Technical Contents

Engineering Guide: R&D Machining

Engineering Insight: R&D Machining – Where Precision Defines Innovation

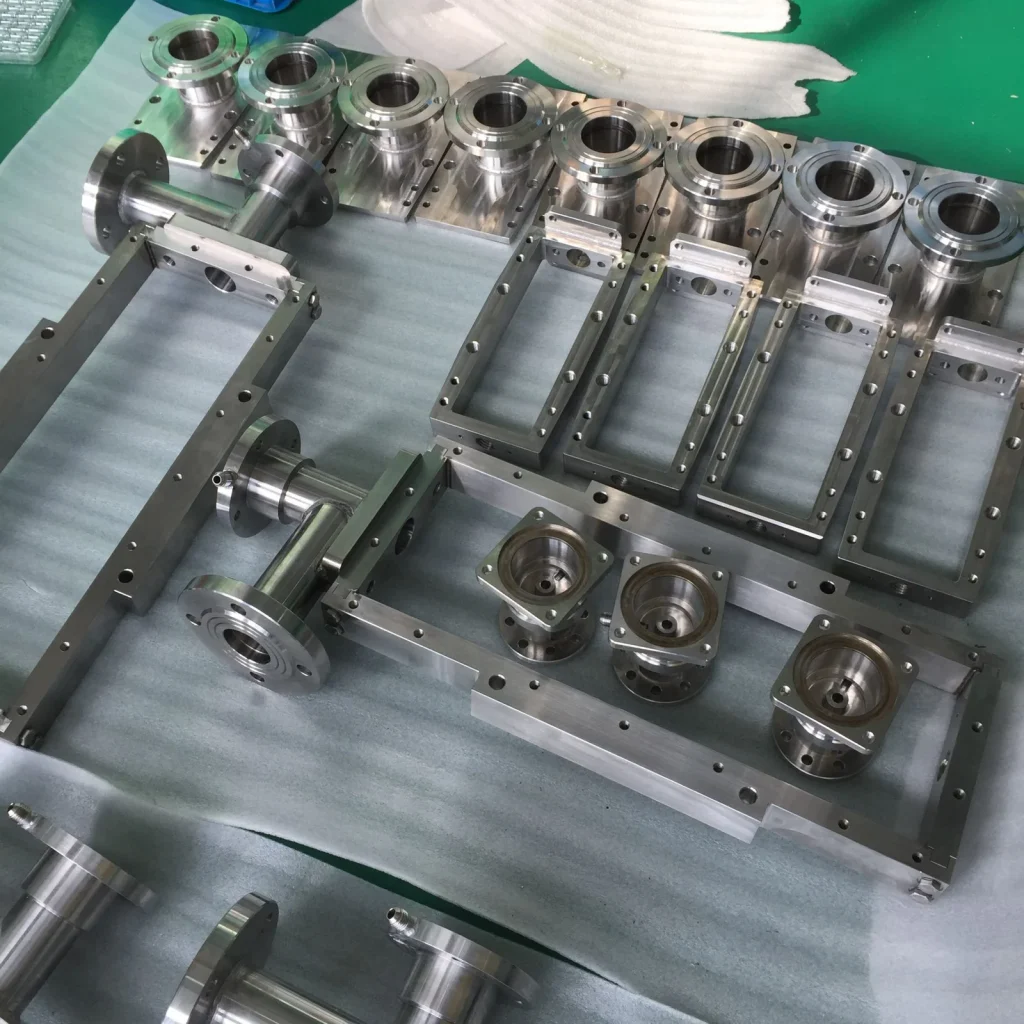

In the realm of advanced manufacturing, R&D machining stands as a critical bridge between conceptual design and scalable production. Unlike conventional machining, which prioritizes volume and repeatability, R&D machining demands an elevated standard of precision, adaptability, and technical foresight. At Wuxi Lead Precision Machinery, we recognize that the success of pioneering engineering projects—especially in aerospace, defense, and high-performance sports equipment—relies on the ability to translate intricate designs into flawless physical prototypes. This is where precision is not merely a metric; it is the foundation of innovation.

