily for color coding in medical devices, though the process differs significantly from aluminum.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Enclosures, heat sinks | Yes (Type II & III) |

| Stainless Steel | 316L | 580 | 8.0 | Medical, marine parts | No |

| Alloy Steel | 4140 | 655 | 7.85 | Tooling, shafts | No |

| Titanium | Ti-6Al-4V | 950 | 4.43 | Aerospace, implants | Yes (decorative) |

Choosing the optimal material involves balancing mechanical requirements, environmental exposure, weight constraints, and post-processing needs. At Wuxi Lead Precision Machinery, we support clients from design to delivery, ensuring each material is machined to exacting standards and finished to meet functional and regulatory demands.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, achieving zero defects in high-end CNC machining is not aspirational—it is engineered into every phase of our production process. We integrate rigorous methodology with advanced technology to transform client specifications into flawless components, critical for aerospace, medical, and semiconductor applications where failure is not an option. Our structured workflow ensures predictability, minimizes risk, and guarantees conformance to the most demanding international standards.

The process begins with Design Validation and Process Planning. Our engineering team collaborates closely with client CAD/CAM data, conducting comprehensive DFM (Design for Manufacturability) analysis. We identify potential geometric conflicts, material stress points, and fixture challenges before metal is cut. This phase defines the optimal machining strategy, toolpath sequencing, and in-process inspection points using Siemens NX and Mastercam simulation software. Material certification and first-article inspection criteria are locked in, establishing the baseline for zero-defect execution.

Prototyping and Process Refinement follows immediately. We produce functional prototypes using the exact materials and production-grade CNC equipment intended for final manufacture—typically 5-axis milling or precision turning centers. Each prototype undergoes full CMM (Coordinate Measuring Machine) validation against GD&T requirements, surface roughness analysis, and material property verification. Crucially, this stage identifies micro-inefficiencies; we iterate tooling, speeds/feeds, or fixturing based on empirical metrology data, not assumptions. Client sign-off on the validated prototype confirms process readiness, eliminating downstream surprises.

Zero-Defect Mass Production leverages the perfected process. Production runs deploy automated tool compensation, in-machine probing for real-time dimensional feedback, and integrated SPC (Statistical Process Control) monitoring. Every critical dimension is measured at defined intervals using calibrated optical comparators and CMMs, with data fed directly into our quality management system. Automated part handling minimizes human error, while 100% first-piece and periodic in-process inspections ensure continuous conformance. Final shipment includes full traceability documentation—material certs, CMM reports, and process parameter logs—for absolute accountability.

This phased approach, underpinned by continuous data analysis and proactive correction, transforms zero defects from a goal into a measurable outcome. We do not rely on end-of-line inspection alone; defects are prevented at the source through predictive process control.

Key process specifications ensuring zero-defect output are maintained throughout:

| Process Phase | Critical Control Parameter | Target Specification | Verification Method |

|---|---|---|---|

| Design Validation | Geometric Tolerance Compliance | 100% GD&T Conformance | NX Simulation / DFM Report |

| Prototyping | Prototype Iteration Cycles | ≤ 2 Cycles | CMM Report / Client Sign-off |

| Mass Production | Process Capability (Cpk) | ≥ 1.67 | Real-time SPC Charting |

| Mass Production | In-Process Inspection Rate | Min. 100% First Piece + 5% Lot | Automated Probing / CMM Sampling |

| Final Verification | Dimensional Accuracy | ±0.002 mm (Typical) | 3D CMM with NIST-Traceable Calibration |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, precision, reliability, and speed are not just advantages—they are requirements. As a globally recognized leader in precision CNC machining, we specialize in delivering custom-engineered components that meet the most demanding tolerances and performance standards. Our advanced manufacturing capabilities, combined with decades of engineering expertise, make us the strategic partner of choice for industries ranging from aerospace and medical devices to automotive and industrial automation.

When you partner with Lead Precision, you gain more than just a supplier—you gain a committed collaborator focused on your success. Our end-to-end service model includes precision CNC turning, milling, grinding, and multi-axis machining, all executed in a fully ISO 9001:2015-certified facility. We utilize state-of-the-art equipment from industry leaders such as DMG MORI, Haas, and Okuma, ensuring consistent quality and repeatability across every production run. From prototype development to high-volume manufacturing, our agile systems support rapid turnaround without compromising on accuracy or material integrity.

Our engineering team works closely with your design and R&D departments to optimize manufacturability, reduce lead times, and lower total production costs. Whether you require tight-tolerance components in exotic alloys, complex geometries, or micro-machined parts, we apply advanced simulation and metrology tools—including CMM and 3D scanning—to validate every dimension. Our facility is equipped to handle materials such as titanium, Inconel, stainless steel, aluminum, and high-performance polymers, ensuring compatibility with even the most specialized applications.

We are committed to transparency, responsiveness, and continuous improvement. Every project is managed through a dedicated account engineer who provides real-time updates, full documentation, and rigorous quality reporting. With streamlined logistics and global shipping capabilities, we ensure on-time delivery to clients across North America, Europe, and Asia.

To experience the Lead Precision difference, contact us today. Let our team help you transform your most challenging designs into high-performance reality.

Technical Capabilities Overview

| Parameter | Specification |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm (47.2 x 31.5 x 25.6 in) |

| Minimum Tolerance | ±0.002 mm (±0.00008 in) |

| Spindle Speed (Max) | 24,000 RPM |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Processed | Steel, Stainless, Aluminum, Titanium, Inconel, Brass, Plastics |

| Surface Finish (Typical) | Ra 0.4 µm (16 µin) or better |

| Quality Standards | ISO 9001:2015, Full First Article Inspection |

| Lead Time (Prototype) | 7–15 days (varies by complexity) |

| Production Capacity | Low to high volume, scalable batches |

For immediate support or to request a quote, email us at [email protected]. Our engineering team is ready to collaborate and deliver precision that leads.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.