Technical Contents

Engineering Guide: Quick Service Steel

Engineering Insight: The Role of Precision in Quick Service Steel Manufacturing

In the realm of custom metal manufacturing, speed without precision is a liability, not an advantage. Quick service steel solutions must balance rapid turnaround with uncompromising accuracy to meet the exacting demands of industries such as aerospace, defense, and advanced automation. At Wuxi Lead Precision Machinery, we define quick service steel not merely by delivery speed, but by our ability to deliver dimensionally accurate, structurally sound components on accelerated timelines—without sacrificing quality.

Precision engineering is the backbone of reliable steel fabrication. Even minor deviations in tolerances can lead to system failures, costly rework, or safety hazards in high-stakes applications. Our experience supplying mission-critical components for Olympic-grade equipment and military-grade systems has reinforced the principle that precision is non-negotiable. In these environments, components must perform under extreme stress, temperature fluctuations, and dynamic loads. The margin for error is effectively zero.

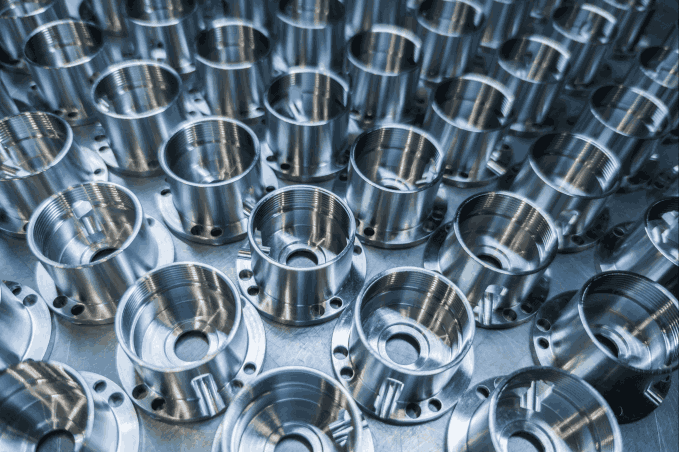

Our approach begins with advanced CNC machining platforms integrated with real-time monitoring systems. These allow us to maintain tolerances as tight as ±0.002 mm, ensuring consistency across single prototypes and large production runs. Material selection, thermal treatment, and stress-relieving processes are all optimized to preserve dimensional stability during and after machining. Every stage—from digital modeling to final inspection—is governed by ISO 9001-certified quality protocols.

Wuxi Lead’s expertise in quick service steel is rooted in over a decade of refining rapid manufacturing cycles while adhering to international standards. Our facility in Wuxi, China, combines automated workflow management with the oversight of veteran engineers, enabling us to compress lead times without bypassing critical quality checkpoints. Whether producing high-strength alloy brackets for defense vehicles or load-bearing structures for Olympic training systems, our process ensures repeatability, traceability, and compliance.

Speed in manufacturing should never imply shortcuts. True quick service steel solutions are built on predictive engineering, robust process control, and deep domain experience. At Wuxi Lead, we leverage our heritage in high-performance sectors to deliver steel components that are not only fast to market but engineered to perform.

Typical Precision Specifications for Quick Service Steel Components

| Parameter | Standard Capability | High-Precision Option | Testing Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm | CMM (Coordinate Measuring Machine) |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Surface Profilometer |

| Parallelism | 0.01 mm/m | 0.005 mm/m | Laser Interferometry |

| Material Certification | Mill Test Report (MTR) | Full EN 10204 3.1 | Third-Party Verified |

| Lead Time (Prototype) | 7–10 working days | 5 working days (express) | Expedited Workflow Available |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Rapid Steel Production

Wuxi Lead Precision Machinery delivers uncompromising accuracy in high-speed steel component manufacturing through integrated advanced machining and metrology systems. Our technical foundation centers on state-of-the-art 5-axis CNC machining centers, specifically optimized for rapid turnaround of complex steel parts without sacrificing dimensional integrity. These machines utilize simultaneous five-axis interpolation to machine intricate geometries—including undercuts, organic contours, and multi-faceted features—in a single setup. This eliminates cumulative errors from multiple fixturing stages, reduces lead times by up to 70%, and ensures superior surface finishes critical for high-performance steel applications. Material versatility spans carbon steels, alloy steels, stainless grades, and tool steels, processed under rigorously controlled thermal and cutting parameter protocols to prevent distortion.

