Technical Contents

Engineering Guide: Rapid Services

Engineering Insight: The Critical Role of Precision in Rapid Manufacturing Services

In high-stakes custom metal manufacturing, the demand for rapid services often creates a dangerous misconception: that speed necessitates compromise on precision. This is a fundamental error with severe consequences. True rapid manufacturing for critical applications demands uncompromising accuracy from the initial design phase through final inspection. Sacrificing dimensional integrity or geometric tolerances to meet accelerated timelines inevitably leads to component failure, assembly delays, and significant cost overruns downstream – negating any perceived time savings. At Wuxi Lead Precision Machinery, we engineer speed through precision, not at its expense. Our rapid service protocols are built upon decades of mastering sub-micron repeatability under the most demanding conditions, proven in projects where failure was not an option.

Our experience delivering mission-critical components for Olympic timing systems and advanced military aerospace actuators underscores this principle. These applications require not only extreme accuracy (±0.001mm tolerances) but also flawless performance under dynamic stress and environmental extremes. Rushing such projects without rigorous process control and advanced metrology would be catastrophic. We apply this same disciplined approach to all rapid service engagements. Our integrated workflow leverages high-speed multi-axis CNC machining centers with in-process probing, coupled with real-time thermal compensation systems and stringent first-article inspection protocols. This ensures every part meets exacting specifications on the first run, eliminating rework loops that destroy timelines. Speed is achieved by perfecting the process, not by cutting corners.

Precision is the non-negotiable foundation of reliable rapid manufacturing. It enables seamless integration into final assemblies, guarantees functional performance, and provides the data integrity necessary for true process acceleration. When dimensional stability and geometric complexity are maintained at the highest levels, rapid delivery becomes a strategic advantage, not a risk. Wuxi Lead’s rapid services deliver this critical balance, transforming urgent requirements into on-time, right-first-time outcomes for industries where precision is paramount.

Wuxi Lead Rapid Service Precision Specifications

| Parameter | Capability | Verification Method | Typical Lead Time (Complex Part) |

|---|---|---|---|

| Positional Tolerance | ±0.001 mm | CMM (Zeiss CONTURA) | 72 hours |

| Surface Finish (Ra) | 0.2 µm – 1.6 µm | Profilometer (Mitutoyo SJ-410) | 72 hours |

| Geometric Tolerance (GD&T) | ISO 2768-mK / Custom GD&T | CMM + Optical Comparator | 72 hours |

| Material Verification | Full Mill Cert + In-House PMI | Spectrometer (Spectro MAXx) | Included in lead time |

| Process Control | SPC, In-Process Probing, Thermal Compensation | Real-time Data Logging | Integrated into workflow |

Precision Specs & Tolerances

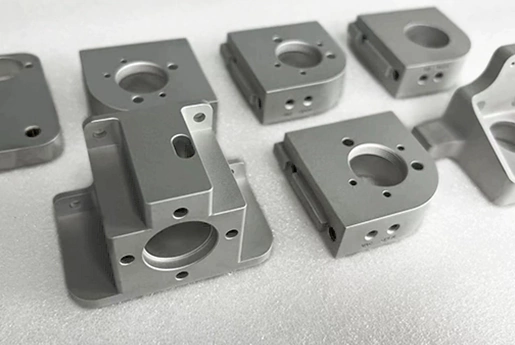

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions through precision engineering and state-of-the-art production technologies. At the core of our technical capabilities is our 5-axis CNC machining platform, enabling the production of highly complex geometries with exceptional accuracy and surface finish. Our multi-axis systems allow simultaneous movement across five planes, reducing setup times and part handling while maintaining tight tolerances across intricate features. This capability is especially critical for clients in aerospace, medical, and high-performance industrial sectors where component integrity and repeatability are non-negotiable.

Our machining centers are operated by experienced engineers who utilize advanced CAM software to optimize toolpaths, minimize cycle times, and ensure material efficiency. We work with a broad range of metals, including aluminum alloys, stainless steel, titanium, Inconel, and brass, supporting both prototyping and high-volume production runs. The integration of 5-axis technology allows us to machine complex contours, deep cavities, and asymmetrical forms in a single setup, significantly improving dimensional consistency and reducing the risk of human error.

Quality control is embedded into every stage of the manufacturing process. All critical components undergo comprehensive inspection using our Coordinate Measuring Machine (CMM), which provides metrology-grade verification of geometric dimensions and tolerances. The CMM system ensures compliance with ISO 10360 standards and supports full first-article inspection reporting (FAIR) and production batch traceability. Our quality technicians are trained to interpret GD&T specifications and deliver certified inspection documentation with every order.

