Technical Contents

Engineering Guide: Quick Turn Injection Molding

Engineering Insight: Precision as the Non-Negotiable Core of Quick Turn Injection Molding

In high-stakes custom metal manufacturing, the demand for rapid prototyping and low-volume production through quick turn injection molding is intensifying. However, speed without uncompromising precision is a false economy. True quick turn capability is not merely about cycle time reduction; it is fundamentally anchored in the ability to consistently achieve micron-level tolerances and flawless part geometry on accelerated schedules. This precision is the critical differentiator between a functional component and a costly failure, especially when integrating molded elements into complex metal assemblies. At Wuxi Lead Precision Machinery, we engineer our entire quick turn process around this principle. Our advanced CNC-machined mold bases, coupled with in-process metrology and real-time process control, ensure dimensional stability and repeatability from the first shot to the final piece. Sacrificing tolerance control for speed inevitably leads to assembly issues, performance degradation, and extended time-to-market – negating the very purpose of a quick turn solution.

The precision achievable directly dictates the application scope for quick turn molding. Components destined for aerospace subsystems, medical devices, or high-performance automotive systems demand tolerances often within ±0.025mm. Meeting these specifications under compressed timelines requires more than just fast machines; it demands a deep understanding of material behavior, thermal dynamics within the mold, and the intricate interplay between mold design and process parameters. Our facility leverages decades of specialized experience, rigorously validated in environments where failure is not an option. This includes producing critical components for Olympic timing systems requiring absolute reliability under global scrutiny and contributing to military-grade equipment where environmental resilience and dimensional integrity are paramount. This heritage informs every aspect of our quick turn methodology, embedding robust quality assurance protocols that operate concurrently with speed optimization.

Our commitment to precision-engineered quick turn services is reflected in the core capabilities of our dedicated production cell. The table below outlines the critical specifications underpinning our ability to deliver complex, high-tolerance parts rapidly.

| Specification | Capability | Relevance to Precision & Speed |

|---|---|---|

| Typical Tolerance Range | ±0.025mm to ±0.05mm | Enables integration into tight-tolerance metal assemblies |

| Max Clamping Force | 550 Tons | Supports complex, multi-cavity molds for small batches |

| Material Range | Engineering Thermoplastics (PEEK, PSU, PP, ABS, PC, etc.) | Handles high-temp, high-strength polymers for demanding applications |

| In-Process Metrology | On-machine CMM verification | Ensures real-time dimensional control, minimizing scrap and rework |

| Lead Time (Prototype) | 7-10 Business Days (Complex Parts) | Combines speed with guaranteed dimensional accuracy |

Precision is the silent enabler of genuine quick turn success. It transforms accelerated production from a logistical exercise into a strategic advantage, delivering parts that perform as intended, right from the first delivery. Wuxi Lead Precision Machinery integrates the discipline of high-accuracy metal manufacturing into our polymer processes, ensuring your rapid injection molding outcomes meet the exacting standards demanded by advanced engineering applications. Speed without precision is merely haste; our approach delivers accelerated results you can build upon with absolute confidence.

