Technical Contents

Engineering Guide: Quick Parts 3D Printing

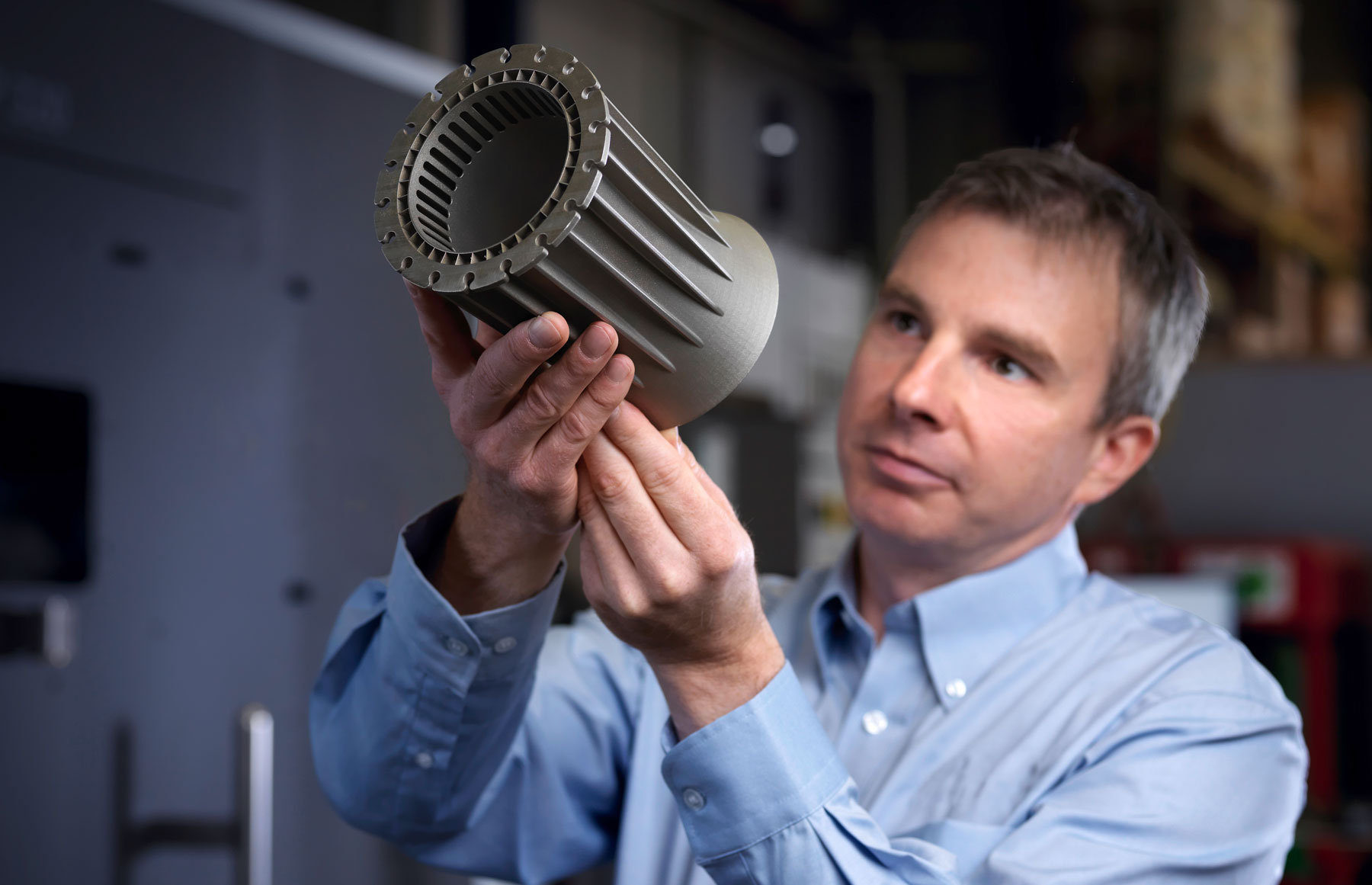

Engineering Insight: Precision as the Foundation of Rapid Metal Additive Manufacturing

In high-stakes industries where component failure is not an option, the term quick parts 3D printing must never compromise dimensional integrity. At Wuxi Lead Precision Machinery, we define “quick” not merely by lead time acceleration but by delivering flight-certified and mission-critical metal components with uncompromised accuracy—proven through deployments in Olympic infrastructure projects and Tier-1 military supply chains. Speed without precision creates costly rework; true rapid manufacturing integrates metrology-grade tolerances from the first layer.

