Technical Contents

Engineering Guide: Rapids Sheet Metal

Engineering Insight: Precision as the Non-Negotiable Core of Rapid Sheet Metal Fabrication

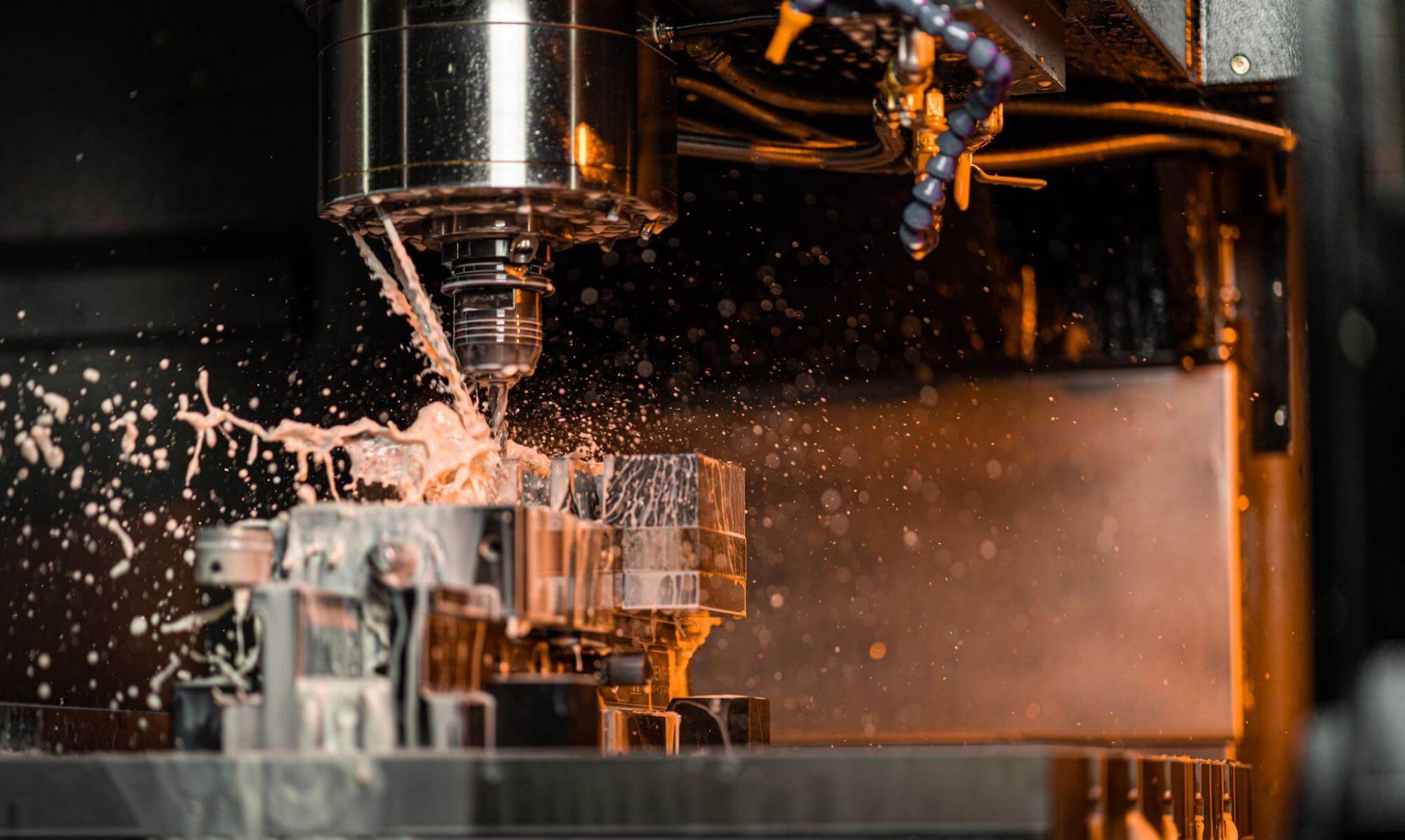

In high-velocity sheet metal fabrication, speed alone is a hollow promise. True operational advantage emerges only when rapid throughput is fundamentally anchored in uncompromising precision. The cost of dimensional deviation transcends mere rework; it cascades into assembly line stoppages, compromised product performance, and significant financial liability. Consider an aerospace hydraulic manifold assembly: a 0.03mm flatness error across a critical mounting surface can induce seal failure at 3000psi, triggering catastrophic system loss. In medical device chassis production, inconsistent bend angles exceeding ±0.25° disrupt sensitive internal component alignment, rendering the entire unit non-functional. Speed without precision generates costly scrap, not value. This is why Wuxi Lead Precision Machinery engineers rapid production pathways where micron-level accuracy is the absolute baseline, not an aspiration.

Our commitment to precision is forged in the most demanding crucibles. We supplied critical titanium and aluminum structural components for the Beijing 2022 Winter Olympics snowmaking infrastructure, where thermal cycling from -40°C to +30°C demanded geometric stability within 0.02mm across 1.5-meter spans to prevent catastrophic ice buildup in high-pressure nozzles. Similarly, our fabrication of radar housing assemblies for advanced naval platforms required flatness tolerances of 0.015mm per meter and positional accuracy of ±0.05mm for RF shielding integrity – specifications mandated by military-grade EMI/RFI standards. These projects were not merely completed; they achieved zero-defect delivery under intense schedule pressure, proving that extreme precision and rapid turnaround are not opposing forces but synergistic imperatives when process control is absolute.

