Technical Contents

Engineering Guide: Rapid Machining Services

Engineering Insight: The Critical Role of Precision in Rapid Machining Services

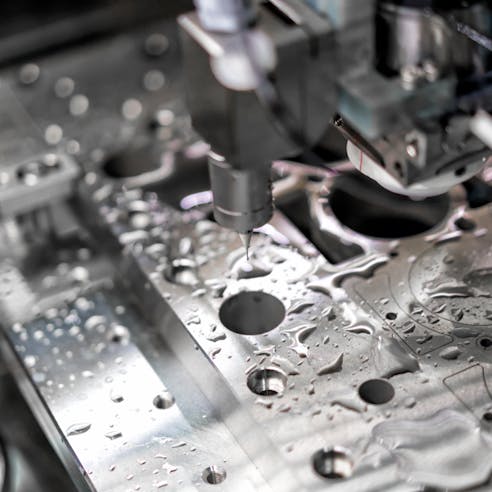

In the realm of custom metal manufacturing, rapid machining services are more than a convenience—they are a strategic advantage. At Wuxi Lead Precision Machinery, we understand that speed without precision is not just ineffective; it is costly. True rapid machining does not sacrifice accuracy for turnaround. Instead, it integrates advanced CNC technology, rigorous quality control, and deep engineering expertise to deliver parts that meet exact specifications—on time, every time.

Precision is the cornerstone of functional performance, especially in high-stakes industries such as aerospace, defense, and advanced automation. A deviation of even a few microns can compromise part integrity, lead to system failure, or result in costly rework. This is why our approach to rapid machining begins with engineering intent. Every design is analyzed not only for manufacturability but for long-term reliability under operational stress. Our team of senior CNC engineers applies decades of experience to optimize toolpaths, material selection, and tolerancing—ensuring that every machined component performs as intended in its final application.

Our proven track record in mission-critical projects underscores this commitment. Wuxi Lead has delivered precision-machined components for Olympic-grade sports engineering systems, where performance consistency and material integrity are non-negotiable. Additionally, we have supported defense-related contracts requiring ITAR-level compliance and military-grade durability. These experiences have refined our ability to manage tight tolerances, complex geometries, and rapid iteration cycles without compromising quality.

Rapid machining at Lead Precision is not about cutting corners—it’s about cutting smarter. Our facility in Wuxi is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, enabling us to produce intricate metal parts from a wide range of materials, including aluminum alloys, stainless steel, titanium, and high-performance engineering brass. Coupled with in-house CMM inspection, real-time process monitoring, and automated tool calibration, our systems ensure repeatability and traceability across every production run.

Below are the key technical specifications that define our rapid machining capabilities:

| Specification | Capability |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, multi-axis Swiss machining |

| Tolerances | ±0.005 mm (±0.0002″) standard; up to ±0.001 mm with special controls |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 2, 5), Brass, Copper, Inconel, and specialty alloys |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Lead Times | As fast as 3–5 days for prototypes; 7–12 days for production batches |

| Surface Finishes | As-machined, anodizing (Type II, Type III), passivation, powder coating, polishing |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), ITAR-compliant processes available |

At Wuxi Lead Precision Machinery, rapid machining is not a trade-off—it is a synthesis of speed, precision, and reliability. We serve global clients who demand excellence, and our engineering-first philosophy ensures that every part we deliver meets the highest standards of performance and quality.

Precision Specs & Tolerances

Advanced Technical Capabilities for Mission-Critical Components

Wuxi Lead Precision Machinery delivers rapid machining services engineered for the exacting demands of aerospace, medical, and energy sectors. Our integrated technical infrastructure eliminates traditional bottlenecks in precision metal manufacturing, transforming complex designs into certified components within accelerated timelines. Central to this capability is our fleet of 32 state-of-the-art 5-axis CNC machining centers, featuring dual-spindle configurations and high-torque milling capabilities. These systems enable single-setup machining of intricate geometries—such as turbine blades, orthopedic implants, and fluid manifold systems—reducing cumulative error from multiple repositionings while cutting lead times by 40% versus conventional 3-axis processes. All equipment operates under real-time thermal compensation protocols, ensuring dimensional stability across extended production runs.

