Technical Contents

Engineering Guide: Quality Machine And Fabrication

Engineering Insight: The Non-Negotiable Imperative of Precision in Sheet Metal Fabrication

In high-stakes sheet metal fabrication, precision transcends mere specification; it is the foundational pillar of functional integrity, assembly success, and ultimate product lifecycle performance. Tolerances measured in fractions of a millimeter directly impact structural stability, component fit, operational efficiency, and safety. Deviations, however seemingly minor, cascade into costly rework, production delays, field failures, and reputational damage. For industries like aerospace, defense, medical technology, and advanced energy systems, where Wuxi Lead Precision Machinery operates, precision is not an option—it is a non-negotiable engineering requirement mandated by stringent regulatory frameworks and the relentless demands of performance-critical applications.

Wuxi Lead Precision Machinery has honed its mastery of micron-level accuracy through decades of delivering components where failure is inconceivable. Our engineering teams possess deep, proven experience meeting the exacting standards required for Olympic-grade sporting equipment and critical military hardware. These projects demand absolute consistency, traceable quality control, and the ability to transform complex, high-tolerance designs into flawless physical reality under rigorous certification protocols. This heritage instills a culture where precision is engineered into every process, from initial material selection through final inspection, ensuring parts perform reliably in the most demanding environments.

Achieving this level of precision requires more than advanced machinery; it demands integrated engineering expertise. Our approach begins at the design phase, leveraging DFM analysis to optimize manufacturability while maintaining critical tolerances. This proactive collaboration prevents costly iterations and ensures the final component meets both form and function requirements. The table below outlines the core capabilities underpinning our precision sheet metal fabrication:

| Capability | Specification Range | Key Performance Indicator |

|---|---|---|

| Laser Cutting Tolerance | ±0.05 mm to ±0.1 mm | Material thickness dependent |

| CNC Punching Accuracy | ±0.03 mm | Positional repeatability |

| Press Brake Forming | ±0.1° angular tolerance | Bend radius consistency |

| Material Thickness Range | 0.5 mm to 6.0 mm (Stainless, Carbon, Al) | Process optimized per material |

| Critical Dimension Control | Verified via CMM & Optical Measurement | Full traceability to ISO 9001 |

The true value of precision fabrication lies not just in hitting a number on a drawing, but in delivering predictable, repeatable results that enable seamless integration into complex assemblies. It minimizes waste, accelerates time-to-market, and provides the confidence that every component will perform as engineered, cycle after cycle. For discerning manufacturers, partnering with a fabricator possessing demonstrable precision pedigree—validated through projects serving the highest echelons of sport and defense—is essential for mitigating risk and achieving uncompromised product excellence. Precision, rigorously engineered and consistently delivered, remains the definitive hallmark of quality in advanced sheet metal fabrication.