The misconception that additive speed sacrifices accuracy stems from early-generation systems and unvetted service providers. Modern metal AM—when executed with aerospace-grade process control—achieves tolerances rivaling CNC machining. Critical applications like turbine blades or satellite couplings demand ±0.05 mm geometric accuracy and surface finishes below Ra 3.2 μm as-built, eliminating secondary operations that negate time savings. Our in-house experience with Inconel 718 for hypersonic test rigs and Ti-6Al-4V for paralympic prosthetics demonstrates that precision enables speed: validated first-article parts bypass iterative corrections, compressing development cycles by 60–70%.

Below are key specifications achievable with our certified metal AM processes for mission-critical components:

| Parameter | Capability | Industry Standard Comparison |

|---|---|---|

| Material Range | Ti-6Al-4V, Inconel 718, 17-4PH, AlSi10Mg | Matches aerospace casting alloys |

| Dimensional Tolerance | ±0.05 mm (critical features) | Within CNC milling tolerances |

| Surface Roughness | As-built Ra 2.5–4.0 μm | Reduces post-processing time by 50% |

| Lead Time | 5–10 days (from CAD to NDT-certified part) | 3–5x faster than traditional tooling |

| Certification | ISO 13485, AS9100, MIL-STD-883 | Full traceability to raw material |

Achieving this requires embedding precision at every phase. Our process begins with topology-optimized CAD models validated via finite element analysis (FEA), followed by layer-by-layer thermal simulation to preempt distortion. In-build monitoring tracks melt pool dynamics at 1,000 fps, while post-process coordinate measuring machine (CMM) validation ensures compliance with ASME Y14.5 geometric dimensioning standards. Crucially, we treat support structure design as a precision engineering task—not an afterthought—minimizing residual stress in thin-walled features down to 0.3 mm thickness.

For B2B clients, the ROI of precision-driven rapid manufacturing is quantifiable: a defense contractor reduced drone actuator validation from 14 weeks to 9 days using our certified AM parts, with zero field failures across 200+ units. When lead time compression meets uncompromised quality, “quick” transitions from a marketing claim to a strategic advantage. At Lead Precision, we engineer speed through science—not shortcuts. Your mission-critical timeline starts with a single, perfect part.