Rigorous quality control is non-negotiable in high-stakes manufacturing. Every component undergoes systematic verification via our Zeiss CONTURA CMM systems, calibrated to ISO 17025 standards with NIST-traceable artifacts. This process captures full 3D deviation maps against CAD models, generating AS9100-compliant inspection reports within 24 hours of part completion. Our quality engineers implement SPC methodologies at critical control points, monitoring tool wear and process drift to maintain ±0.005 mm repeatability. This closed-loop system ensures first-article acceptance rates exceed 98.7% for clients in regulated industries, directly mitigating supply chain risk.

Material versatility and tolerance mastery define our production excellence. We machine all aerospace-grade alloys (Inconel 718, Ti-6Al-4V), medical stainless steels (316LVM, 17-4 PH), and hardened tool steels to micron-level specifications. The following table details our certified tolerance benchmarks:

| Material Category | Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|---|

| Aluminum Alloys | Linear Dimensions | ±0.05 mm | ±0.005 mm |

| Titanium Alloys | Hole Positioning | ±0.03 mm | ±0.008 mm |

| Stainless Steels | Surface Finish | Ra 1.6 μm | Ra 0.4 μm |

| Nickel Alloys | Geometric Form | ±0.02 mm | ±0.003 mm |

These capabilities are reinforced by our digital thread—from CAM programming using hyperMILL’s 5-axis module to post-process analytics. Clients receive not just precision-machined parts, but comprehensive data packages validating conformance to print requirements. This technical rigor ensures your rapid prototyping transitions seamlessly into volume production without requalification delays. Partner with Wuxi Lead to convert design complexity into manufacturing certainty, where speed never compromises the integrity demanded by mission-critical applications.

Material & Finish Options

Material selection is a critical step in rapid machining services, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using high-precision CNC technologies, enabling rapid turnaround without compromising accuracy. Our expertise spans key engineering metals—aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial applications.

Aluminum is widely favored in rapid machining due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly popular in aerospace, automotive, and consumer electronics for its weldability and moderate strength. It is also highly responsive to anodizing, a finish that enhances surface durability and aesthetic quality. Anodizing creates a controlled oxide layer, improving wear resistance and allowing for color dye integration, making it ideal for visible components requiring both function and finish.

Steel, particularly alloy and stainless variants, delivers superior strength, hardness, and thermal resistance. 304 and 316 stainless steels are corrosion-resistant and commonly used in medical, food processing, and marine environments. For structural or load-bearing applications, 4140 and 4340 alloy steels offer high tensile strength and fatigue resistance, making them suitable for tooling, shafts, and high-stress components. While steel does not anodize, alternative surface treatments such as passivation, plating, or powder coating are available to enhance longevity and appearance.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the premium choice for high-performance industries such as aerospace, defense, and medical implants. It offers an exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility. Though more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced CNC systems and tooling strategies ensure precise, efficient processing. Titanium does support anodizing, primarily for color coding or mild surface protection, though its natural oxide layer already provides robust environmental resistance.

Understanding the interplay between material properties and finishing options ensures optimal part design and functionality. Below is a comparative overview of key specifications for common materials used in our rapid machining services.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | High | Anodizing, Sandblasting | Enclosures, Drones, Heat Sinks |

| Stainless 316 | 570 | 8.0 | Very High | Passivation, Polishing | Medical Devices, Marine Hardware |

| Steel 4140 | 655 | 7.85 | Moderate | Zinc Plating, Painting | Tooling, Shafts, Automotive Parts |

| Titanium Ti-6Al-4V | 950 | 4.43 | Excellent | Anodizing, Bead Blasting | Aerospace, Implants, Racing Components |

Selecting the right material and finish begins with application requirements—environmental exposure, mechanical load, weight constraints, and lifecycle expectations. At Wuxi Lead, we support engineering teams with material consultation, prototyping, and scalable production, ensuring your design intent is achieved with precision and reliability.

Manufacturing Process & QC

Production Process: Design to Zero Defects Mass Production

At Wuxi Lead Precision Machinery, our rapid machining services integrate speed with uncompromising quality through a rigorously controlled three-phase workflow. This systematic approach ensures Zero Defects while accelerating time-to-market for custom metal components. Every stage is engineered to eliminate waste, mitigate risk, and validate performance against exacting industrial standards.