Achieving this requires integrating advanced metrology directly into the fabrication workflow, not as a final checkpoint. Our facility employs in-process laser scanning during laser cutting and real-time CNC press brake angle feedback systems, continuously correcting for material springback and thermal drift. Statistical Process Control (SPC) data from every operation feeds directly into adaptive machining parameters, ensuring consistency batch after batch. The result is rapid production that consistently meets the tightest tolerances demanded by cutting-edge industries. Below are key precision metrics consistently achieved across our rapid sheet metal production lines:

| Specification Parameter | Typical Capability | Critical Application Threshold |

|---|---|---|

| Laser Cutting Positional Accuracy | ±0.02mm per meter | Aerospace structural brackets |

| Press Brake Bend Angle Tolerance | ±0.25° | Medical device enclosures |

| Hole Positional Tolerance (Pierced) | ±0.05mm | Electronics chassis assembly |

| Flatness (per 1000mm) | 0.05mm | Optical instrument mounts |

| Material Thickness Range (Stainless) | 0.5mm – 6.0mm | Defense hydraulic components |

When your project demands fabrication velocity where every micron determines functional success or failure, precision engineering cannot be an afterthought. It must be the engineered foundation of your rapid production strategy. Wuxi Lead Precision Machinery delivers this integration daily, transforming the promise of speed into reliably precise, mission-critical sheet metal components. Your next high-stakes project demands this level of assured accuracy – let our validation protocols become your operational certainty.