Our experience in R&D machining has been shaped by some of the most demanding applications in modern engineering. We have supported projects for military-grade components requiring micron-level tolerances and contributed to equipment used in Olympic competitions, where performance margins are measured in thousandths of an inch. These engagements underscore a fundamental truth: when failure is not an option, precision machining becomes a strategic imperative.

In R&D environments, components often feature complex geometries, exotic materials, and tight integration requirements. Standard machining practices may compromise dimensional accuracy or surface integrity, leading to flawed test data or prototype failure. At Lead Precision, we employ advanced 5-axis CNC systems, in-process metrology, and proprietary fixturing techniques to maintain tolerances down to ±0.001 mm. Our engineers work closely with clients during the design-for-manufacturability phase, ensuring that theoretical models are translated into machinable, high-fidelity prototypes without sacrificing performance intent.

Material selection further amplifies the need for precision. Whether working with titanium alloys, Inconel, or high-strength aluminum composites, our machining protocols are calibrated to account for thermal expansion, tool wear, and residual stress—factors that can derail R&D timelines if unmanaged. Each prototype is treated as a mission-critical component, with full traceability, inspection reports, and iterative feedback loops to support rapid design evolution.

The following table outlines the core capabilities that define our R&D machining services:

| Specification | Capability |

|---|---|

| Positioning Accuracy | ±0.001 mm |

| Repeatability | ±0.0005 mm |

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Spindle Speed (5-Axis) | Up to 24,000 RPM |

| Materials Supported | Titanium, Inconel, Aluminum, Stainless Steel, Tool Steels |

| Surface Finish (Ra) | As low as 0.2 µm |

| Lead Time (Prototype Batch) | 7–15 days (depending on complexity) |

At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we enable breakthroughs. Our commitment to precision in R&D machining ensures that every prototype meets the exacting standards required for validation, testing, and eventual production. For engineers pushing the boundaries of what’s possible, that level of reliability is not just valuable; it is indispensable.

Precision Specs & Tolerances

Technical Capabilities for Advanced R&D Machining

At Wuxi Lead Precision Machinery, we specialize in delivering micron-level precision for complex R&D projects requiring rapid iteration and uncompromising quality. Our technical foundation centers on state-of-the-art 5-axis CNC machining systems, enabling the production of intricate geometries unachievable with conventional 3-axis platforms. These HAAS and DMG MORI platforms feature high-speed spindles (up to 24,000 RPM), rigid thermal compensation, and integrated probing for in-process verification. This capability eliminates multiple fixturing stages, reducing part handling errors and accelerating prototype-to-production cycles—critical for time-sensitive R&D initiatives in aerospace, medical device development, and semiconductor equipment.

Material versatility defines our R&D support. We machine challenging alloys including Inconel 718, titanium Grade 5, beryllium copper, and advanced composites with equal proficiency. Our engineering team collaborates directly with clients during the design phase to optimize part geometry for manufacturability, leveraging simulation software to predict tool deflection, thermal drift, and surface integrity. This proactive approach minimizes costly redesigns and ensures first-article success, even for components with thin walls, deep cavities, or complex organic contours.

Quality control is non-negotiable in R&D validation. Every component undergoes rigorous inspection using Zeiss CONTURA CMM systems with 0.5 µm volumetric accuracy, supported by optical comparators and surface roughness testers. Full first-article inspection reports (FAIRs) with GD&T analysis are standard, providing traceable data for design verification and regulatory compliance. Our ISO 9001-certified process includes real-time SPC monitoring during production, ensuring dimensional stability across low-volume batches. This eliminates guesswork in performance testing and builds confidence in prototype fidelity.

The table below details achievable tolerances across common R&D materials, reflecting our commitment to repeatability under controlled environmental conditions (20±0.5°C). These specifications are validated through our CMM workflow and represent typical production capabilities, not theoretical limits.

| Feature | Tolerance Range | Material Examples |

|---|---|---|

| Linear Dimensions | ±0.005 mm to ±0.01 mm | Aluminum 7075, Stainless 17-4PH |

| Geometric Tolerances | ±0.003 mm (Position) | Titanium Ti-6Al-4V, Inconel 718 |

| Surface Roughness (Ra) | 0.4 µm to 0.8 µm | Tool Steel H13, Beryllium Copper |

| Hole Concentricity | ±0.005 mm | Magnesium AZ31, Tungsten Carbide |

| Angular Features | ±0.001° | Graphite, PEEK, CFRP Composites |

Our facility integrates these capabilities within a closed-loop manufacturing ecosystem. CAD/CAM data flows directly from client models to machine control, while inspection results feed back into process refinement. For R&D teams, this means reduced iteration time, higher confidence in test data, and a seamless transition from concept to qualified production. We understand that in innovation-driven development, precision isn’t just a specification—it’s the foundation of discovery. Partner with Wuxi Lead to transform your most demanding R&D concepts into physically validated realities.

