Technical Contents

Engineering Guide: Pvc Injection Molding

Engineering Insight: Precision in PVC Injection Molding

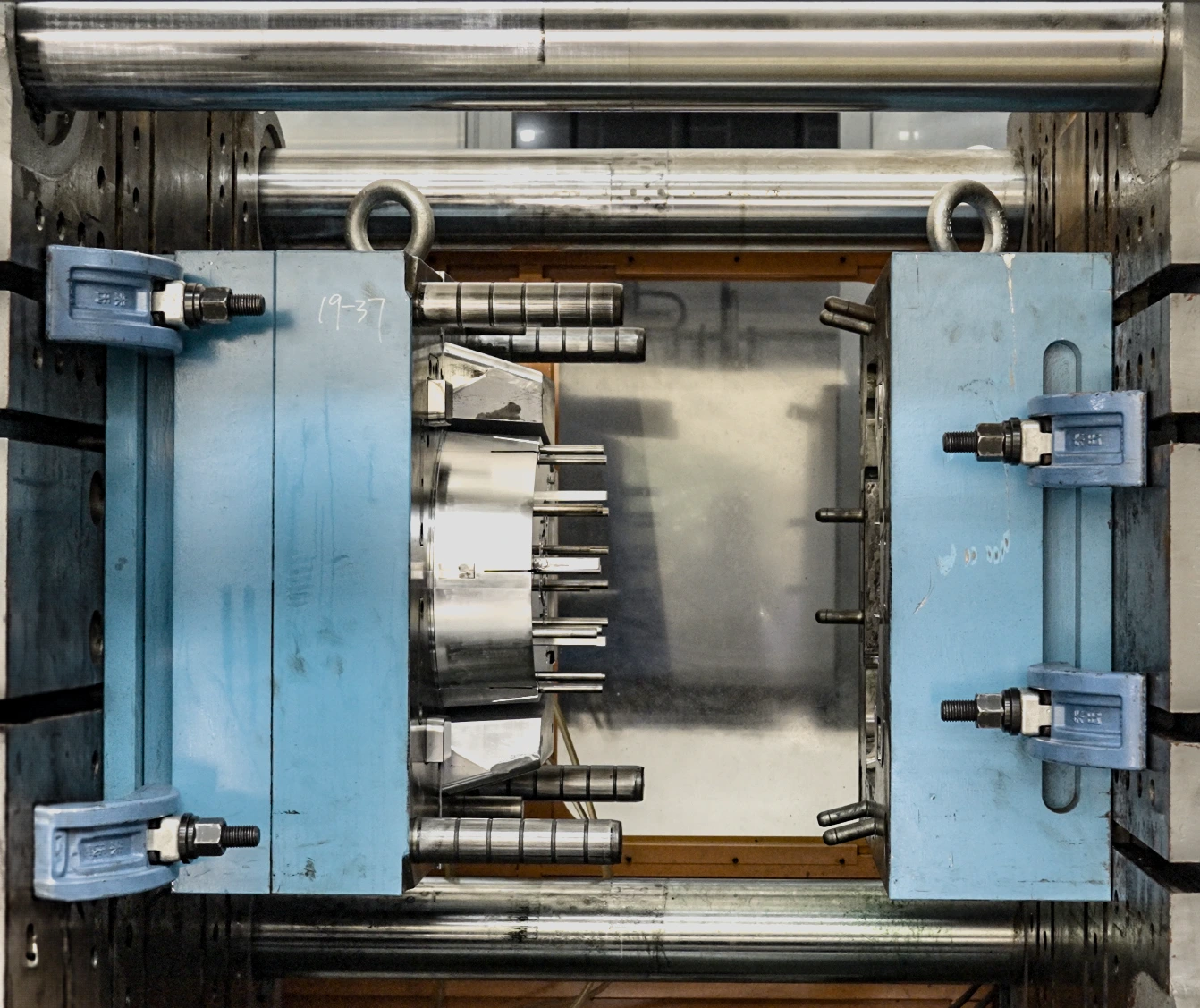

In high-performance industrial manufacturing, PVC injection molding is not merely a process—it is a science that demands exacting control, thermal stability, and micron-level precision. At Wuxi Lead Precision Machinery, we approach PVC injection molding as a critical engineering discipline, where material behavior, mold integrity, and process repeatability converge to define product performance. Polyvinyl chloride (PVC), while widely used for its chemical resistance and durability, presents unique challenges due to its sensitivity to heat and shear. Without precise temperature regulation and injection control, PVC can degrade, leading to compromised mechanical properties, discoloration, and part failure.