Precision Specs & Tolerances

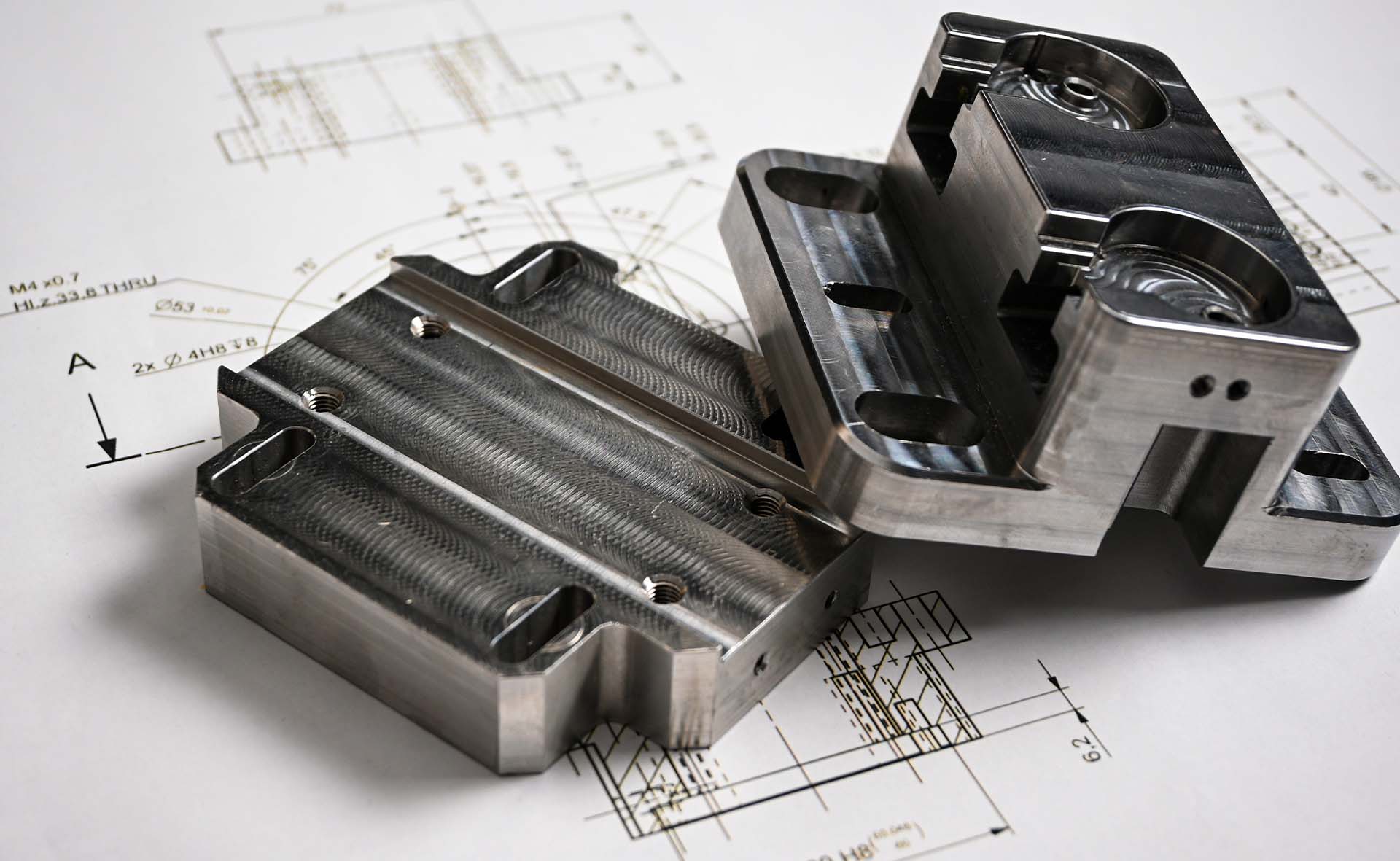

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for high-precision industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, which enable complex geometries, tight tolerances, and superior surface finishes across a wide range of metal alloys. These multi-axis platforms provide simultaneous movement across five planes, allowing for intricate contours and detailed features that traditional 3-axis machines cannot achieve. This level of precision is essential for industries such as aerospace, medical devices, and high-end automation, where component integrity and dimensional accuracy are non-negotiable.

Our sheet metal processing integrates laser cutting, precision bending, and high-speed milling, all controlled through advanced CAD/CAM software. This digital workflow ensures seamless translation from design to production, minimizing human error and maximizing repeatability. Materials including stainless steel, aluminum, titanium, and specialty alloys are routinely processed with consistent quality and structural integrity. The flexibility of our 5-axis CNC systems allows for rapid reconfiguration between jobs, supporting both low-volume prototyping and high-volume production runs with equal efficiency.

Quality control is embedded at every stage of manufacturing. Each component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), which provides micron-level verification of critical dimensions and geometric features. The CMM system operates with a calibrated accuracy of ±0.0001 inches, ensuring compliance with ISO 10360 standards. Data from inspections are documented and traceable, providing full quality assurance documentation for every batch produced. This metrology-backed validation process guarantees that all parts meet or exceed customer specifications and industry standards.

In addition to equipment precision, our team of certified CNC engineers and manufacturing technicians apply decades of collective experience to optimize toolpaths, reduce cycle times, and enhance material utilization. This technical expertise, combined with real-time process monitoring, ensures minimal waste and maximum throughput without compromising quality.