Material & Finish Options

Material selection is a foundational element in precision R&D machining, directly influencing performance, durability, and manufacturability of custom metal components. At Wuxi Lead Precision Machinery, we guide engineering teams through informed decisions based on mechanical requirements, environmental exposure, and functional objectives. Among the most widely used materials in advanced prototyping and low-volume production are aluminum, steel, and titanium—each offering distinct advantages depending on application demands.

Aluminum is favored in R&D applications requiring a high strength-to-weight ratio, excellent thermal conductivity, and good machinability. Grades such as 6061-T6 and 7075-T6 are commonly specified in aerospace, robotics, and electronics enclosures. Its lightweight nature reduces inertia in moving parts, while its natural corrosion resistance makes it suitable for uncoated use in controlled environments. When enhanced surface properties are required, aluminum is highly compatible with anodizing—a process that electrochemically forms a durable, insulative oxide layer. Type II (sulfuric acid) and Type III (hardcoat) anodizing improve wear resistance and allow for color dyeing, making it ideal for both functional and aesthetic finishes.

Steel, particularly in alloy forms like 4140 and 1018, provides superior strength, hardness, and wear resistance. It is the material of choice for load-bearing components, tooling, and fixtures subjected to high stress or repetitive use. While heavier than aluminum, steel’s dimensional stability and predictable response to heat treatment make it indispensable in precision mechanical systems. For corrosive environments, stainless steels such as 304 and 316 offer enhanced oxidation and chemical resistance, though they present greater challenges in machining due to work hardening.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, low density, and corrosion resistance, especially in extreme conditions. It is widely used in aerospace, medical implants, and high-performance automotive applications. Despite its high cost and demanding machining parameters—requiring rigid setups and controlled feeds and speeds—titanium’s performance in high-temperature and salt-exposed environments justifies its use in mission-critical components.

Surface finishing plays a pivotal role in functional performance. Anodizing, primarily applied to aluminum, not only enhances surface hardness but also provides electrical insulation and improved adhesion for paints or coatings. The thickness and sealing method of the anodized layer can be tailored to meet specific MIL-SPEC or ASTM standards, ensuring reliability in field applications.

The following table summarizes key mechanical and finishing properties of commonly machined materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Compatible Finishes |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Enclosures, brackets | Anodizing (Type II/III), powder coat |

| Steel 4140 | 655 | 7.85 | Shafts, tooling | Zinc plating, passivation, painting |

| Stainless 316 | 580 | 8.0 | Marine, medical | Electropolishing, passivation |

| Titanium Ti-6Al-4V | 900 | 4.43 | Aerospace, implants | Anodizing, laser marking, polishing |

Selecting the right material and finish requires a systems-level approach. At Wuxi Lead, our engineering team collaborates closely with clients to match material properties with functional requirements, ensuring optimal performance in the final application.

Manufacturing Process & QC

Precision-Driven Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our R&D machining process is engineered for uncompromising quality and efficiency, transforming complex designs into flawless metal components. We integrate advanced engineering with rigorous quality control across three critical phases, ensuring zero defects from initial concept to full-scale production. This systematic approach minimizes risk, accelerates time-to-market, and guarantees parts meet the most demanding aerospace, medical, and industrial specifications.

The foundation lies in our collaborative Design for Manufacturability (DFM) phase. Our engineering team partners directly with your R&D department to analyze CAD models, identifying potential manufacturability challenges before metal is cut. We leverage simulation software to predict material behavior, optimize toolpaths, and validate geometric tolerances, ensuring the design is not only innovative but inherently producible to micron-level accuracy. This proactive review eliminates costly revisions later, embedding quality into the blueprint and establishing the parameters for defect prevention.