Precision Specs & Tolerances

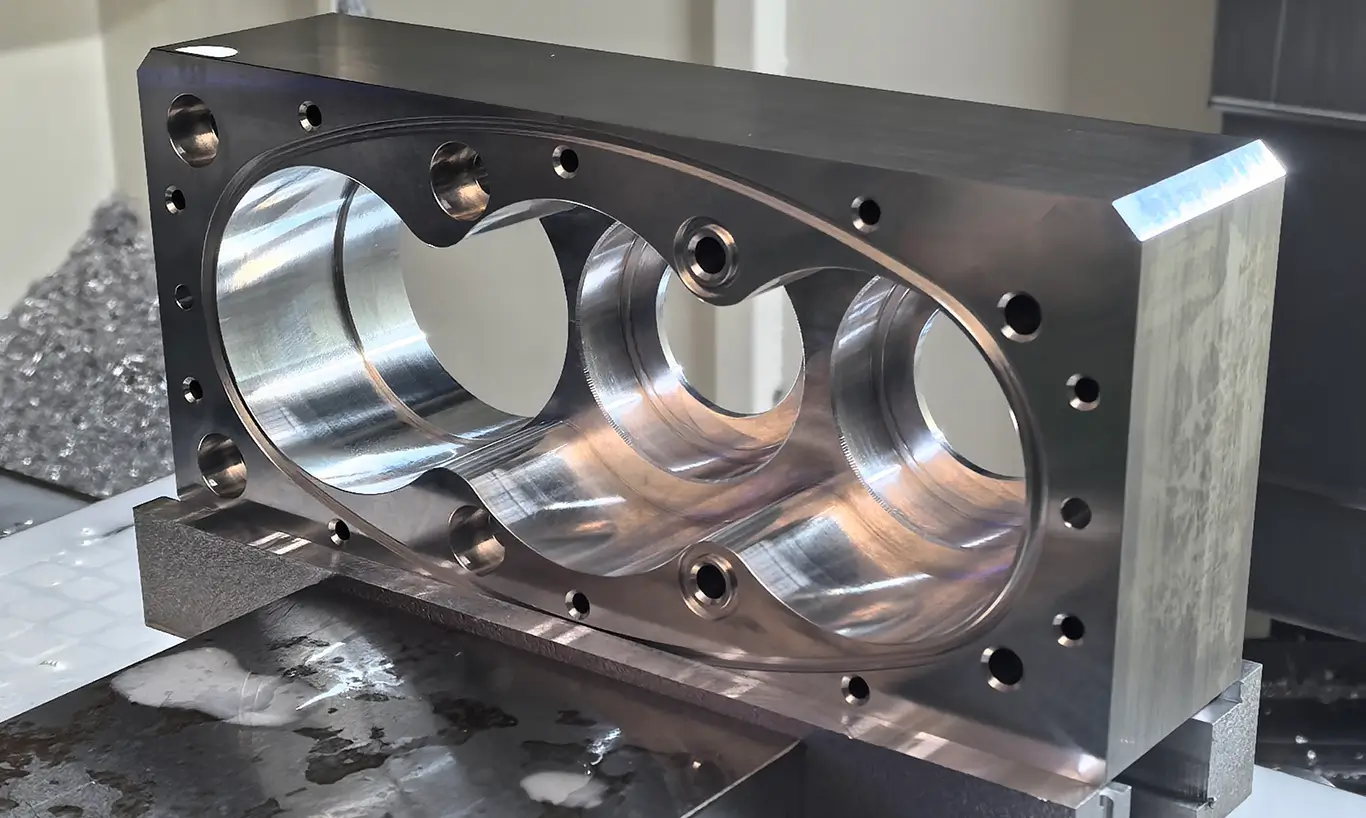

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for industries requiring reliability, repeatability, and tight tolerances. At the core of our production infrastructure is a suite of 5-axis CNC machining centers, enabling complex geometries and multi-faceted part processing in a single setup. This technology eliminates cumulative alignment errors and significantly reduces lead times, making it ideal for both prototyping and low-to-medium volume production runs associated with quick turn injection molding applications.

Our 5-axis CNC systems provide simultaneous motion across all five axes, allowing for optimal tool positioning and improved surface finish. This capability is critical when producing intricate mold cores, cavities, inserts, and precision components used in injection molding tooling. Advanced CAM software ensures efficient toolpath generation, minimizing cycle times while maintaining micron-level accuracy. Materials commonly processed include tool steels, stainless steels, aluminum alloys, and high-performance alloys such as Inconel and titanium, all machined to exacting customer specifications.

To ensure dimensional integrity and compliance with engineering requirements, every critical component undergoes comprehensive quality control using state-of-the-art Coordinate Measuring Machine (CMM) inspection. Our CMM systems operate in temperature-controlled environments to eliminate thermal drift, delivering repeatable and traceable measurement data. Full first-article inspection reports (FAIR) and production-level inspection documentation are available upon request, supporting ISO and automotive-grade quality standards.

All inspection routines are integrated into the manufacturing workflow, enabling real-time feedback and corrective actions during production. This closed-loop quality process ensures that every component conforms to design intent and performs reliably in high-cycle molding environments. Our quality management system is aligned with international standards, supporting traceability, material certification, and process validation.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC machining and inspection processes:

| Feature | Standard Tolerance | Precision Capability (Optimized) |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Angular Dimensions | ±0.1° | ±0.05° |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Circular Runout | 0.01 mm | 0.005 mm |

These specifications reflect our commitment to precision engineering and rapid turnaround without compromising quality. By combining advanced 5-axis CNC technology with rigorous CMM-based inspection protocols, Wuxi Lead Precision Machinery ensures that every custom metal component meets the demanding requirements of modern injection molding applications.