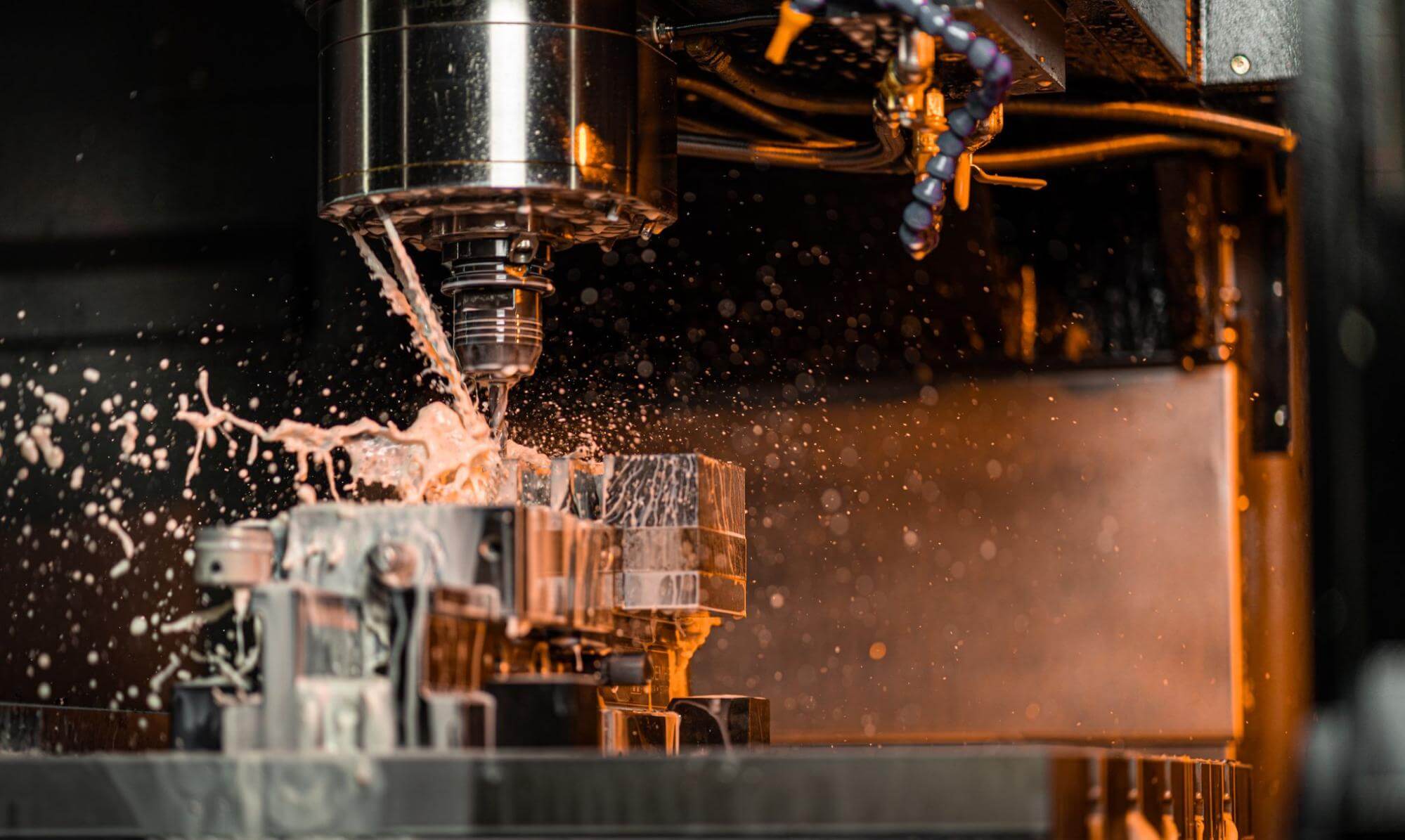

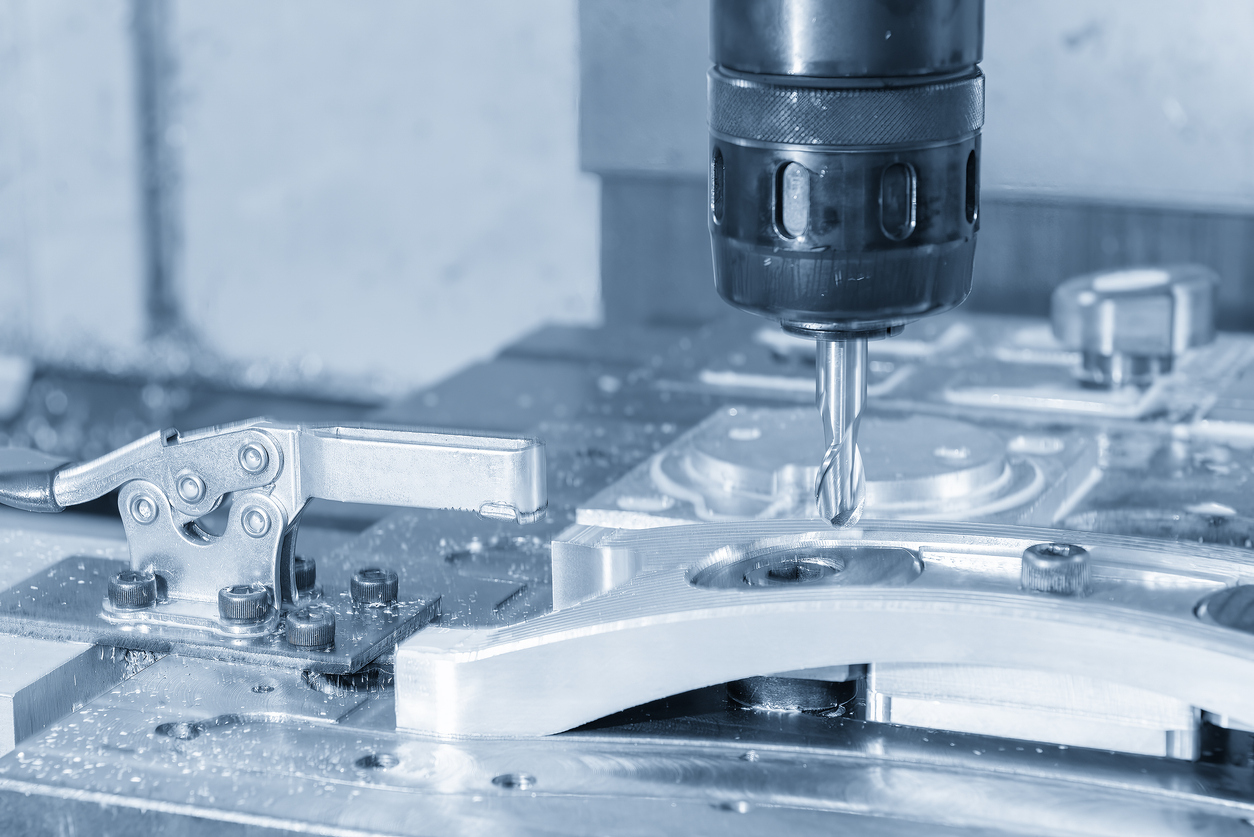

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, which enable complex geometries, tight tolerances, and superior surface finishes across a wide range of metals. These multi-axis platforms provide simultaneous movement across five planes, allowing for intricate part programming and reduced setup cycles. This ensures faster turnaround times without compromising dimensional accuracy or structural integrity, making our processes ideal for aerospace, medical, energy, and automation sectors where component reliability is critical.

Our fabrication workflow integrates precision cutting, bending, welding, and finishing operations, all supported by a comprehensive quality control infrastructure. Every stage of production adheres to ISO 9001 standards, with real-time monitoring and documentation to ensure full traceability. Central to our quality assurance is the use of Coordinate Measuring Machine (CMM) inspection, which provides micron-level verification of part dimensions and geometric features. This metrology-grade validation ensures that all components meet or exceed design specifications and industry compliance requirements.

We process a wide range of materials including stainless steel, aluminum, carbon steel, copper, and specialty alloys, supporting both low-volume prototypes and high-volume production runs. Our 5-axis CNC systems eliminate the need for multiple fixtures, minimizing human error and enhancing consistency across batches. Advanced CAD/CAM software enables seamless translation from design to execution, ensuring optimal toolpaths and material utilization.

The following table outlines the standard technical specifications and tolerances achievable through our sheet metal fabrication and 5-axis CNC machining processes:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positional Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Angular Tolerance | ±0.1° |

| Hole Position Tolerance | ±0.02 mm |

| Feature-to-Feature Tolerance | ±0.03 mm |

| Edge Straightness | 0.05 mm per 100 mm length |

| Flatness | 0.1 mm per 300 mm² |

All fabricated components undergo rigorous in-process and final inspections using CMM, optical comparators, and laser measurement tools. This ensures conformity to GD&T (Geometric Dimensioning and Tolerancing) standards and customer-specific blueprints. Wuxi Lead Precision Machinery combines advanced equipment, skilled engineering, and a disciplined quality system to deliver fabricated components that meet the highest benchmarks in performance and precision.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally impacts the performance, cost, and manufacturability of precision sheet metal components. At Wuxi Lead Precision Machinery, we guide clients through critical trade-offs between mechanical properties, environmental resistance, and production efficiency. Aluminum, steel, and titanium each serve distinct high-end applications, while finishes like anodizing enhance durability and aesthetics. Understanding these options ensures optimal part lifecycle and value.