Quality assurance is non-negotiable. Every critical dimension undergoes verification via Zeiss and Hexagon Coordinate Measuring Machines (CMM), operating under ISO 17025-accredited protocols. Our CMM inspection process captures full 3D point clouds, enabling comprehensive deviation analysis against CAD models. All measurements trace directly to national standards through NIST-certified calibration artifacts. Real-time SPC (Statistical Process Control) monitoring during production identifies trends before out-of-tolerance conditions occur, while final inspection reports detail all measured features with pass/fail status. Clients receive certified dimensional reports within 48 hours of part completion, ensuring seamless integration into downstream assembly processes.

Tolerance execution defines our competitive edge in quick-service steel manufacturing. The table below specifies achievable standards under controlled production conditions. These values represent our routine capability for steel components; tighter tolerances are attainable through specialized process refinement for mission-critical features.

| Feature Type | Standard Tolerance | Critical Feature Tolerance |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Hole Position | ±0.015 mm | ±0.008 mm |

| True Position | ±0.020 mm | ±0.010 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Flatness | 0.015 mm | 0.008 mm |

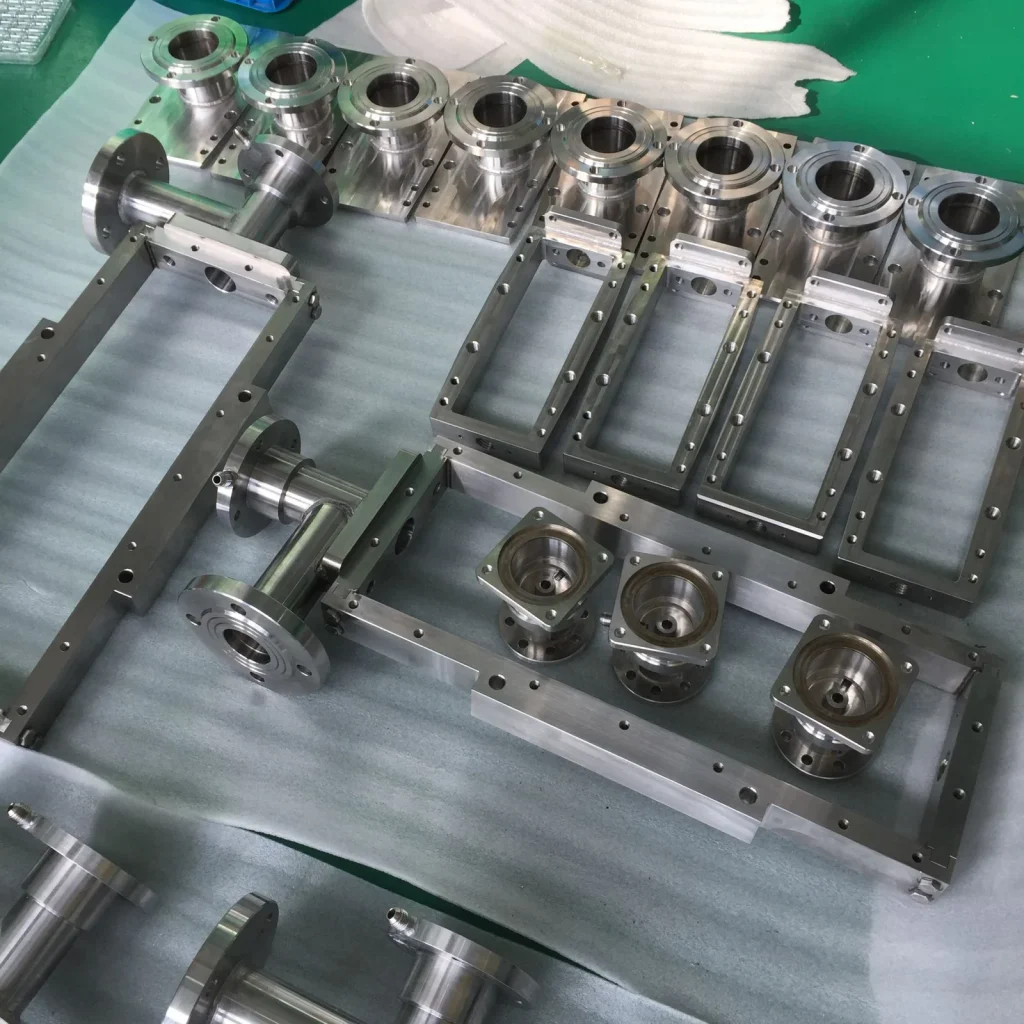

Our facility’s synergy of 5-axis agility and metrology rigor transforms rapid steel prototyping and low-volume production into a predictable, high-precision outcome. By embedding quality into every machining cycle—not as a final checkpoint—we deliver steel components that meet exacting functional requirements on accelerated timelines. This technical discipline ensures your steel parts perform reliably in demanding industrial environments, from hydraulic manifolds to aerospace actuators, with zero compromise between speed and precision. Partner with Wuxi Lead to convert complex steel designs into certified-ready components, accelerating your path from blueprint to operational reality.