Material & Finish Options

Material Selection for High-Performance Quick Turn Injection Molding

Selecting the optimal material is paramount for achieving precision, durability, and rapid turnaround in custom injection mold manufacturing. At Wuxi Lead Precision Machinery, our expertise ensures materials align with your project’s thermal, mechanical, and production speed requirements. Aluminum, steel, and titanium each offer distinct advantages, while finishes like anodizing enhance functionality and longevity. Understanding these options prevents costly delays and ensures mold performance meets demanding production cycles.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are the cornerstone of quick turn projects. Their exceptional machinability allows for rapid cavity and core fabrication, significantly reducing lead times. High thermal conductivity ensures efficient cooling cycles, critical for maintaining tight tolerances in accelerated production runs. While ideal for prototypes and medium-volume production (up to 100,000 shots), aluminum’s lower hardness necessitates protective finishes for abrasive materials. Steel remains the standard for high-volume, long-life molds. 4140 chrome-moly steel provides excellent toughness and wear resistance for general applications, while 17-4PH stainless steel offers superior corrosion resistance for medical or chemical environments. Steel’s slower machining speed is offset by its ability to withstand millions of cycles, though heat treatment adds time. Titanium alloys (e.g., Ti-6Al-4V) deliver unmatched strength-to-weight ratios and corrosion resistance for extreme conditions. However, its challenging machinability and higher cost typically reserve it for specialized aerospace or medical molds where weight savings justify extended lead times, making it less common in pure quick turn scenarios.

Anodizing is the premier finish for aluminum molds, directly impacting performance and lifespan in accelerated production. Type II (sulfuric acid) anodizing provides a cost-effective, decorative, and moderately wear-resistant layer suitable for many quick turn applications. For molds processing glass-filled or abrasive resins, Type III (hardcoat) anodizing is essential. Its significantly thicker, harder ceramic layer (60-70 HRC) drastically improves wear resistance and release properties, protecting the mold surface without compromising dimensional accuracy. This finish is critical for maintaining part quality over the mold’s operational life in high-speed production.

Key material properties directly influencing quick turn feasibility and mold performance are summarized below:

| Material | Machinability (Relative) | Thermal Conductivity (W/m·K) | Typical Hardness (HB) | Best Suited For Quick Turn Volume |

|---|---|---|---|---|

| Aluminum 6061-T6 | Excellent (100%) | 167 | 95 | Prototypes, Low-Medium (10k-100k) |

| Steel 4140 | Good (65%) | 42 | 200 | Medium-High (100k-1M+) |

| Steel 17-4PH | Fair (50%) | 18 | 330 | Medium-High (Corrosive Env.) |

| Titanium Ti-6Al-4V | Poor (20%) | 7.2 | 360 | Low Volume (Specialized Only) |

Material choice fundamentally dictates your quick turn timeline and mold ROI. Prioritize aluminum with hardcoat anodizing for the fastest path from design to production for most applications. For sustained high-volume runs, invest in tool steel. Wuxi Lead Precision Machinery leverages advanced CNC milling and EDM capabilities to machine these materials to ±0.005mm tolerances, ensuring your mold is optimized for rapid deployment and consistent part quality from the first shot. Consult our engineering team to match material properties precisely to your resin, volume, and timeline constraints.

Manufacturing Process & QC

Design: The Foundation of Zero Defects

At Wuxi Lead Precision Machinery, the journey to flawless injection-molded metal components begins with precision engineering at the design phase. Our in-house design team collaborates closely with clients to translate conceptual requirements into manufacturable, high-tolerance designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize part geometry, wall thickness, gate locations, and cooling channels to eliminate potential defects such as warping, sink marks, or porosity. Every design undergoes rigorous simulation using Moldflow and ANSYS to predict material flow, thermal behavior, and structural integrity under real-world conditions. This virtual validation ensures that only fully optimized designs proceed to prototyping, minimizing downstream risks and accelerating time-to-market.

Prototyping: Validating Performance Before Scale

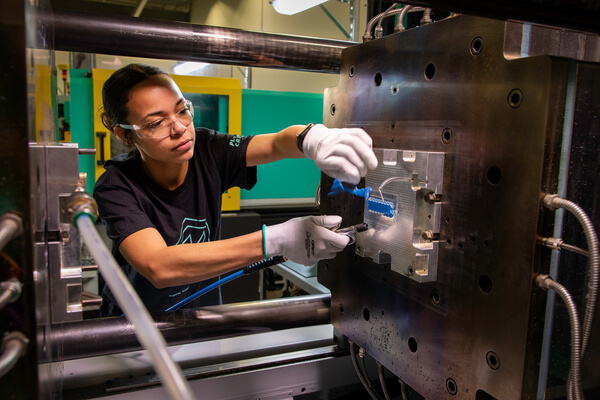

Once the design is finalized, we move to rapid prototyping using high-precision CNC-machined molds or soft tooling, depending on material and volume requirements. This phase is critical for physical validation of form, fit, and function. At Wuxi Lead, prototypes are produced on the same class of machinery used in full-scale production, ensuring accurate representation of final part quality. Each prototype undergoes comprehensive metrological inspection using CMM (Coordinate Measuring Machines), optical scanners, and X-ray tomography for internal defect detection. Material compatibility, mechanical strength, and surface finish are rigorously tested against client specifications. Feedback from this stage is looped directly into mold refinement, ensuring that any micro-adjustments are implemented before mass production begins. This closed-loop process is central to our zero-defect philosophy.

