Technical Contents

Engineering Guide: Pvc Moulds

Engineering Insight: The Critical Role of Precision in PVC Moulds

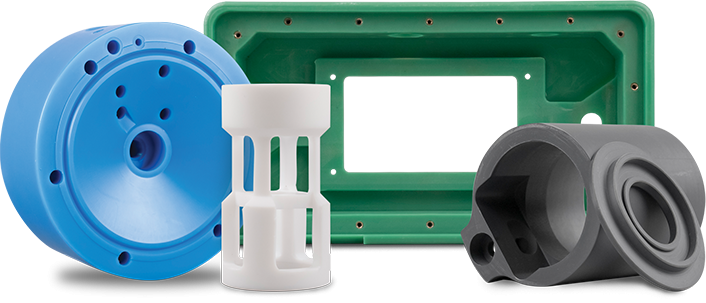

In the realm of custom metal manufacturing, PVC moulds represent a convergence of material science, thermal dynamics, and high-tolerance engineering. These moulds are not merely tools—they are precision instruments that define the dimensional accuracy, surface finish, and structural integrity of the final PVC product. At Wuxi Lead Precision Machinery, we approach PVC mould development with the same rigor applied to aerospace and defense components, ensuring every cavity, runner, and cooling channel meets exacting standards.

Precision in PVC moulds directly influences production efficiency, part consistency, and tool longevity. Even micron-level deviations can lead to flash, warpage, or incomplete filling—defects that compromise performance and increase scrap rates. The challenge is amplified by the thermoplastic behavior of PVC, which exhibits variable flow characteristics under different temperature and pressure conditions. A well-engineered mould must account for thermal expansion, shrinkage rates, and shear-induced degradation, all while maintaining tight tolerances across thousands of cycles.

