Technical Contents

Engineering Guide: Rapid Prototyping Cnc Machining

Engineering Insight: The Critical Role of Precision in Rapid Prototyping CNC Machining

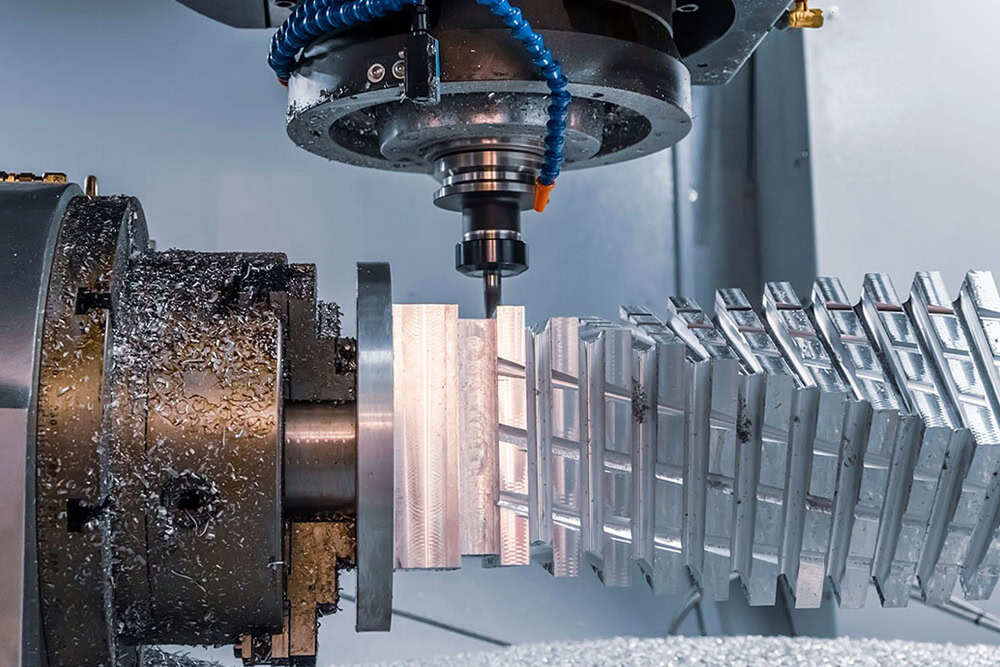

In the realm of advanced manufacturing, rapid prototyping through CNC machining stands as a cornerstone for innovation, enabling engineers and product developers to transition from concept to functional prototype with unprecedented speed and accuracy. At Wuxi Lead Precision Machinery, we understand that speed without precision is not progress—it is waste. True rapid prototyping demands not only fast turnaround but also uncompromising dimensional accuracy, surface integrity, and material consistency. This balance defines the standard of excellence we uphold in every project.

Precision in CNC rapid prototyping ensures that design intent is faithfully reproduced, allowing for reliable testing, validation, and iteration. Components used in aerospace, medical devices, and high-performance industrial systems must meet exacting tolerances—often within ±0.005 mm—to function safely and effectively. At Lead Precision, our CNC machining processes are engineered to achieve such tolerances consistently, supported by state-of-the-art 3-, 4-, and 5-axis machining centers, in-house quality inspection labs, and a team of seasoned engineers with over 15 years of specialized experience in high-precision manufacturing.

Our commitment to precision is not theoretical—it has been tested in the most demanding environments. We have contributed to projects aligned with Olympic-standard equipment manufacturing, where performance margins are measured in microns, and components must endure extreme conditions without failure. Similarly, our work in defense and military-support applications has required adherence to strict compliance standards, including ISO 9001 and AS9100, ensuring full traceability, material certification, and repeatable quality under rigorous scrutiny.

This depth of experience directly benefits our clients in the rapid prototyping phase. When prototypes are machined to exact specifications, downstream processes—from fit checks to performance trials—proceed without costly delays or redesign loops. Moreover, our ability to seamlessly scale from one-off prototypes to low-volume production ensures that design integrity is maintained across all stages of product development.

Below are the key technical specifications that define our rapid prototyping CNC machining capabilities:

| Specification | Detail |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Standard Tolerances | ±0.005 mm (custom up to ±0.001 mm) |

| Surface Roughness | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 316), Titanium (Grade 5), Brass, PEEK, Delrin |

| Lead Time (Prototype) | 3–7 days (based on complexity) |

At Wuxi Lead Precision Machinery, precision is not just a metric—it is a mindset. By integrating advanced technology with proven engineering rigor, we deliver rapid prototyping solutions that accelerate innovation without sacrificing quality. For industries where performance is non-negotiable, our CNC machining services provide the foundation for success.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Rapid Prototyping Excellence

At Wuxi Lead Precision Machinery, our rapid prototyping CNC machining services merge agility with uncompromising precision, specifically engineered to accelerate your product development cycle without sacrificing quality. Central to this capability is our advanced fleet of 5-axis CNC machining centers, featuring知名品牌 like DMG MORI and MAZAK. These systems enable complex geometries in a single setup, eliminating cumulative errors from multiple fixtures and reducing lead times by up to 40% compared to conventional 3-axis processes. Our machines maintain sub-5-micron positional accuracy across X, Y, and Z axes, with simultaneous 5-axis interpolation ensuring seamless contouring for aerospace impellers, medical implants, and intricate automotive components. Material versatility spans aluminum alloys (7075-T6, 6061), titanium (Grade 5), stainless steel (316L, 17-4PH), engineering plastics (PEEK, Delrin), and high-temperature superalloys, all processed under strict environmental controls to minimize thermal drift.