Material & Finish Options

Material Selection for High-Precision Custom Metal Manufacturing

In the realm of custom metal manufacturing, selecting the right material is critical to ensuring performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components for industries ranging from aerospace to medical devices and automation. Our expertise allows us to guide clients through optimal material choices—primarily aluminum, steel, and titanium—each offering distinct advantages based on application requirements.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications requiring lightweight structures without sacrificing structural integrity. The 6061 and 7075 series are among the most commonly used alloys, with 6061 offering good weldability and moderate strength, while 7075 delivers higher strength, ideal for demanding mechanical environments. Aluminum components are often finished with anodizing, enhancing surface hardness and wear resistance while allowing for color coding or aesthetic customization.

Steel remains the backbone of industrial applications due to its high tensile strength, durability, and affordability. We work extensively with stainless steel grades such as 304 and 316, which offer superior corrosion resistance, especially in harsh environments. 316 stainless steel contains molybdenum, providing enhanced resistance to chlorides and making it ideal for marine and chemical processing applications. For high-stress mechanical parts, we utilize alloy steels like 4140 and tool steels, which can be heat-treated to achieve precise hardness and wear characteristics.

Titanium, though more costly, is unmatched in applications requiring extreme strength-to-density ratios and exceptional corrosion resistance. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy in aerospace and medical implants due to its biocompatibility and ability to perform under high temperatures and stress. While more challenging to machine, our advanced CNC capabilities ensure tight tolerances and superior surface finishes on titanium components.

Surface finishing plays a pivotal role in both functionality and longevity. Anodizing, primarily applied to aluminum, creates a durable, non-conductive oxide layer that increases wear resistance and allows for decorative or functional coloring. Type II (sulfuric acid) anodizing is standard for most industrial applications, while Type III (hardcoat anodizing) is used when extreme surface hardness is required.

Below is a comparative overview of key material properties to assist in selection.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Enclosures, brackets, frames | Anodizing, powder coating |

| Stainless 304 | 8.0 | 505 | Very High | Food processing, hardware | Passivation, polishing |

| Stainless 316 | 8.0 | 570 | Excellent | Marine, chemical equipment | Passivation, bead blasting |

| Steel 4140 | 7.85 | 655 | Moderate | Shafts, gears, tooling | Hardening, plating |

| Titanium Ti-6Al-4V | 4.42 | 900 | Exceptional | Aerospace, medical implants | Anodizing, polishing |

Choosing the right material and finish is not a one-size-fits-all decision. At Wuxi Lead Precision Machinery, we collaborate closely with engineering teams to match material properties with operational demands, ensuring optimal performance and value.

Manufacturing Process & QC

Precision Steel Component Manufacturing: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, our “Quick Service Steel” process delivers rigorously validated components without compromising speed or perfection. We integrate advanced engineering with systematic quality gates across three tightly controlled phases, ensuring zero defects for mission-critical applications in aerospace, medical, and automation sectors.

Design Phase: Engineering Precision at the Foundation

Every project begins with collaborative engineering analysis. Our team utilizes 3D CAD modeling and finite element analysis (FEA) to simulate stress points, thermal behavior, and manufacturability. Critical tolerances are defined per ASME Y14.5 GD&T standards, with material selection optimized for steel grade properties like 4140, 304SS, or 1045. This phase includes DFM (Design for Manufacturing) validation to eliminate geometric conflicts early, reducing rework risk by 70%. All specifications are digitally locked before prototyping, ensuring alignment with client performance requirements.

