Technical Contents

Engineering Guide: Quick Turn Cnc Machining

Engineering Insight: The Critical Role of Precision in Quick Turn CNC Machining

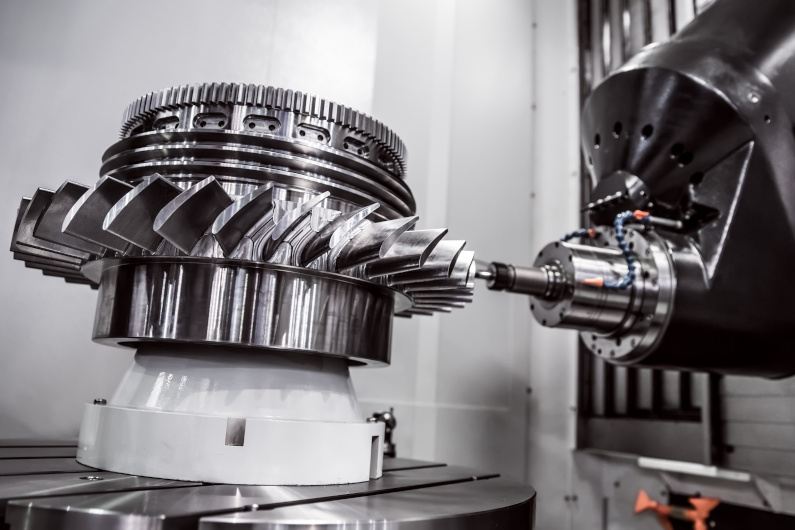

In high-performance industries such as aerospace, defense, and advanced medical technology, the margin for error is effectively zero. Quick turn CNC machining has emerged as a vital solution for accelerating product development and reducing time-to-market, but speed must never compromise precision. At Wuxi Lead Precision Machinery, we understand that true efficiency lies at the intersection of rapid production and uncompromising accuracy. Our engineering philosophy centers on delivering quick turn services that maintain micron-level tolerances, ensuring every component performs as intended under the most demanding conditions.

Precision in CNC machining is not merely a measure of dimensional accuracy—it reflects the consistency, repeatability, and integrity of the entire manufacturing process. From material selection and toolpath optimization to in-process inspection and thermal compensation, each step must be tightly controlled. At Lead Precision, our state-of-the-art 5-axis CNC machining centers are equipped with high-resolution probing systems and real-time monitoring to detect deviations before they impact output. This level of control enables us to offer rapid prototyping and low-volume production with tolerances as tight as ±0.002 mm, a standard demanded by our military and Olympic-grade projects.

Our experience in supporting mission-critical applications has shaped our approach to quick turn machining. Components developed for China’s national defense systems and precision equipment used in Olympic competition environments require flawless performance. These projects demand materials such as titanium, Inconel, and high-strength aluminum alloys, which are notoriously difficult to machine but essential for durability and performance. Our engineers apply deep material science knowledge and adaptive machining strategies to maintain surface integrity and geometric accuracy, even in the most challenging alloys.

Speed without control leads to waste. That is why our quick turn process integrates automated quality assurance protocols, including first-article inspection (FAI) and coordinate measuring machine (CMM) validation, ensuring every part meets or exceeds customer specifications. By combining advanced machinery, rigorous process control, and decades of engineering expertise, we deliver rapid turnaround times without sacrificing the precision that defines our reputation.

Below are key technical specifications that define our quick turn CNC machining capabilities:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 650 mm |

| Spindle Speed | Up to 24,000 RPM |

| Axis Configuration | 3-axis, 4-axis, 5-axis simultaneous |

| Materials Supported | Aluminum (7075, 6061), Titanium (Gr5, Gr2), Stainless Steel (316L, 17-4PH), Inconel 718, Brass, Engineering Plastics |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

| Lead Time (Prototype) | As fast as 5–7 days |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace compliance) |

At Wuxi Lead Precision Machinery, we do not simply offer fast turnaround—we deliver precision-engineered confidence, on schedule.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Rapid Execution

Wuxi Lead Precision Machinery delivers definitive technical capability in high-mix, quick-turn CNC machining, anchored by our advanced multi-axis machining centers. Our core production fleet comprises state-of-the-art 5-axis CNC machining centers from leading OEMs including DMG MORI and Haas. These machines feature simultaneous 5-axis contouring, high-torque spindles (up to 24,000 RPM), and rigid construction enabling the precise, single-setup fabrication of complex geometries across aerospace alloys, medical-grade stainless steels, titanium, and high-performance engineering plastics. This integrated capability eliminates costly secondary operations and fixture changes, directly accelerating lead times while maintaining geometric integrity for components demanding tight positional accuracy between critical features. Our machining envelope supports parts up to Ø 650 mm x 1000 mm, accommodating a broad spectrum of prototyping and low-to-mid volume production requirements without compromising dimensional stability.