In addition to CMM inspection, we employ visual surface analysis, hardness testing, and dimensional spot checks to maintain consistent output across production batches. Our quality management system is ISO 9001 certified, reflecting our commitment to continuous improvement and customer-specific requirements.

The table below outlines the standard tolerance capabilities we achieve under normal production conditions using 5-axis CNC machining and CMM-verified inspection protocols.

| Feature Type | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Diameter | ±0.02 mm | ±0.008 mm | Shafts, bores |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.02 mm | 0.005 mm | Per 100 mm |

| Surface Finish (Ra) | 3.2 µm | 0.4 µm | As machined or polished |

| Angular Features | ±0.1° | ±0.05° | Critical mating surfaces |

These specifications are consistently maintained across diverse materials and part complexities, underpinned by rigorous machine calibration and environmental control within our facility. Wuxi Lead Precision Machinery is equipped to meet the most demanding technical requirements, delivering components that conform precisely to engineering intent.

Material & Finish Options

Material Selection for Precision Rapid Manufacturing

Material choice fundamentally impacts performance, cost, and lead time in rapid custom metal manufacturing. At Wuxi Lead Precision Machinery, our advanced CNC capabilities process aluminum, steel, and titanium with equal precision, but optimal selection depends on your application’s specific mechanical, environmental, and functional demands. Understanding core properties ensures your rapid prototype or production run meets exacting standards without compromise.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and excellent machinability. These alloys enable rapid production of complex, lightweight components while offering good corrosion resistance. Aluminum’s high thermal and electrical conductivity is critical for heat sinks and electrical housings. When surface hardness and wear resistance are required, anodizing transforms the aluminum surface into a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing provides standard corrosion protection and dye receptivity for identification, while hardcoat Type III anodizing delivers significantly enhanced abrasion resistance for demanding mechanical interfaces. Note that anodizing is exclusive to aluminum and its alloys; it is not applicable to steel or titanium.

Steel, especially 304/316 stainless and 4140 alloy steel, is selected for applications demanding high strength, structural integrity, and superior wear resistance. Stainless grades offer essential corrosion resistance in medical, food processing, and marine environments. Carbon and alloy steels provide the toughness needed for heavy-duty tooling, shafts, and structural components. While steel does not anodize, rapid manufacturing benefits from its excellent machinability in pre-hardened states. Alternative finishing options like passivation (for stainless), plating, or powder coating address specific corrosion or aesthetic needs.

Titanium (primarily Grade 5 Ti-6Al-4V) is the material of choice for extreme environments requiring unparalleled strength-to-weight ratio, exceptional corrosion resistance (especially against chlorides and acids), and biocompatibility. Its use is critical in aerospace, medical implants, and high-performance marine components. Titanium’s low thermal conductivity and high chemical reactivity necessitate specialized CNC parameters and tooling to prevent work hardening and ensure precision – a capability central to Wuxi Lead’s rapid titanium manufacturing process. Surface treatments like acid etching or specialized coatings enhance biocompatibility or wear properties, but anodizing is not standard for titanium in industrial applications.

Material properties directly influence manufacturability and speed. The table below provides key comparative data for rapid service decision-making:

| Property | Aluminum 6061-T6 | Steel 304 Stainless | Titanium Ti-6Al-4V |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 505 | 900 |

| Yield Strength (MPa) | 276 | 215 | 830 |

| Density (g/cm³) | 2.7 | 8.0 | 4.4 |

| Corrosion Resistance | Good | Excellent | Exceptional |

| Machinability Rating | Excellent (A) | Fair (C) | Poor (E) |

| Typical Rapid Use | Enclosures, Drones | Valves, Medical Tools | Implants, Jet Parts |

Select aluminum for lightweight, conductive parts where anodizing enhances surface properties. Choose steel for maximum strength, hardness, and structural applications requiring alternative finishes. Opt for titanium only when its unique strength, weight, and corrosion advantages are non-negotiable, acknowledging its demanding machining requirements. Wuxi Lead Precision Machinery leverages deep material science expertise and state-of-the-art CNC technology to execute your rapid manufacturing project flawlessly, regardless of the metal selected. Consult our engineering team early to align material properties with your functional requirements and accelerate time-to-market.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process is engineered for precision, consistency, and zero-defect outcomes across every stage of custom metal manufacturing. We integrate advanced CNC technology with rigorous quality assurance to deliver high-performance components tailored to exact client specifications. Our end-to-end workflow spans from initial design through prototyping to full-scale mass production, ensuring seamless scalability and uncompromised quality.