Aluminum Alloys dominate aerospace, electronics, and medical sectors due to their exceptional strength-to-weight ratio and thermal conductivity. 6061-T6 offers balanced weldability and moderate strength for structural frames, while 5052-H32 excels in marine environments with superior corrosion resistance. Aluminum’s low density reduces shipping costs and energy consumption in dynamic assemblies. However, its lower hardness necessitates protective finishes for wear-prone surfaces.

Steel Variants provide unmatched tensile strength and cost efficiency for industrial machinery and heavy equipment. Cold-rolled steel (CRS) ensures tight tolerances for precision brackets, whereas 304 and 316 stainless steels deliver critical corrosion resistance in food processing or chemical handling. Note that austenitic stainless grades (e.g., 316) work-harden aggressively during CNC bending, requiring specialized tooling and slower feed rates to prevent cracking.

Titanium Alloys, particularly Grade 5 (Ti-6Al-4V), are indispensable for extreme environments like aerospace turbines or biomedical implants. Its biocompatibility, near-immunity to saltwater corrosion, and strength at high temperatures justify premium costs. Yet titanium’s low thermal conductivity challenges machining—it demands rigid CNC setups, sharp carbide tools, and controlled speeds to avoid work hardening and tool galling. Lead times may extend 20–30% versus aluminum due to processing complexity.

Anodizing: The Essential Aluminum Finish

Anodizing transforms aluminum’s surface into a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing offers economical corrosion and wear resistance with dyeing capabilities for branding. For mission-critical parts, Type III (hardcoat) anodizing delivers 50–100 μm thickness, doubling surface hardness to 60 HRC—ideal for hydraulic components or military hardware exposed to abrasion. Both types improve paint adhesion but require precise voltage control to maintain dimensional tolerances.

Comparative Material Specifications

| Property | 6061-T6 Aluminum | 304 Stainless Steel | Grade 5 Titanium |

|---|---|---|---|

| Tensile Strength (MPa) | 310 | 585 | 900 |

| Yield Strength (MPa) | 276 | 205 | 830 |

| Density (g/cm³) | 2.7 | 8.0 | 4.4 |

| Corrosion Resistance | Moderate | Excellent | Exceptional |

| Machinability Rating | Excellent | Good | Poor |

| Typical Anodizing | Type II/III | Not Applicable | Not Applicable |

Material selection must align with functional demands and production realities. Wuxi Lead’s engineering team evaluates your application’s stress points, environmental exposure, and volume requirements to recommend the optimal material-finish combination. We leverage advanced CNC capabilities—including 5-axis milling and laser cutting—to overcome inherent challenges in titanium or stainless steel, ensuring zero-compromise quality. Consult our specialists early in design to avoid costly iterations and accelerate time-to-market.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, repeatability, and zero-defect delivery. We integrate advanced technology with rigorous quality assurance to ensure every component meets the highest standards of performance and reliability. Our end-to-end workflow spans three critical phases: Design, Prototyping, and Mass Production—each stage meticulously controlled to eliminate variability and ensure consistency.

The process begins with Design, where our engineering team collaborates closely with clients to translate concepts into manufacturable solutions. Utilizing industry-leading CAD/CAM software, we develop detailed 3D models and technical drawings that define material specifications, tolerances, and fabrication sequences. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to optimize structural integrity, reduce material waste, and streamline downstream processes. This phase establishes the foundation for precision, ensuring every dimension aligns with functional requirements.

Prototyping follows design finalization, serving as a physical validation of the engineering model. We employ CNC punching, laser cutting, bending, and welding on sample batches to produce functional prototypes. These are subjected to comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and first-article inspection (FAI) protocols. Dimensional accuracy, surface finish, and assembly fit are rigorously verified. Client feedback is incorporated at this stage, allowing for iterative refinement before committing to full-scale production. This step is critical in mitigating risk and ensuring that the final product performs as intended.