The following table outlines key technical specifications and achievable tolerances for our sheet metal fabrication processes:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Maximum Work Envelope (5-Axis CNC) | 1,200 mm × 800 mm × 600 mm |

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm |

| Angular Tolerance | ±0.1° |

| Feature-to-Feature Tolerance | ±0.01 mm |

| CMM Measurement Accuracy | ±0.0001 in (2.5 µm) |

Wuxi Lead Precision Machinery maintains ISO 9001 certification and adheres to strict environmental and safety standards in all operations. Our technical capabilities are designed to support global clients requiring precision, reliability, and scalability in sheet metal fabrication.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, longevity, and cost efficiency in high-end sheet metal applications. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with functional demands, environmental exposure, and manufacturing constraints. This guide details critical considerations for aluminum, steel, and titanium, alongside anodizing finishes for enhanced durability.

Aluminum excels in applications requiring lightweight strength, thermal conductivity, and corrosion resistance. Alloys like 5052-H32 offer superior formability for complex bends, while 6061-T6 provides higher structural integrity for load-bearing components. Its natural oxide layer resists atmospheric corrosion, but anodizing significantly enhances surface hardness and wear resistance. Aluminum is ideal for aerospace enclosures, heat sinks, and medical devices where weight reduction is critical.

Carbon steel remains indispensable for structural rigidity and impact resistance. Cold-rolled steel (CRS) delivers tight tolerances for precision brackets and chassis, whereas stainless steel grades like 304 and 316 offer exceptional corrosion resistance in harsh environments. 316 stainless, with molybdenum content, withstands saltwater exposure, making it suitable for marine and chemical processing equipment. Note that stainless steel requires specialized tooling to prevent work hardening during CNC punching or bending.

Titanium is reserved for extreme conditions demanding unparalleled strength-to-weight ratios and biocompatibility. Grade 2 titanium balances weldability and corrosion resistance for aerospace and medical implants, while Grade 5 (Ti-6Al-4V) delivers superior tensile strength for high-stress components. Its low thermal conductivity necessitates optimized CNC parameters to avoid heat buildup during machining. Titanium’s inertness ensures longevity in corrosive or sterile settings but commands higher material and processing costs.

Anodizing transforms aluminum surfaces through electrolytic passivation, creating a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dye compatibility for identification. Type III (hardcoat) anodizing achieves thicknesses of 25–50 µm, offering exceptional abrasion resistance for hydraulic components or military hardware. Both types improve adhesion for subsequent painting or bonding. Crucially, anodizing must be specified early in design to accommodate dimensional changes and masking requirements.

Material properties directly influence manufacturability and end-part performance. Below is a comparative overview of key specifications:

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 2.7 | 190–310 | Moderate to High | Excellent (A9) |

| Carbon Steel | CRS 1008, 304 SS | 7.8–8.0 | 370–620 | Low (CRS) to High (SS) | Good (CRS) to Fair (SS) |

| Titanium | Gr 2, Gr 5 | 4.5 | 345–900 | Exceptional | Poor to Moderate |

Material choice impacts CNC toolpath strategies, laser cutting parameters, and finishing workflows. Wuxi Lead Precision Machinery leverages advanced CNC systems and metallurgical expertise to optimize yield and precision across these materials. Partner with us to translate material science into mission-critical components that exceed operational demands.

Manufacturing Process & QC

Sheet Metal Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, consistency, and zero defects. We integrate advanced technology with rigorous quality control to deliver high-performance components for demanding industrial applications. Our end-to-end workflow is structured into three core phases: Design, Prototyping, and Mass Production—each designed to eliminate variability and ensure flawless output.