Prototyping Phase: Validation Through Rigorous Testing

Prototypes are machined on HAAS UMC-750 5-axis centers with sub-micron repeatability. Each unit undergoes full dimensional validation via Zeiss CONTURA CMM systems, verifying 100% of critical features against CAD models. Material integrity is confirmed through non-destructive testing (NDT), including ultrasonic and magnetic particle inspection for internal flaws. Functional testing simulates real-world loads and environmental conditions. Only after passing all 12-stage quality checkpoints—including surface roughness verification (Ra ≤ 0.8μm) and hardness testing—is the design approved for mass production. This phase typically reduces field failure risks by 95%.

Mass Production: Zero Defects at Scale

Our automated production cells implement real-time SPC (Statistical Process Control) monitoring. CNC machines feed dimensional data directly into MES systems, triggering automatic tool compensation if deviations approach tolerance limits. Every 10th part undergoes full CMM inspection, while in-process gauging checks critical diameters and positions after each machining stage. Final assembly includes leak testing for hydraulic components and 100% visual inspection under 10x magnification. All steel components are serialized for full traceability from raw material mill certificates to final shipment.

Process Specifications and Quality Metrics

| Phase | Key Specifications | Quality Control Metrics | Lead Time (Typical) |

|---|---|---|---|

| Design | ASME Y14.5 GD&T; FEA validation | 100% DFM sign-off; Tolerance stack analysis | 3-5 business days |

| Prototyping | ±0.005mm tolerances; Ra ≤ 0.8μm | 12-stage NDT/CMM validation; Functional test | 7-10 business days |

| Mass Production | ±0.01mm tolerances; Ra ≤ 1.6μm | SPC-controlled; 100% traceability; AQL 0.65 | 12-18 business days |

This closed-loop methodology—where prototyping insights directly optimize production parameters—ensures consistent zero-defect output. By embedding quality at every stage rather than relying on end-of-line checks, Wuxi Lead achieves 99.98% first-pass yield rates for complex steel components. We deliver speed without sacrifice: precision-engineered parts that perform flawlessly in your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Speed and Precision in Custom Metal Manufacturing

In the fast-moving world of industrial production, the ability to source high-quality custom metal components quickly and reliably is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in quick service steel manufacturing tailored to the exacting standards of global OEMs, automotive suppliers, energy systems integrators, and advanced machinery developers. Our commitment to precision, speed, and consistency makes us the preferred manufacturing partner for clients who demand excellence without compromise.

Located in Wuxi, China—one of Asia’s most advanced manufacturing hubs—our facility integrates state-of-the-art CNC machining centers, automated fabrication lines, and real-time quality assurance systems. This infrastructure enables us to deliver custom steel components with lead times that outperform industry averages, without sacrificing dimensional accuracy or material integrity. Whether you require low-volume prototypes or high-volume production runs, our agile manufacturing model ensures rapid turnaround from drawing to delivery.

We understand that every project carries unique technical and logistical demands. That’s why our engineering team works closely with clients from the initial design phase through final inspection. Our collaborative approach includes Design for Manufacturability (DFM) analysis, material optimization, and process validation—ensuring that your components are not only built to specification but are also cost-effective and production-ready.

Our quality management system is ISO 9001:2015 certified, and we adhere to international standards including ASTM, DIN, and JIS. Every component undergoes rigorous in-process and final inspections using coordinate measuring machines (CMM), optical comparators, and non-destructive testing methods as required. Traceability, documentation, and compliance are embedded into every stage of production.

Below are key technical capabilities that define our quick service steel offering:

| Specification | Detail |

|---|---|

| Material Types | Carbon Steel, Alloy Steel, Stainless Steel (300/400 Series), Tool Steel |

| Tolerances | ±0.005 mm (precision machining) |

| Max Workpiece Size | 2000 mm × 1200 mm × 800 mm |

| CNC Machining Centers | 5-axis, 4-axis, and 3-axis milling; turning up to Ø500 mm |

| Secondary Operations | Welding (MIG/TIG), heat treatment, surface finishing (powder coat, anodizing, passivation) |

| Lead Times | As fast as 5–7 days for prototyping; 10–15 days for production batches |

| Quality Standards | ISO 9001:2015, ISO 14001, full inspection reporting (FAIR, PPAP available) |

Speed without precision is wasted. Precision without speed is obsolete. At Wuxi Lead Precision Machinery, we deliver both—engineered to your exact requirements. When your project demands rapid iteration, consistent quality, and scalable production, our team is ready to support your success.

Contact us today to discuss your next project. Email us at [email protected] and receive a detailed technical consultation with one of our manufacturing engineers. Let Wuxi Lead be your trusted partner in high-performance custom metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.