The process begins with collaborative design engineering. Our team works closely with clients to analyze technical drawings, material requirements, tolerances, and functional applications. Using CAD/CAM software and finite element analysis, we optimize part geometry for manufacturability, strength, and cost-efficiency. This phase includes material selection from a broad spectrum of metals, including aluminum alloys, stainless steel, titanium, and specialty alloys, based on performance demands such as corrosion resistance, thermal stability, or structural load.

Once the design is finalized, we proceed to prototyping. This critical stage allows for physical validation of form, fit, and function. Utilizing 5-axis CNC machining and precision turning, we produce low-volume prototypes with the same process parameters as mass production, ensuring accurate representation of final part quality. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage is incorporated into any necessary design refinements before approval for series production.

Mass production is executed on our automated CNC machining lines, where process stability and repeatability are paramount. Our manufacturing cells are equipped with real-time monitoring systems that track tool wear, spindle load, and dimensional accuracy. Every component is subject to in-process inspections and final quality audits aligned with ISO 9001 standards. Statistical process control (SPC) methodologies are applied to detect and correct deviations before they impact output, ensuring a zero-defect manufacturing environment.

Our commitment to quality extends beyond production. All finished parts are packaged to prevent damage during transit and delivered with full traceability documentation, including material certifications and inspection reports.

Below are key specifications of our production capabilities.

| Parameter | Specification |

|---|---|

| Machining Tolerances | ±0.005 mm |

| Surface Roughness | Ra 0.2 – 3.2 µm (adjustable) |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials | Aluminum, Stainless Steel, Titanium, Brass, Inconel, Carbon Steel |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, 100% Dimensional Inspection, SPC Monitoring |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (volume-dependent) |

Wuxi Lead Precision Machinery ensures that every component meets the highest standards of precision and reliability, making us a trusted partner in high-end industrial manufacturing.

Why Choose Wuxi Lead Precision

Your Precision Manufacturing Imperative

In the high-stakes arena of custom metal manufacturing, delays cascade into lost revenue and compromised competitiveness. Wuxi Lead Precision Machinery exists to eliminate this risk. We are not merely a service provider; we are your embedded engineering partner for rapid, mission-critical production. Our ISO 9001:2015-certified facility in Wuxi integrates decades of aerospace and medical-grade CNC expertise with agile workflows designed for urgent timelines. When your project demands uncompromising accuracy under compressed schedules, our infrastructure guarantees delivery without concession to quality.

Our rapid-service capability is engineered into every process. Below are the technical benchmarks that define our responsiveness:

| Capability | Specification | Impact for Your Project |

|---|---|---|

| Lead Time | 5–10 days for complex prototypes | Accelerate R&D cycles by 40%+ |

| Tolerance Control | ±0.001mm (sub-micron achievable) | Eliminate assembly rework |

| Material Range | Titanium, Inconel, 7075 Aluminum | Solve extreme environment challenges |

| Max Work Envelope | 1,200 x 800 x 650mm | Consolidate multi-part assemblies |

| Surface Finish | Ra 0.2µm (mirror-grade) | Meet stringent medical/aerospace specs |

This precision is sustained through our dual-path workflow: dedicated rapid-response cells operate parallel to standard production, ensuring urgent orders never wait in queue. Our engineers collaborate from RFQ stage—proactively identifying manufacturability risks in your CAD files to prevent delays before machining begins. Unlike transactional vendors, we deploy metrology-certified technicians who validate each critical dimension against your original intent, not just nominal tolerances. This prevents costly downstream failures in assembly or performance.

The true differentiator lies in our accountability. We assign a single-point engineering lead for your project, providing real-time access to machine telemetry and inspection data via secure portal. No more chasing updates; you monitor progress with the same rigor we apply internally. This transparency builds trust where it matters most: when a $500k production line hinges on one bracket arriving tomorrow.

Your next breakthrough component cannot afford generic solutions. It demands a partner who treats your urgency as their operational mandate. We have reduced lead times for Fortune 500 clients by 35% while maintaining 99.8% first-pass yield—proving speed and perfection are not trade-offs but engineered outcomes.

Initiate your rapid manufacturing solution today. Email [email protected] with your project specifications and timeline. Our engineering team will respond within 4 business hours with a validated feasibility assessment and actionable path to production. Do not let supply chain inertia dictate your innovation velocity. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.