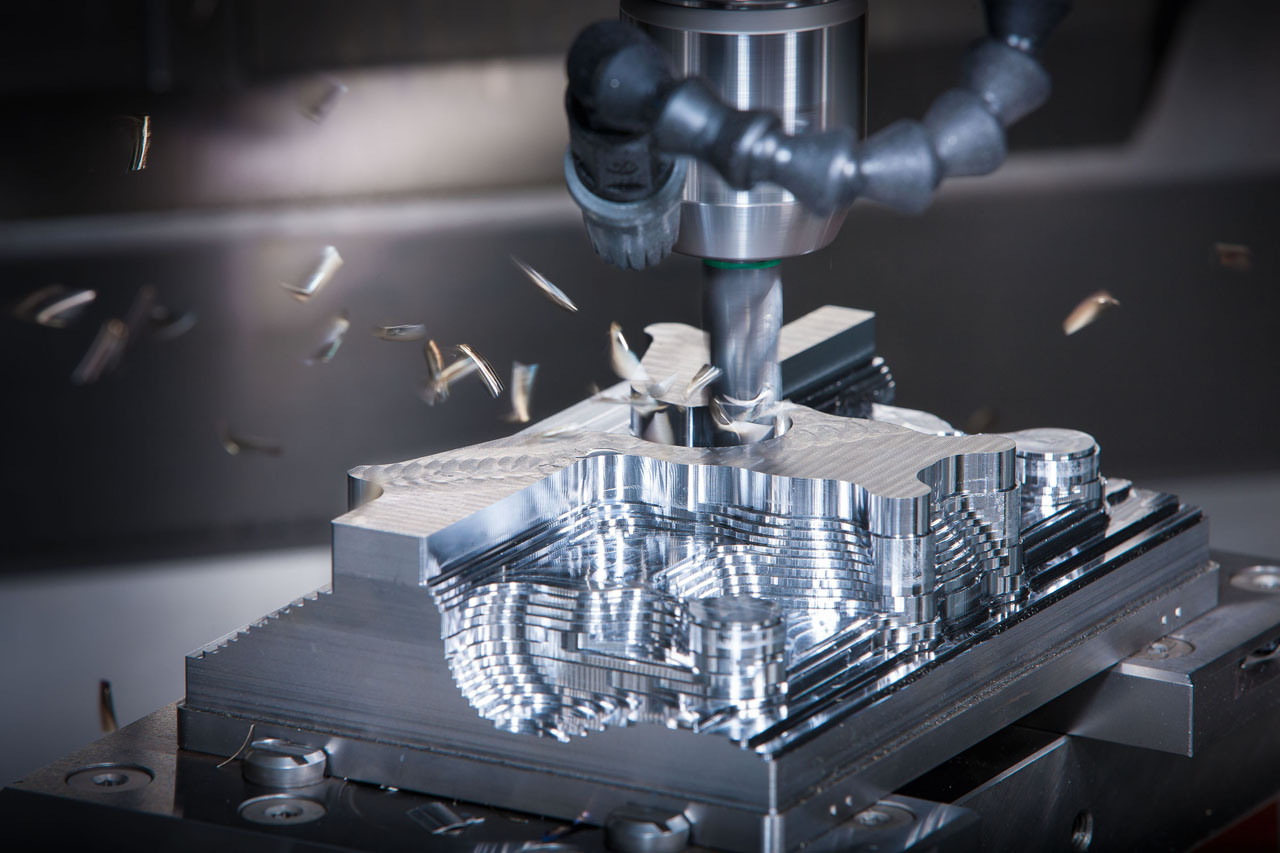

Our engineering team leverages advanced simulation software to model melt flow, cooling uniformity, and stress distribution prior to fabrication. This predictive capability allows us to optimize gate locations, venting, and ejection systems—minimizing trial-and-error during commissioning. CNC machining is performed on HAAS and DMG MORI platforms with sub-micron repeatability, ensuring that the physical tool matches the digital twin with minimal variance.

Wuxi Lead Precision Machinery brings over 15 years of experience in high-demand sectors, including projects supporting Olympic infrastructure developments and military-grade component manufacturing. These engagements demanded zero-defect performance under extreme conditions—standards we now apply to every PVC mould we produce. Whether manufacturing complex window profile dies or large-scale pipe extrusion tooling, our discipline in material selection, surface treatment, and quality validation ensures unmatched reliability.

Our commitment extends beyond delivery. We provide full documentation, including 3D models, tolerance reports, and maintenance guidelines, ensuring seamless integration into our clients’ production ecosystems. Each mould undergoes rigorous in-house testing, including dry runs and first-article inspection, before shipment.

The result is a tool that delivers consistent part quality, reduced downtime, and extended service life—critical advantages in competitive markets where uptime and precision define profitability.

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, S136, H13, Stainless Steel |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished/mirror) |

| Cooling Channel Design | Conformal or straight, CNC drilled or EDM |

| Lead Time | 4–8 weeks (depending on complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), CMM Reports |

| Applications | Window profiles, pipe extrusion, sheet forming, technical components |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for PVC Mould Excellence

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of high-performance PVC mould manufacturing. We specialize in transforming complex geometries into production-ready tooling through advanced metal fabrication processes, ensuring dimensional stability, surface integrity, and extended service life. Our facility integrates cutting-edge equipment with rigorous quality protocols, delivering moulds that consistently achieve tight tolerances and superior part replication for extrusion, injection, and blow moulding applications.

Central to our operation is a dedicated fleet of 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems enable simultaneous multi-axis interpolation, eliminating repositioning errors and achieving intricate contours in a single setup. We machine critical components from premium tool steels (P20, H13, S136) and hardened alloys, maintaining thermal stability through controlled coolant systems and in-process probing. This capability ensures seamless core/cavity matching, optimized cooling channel placement, and precise venting paths—critical factors for minimizing PVC warpage and cycle times. Our programming leverages Siemens NX CAM for adaptive toolpath strategies, reducing tool wear while sustaining surface finishes below Ra 0.4 µm on critical sealing surfaces.

Quality verification is non-negotiable in PVC mould production. Every component undergoes comprehensive metrology using Zeiss CONTURA CMM systems, calibrated to ISO 17025 standards. Our inspection protocol includes full 3D scanning of cavity/core geometry, parting line flatness validation, and cooling circuit integrity checks. Data from CMM reports is directly correlated to CAD models via PolyWorks software, enabling real-time deviation analysis and closed-loop process correction. This eliminates subjective interpretation, guaranteeing that tolerances are met before assembly. Statistical process control (SPC) metrics are maintained for all critical features, providing clients with traceable evidence of conformance.