Quality assurance is non-negotiable. Every prototype undergoes comprehensive dimensional validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating in a temperature-stabilized metrology lab (20°C ±0.5°C). Our first-article inspection (FAI) reports detail GD&T compliance, surface roughness (Ra 0.4µm to 3.2µm achievable), and critical feature verification against CAD models, with full traceability through our ISO 9001-certified workflow. Statistical process control (SPC) monitors tool wear and machine performance in real time, ensuring repeatability across iterative design changes. This integrated approach transforms rapid prototyping from a mere speed exercise into a reliable gateway to production readiness, mitigating downstream manufacturing risks.

The following table details our standard tolerance capabilities for rapid prototyping, reflecting achievable results under optimal conditions with proper design for manufacturability (DFM) considerations:

| Material Category | Linear Tolerance (mm) | Geometric Tolerance (mm) | Max Feature Size (mm) |

|---|---|---|---|

| Aluminum Alloys | ±0.025 | ±0.015 (Flatness) | 650 x 500 x 400 |

| Titanium/Steel | ±0.030 | ±0.020 (Concentricity) | 550 x 400 x 350 |

| Engineering Plastics | ±0.050 | ±0.030 (Profile) | 700 x 600 x 500 |

| Exotic Alloys | ±0.035 | ±0.025 (Position) | 450 x 350 x 300 |

These specifications are validated through iterative process refinement and direct collaboration with your engineering team during the quoting phase. We prioritize design feedback to optimize manufacturability—such as recommending minimum wall thickness adjustments or draft angles—ensuring prototypes function as true representations of end-use parts. With in-house anodizing, bead blasting, and precision tapping complementing our core machining, Wuxi Lead delivers fully finished, test-ready components in as little as 5–7 business days. This fusion of cutting-edge equipment, metrology rigor, and engineering partnership ensures your rapid prototypes achieve the exact balance of speed and precision demanded by high-stakes industries. Trust our capabilities to transform your concepts into validated realities, accelerating time-to-market while de-risking scale-up.

Material & Finish Options

Material selection is a critical factor in rapid prototyping via CNC machining, directly influencing part performance, durability, and suitability for end-use applications. At Wuxi Lead Precision Machinery, we prioritize material compatibility with both design intent and manufacturing efficiency. Among the most widely used materials in high-precision prototyping are aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages.

Aluminum, particularly grades 6061 and 7075, is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace components, automotive prototypes, and lightweight structural parts. Its thermal and electrical conductivity further expand its utility in electronics and heat dissipation applications. For prototypes requiring surface enhancement, aluminum is highly compatible with anodizing—a process that increases surface hardness and corrosion resistance while allowing for color coding or aesthetic customization. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied based on functional requirements.

Steel, especially stainless steel 303 and 304, offers superior strength, wear resistance, and temperature stability. These properties make it suitable for medical devices, industrial tooling, and high-stress mechanical components. While heavier than aluminum, steel provides exceptional durability and is often selected when long-term reliability under load is paramount. Machining stainless steel requires optimized toolpaths and tooling due to its tendency to work-harden, a challenge our advanced CNC systems are engineered to manage with precision.

Titanium, primarily Grade 5 (Ti-6Al-4V), delivers an outstanding strength-to-density ratio and exceptional resistance to extreme environments, including high temperatures and corrosive media. It is widely used in aerospace, defense, and biomedical implants. Though more difficult and costly to machine due to its low thermal conductivity and high chemical reactivity, titanium’s performance in mission-critical applications justifies its use. Our CNC processes employ specialized cutting strategies and tooling to maintain dimensional accuracy and surface integrity when machining titanium prototypes.

Surface finishing plays a complementary role in material performance. Anodizing, primarily applicable to aluminum, not only enhances wear and corrosion resistance but also provides electrical insulation and aesthetic control. Other finishes such as bead blasting, powder coating, or passivation may be selected depending on material and use case.

The following table summarizes key material properties and compatibility with anodizing:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Automotive, Electronics | Yes |

| Stainless Steel | 304 | 505–585 | 8.0 | Medical, Industrial, Food Processing | No |

| Titanium | Ti-6Al-4V | 900–950 | 4.43 | Aerospace, Defense, Biomedical | No |

Selecting the right material involves balancing mechanical demands, environmental exposure, weight constraints, and finish requirements. At Wuxi Lead, our engineering team collaborates closely with clients to ensure optimal material and finish selection for every rapid prototyping project.