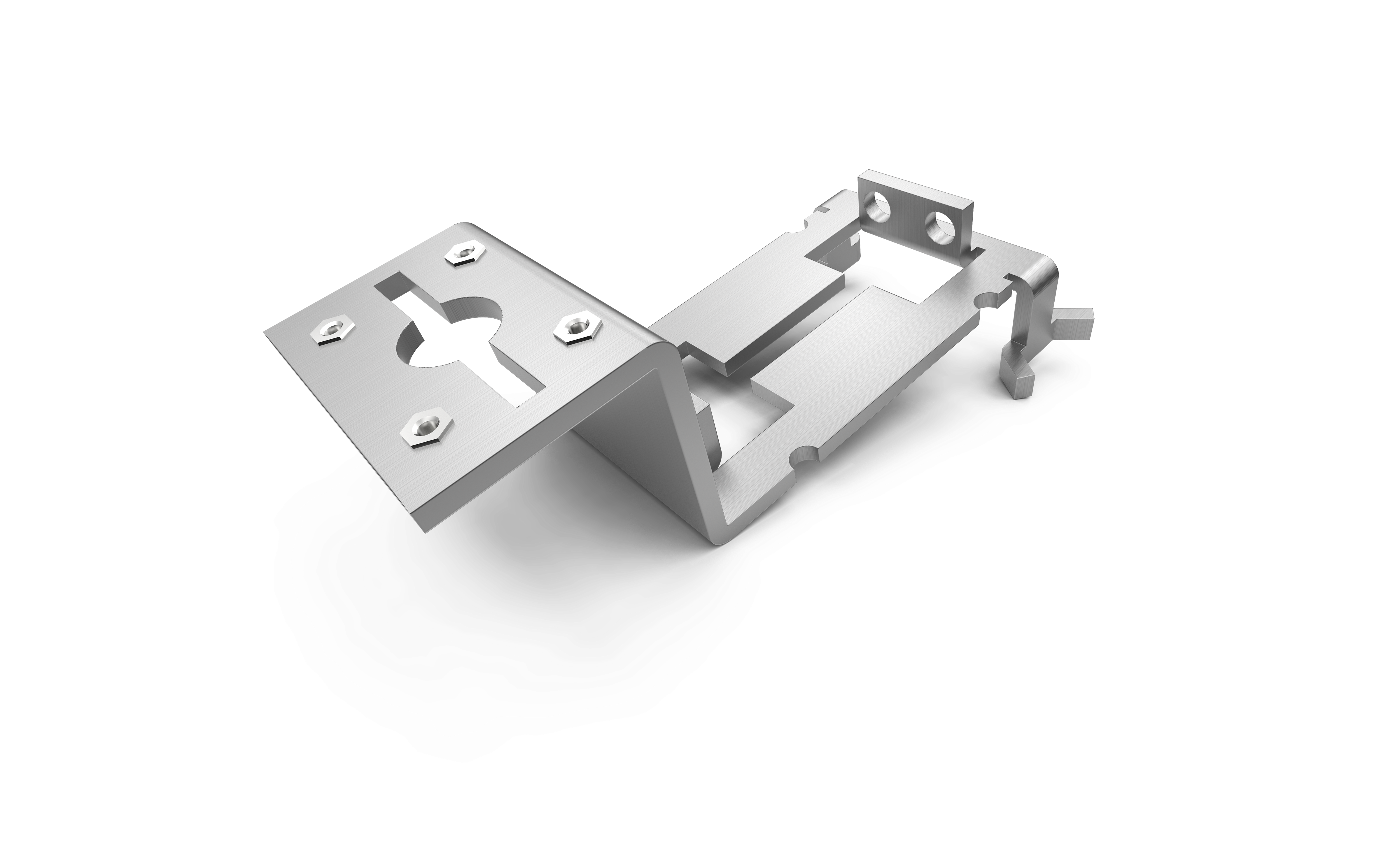

The process begins with Design, where our engineering team collaborates closely with clients to translate concepts into manufacturable designs. Using advanced CAD/CAM software, we optimize part geometry, material selection, and manufacturability. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to identify potential stress points, weld integrity, and tooling requirements. This stage ensures that every component is not only functional but also optimized for high-precision fabrication.

Next, we move to Prototyping, a critical phase for validation. Utilizing our state-of-the-art laser cutting, CNC punching, and bending equipment, we produce functional prototypes that mirror final production conditions. These prototypes undergo comprehensive dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify tolerances and fit. Surface finish, material integrity, and assembly compatibility are rigorously tested. Client feedback is incorporated at this stage, allowing for rapid iteration without impacting the production timeline.