The table below summarizes our standard tolerance benchmarks for PVC mould components, reflecting industry best practices for dimensional and geometric accuracy:

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Cavity/Core Matching | ±0.005 mm | CMM 3D Scanning |

| Parting Line Flatness | 0.01 mm per 100 mm | Laser Interferometer |

| Cooling Channel Diameter | +0.02 / -0.00 mm | Optical Comparator |

| Ejection Pin Bore | H7 (±0.006 mm) | CMM Probe |

| Surface Finish (Ra) | ≤ 0.4 µm (critical) | Profilometer |

These capabilities directly translate to client value: reduced trial runs, lower scrap rates, and extended mould longevity under aggressive PVC processing conditions. By controlling the full spectrum from material sourcing to final inspection, Wuxi Lead Precision Machinery ensures your PVC moulds perform predictably at scale. We partner with engineers to refine designs for manufacturability, applying decades of moulding science to preempt defects like flash or sink marks. Contact our technical team to discuss how our precision engineering framework can optimize your next PVC tooling project.

Material & Finish Options

Material Selection for High-Performance PVC Moulds

Selecting the appropriate material for PVC moulds is critical to ensuring long-term durability, dimensional accuracy, and production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for demanding industrial applications, and our expertise enables clients to make informed decisions based on operational requirements, production volume, and performance expectations. The three primary materials used in precision mould fabrication—aluminum, steel, and titanium—each offer distinct advantages depending on the application.

Aluminum is widely favored for low- to medium-volume production runs due to its excellent thermal conductivity and ease of machining. Its lightweight nature allows for faster cycle times and reduced wear on moulding equipment. While not as hard as steel or titanium, high-grade aluminum alloys such as 7075-T6 provide sufficient strength and wear resistance for many PVC extrusion and injection applications. Aluminum is particularly effective when rapid prototyping or frequent design iterations are required.

Steel remains the standard for high-volume manufacturing environments. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and longevity under continuous operation. These properties make steel ideal for complex PVC profiles requiring tight tolerances over extended production cycles. While steel moulds have higher initial machining costs and longer lead times, their extended service life often results in lower total cost of ownership for large-scale operations.

Titanium, though less common due to cost and machining complexity, delivers exceptional strength-to-density ratio and corrosion resistance. It is typically reserved for highly corrosive environments or specialized applications where weight reduction and extreme durability are paramount. While titanium moulds are not standard in general PVC processing, they may be considered for niche aerospace or medical-grade polymer applications where contamination control and material integrity are non-negotiable.

Surface finish also plays a crucial role in mould performance. Anodizing is a widely used post-processing technique for aluminum moulds, enhancing surface hardness and providing a protective oxide layer that resists wear and corrosion. Hard anodizing, in particular, can increase surface hardness up to 600 HV, significantly extending tool life. For steel moulds, alternatives such as nitriding or chrome plating are more common, though anodizing remains exclusive to aluminum substrates.

Below is a comparative overview of key material properties relevant to PVC mould performance.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Machinability | Corrosion Resistance |

|---|---|---|---|---|---|

| Aluminum 7075 | 40–45 (T6) | 130 | Prototyping, low-volume production | Excellent | Moderate (improved with anodizing) |

| P20 Steel | 28–32 | 30 | Medium- to high-volume production | Good | Low to moderate |

| H13 Steel | 48–52 | 35 | High-stress, high-temperature cycles | Moderate | Moderate |

| Titanium Grade 5 | 36–41 (equivalent) | 7 | Specialized, high-durability needs | Poor | Excellent |

Material selection must be aligned with production goals, environmental conditions, and lifecycle cost analysis. Wuxi Lead Precision Machinery supports clients in evaluating these factors to deliver optimized, application-specific PVC mould solutions.

Manufacturing Process & QC

PVC Mold Production Process: Engineering Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, our PVC mold production process is engineered for absolute precision and zero defects, critical for high-volume plastic extrusion and injection applications. We integrate advanced engineering with rigorous quality control across three disciplined phases: Design, Prototyping, and Mass Production. This methodology ensures molds deliver consistent part quality, extended service life, and maximum operational efficiency for our clients.

The Design phase forms the bedrock of defect prevention. Our engineering team utilizes integrated CAD/CAM systems (SolidWorks, Siemens NX) to develop 3D models incorporating extensive Design for Manufacturability (DFM) analysis specific to PVC’s thermal and flow characteristics. We meticulously simulate melt flow, cooling dynamics, and structural stresses to identify potential weaknesses—such as weld lines, sink marks, or uneven cooling—before metal is cut. Client collaboration is continuous, ensuring cavity layouts, gating systems, and ejection mechanisms align precisely with part geometry and production requirements. Material selection is optimized based on PVC formulation (rigid, flexible, filled) and production volume, directly impacting wear resistance and thermal stability.