The foundation of successful PVC injection molding lies in mold design and material handling. Our engineering team employs advanced simulation software to model flow dynamics, ensuring uniform cavity filling and minimizing internal stress. This is particularly crucial in applications where dimensional accuracy and long-term reliability are non-negotiable—such as in military-grade connectors, medical housings, or infrastructure components used in Olympic-scale construction projects. At Lead Precision, our experience in delivering mission-critical metal components for defense and large-scale public infrastructure has directly informed our approach to molding processes. The same rigorous tolerances and quality assurance protocols applied to aerospace-grade alloys are mirrored in our PVC molding systems.

Precision extends beyond the mold. Our custom injection units feature closed-loop pressure control, servo-driven pumps, and real-time monitoring to maintain consistency across production runs. We utilize hardened tool steels with micro-finished surfaces to prevent sticking and ensure surface fidelity, especially for complex geometries or thin-walled designs. Each mold is validated through iterative prototyping and in-line metrology, guaranteeing that final parts meet ISO 2768-mK or tighter specifications.

Our clients in sectors ranging from urban infrastructure to high-reliability electronics depend on us not only for equipment but for engineered solutions. Whether producing seals for water treatment systems or insulating components for electrical enclosures, the integrity of the final product is directly traceable to the precision of the molding process.

Below are key specifications representative of our PVC injection molding systems, engineered and validated for industrial-grade performance.

| Parameter | Specification |

|---|---|

| Clamping Force Range | 800 kN – 6,000 kN |

| Injection Pressure | Up to 220 MPa |

| Screw Diameter | 30 mm – 80 mm |

| Shot Weight (PVC, max) | 1,200 g |

| Temperature Control Accuracy | ±1°C across all zones |

| Repeatability (Shot Weight) | ±0.3% |

| Mold Compatibility | Custom H13 or S136, hardened to 52–54 HRC |

| Control System | Siemens S7-1500 with OPC UA integration |

At Wuxi Lead Precision Machinery, we integrate decades of metal fabrication expertise with advanced polymer processing to deliver molding systems that meet the highest standards of precision and reliability. Our work with demanding sectors underscores our capability: when performance cannot be compromised, engineering excellence must lead.

Precision Specs & Tolerances

Technical Capabilities for Precision PVC Injection Molding Tooling

At Wuxi Lead Precision Machinery, our expertise in custom metal manufacturing directly enables superior PVC injection molding outcomes. PVC’s sensitivity to temperature fluctuations and viscosity demands exceptional tooling precision to prevent defects like flash, sink marks, or inconsistent wall thickness. We specialize in fabricating hardened steel and pre-hardened alloy molds, cores, cavities, and inserts where micron-level accuracy ensures optimal polymer flow, cooling uniformity, and part repeatability. Our integrated workflow eliminates dimensional drift between design, machining, and validation phases, critical for complex geometries in medical, automotive, and construction PVC components.

Central to our process is a dedicated fleet of 5-axis CNC machining centers, including DMG MORI and Makino systems. These platforms execute intricate contouring and deep-cavity milling in a single setup, reducing cumulative error from multiple fixturing stages. We machine P20, H13, S136, and maraging steels to tight tolerances while maintaining critical surface finishes down to Ra 0.2 µm. This capability is non-negotiable for PVC molds, where even 0.005 mm deviations can cause material hang-up or ejection failures due to PVC’s high friction coefficient. All machining operations leverage offline programming with Siemens NX CAM, ensuring optimal toolpaths for thermal stability during high-cycle production runs exceeding 500,000 shots.

Quality validation is anchored in Zeiss CONTURA CMM systems operating in a climate-controlled metrology lab. Every mold component undergoes full-spectrum inspection against 3D CAD models, with reports documenting GD&T compliance, flatness, and critical feature alignment. We prioritize real-time SPC data collection during machining to preempt deviations, not just correct them post-process. This proactive QC framework guarantees that mold plates interface perfectly, runner systems balance flow precisely, and cooling channels maintain uniform thermal gradients—directly translating to reduced PVC material waste and cycle time optimization for our clients.

Our commitment to dimensional integrity is quantified through rigorously maintained tolerance standards, as demonstrated below:

| Feature | Capability | Impact on PVC Molding Performance |

|---|---|---|

| Linear Dimensions | ±0.002 mm | Eliminates flash at parting lines; ensures seal integrity |

| Bore Concentricity | 0.003 mm TIR | Prevents core shift; maintains uniform wall thickness |

| Surface Flatness | 0.0015 mm per 100 mm | Guarantees even clamping force; avoids warpage |

| Cavity-to-Core Alignment | 0.0025 mm | Critical for multi-cavity balance; reduces shot-to-shot variation |

| Thread Pitch Accuracy | Class 3A (ASME B1.1) | Ensures leak-proof assembly in fluid-handling components |

This technical foundation allows Wuxi Lead to deliver molds that maximize PVC process efficiency. By controlling metal tooling precision at every stage—from raw material certification through final assembly—we mitigate the root causes of PVC molding instability. The result is extended tool life, reduced scrap rates, and consistent part conformance to ISO 2768-mK or client-specific standards. For high-value PVC applications where regulatory compliance and functional performance are paramount, our capabilities transform design intent into manufacturing reality.