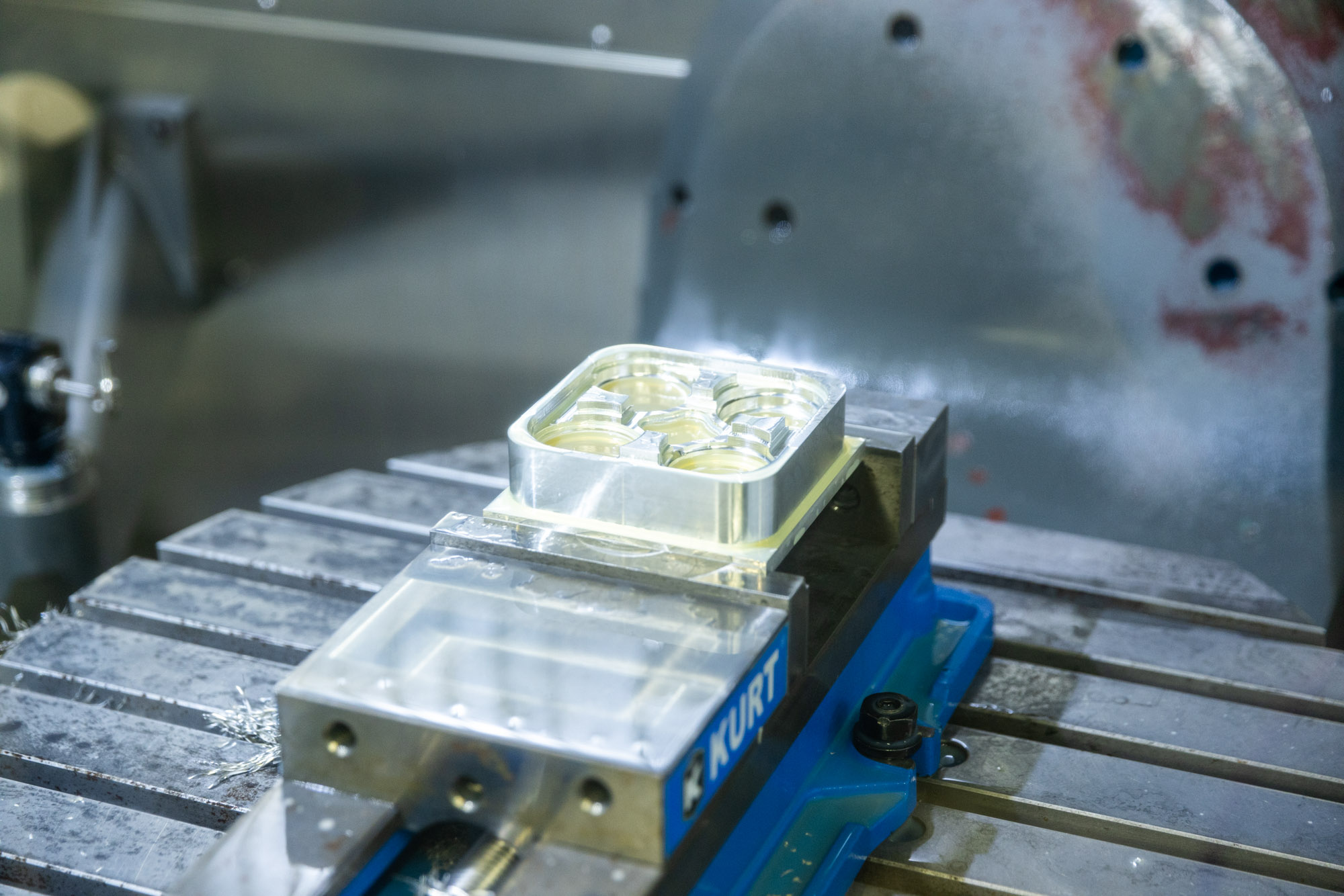

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for precision, repeatability, and performance in high-demand industrial applications. At the core of our technical capabilities is a modern fleet of 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility for machining intricate contours, deep cavities, and organic forms that are common in aerospace, medical, and energy sector components. Our machines are maintained to OEM specifications and operated by certified machinists with over a decade of experience in high-tolerance metal fabrication.

All machining operations are supported by a comprehensive digital workflow, starting from 3D CAD model analysis through to toolpath optimization using industry-leading CAM software. This ensures efficient material removal, minimized tool wear, and consistent part quality across both prototype and production runs. We work with a broad range of engineering-grade metals, including titanium alloys, Inconel, aluminum 7075-T6, stainless steels (316L, 17-4PH), and tool steels, accommodating tight lead times without compromising dimensional integrity.

Quality control is integrated at every stage of production. Our metrology laboratory is anchored by a Zeiss DuraMax Coordinate Measuring Machine (CMM), which performs full-dimensional inspection with a measurement accuracy of ±0.0001″ (±0.0025 mm). Each critical feature is verified against the original engineering drawing, with inspection reports available upon request. First-article inspections, in-process checks, and final audits ensure compliance with ISO 9001:2015 standards and customer-specific requirements. Surface roughness is routinely measured using portable profilometers, with typical finishes achieving Ra 1.6 µm or better, depending on design intent.

Our commitment to precision is reflected in the tolerances we consistently achieve across diverse part configurations and materials. Below is a summary of our standard and precision capability ranges.

| Feature Type | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm | Up to 300 mm |

| Linear Dimensions (in) | ±0.002 in | ±0.0004 in | Up to 12 in |

| Positional Tolerance | ±0.05 mm | ±0.01 mm | Relative to datum |

| Hole Diameter (reamed) | ±0.025 mm | ±0.005 mm | Through or blind |

| Surface Flatness | 0.05 mm | 0.01 mm per 100 mm | Measured via CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined or post-processed |

| Angular Features | ±0.1° | ±0.05° | Five-axis interpolated |

These specifications are maintained through continuous process validation, environmental control in machining zones, and routine calibration of all measurement equipment. Wuxi Lead Precision Machinery is equipped to support rapid turnaround for quick parts 3D printing integration with secondary CNC finishing, ensuring prototypes and production units meet the highest benchmarks in dimensional accuracy and functional performance.