Mass Production leverages automated manufacturing cells, robotic material handling, and real-time process monitoring to achieve high throughput without compromising quality. Each fabrication line is governed by standardized work instructions and statistical process control (SPC) systems that detect deviations before they impact output. In-process inspections occur at key control points—post-cutting, post-bending, and post-welding—to maintain dimensional stability. Final assemblies undergo 100% visual and functional testing, supported by traceability systems that log material lot numbers, machine parameters, and operator data for full auditability.

Our commitment to zero defects is reinforced by ISO 9001-certified quality management practices and continuous improvement methodologies such as Six Sigma and 5S. Every component leaving our facility is not only dimensionally accurate but also consistent across batches, ensuring seamless integration into the client’s end product.

Key production capabilities are summarized below:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance (Standard) | ±0.1 mm |

| Laser Cutting Accuracy | ±0.05 mm |

| Max Part Size | 4000 mm × 2000 mm |

| Bending Tolerance | ±0.2° |

| Welding Processes | MIG, TIG, Spot, Robotic Arc |

| Surface Finishes | Mill, Anodized, Powder Coated, Passivated |

| Quality Standards | ISO 9001, ISO 14001, IATF 16949 |

From initial concept to final shipment, Wuxi Lead Precision Machinery delivers unmatched precision and reliability in sheet metal fabrication—ensuring quality is built into every stage of production.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Precision Sheet Metal Fabrication Authority

In high-stakes industrial manufacturing, component integrity isn’t negotiable. Compromised tolerances, inconsistent finishes, or delayed deliveries erode your production efficiency and reputation. Wuxi Lead Precision Machinery operates at the intersection of engineering rigor and scalable fabrication—where CNC expertise meets uncompromising quality control. We don’t just manufacture parts; we engineer solutions that integrate seamlessly into your assembly line, reducing scrap rates and accelerating time-to-market. Our facility in Wuxi, China, is ISO 9001-certified and equipped with state-of-the-art Amada and Trumpf systems, operated by engineers who speak G-code fluently. When you partner with us, you gain a team that treats your specifications as non-negotiable commitments, not suggestions.

Our technical capabilities are engineered for mission-critical applications across aerospace, medical devices, and industrial automation. We specialize in complex geometries, tight-tolerance bending, and multi-stage assemblies where micron-level accuracy defines success. Unlike generic fabricators, we deploy in-process CMM validation and first-article inspection protocols aligned with AS9100 and ISO 13485 standards. This eliminates guesswork and ensures every batch meets your engineering intent—without costly rework. Below are core specifications defining our precision sheet metal capacity:

| Capability | Lead Precision Specification | Industry Standard Benchmark |

|---|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm | 0.8 mm – 4.0 mm |

| Tolerance Control | ±0.025 mm | ±0.1 mm |

| Max. Punching Force | 300 kN | 200 kN |

| Laser Cutting Accuracy | ±0.01 mm/m | ±0.05 mm/m |

| Surface Roughness (Ra) | ≤0.8 μm | ≤3.2 μm |

This precision is sustained through real-time process monitoring and a closed-loop feedback system between our CNC programmers and shop floor technicians. We proactively identify potential deviations before material is cut—transforming quality assurance from a checkpoint into an embedded workflow. Your technical drawings undergo rigorous manufacturability analysis, with actionable feedback provided within 24 hours to prevent design-for-manufacturing pitfalls.

Choosing a fabrication partner is a strategic decision impacting your product’s reliability and cost structure. At Lead Precision, we prioritize transparency: you receive digital work logs, inspection reports, and production updates via a secure client portal—not opaque email chains. Our engineers collaborate with your R&D team to optimize designs for yield without sacrificing performance, often reducing your total part cost by 18–22% through material utilization and process refinement.

The next step requires no commitment—only clarity. Email Contact [email protected] with your fabrication challenge or engineering package. Within one business day, our applications engineering team will respond with a feasibility assessment, timeline, and actionable recommendations. No generic quotes. No sales scripts. Just precision-engineered solutions, delivered with the technical authority your project demands. Partner with engineers who measure success in microns, not margins.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.