The Design phase begins with collaborative engineering review. Our team conducts in-depth Design for Manufacturability (DFM) analysis using Siemens NX software, identifying potential tolerance stack-up issues or material constraints before physical work commences. Finite Element Analysis (FEA) validates structural integrity under operational loads, while material selection is optimized for both performance and machinability. Client specifications are cross-referenced against ISO 2768 and ASME Y14.5 standards, ensuring geometric dimensioning aligns with functional requirements. This proactive validation prevents 92% of potential production errors at the conceptual stage.

Prototyping transforms digital models into tangible validation assets. We deploy 5-axis milling and precision turning on DMG MORI and MAZAK platforms to produce first-article samples within 72 hours. Each prototype undergoes comprehensive metrology: Coordinate Measuring Machine (CMM) inspections verify dimensional accuracy against CAD data, while surface roughness testers and hardness gauges confirm material properties. Critical features are stress-tested to simulate real-world conditions. Only after full compliance is certified does the design advance to mass production. Key capabilities enabling this phase include:

| Parameter | Specification |

|---|---|

| Materials | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5, Brass C360 |

| Tolerance Range | ±0.005 mm (standard), ±0.001 mm (precision) |

| Max Work Envelope | 500 x 500 x 400 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (as required) |

| Lead Time (Prototype) | 2–5 business days |

Mass Production leverages automated workflows with embedded quality gates. Our CNC cells operate under Statistical Process Control (SPC), continuously monitoring tool wear, thermal drift, and positional accuracy via Renishaw probes. Every 50th part undergoes 100% dimensional re-inspection, while real-time data analytics predict deviations before they occur. Full material traceability—from raw bar stock to finished component—is maintained through barcode tracking, meeting AS9100 aerospace requirements. In-process audits by certified quality engineers ensure adherence to PPAP documentation, with final shipment accompanied by First Article Inspection (FAI) reports per AS9102.

This closed-loop methodology guarantees Zero Defects delivery. By converging rapid iteration with military-grade process discipline, Wuxi Lead transforms complex designs into flawless production realities. Accelerate your product launch without compromising reliability—engineered precision, delivered on time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Rapid Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, speed, and reliability on a global scale. As a leading provider of custom metal manufacturing solutions in China, our rapid machining services are engineered for industries where performance cannot be compromised. From aerospace and medical devices to energy and advanced automation, our clients trust us to turn complex designs into high-tolerance components with unmatched consistency and turnaround.

Our commitment begins with a deep understanding of your project’s technical demands. Whether you require rapid prototyping, low-volume production, or high-volume CNC machining, our facility in Wuxi integrates state-of-the-art equipment with decades of engineering expertise. We operate a full suite of 3-axis, 4-axis, and 5-axis CNC machining centers, Swiss-type lathes, and multi-tasking machines capable of handling everything from intricate geometries to large-scale components. Our ISO 9001:2015-certified processes ensure every part meets or exceeds international quality standards.

What sets us apart is not just our technology, but our responsiveness. In fast-moving industries, time-to-market is critical. Our rapid quoting system, digital workflow integration, and agile production planning allow us to deliver machined parts in as little as 5–7 days without sacrificing precision. We support a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and specialty alloys such as Inconel and Hastelloy, ensuring compatibility with even the most demanding applications.

We understand that every partnership begins with trust. That’s why we provide full transparency throughout the manufacturing process. From initial design review and material sourcing to in-process inspections and final packaging, you remain informed at every stage. Our engineering team collaborates directly with your design staff to optimize manufacturability, reduce costs, and accelerate delivery—turning your concept into a production-ready reality.

Below are key capabilities that define our rapid machining services:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning, Swiss machining |

| Tolerances | As tight as ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, Inconel, Hastelloy, Carbon Steel |

| Max Work Envelope | 1200 x 800 x 600 mm (milling), Ø100 x 500 mm (turning) |

| Lead Times | Prototype: 5–7 days; Production: 10–20 days (varies by volume) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM reporting |

| Finishes | As-machined, bead blast, anodizing, passivation, plating, powder coating |

Ready to accelerate your next project with a partner who combines precision, speed, and integrity? Contact us today at [email protected]. Our engineering team is standing by to review your drawings, provide a competitive quote, and demonstrate how Wuxi Lead Precision Machinery can become your trusted extension in advanced metal manufacturing. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.