Material & Finish Options

Material Selection for Metal 3D Printed Quick Parts

Selecting the optimal material is critical for achieving functional performance, durability, and cost-efficiency in metal 3D printed components. At Wuxi Lead Precision Machinery, our industrial-grade metal additive systems produce near-net-shape parts requiring minimal post-processing. Understanding the core properties of Aluminum, Steel, and Titanium alloys ensures your rapid prototypes or end-use parts meet exacting application demands from the outset. Material choice directly impacts mechanical behavior, thermal response, weight, corrosion resistance, and suitability for secondary finishing like anodizing.

Aluminum Alloys

Aluminum alloys, particularly AlSi10Mg, dominate aerospace and automotive applications requiring lightweight strength. This alloy offers excellent castability inherent to the powder bed fusion process, good thermal conductivity, and moderate strength-to-weight ratio. It is ideal for complex brackets, heat exchangers, and fluid system components where weight reduction is paramount. Note that aluminum is the primary candidate for anodizing surface treatments to enhance wear and corrosion resistance.

Stainless Steel Alloys

Stainless steels, especially 17-4 PH and 316L, deliver superior strength, hardness, and corrosion resistance across demanding environments. 17-4 PH provides high yield strength achievable through precipitation hardening, making it suitable for hydraulic fittings, valves, and tooling inserts. 316L offers exceptional resistance to marine and chemical exposure, critical for medical implants and marine hardware. These steels generally do not receive anodizing; alternative finishes like passivation or electropolishing are standard.

Titanium Alloys

Titanium Grade 5 (Ti6Al4V) is the benchmark for high-performance applications demanding exceptional strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosion. Its use is prevalent in aerospace structural components, medical implants, and high-end motorsport parts. While inherently corrosion-resistant, titanium parts typically undergo machining or bead blasting for final surface refinement rather than anodizing.

Anodizing for Aluminum Parts

Anodizing is an electrochemical process exclusively applied to aluminum 3D printed parts post-build. It creates a durable, non-conductive oxide layer significantly improving surface hardness, wear resistance, and corrosion protection. Type II (Sulfuric Acid) anodizing provides good general-purpose protection and dye receptivity for color coding. Type III (Hardcoat) anodizing delivers maximum abrasion resistance for high-wear applications, though dimensional tolerances require careful pre-anodize machining allowance planning. Steel and titanium parts utilize different finishing protocols.

Material properties guide final part performance. The following table summarizes key mechanical characteristics for common alloys processed on our EOS and SLM systems.

| Material | Typical Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Applications |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 400 – 450 | 250 – 300 | 5 – 10 | Lightweight brackets, heat sinks |

| Stainless Steel | 17-4 PH | 1000 – 1300 | 850 – 1100 | 10 – 15 | Hydraulic components, tooling |

| Stainless Steel | 316L | 550 – 650 | 250 – 400 | 35 – 45 | Medical devices, marine hardware |

| Titanium | Ti6Al4V | 900 – 1000 | 830 – 900 | 10 – 15 | Aerospace fittings, medical implants |

Partner with Wuxi Lead Precision Machinery to leverage our material science expertise and advanced metal 3D printing capabilities. We ensure your quick parts selection aligns precisely with functional requirements and production timelines.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process begins with a rigorous design phase that integrates advanced CAD modeling and DFM (Design for Manufacturability) analysis. Our engineering team collaborates directly with clients to refine geometries, optimize material usage, and ensure dimensional stability under operational loads. Every design is validated through finite element analysis (FEA) and thermal stress simulation, ensuring performance under real-world conditions. This stage is critical to eliminating downstream defects and establishing a zero-defect manufacturing pathway. We support native file formats including STEP, IGES, and Parasolid, enabling seamless integration with global engineering workflows.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move to rapid prototyping using high-precision 3D printing technologies, including selective laser melting (SLM) and direct metal laser sintering (DMLS). These additive methods allow for the creation of fully dense metal parts in materials such as 316L stainless steel, Inconel 718, Ti-6Al-4V, and AlSi10Mg. Prototypes are manufactured with the same material specifications and post-processing standards as final production units, enabling accurate functional testing. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and is subject to non-destructive testing (NDT) when required. This phase ensures design integrity, fit, and performance before transitioning to mass production.