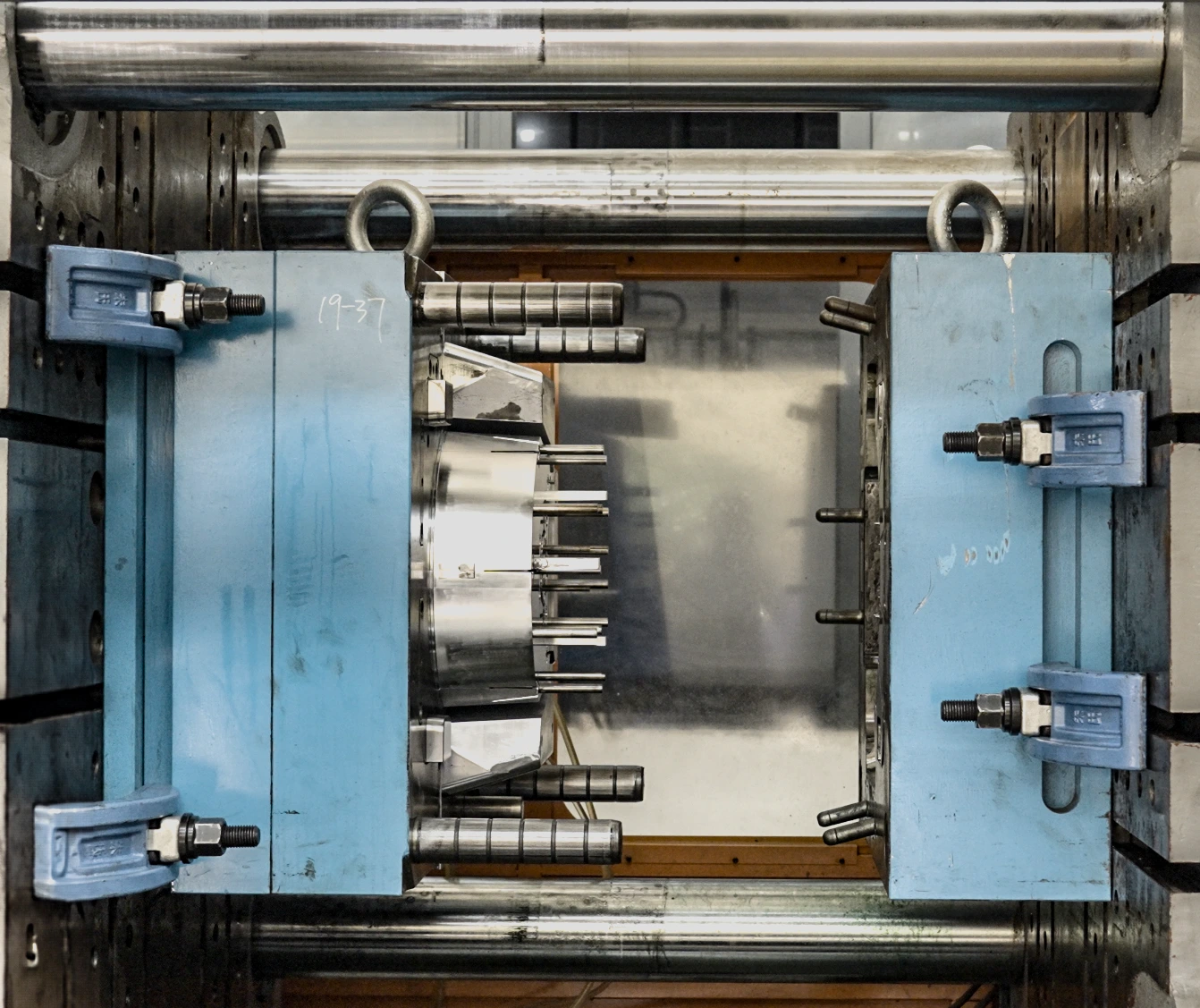

Prototyping transforms validated designs into tangible, testable assets under real-world conditions. We produce functional prototype molds using hardened tool steels, subjecting them to controlled trial runs on client-specified machinery. Every parameter—temperature profiles, injection speed, pressure, cycle time—is meticulously recorded and analyzed against the initial simulation data. Critical dimensions of molded PVC parts undergo 100% inspection via Coordinate Measuring Machines (CMM) and optical comparators, verifying conformity to tolerances and identifying micro-defects invisible to the naked eye. This phase is iterative; minor adjustments to venting, cooling channels, or surface finishes are implemented based on empirical data, not assumptions, eliminating root causes of defects before full-scale production begins.