Material & Finish Options

Material Selection for High-Performance PVC Injection Molding Components

In the precision-driven field of PVC injection molding, the selection of mold materials is critical to ensuring durability, dimensional accuracy, and long-term cost efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-cycle, high-pressure molding applications. Our engineering expertise supports the strategic use of aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental exposure.

Aluminum alloys, particularly 7075 and 6061-T6, are widely used for prototyping and low-to-medium volume production. Their excellent thermal conductivity enables faster cooling cycles, reducing part ejection time and increasing throughput. Additionally, aluminum is easier to machine, allowing for rapid tooling turnaround. However, its lower hardness and wear resistance make it less suitable for extended production runs or abrasive additives in PVC formulations.

Steel, especially hardened tool steels like H13 and P20, remains the standard for high-volume PVC molding. These materials offer superior hardness, wear resistance, and thermal stability under continuous operation. H13 steel, in particular, provides excellent resistance to thermal fatigue, making it ideal for molds subjected to repeated heating and cooling cycles. While initial machining time and cost are higher, the extended service life of steel molds delivers a lower total cost of ownership in large-scale manufacturing.

Titanium alloys, though less common, are emerging in specialized applications requiring extreme corrosion resistance and high strength-to-density ratios. In environments where aggressive flame retardants or chlorinated PVC compounds are used, titanium’s inert surface minimizes degradation and reduces maintenance downtime. While cost and machinability remain challenges, titanium is a strategic choice for mission-critical components in medical or aerospace-grade PVC molding systems.

Surface finishing further enhances mold performance and longevity. Anodizing, particularly hard anodizing, is a key treatment for aluminum molds. This electrochemical process increases surface hardness, improves wear resistance, and enhances corrosion protection—extending tool life by up to 300% in aggressive molding environments. For steel molds, nitriding or chrome plating is typically preferred, though anodizing may be applied in hybrid systems where aluminum sub-components are integrated.

Below is a comparative overview of key material properties relevant to PVC injection molding applications.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Typical Use Case | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum 7075 | 40–45 | 130 | 570 | Prototyping, low-volume production | Yes (hard anodizing) |

| Steel H13 | 48–52 | 35 | 1,300 | High-volume, high-temperature molds | No |

| Steel P20 | 28–32 | 30 | 900 | Medium-to-high volume production | No |

| Titanium Grade 5 | 36–40 | 7 | 900 | Corrosion-resistant, specialty molds | Limited |

Material and finish selection must align with production goals, chemical exposure, and lifecycle requirements. At Wuxi Lead Precision Machinery, we support clients in optimizing these choices through advanced simulation, material testing, and precision manufacturing.

Manufacturing Process & QC

PVC Injection Molding: Precision Process for Zero Defects Production

Achieving flawless PVC injection molded components demands an integrated, rigorously controlled process from initial concept to final shipment. At Wuxi Lead Precision Machinery, our custom metal manufacturing expertise underpins every stage, ensuring the tooling and machinery deliver the dimensional stability and thermal precision PVC requires. The journey begins with collaborative Design Engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis, focusing on PVC’s specific thermal behavior, shrinkage characteristics, and flow dynamics. We optimize gate locations, wall thickness transitions, and cooling channel layouts within the mold design using advanced simulation software. This critical phase identifies potential sinks, warpage, or knit lines before metal is cut, establishing the foundation for Zero Defects by ensuring the design is inherently manufacturable to tight tolerances under precise thermal control.

Prototyping transitions the validated design into physical reality under true production conditions. Utilizing our high-precision CNC-machined mold bases and cavities, we produce functional prototypes on production-intent machinery. This is not merely a form check; it is a comprehensive process validation. We meticulously monitor and adjust critical parameters – melt temperature, injection speed, packing pressure, and cooling time – while measuring prototype dimensions against CAD data. Material batch consistency is verified, and initial cycle times are established. Any micro-defect, however minor, triggers immediate root cause analysis and mold or process refinement. This iterative prototyping phase, conducted with production-grade tooling, eliminates unforeseen issues and locks in the optimal parameter window before scaling.