Mass Production: Consistency, Quality, and Zero Defects

Our mass production phase leverages automated 3D printing cells, in-process monitoring systems, and a closed-loop quality control protocol to maintain absolute consistency. Each build is monitored in real time using melt pool analysis and layer-wise imaging to detect anomalies immediately. Post-build, parts undergo stress relieving, support removal, and precision machining where necessary. Surface treatments such as shot peening, polishing, or passivation are applied per customer specifications. Final inspection includes full geometric reporting, material certification, and, when required, microstructure analysis. Our quality management system is ISO 9001 certified, with traceability maintained at the serial level for every component.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Supported Materials | 316L, 17-4PH, Inconel 718, Ti-6Al-4V, AlSi10Mg, Cobalt Chrome, Tool Steel (H13, M2) |

| Layer Thickness | 20–50 μm |

| Build Envelope | Up to 250 x 250 x 300 mm |

| Dimensional Accuracy | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processing Options | CNC Machining, Heat Treatment, HIP, Polishing, Passivation, Coating |

| Quality Standards | ISO 9001, Full First Article Inspection (FAI), CMM & NDT Reports |

Through seamless integration of design validation, iterative prototyping, and tightly controlled mass production, Wuxi Lead ensures every metal component meets the highest standards of precision, reliability, and performance—delivering true zero-defect manufacturing for critical industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Speed and Precision in Metal 3D Printing

In high-stakes manufacturing environments, delays in prototype or low-volume production cripple innovation cycles and market responsiveness. Traditional metal fabrication routes often introduce weeks of waiting, incompatible with the urgent demands of aerospace validation, medical device iteration, or complex industrial tooling. Wuxi Lead Precision Machinery exists to eliminate this bottleneck. We specialize in rapid, industrial-grade metal additive manufacturing, transforming your critical CAD files into fully functional, precision-engineered metal components within days, not months. Our integrated facility in Wuxi, strategically located near Shanghai port, combines cutting-edge technology with rigorous quality control to deliver parts that meet the most stringent industry standards, directly supporting your accelerated development and production schedules.

Our Quick Parts 3D Printing service leverages state-of-the-art metal laser powder bed fusion systems operating under ISO 9001-certified processes. We focus exclusively on producing end-use metal components where speed, material integrity, and dimensional accuracy are non-negotiable. This isn’t prototyping; it’s rapid production for demanding applications. The table below outlines our core technical capabilities for immediate project assessment:

| Specification | Capability |

|---|---|

| Materials | Stainless Steel 316L, 17-4PH; Titanium Ti6Al4V; Inconel 718; Aluminum AlSi10Mg; Maraging Steel |

| Build Volume | 250 x 250 x 325 mm (Standard Platform) |

| Typical Tolerance | ±0.05 mm to ±0.1 mm (Feature dependent) |

| Surface Roughness | As-built: Ra 12-25 µm; Post-processed: Ra < 3.2 µm |

| Standard Lead Time | 5-7 Business Days (From Approved CAD to Shipment) |

What distinguishes Lead Precision is our engineering-led approach. Our senior CNC and additive manufacturing engineers collaborate directly with your team from the initial design review through to final inspection. We proactively identify potential manufacturability issues, optimize support structures for minimal post-processing, and ensure geometric complexity is leveraged effectively – not just accommodated. This deep technical partnership guarantees parts arrive ready for immediate testing or integration, avoiding costly rework cycles. Our facility features in-house CNC finishing, precision metrology (including CMM verification), and material certification, providing a single-source solution for parts requiring tight tolerances and certified material properties. We understand that “quick” is meaningless without “precise” and “reliable” in mission-critical sectors.

Stop letting slow fabrication processes dictate your project timelines. Wuxi Lead Precision Machinery delivers the speed of additive manufacturing fused with the uncompromising quality standards of traditional precision engineering. Whether you require a single complex turbine blade for validation, a set of customized surgical instrument components, or low-volume production tooling, our team ensures your metal parts meet exact specifications on an accelerated schedule. The efficiency gains and risk reduction for your development pipeline are immediate and measurable.

Send your CAD file today to Contact [email protected]. Our engineering team will provide a rapid manufacturability assessment and a firm quote within 24 business hours, initiating your path to faster, more reliable metal part production. Partner with precision. Partner with speed. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.