Mass Production leverages the insights gained from prototyping within a locked-down, monitored workflow. CNC machining centers (Makino, DMG MORI), EDM systems, and precision grinders operate under strict environmental controls, adhering to the finalized toolpath programs and process parameters. Real-time in-process monitoring tracks critical variables like coolant temperature, spindle load, and positional accuracy. Statistical Process Control (SPC) charts analyze dimensional data from sampled parts, enabling immediate corrective action if trends approach tolerance limits. Final molds undergo comprehensive validation: pressure testing, full cavity dimensional certification, and a minimum 500-cycle production run with documented part quality metrics. Only molds meeting our zero-defect standard—verified by signed-off CMM reports and client approval—ship to the production floor.

This closed-loop process, governed by ISO 9001:2015 standards, ensures every Wuxi Lead PVC mold achieves exceptional repeatability and longevity. Below are key capability specifications underpinning our zero-defect commitment.

| Parameter | Standard Capability | Premium Capability | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.002 mm | CMM (Zeiss CONTURA) |

| Surface Roughness (Cavity) | Ra 0.2 µm | Ra 0.05 µm (Mirror Polish) | Profilometer (Mitutoyo) |

| Material Hardness | HRC 48-52 (H13) | HRC 52-54 (Custom Alloys) | Rockwell Hardness Tester |

| Cooling Channel Alignment | ±0.01 mm | ±0.005 mm | Optical Alignment System |

| Run Validation | 500 cycles (Zero Defect) | 2,000 cycles (Zero Defect) | SPC & Visual Inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched PVC Mould Manufacturing Excellence

When precision, durability, and performance define your production standards, your choice of mould manufacturer becomes a strategic decision. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance PVC moulds, engineered to meet the exacting demands of modern extrusion and injection processes. With over 15 years of expertise in advanced CNC machining, metallurgical optimization, and industrial design, we deliver mould solutions that enhance throughput, reduce downtime, and ensure dimensional consistency across thousands of production cycles.

Our engineering team collaborates directly with clients to translate technical requirements into high-precision tooling. Whether you’re producing window profiles, pipe fittings, or complex architectural components, our PVC moulds are built using premium-grade tool steels, corrosion-resistant coatings, and thermally efficient designs that ensure uniform material flow and minimal warpage. Every mould undergoes rigorous quality validation, including CMM inspection, surface roughness testing, and trial-run certification, guaranteeing seamless integration into your existing production line.

We understand that in competitive markets, time-to-market and operational reliability are critical. That’s why we offer end-to-end project management—from 3D modeling and finite element analysis (FEA) to final assembly and global shipping—all under ISO 9001-certified processes. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC centers, wire EDM, and automated polishing systems, enabling us to achieve tolerances as tight as ±0.005 mm and surface finishes down to Ra 0.2 µm.

Below are key technical specifications that define our PVC mould capabilities:

| Specification | Detail |

|---|---|

| Mould Type | Custom PVC Extrusion & Injection Moulds |

| Materials Used | P20, H13, 1.2311 Tool Steels; Stainless Variants Available |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2 – 0.8 µm (Polished, Textured, or Coated) |

| Cooling System Design | Optimized Conformal Cooling Channels |

| Lead Time | 4–8 Weeks (Based on Complexity) |

| Quality Standards | ISO 9001:2015, Full CMM Inspection Report Provided |

| Applications | Window Profiles, Door Frames, Pipes, Siding, Technical Components |

Partnering with Wuxi Lead Precision Machinery means aligning with a team committed to engineering integrity and long-term operational success. We don’t just build moulds—we build partnerships based on precision, transparency, and performance.

For technical consultations or to request a quotation, contact us today at [email protected]. Let us help you elevate your PVC manufacturing capability with custom tooling engineered to lead the industry.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.