Manufacturing Process & QC

Integrated Production Process: From Concept to Zero Defect Mass Production

At Wuxi Lead Precision Machinery, our rapid prototyping CNC machining process is engineered as a seamless continuum, eliminating traditional silos between design, prototyping, and volume production. This integrated approach is fundamental to achieving our Zero Defects mandate for high-end manufacturing clients. We begin with rigorous Design for Manufacturability (DFM) analysis, where our engineering team collaborates directly with your designers. Using advanced simulation software, we identify potential machining challenges, material constraints, and geometric complexities before any metal is cut. This proactive validation ensures the digital model translates flawlessly into a physical part, optimizing toolpaths and fixture strategies to prevent errors at the source.

The prototyping phase leverages our high-precision 3-axis, 4-axis, and 5-axis CNC milling and turning centers. Rapid iteration is enabled by our streamlined workflow; digital models transition directly to machine control systems within hours. Crucially, every prototype undergoes the same stringent metrology protocols as final production parts. Our Coordinate Measuring Machines (CMMs), optical comparators, and in-process probes verify critical dimensions against the original CAD data to tolerances as tight as ±0.001mm. This is not merely validation; it is the critical feedback loop that refines the process parameters, tooling, and inspection routines for flawless scale-up. Any deviation triggers immediate root cause analysis and process correction, ensuring the prototype is a true predictor of mass production capability.

Transitioning to mass production, the validated process parameters and inspection plans are deployed without alteration. Our production cells operate under strict Statistical Process Control (SPC), with automated in-process inspection at defined intervals monitoring key characteristics. Real-time data feeds into our manufacturing execution system, enabling predictive adjustments before minor drifts become defects. Full first-article inspection (FAI) per AS9102 or client-specific standards is mandatory, followed by ongoing lot acceptance based on AQL sampling. This closed-loop system, combined with operator certification and rigorous material traceability, guarantees consistent output meeting the most demanding aerospace, medical, and semiconductor specifications.

Key Process Capabilities Enabling Zero Defects

| Parameter | Capability | Impact on Zero Defects Goal |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (standard) | Eliminates fit/function failures |

| Surface Finish (Ra) | As low as 0.4 µm | Ensures sealing, coating adhesion |

| Material Range | Aluminum, Titanium, Stainless, Plastics, Exotics | Validates material-specific processes |

| Max Work Envelope | 1200 x 600 x 500 mm | Supports complex, large assemblies |

| Lead Time (Prototype) | As fast as 3-5 working days | Accelerates validation cycles |

| First-Pass Yield Rate | ≥ 99.98% | Direct metric of process stability |

This end-to-end discipline transforms rapid prototyping from a simple feasibility check into the definitive blueprint for perfect mass production. Wuxi Lead’s commitment to Zero Defects is operationalized through this unified process, where every prototype iteration directly hardens the production system, eliminating downstream validation delays and guaranteeing that your final components arrive ready for integration, every time. Trust precision engineered from the first cut.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Rapid Prototyping CNC Machining Excellence

At Wuxi Lead Precision Machinery, we understand that speed, precision, and reliability are non-negotiable in today’s competitive manufacturing landscape. When it comes to rapid prototyping CNC machining, your choice of partner directly impacts time-to-market, product performance, and long-term scalability. As a leading provider of precision CNC machining services in China, we combine advanced technology, engineering expertise, and a customer-first approach to deliver prototypes that meet exacting standards—fast.

Our rapid prototyping services are engineered for industries where precision is paramount—medical devices, aerospace, robotics, and high-performance industrial equipment. We specialize in turning complex 3D CAD models into fully functional prototypes in as little as 3 to 5 working days, without compromising on accuracy or material integrity. Whether you’re validating a design, preparing for pilot production, or conducting functional testing, our CNC machining processes ensure dimensional tolerances as tight as ±0.005 mm and superior surface finishes.

What sets Wuxi Lead apart is our end-to-end control over the manufacturing process. From material selection and CNC programming to quality inspection and logistics, every step is managed in-house using state-of-the-art 3-axis, 4-axis, and 5-axis machining centers. Our facility is ISO 9001:2015 certified, and we employ rigorous quality assurance protocols, including CMM inspection and first-article reporting, to ensure every prototype meets your specifications.

We work with a broad range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), titanium, brass, and high-performance plastics such as PEEK, Delrin, and nylon. Our team collaborates closely with your engineers to recommend optimal materials, machining strategies, and design improvements that enhance manufacturability and reduce costs.

Below are key technical capabilities of our rapid prototyping CNC machining services:

| Specification | Capability |

|---|---|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.003 mm |

| Maximum Work Envelope | 1200 x 600 x 500 mm |

| Spindle Speed | Up to 24,000 RPM |

| Tolerance | ±0.005 mm (standard), tighter on request |

| Surface Finish | As low as Ra 0.8 μm |

| Supported File Formats | STEP, IGES, STL, DWG, DXF, PDF |

| Lead Time | 3–5 days (standard), expedited options available |

Partnering with Wuxi Lead Precision Machinery means gaining a reliable, technically advanced manufacturing ally who values your timeline and quality expectations as much as you do. We don’t just deliver parts—we deliver confidence in your product development cycle.

For fast, professional support and a free quote on your next rapid prototyping project, contact us today at [email protected]. Let’s turn your concept into reality—precisely, efficiently, and without compromise.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.