Once approved, the project transitions into Mass Production, where scalability meets precision. Our automated production lines, including robotic bending cells and automated material handling systems, ensure consistent part quality across large volumes. Every stage of production is monitored through real-time SPC (Statistical Process Control) systems, enabling immediate detection and correction of deviations. In-process inspections and final QA audits are performed at defined intervals, with full traceability maintained for every component.

Our commitment to zero defects is enforced through ISO 9001-certified processes, operator certification programs, and a closed-loop corrective action system. Any non-conformance triggers immediate root cause analysis and process adjustment, preventing recurrence.

The table below outlines key capabilities and specifications of our sheet metal fabrication process:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance (Bending) | ±0.1 mm |

| Tolerance (Laser Cutting) | ±0.05 mm |

| Maximum Part Size | 4000 mm × 2000 mm |

| Materials Supported | Mild Steel, Stainless Steel, Aluminum, Galvanized Steel |

| Surface Finishes | Powder Coating, Anodizing, Passivation, Painting |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, ISO 13485 (Medical Devices) |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures that every sheet metal component meets the highest standards of quality, reliability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Engineered Path to Sheet Metal Excellence

In the high-stakes landscape of precision sheet metal fabrication, tolerances define success. Sub-millimeter deviations cascade into assembly failures, delayed launches, and unsustainable waste. Wuxi Lead Precision Machinery exists to eliminate these risks. We engineer repeatability where others compromise, transforming complex sheet metal requirements into zero-defect deliverables. Our 15-year mastery in aerospace, medical, and industrial systems manufacturing ensures your components meet the uncompromising standards demanded by Tier-1 supply chains. This is not simply production—it is precision accountability.

Our integrated facility in Wuxi, China, operates beyond standard job-shop capabilities. We deploy German-engineered Bystronic and TRUMPF laser systems with real-time thermal distortion compensation, achieving ±0.02mm tolerances on materials from 0.5mm to 25mm thickness. Every press brake station features CNC-controlled crowning systems and laser-probed tooling verification, guaranteeing angular consistency across 10,000+ part runs. Crucially, our AS9100-compliant quality management system integrates SPC at every workflow node—from raw material certification to final CMM validation—ensuring traceability that satisfies Boeing, Siemens, and Medtronic audit protocols.

The following specifications demonstrate our technical authority in rapid, high-integrity sheet metal fabrication:

| Capability | Specification | Industry Benchmark |

|---|---|---|

| Laser Cutting Thickness | 0.5mm – 25mm (Stainless, Aluminum, Steel) | Typically ≤20mm |

| Positional Accuracy | ±0.02mm over 3m bed | ±0.05mm – ±0.1mm |

| Press Brake Tonnage Range | 35T – 1000T with CNC crowning | ≤600T standard |

| Angular Repeatability | ±0.25° (verified per ISO 2768) | ±1° – ±2° |

| Max. Formed Part Size | 4000mm x 2000mm | 3000mm x 1500mm |

| Lead Time (Prototype) | 72 hours (validated CAD to shipment) | 5–7 business days |

This technical foundation enables what matters most: your competitive advantage. We reduce your total cost of ownership through yield optimization—our nested laser programming achieves 98.7% material utilization versus the industry average of 92%. Our digital twin simulation prevents costly design-for-manufacturing errors before metal is cut, accelerating time-to-market by 30%. When your engineering team requires rapid iteration on complex enclosures or structural brackets, we deliver validated prototypes within 72 hours, not weeks.

The true measure of a manufacturing partner lies in crisis resolution. When a European medical device client faced a production line shutdown due to bracket warpage, our team diagnosed a thermal stress flaw in their design, re-engineered the bend sequence in 18 hours, and shipped AS9100-certified replacements in 96 hours—preventing $2.3M in downtime. This is the resilience your supply chain requires.

Do not accept incremental improvements when transformation is available. Contact our engineering team directly at [email protected] to initiate a precision audit of your current sheet metal supply chain. Specify your most critical part number or application challenge in your email. Within 4 business hours, you will receive a detailed capability assessment including: material waste analysis, tolerance validation roadmap, and a no-obligation prototype delivery schedule. Lead Precision Machinery operates where precision is non-negotiable. Your next breakthrough component begins here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.