Mass Production: Precision, Consistency, Control

With design and prototyping validated, we transition seamlessly into high-volume manufacturing. Our automated injection molding lines are equipped with real-time process monitoring systems that track pressure, temperature, cycle time, and clamp force for every shot. Each mold is built from premium-grade tool steel with PVD or nitride coatings, ensuring longevity and dimensional stability over millions of cycles. In-process statistical process control (SPC) and 100% automated visual inspection guarantee consistent quality. All finished components are subjected to final QA protocols, including batch traceability, material certification, and packaging per international export standards.

Our integrated workflow from design through to mass production ensures that every part meets the highest benchmarks in precision, reliability, and performance—delivering true zero-defect manufacturing for global industrial clients.

| Specification | Detail |

|---|---|

| Material Options | Stainless Steel (304, 316), Tool Steel, Aluminum Alloys, Titanium Alloys |

| Tolerance Range | ±0.005 mm to ±0.02 mm (depending on geometry) |

| Surface Finish | Ra 0.1 µm to Ra 1.6 µm (polished, textured, or as-machined) |

| Production Capacity | 10,000 to 500,000 units/month (scalable) |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 25–45 days after approval |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS, REACH compliant |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Quick Turn Injection Molding

Time-to-market compression demands more than accelerated timelines; it requires a partner capable of delivering precision-engineered plastic components with the same rigor applied to critical metal subsystems. At Wuxi Lead Precision Machinery, our Quick Turn Injection Molding service is engineered specifically for high-end industrial applications where dimensional repeatability, material integrity, and rapid iteration are non-negotiable. We bridge the gap between prototyping urgency and production-grade quality, eliminating the traditional trade-offs that stall innovation in aerospace, medical device, and advanced automation sectors.

Our integrated facility in Wuxi operates under stringent ISO 9001:2015 protocols, leveraging decades of custom metal manufacturing expertise to inform every aspect of our plastic molding process. This unique foundation ensures mold design, material selection, and process validation meet the exacting standards expected for components interfacing with precision-machined metal assemblies. Unlike generalist suppliers, we prioritize engineering collaboration from the initial RFQ stage. Our application engineers work directly with your design team to optimize part geometry for manufacturability, select certified materials meeting USP Class VI or ASTM E84 requirements where applicable, and implement rigorous validation protocols before the first shot. This proactive approach prevents costly redesigns and accelerates path-to-assembly.

The technical backbone of our service resides in controlled environmental molding cells and real-time process monitoring systems. We maintain strict humidity and temperature controls, critical for engineering resins like PEEK, PEI, and liquid crystal polymers, ensuring consistent material properties batch after batch. Every mold undergoes comprehensive metrology verification using calibrated CMMs against your original CAD data, guaranteeing tolerances are held without exception. Secondary operations—including ultrasonic welding, insert molding, and precision machining of critical interfaces—are performed in-house under the same quality umbrella, eliminating supply chain vulnerabilities.

Technical Specifications for Quick Turn Service

| Parameter | Capability | Industrial Relevance |

|---|---|---|

| Standard Lead Time | 7-15 business days | Accelerates design validation cycles |

| Dimensional Tolerance | ±0.025 mm (±0.001″) | Meets tight integration with metal parts |

| Material Range | Engineering thermoplastics (PEEK, PEI, PSU, PPS), LCPs, TPEs, ABS, PC | Supports demanding thermal/chemical environments |

| Mold Steel | P20, H13, Stainless (420, 17-4PH) | Ensures longevity for pilot production |

| Max Shot Weight | 500 grams | Covers 95% of industrial component needs |

| Secondary Operations | Precision machining, welding, assembly, cleanroom packaging | Delivers fully functional sub-assemblies |

Partnering with Lead Precision means engaging a single source accountable for both the plastic component and its metal integration points. We understand that a 0.05mm deviation in a molded housing can cascade into field failures when mated to a CNC-machined gearbox. Our engineers speak the language of GD&T and material science fluently, providing actionable feedback—not just parts. When your project demands speed without sacrificing the precision that defines industrial reliability, initiate the process with validated data.

Contact our engineering team directly at [email protected] to submit your 3D model and requirements. Specify “Quick Turn Injection Molding Inquiry” in the subject line for immediate technical review. We respond to all qualified industrial RFQs within 4 business hours with a feasibility assessment and timeline commitment. Let Lead Precision become your engineered acceleration partner.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.