Mass Production executes the perfected process with unwavering consistency, the core of our Zero Defects commitment. Our custom-built, servo-hydraulic injection molding machines, integrated with the precision molds, maintain exceptional control over all variables. Real-time monitoring tracks melt temperature, hydraulic pressure, screw position, and clamp force against the validated setpoints. Statistical Process Control (SPC) charts continuously analyze critical dimensions from in-process samples, enabling proactive adjustments before drift occurs. Automated vision systems perform 100% inspection on key features for surface defects or dimensional outliers. Rigorous material handling protocols ensure PVC compound integrity, while preventive maintenance on both machine and mold guarantees sustained performance. Every component is traceable, and the process operates within the narrow, proven parameter envelope established during prototyping.

The following table outlines critical process parameters where Wuxi Lead’s precision engineering ensures stability for Zero Defects PVC molding:

| Parameter | Typical PVC Range | Wuxi Lead Precision Control | Significance for Zero Defects |

|---|---|---|---|

| Melt Temperature | 160°C – 210°C | ±1°C | Prevents degradation, ensures consistent flow |

| Injection Pressure | 800 – 1500 bar | ±0.5% tolerance | Eliminates short shots, flash, or internal stress |

| Clamp Force | 50 – 3000+ tons | Dynamic pressure monitoring | Guarantees mold seal, prevents flash |

| Cooling Time | 15 – 60 seconds | ±0.1 second consistency | Controls shrinkage, minimizes warpage |

| Cycle Time | Varies by part | ±0.5% stability | Ensures uniform part cooling, dimensional repeatability |

This disciplined, closed-loop approach – from intelligent design through validated prototyping to tightly controlled mass production – transforms PVC material potential into defect-free, high-performance components. Wuxi Lead Precision Machinery provides the engineered foundation, making Zero Defects not an aspiration, but a measurable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced PVC Injection Molding Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered solutions for complex manufacturing challenges in the PVC injection molding industry. As a trusted leader in precision metal manufacturing, we combine decades of engineering expertise with state-of-the-art CNC fabrication to produce robust, high-tolerance molds and machinery components that ensure repeatable, efficient, and cost-effective production for our global clients.

PVC injection molding demands precision, durability, and material compatibility—qualities that define our engineering philosophy. Our molds are crafted from premium-grade tool steels and treated with advanced surface coatings to resist corrosion and wear, ensuring long service life even under continuous operation. We design every system with optimized flow dynamics, precise temperature control, and efficient ejection mechanisms, tailored specifically to the rheological behavior of PVC—whether rigid or flexible formulations.

Our engineering team works closely with clients from concept through production, offering full DFM (Design for Manufacturability) analysis, mold flow simulation, and prototyping services. This collaborative approach minimizes time-to-market and eliminates costly design iterations. Whether you require single-cavity precision molds or high-cavity automated systems for mass production, we deliver solutions that meet the highest standards of quality, repeatability, and regulatory compliance.

We serve industries where performance and reliability are non-negotiable—medical devices, construction hardware, automotive components, and consumer electronics—delivering molds that maintain micron-level tolerances over millions of cycles. Our in-house manufacturing capabilities include 5-axis CNC machining, wire EDM, grinding, and automated polishing, ensuring complete control over quality and lead times.

Each project is backed by rigorous quality assurance protocols, including CMM inspection, hardness testing, and first-article reporting. We are ISO 9001 certified and maintain a fully documented traceability system for all critical components.

Below are key technical specifications for our PVC injection molding systems:

| Specification | Detail |

|---|---|

| Mold Base Materials | P20, H13, 1.2344, 1.2379, Stainless Steel (custom options available) |

| Tolerance | ±0.005 mm |

| Surface Finish | Mirror polish up to Ra 0.05 µm; textured, sandblasted, or coating options |

| Cavities | 1 to 64 cavities (standard and multi-shot configurations) |

| Runner Systems | Hot runner (Yudo, Hasco, Synventive) or cold runner |

| Gates | Pin-point, submarine, edge, or valve gate |

| Cycle Time Optimization | Integrated cooling channels with conformal cooling design |

| Automation Compatibility | Full integration with robotic extraction and inline inspection |

| Lead Time | 4–8 weeks (depending on complexity) |

| Standards | ISO 9001:2015, DIN, JIS, ANSI, or custom client specifications |

Partnering with Wuxi Lead Precision Machinery means investing in engineering excellence and long-term production stability. We are committed to being an extension of your engineering team—offering responsive support, technical consultation, and continuous improvement throughout the product lifecycle.

For expert guidance on your next PVC injection molding project, contact us today at [email protected]. Let Lead Precision be your trusted partner in manufacturing innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.