Rigorous quality control is non-negotiable in our quick-turn process. Every critical dimension undergoes verification using Zeiss and Hexagon CMMs equipped with high-precision probing systems and PC-DMIS software. These Coordinate Measuring Machines provide NIST-traceable measurement data with sub-micron repeatability, ensuring compliance with stringent client specifications and international standards. Our AS9100D and ISO 9001:2015 certified quality management system mandates comprehensive first-article inspection reports (FAIR) and in-process checks for all production runs. This systematic approach guarantees that rapid delivery never equates to compromised quality; it signifies optimized workflow and unwavering adherence to metrological best practices from material receipt through final packaging.

The following table details our standard achievable tolerances for quick-turn CNC machining, reflecting the precision inherent in our equipment, tooling, and process control. These values represent typical capabilities for machined features under standard production conditions; tighter tolerances are achievable for specific applications with appropriate process validation.

| Feature Category | Capability | Standard Reference | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm (0.0002″) | ISO 2768-mK | Standard for critical features |

| Angular Tolerances | ±0.005° | ISO 2768-c | Verified via CMM |

| Geometric Position | Ø 0.01 mm (0.0004″) | ISO 1101 | Relative to datums, single setup |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | ISO 1302 | As-machined; finer achievable with finishing passes |

| Repeatability | ±0.002 mm (0.00008″) | Process Control | Demonstrated across production batches |

| Material Removal Rate | Optimized per material | N/A | Balanced for speed & surface finish |

This technical foundation—combining sophisticated 5-axis machining, metrology-grade inspection, and disciplined process control—enables Wuxi Lead Precision Machinery to consistently achieve rapid turnaround without sacrificing the precision demanded by aerospace, medical device, and advanced industrial sectors. We transform complex design requirements into certified, high-integrity components, ensuring your project timeline remains uncompromised by quality concerns. Our capability is measured not just in microns, but in the reliability of on-time delivery for mission-critical applications.

Material & Finish Options

Material Selection in Quick Turn CNC Machining: Aluminum, Steel, and Titanium

In high-precision quick turn CNC machining, material selection is a critical decision that directly impacts part performance, durability, manufacturability, and cost. At Wuxi Lead Precision Machinery, we specialize in delivering rapid, high-quality CNC-machined components using industry-leading processes tailored to the unique properties of aluminum, steel, and titanium. Understanding the mechanical characteristics and finishing compatibility of these materials enables engineers and procurement teams to make informed decisions that align with functional requirements and production timelines.

Aluminum is one of the most widely used materials in precision CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly favored in aerospace, automotive, and consumer electronics for its weldability and dimensional stability. Its low density makes it ideal for weight-sensitive applications, while its surface readily accepts anodizing—a common post-machining finish that enhances wear and corrosion resistance. Type II (sulfuric acid) anodizing is standard, providing a durable oxide layer typically 12–25 µm thick, with options for color dyeing for identification or aesthetic purposes.

Steel offers superior strength, hardness, and wear resistance, making it suitable for high-stress mechanical components, tooling, and industrial machinery. We commonly machine alloy steels such as 4140 and 1018, each selected based on required toughness and heat treatment needs. While steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, our advanced CNC toolpaths and coolant strategies ensure tight tolerances and excellent surface finishes. Although steel cannot be anodized, it benefits from alternative surface treatments such as zinc plating, passivation, or powder coating to resist corrosion.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice in aerospace, medical, and defense applications where extreme strength-to-density ratios and biocompatibility are essential. Despite its high cost and challenging machinability—due to low thermal conductivity and tendency to gall—our specialized tooling and slow, controlled cutting parameters ensure defect-free results. Titanium naturally forms a passive oxide layer, offering inherent corrosion resistance, though it is generally not anodized in the same way as aluminum. However, engineered titanium oxide finishes can be applied for color coding or enhanced surface hardness.

The following table summarizes key mechanical properties and finishing compatibility for common materials used in quick turn CNC machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Yes (Type II/III) | Aerospace, Electronics, Automotive |

| Steel | 600–1000 | 7.8 | 4140, 1018, 1045 | No | Industrial Machinery, Tooling |

| Titanium | 900–1000 | 4.5 | Ti-6Al-4V (Gr5) | Limited (specialized) | Medical, Aerospace, Defense |

Selecting the right material involves balancing performance needs with cost and lead time. At Wuxi Lead Precision Machinery, our engineering team supports clients in optimizing material and finish selection to ensure rapid turnaround without compromising quality.

Manufacturing Process & QC

Integrated Production Process: Achieving Zero Defects in Quick Turn CNC Machining

At Wuxi Lead Precision Machinery, our quick turn CNC machining process is engineered for speed without compromise, delivering production-ready components on accelerated timelines while enforcing an absolute zero defects mandate. This rigor begins at the conceptual stage and permeates every phase through disciplined execution and advanced quality control. The seamless transition from Design to Prototyping to Mass Production forms the backbone of our high-integrity manufacturing system, ensuring your critical components meet exacting specifications from the first part to the final shipment.