Prototyping is not merely a validation step but a critical refinement stage within our zero-defect strategy. Using the same high-precision 5-axis CNC machining centers and coordinate measuring machines (CMMs) deployed in mass production, we manufacture functional prototypes under identical process conditions. Every dimension, surface finish, and material property undergoes exhaustive metrology against the validated DFM plan. Statistical process control (SPC) data from this phase fine-tunes machine parameters and inspection protocols, confirming the process capability index (Cpk) exceeds 1.67 before committing to volume production. This ensures the prototype is a true predictor of final part quality.

Mass production executes the perfected process with unwavering consistency. Our integrated manufacturing execution system (MES) monitors every machine in real-time, tracking tool wear, thermal compensation, and in-process measurements. Automated CMM checks at defined intervals, coupled with 100% critical feature verification using optical comparators or laser scanners, provide continuous feedback. Any deviation triggers immediate corrective action, preventing non-conforming parts from progressing. This closed-loop system, combined with our certified ISO 9001:2015 and AS9100D quality management framework, guarantees statistically validated zero defects across the entire production run, delivering parts that perform exactly as designed.

Wuxi Lead Precision R&D Machining Capabilities

| Specification Category | Capability Range | Validation Standard |

|---|---|---|

| Geometric Tolerance | ±0.001 mm (micron-level) | ISO 2768-mK, ASME Y14.5 |

| Surface Finish | Ra 0.1 µm to Ra 3.2 µm | ISO 1302, ASME B46.1 |

| Materials Expertise | Titanium (Gr 2,5), Inconel 718, 17-4PH SS, Aluminum 7075, Tool Steels | ASTM, AMS, EN Standards |

| Max Part Dimensions | 1200 x 800 x 650 mm | CMM Full Volumetric Compensation |

| Process Capability (Cpk) | ≥ 1.67 (Typical) | SPC Real-Time Monitoring |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched R&D Machining Excellence

In the rapidly evolving landscape of advanced manufacturing, the success of research and development initiatives hinges on precision, speed, and technical partnership. At Wuxi Lead Precision Machinery, we specialize in delivering high-accuracy custom metal components tailored to the exacting demands of R&D projects across aerospace, medical devices, automation, and emerging technology sectors. Our mission is to serve as an extension of your engineering team, transforming conceptual designs into fully functional prototypes and low-volume production runs with unmatched consistency.

Our facility in Wuxi, China, integrates state-of-the-art CNC machining centers, multi-axis milling, precision turning, and advanced inspection systems to ensure every component meets micron-level tolerances. We understand that R&D timelines are aggressive and iterations frequent—our agile manufacturing model supports rapid turnaround without compromising quality. Whether you’re developing a new surgical instrument, an aerospace subsystem, or a next-generation industrial sensor, our engineers collaborate closely with your team from design review through final delivery.

We are equipped to work with challenging materials including titanium alloys, Inconel, aluminum 7075, stainless steel 316L, and specialty composites—common in high-performance applications. Our quality management system is ISO 9001:2015 certified, and every process is documented to ensure traceability, repeatability, and compliance with industry-specific standards.

The following table outlines our core machining capabilities for R&D-focused projects:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 800 mm × 500 mm × 400 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish | As low as Ra 0.4 μm (polished to Ra 0.1 μm) |

| Tolerance Range | ±0.01 mm standard, down to ±0.003 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, PEEK, Delrin |

| Machining Types | 3-axis, 4-axis, 5-axis milling, precision turning, micro-machining |

| Secondary Operations | Deburring, passivation, anodizing coordination, laser marking |

| Lead Time (Prototype) | As fast as 5–7 business days |

| Quality Documentation | FAI reports, GD&T inspection reports, material certs |

Partnering with Wuxi Lead Precision Machinery means gaining access to a team that values innovation, confidentiality, and engineering integrity. We treat every R&D project as a strategic collaboration, providing technical feedback, DFM analysis, and material recommendations to optimize performance and manufacturability.

When precision, speed, and reliability are non-negotiable, trust your R&D machining to a partner built for excellence. Contact us today at [email protected] to begin your next breakthrough project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.