The process initiates with collaborative Design for Manufacturability (DFM) analysis. Our engineering team rigorously reviews your CAD models, identifying potential machining challenges, material constraints, and opportunities for optimization before metal is cut. This proactive step prevents downstream errors, reduces non-conformances, and establishes the precise tolerances and surface finishes achievable within your target lead time. Concurrently, our CAM specialists develop optimized, collision-free toolpaths using industry-leading software, ensuring maximum machine efficiency and part consistency from the outset. This foundational phase is critical for eliminating avoidable rework and setting the stage for defect-free production.

Prototyping serves as the vital validation checkpoint. Utilizing the same high-precision CNC equipment (5-axis mills, precision lathes) and materials destined for full production, we manufacture functional prototypes. Each prototype undergoes comprehensive first-article inspection against all critical dimensions and material properties. Dimensional verification employs calibrated CMMs, optical comparators, and surface roughness testers. This phase confirms the DFM recommendations, validates the CAM program, and provides tangible evidence of manufacturability and quality before committing to volume. Any discrepancies trigger immediate engineering feedback loops, resolving issues at the prototype stage to prevent mass production failures.

Mass Production leverages the validated process parameters and tooling. Statistical Process Control (SPC) is implemented in real-time, with critical dimensions monitored at defined intervals using automated data collection. Our ISO 9001-certified workflow mandates 100% visual inspection for surface defects and systematic dimensional sampling per AS9102 or client-specific standards. In-process gauging and final inspection reports provide full traceability. This closed-loop system, combined with operator certification and machine calibration logs, ensures every component adheres strictly to the zero defects standard, batch after batch, regardless of volume.

Wuxi Lead Quick Turn Process Specifications

| Phase | Lead Time Range | Tolerance Range | Key Processes | Inspection Method |

|---|---|---|---|---|

| Design | 24-72 Hours | N/A (Specification) | DFM Analysis, CAM Programming, Material Sourcing | Engineering Review, Feasibility Report |

| Prototyping | 3-7 Days | ±0.005mm – ±0.025mm | Precision Machining (5-Axis/Lathe), Deburring, Basic Finishing | CMM, Optical Comparator, Surface Roughness Test |

| Mass Production | 7-15 Days | ±0.002mm – ±0.0125mm | High-Volume CNC Machining, In-Process SPC, Full Finishing | 100% Visual, SPC Sampling, CMM Final Report |

This integrated methodology, combining upfront engineering rigor, prototype validation, and SPC-driven mass production, is how Wuxi Lead consistently achieves rapid turnaround and zero defect delivery. We transform design intent into flawless physical reality, ensuring your supply chain operates with unwavering confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Speed, Accuracy, and Reliability in CNC Machining

At Wuxi Lead Precision Machinery, we understand that in high-stakes manufacturing environments, time is not just money — it’s competitive advantage. When your project demands rapid turnaround without compromising on precision, partnering with us ensures you gain access to a fully integrated, ISO-certified CNC machining ecosystem engineered for performance. Our quick turn CNC machining services are designed for global OEMs, aerospace innovators, medical device developers, and industrial technology leaders who require parts faster, with tighter tolerances, and full traceability from prototype to production.

Located in the heart of China’s advanced manufacturing corridor, our 12,000-square-meter facility runs 24/7 with a fleet of over 80 CNC machines, including 3-axis, 4-axis, and 5-axis milling centers, precision turning lathes, and multi-spindle Swiss machines. Our in-house capabilities span milling, turning, grinding, tapping, threading, and finishing — all supported by automated tooling systems and real-time quality monitoring. This infrastructure enables us to deliver machined components in as little as 3 business days, with first-article inspection reports and full material certification included.

What sets Lead Precision apart is not just speed — it’s consistency. Every component is machined to ±0.005 mm tolerance, with surface finishes down to Ra 0.8 µm, ensuring seamless integration into your final assembly. Our engineering team collaborates directly with your design and procurement staff to optimize DFM, reduce material waste, and eliminate unnecessary lead time. We support a wide range of materials, including aerospace-grade aluminum (7075, 6061), stainless steel (303, 304, 316), titanium, brass, copper, and high-performance plastics such as PEEK and PTFE.

Our clients rely on us not just as a vendor, but as an extension of their manufacturing strategy. With real-time order tracking, dedicated project managers, and compliance with ISO 9001:2015 and IATF 16949 standards, we ensure every shipment meets the highest benchmarks in quality and repeatability.

Technical Capabilities Overview

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.005 mm |

| Surface Finish Range | Ra 0.8 – 6.3 µm |

| Lead Time (Standard) | 3–7 days |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, PTFE, and more |

| Certifications | ISO 9001:2015, IATF 16949 |

| File Formats Accepted | STEP, IGES, DWG, DXF, PDF, SolidWorks |

When your project timeline is tight and precision is non-negotiable, choose a partner built for speed, scale, and uncompromising quality. Contact us today at [email protected] to discuss your next quick turn CNC machining requirement. Let Wuxi Lead Precision Machinery accelerate your path from design to delivery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.