Technical Contents

Engineering Guide: Prototyping Service Georgia

Engineering Insight Precision Prototyping for Georgia Manufacturers

In Georgia’s competitive manufacturing landscape where aerospace defense and advanced industrial equipment drive economic growth precision prototyping is not merely advantageous—it is nonnegotiable. Submillimeter deviations in early-stage metal components cascade into catastrophic failures during production or field operation eroding margins and damaging reputations. Georgia engineers require prototyping partners who treat dimensional accuracy as foundational not optional. At Wuxi Lead Precision Machinery we engineer this rigor into every prototype leveraging 18 years of mission-critical experience where tolerances directly impact human safety and national security. Our work on timing systems for the 2008 Beijing Olympics and classified aerospace components for military contractors demanded absolute fidelity to specifications—zero defects permitted. This mindset defines our approach for Georgia clients whether developing turbine blades for Savannah aerospace suppliers or hydraulic manifolds for Columbus defense contractors.

Precision begins with material science and process control. We deploy Makino 5-axis vertical machining centers and Zeiss coordinate measuring machines calibrated to NIST standards ensuring repeatability within ±0.001mm. Our engineers collaborate with Georgia design teams during DFM analysis identifying potential tolerance stack-ups or manufacturability risks before metal is cut. This prevents costly redesigns accelerating time-to-prototype by 30% compared to regional benchmarks. Below are core capabilities enabling Georgia manufacturers to de-risk development:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.001mm to ±0.025mm | Critical for aerospace seals and medical implants |

| Material Compatibility | Titanium 6Al-4V Inconel 718 17-4PH Stainless Steel Aluminum 7075 | Matches Georgia’s defense and energy sector requirements |

| Maximum Part Size | 1200 x 800 x 600 mm | Accommodates large-scale industrial prototypes |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm | Essential for fluid dynamics and fatigue resistance |

Georgia’s manufacturers face unique challenges including stringent ITAR compliance for defense work and rapid iteration cycles demanded by Atlanta’s IoT hardware startups. Our ISO 9001 and AS9100 certified facility integrates secure digital workflows with physical production eliminating data leakage risks while providing real-time machining analytics. When a Warner Robins aviation supplier required 12 iterations of a fuel nozzle prototype within 14 days we delivered—all parts within 0.003mm of CAD geometry—enabling their FAA certification deadline. This is the value of precision engineering: transforming Georgia’s innovative concepts into physically perfect validation assets without compromise. Partner with Wuxi Lead to ensure your next prototype isn’t just a model—it’s a production-ready benchmark.

Precision Specs & Tolerances

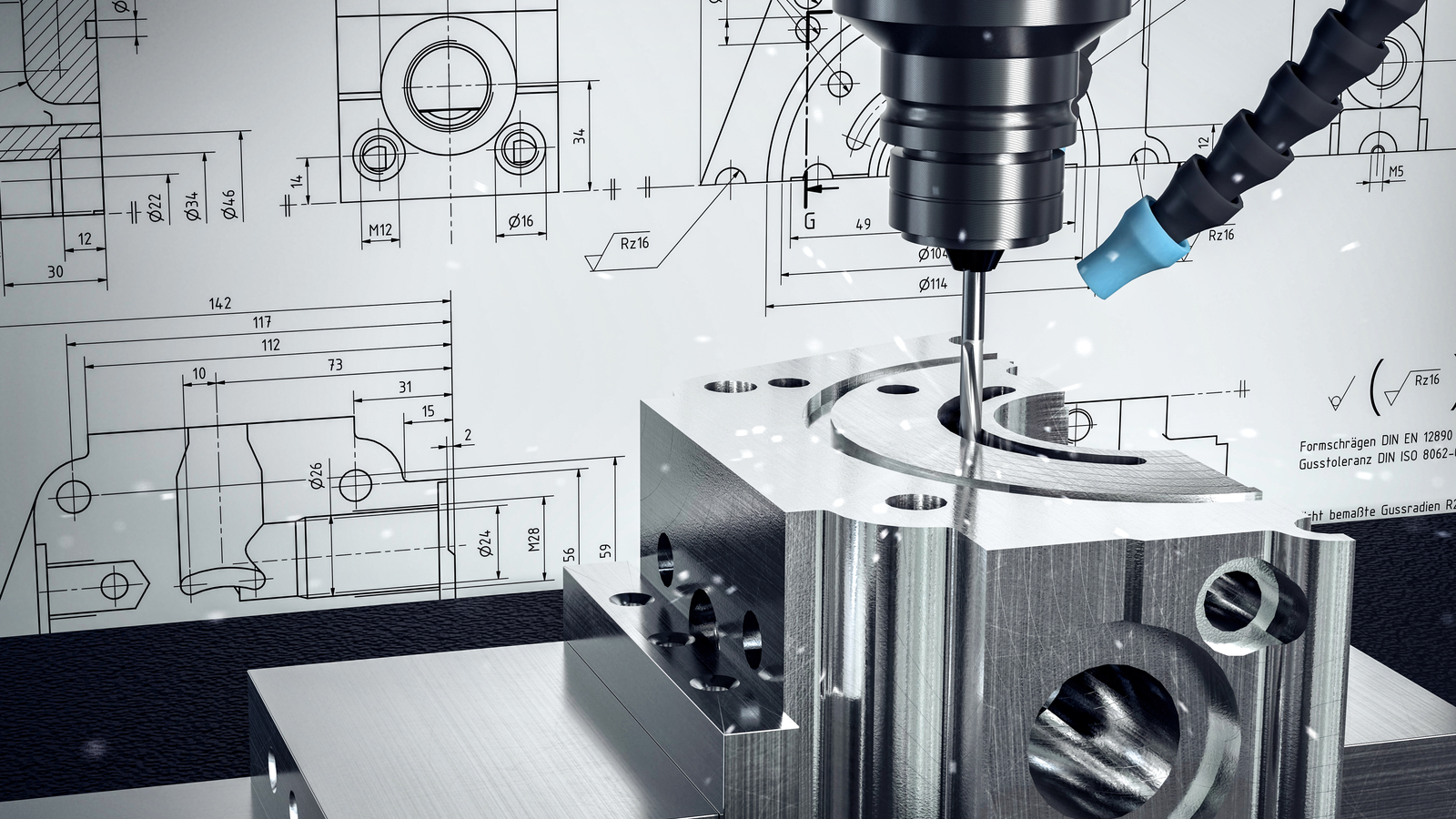

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for global industries requiring precision, repeatability, and rapid turnaround. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with superior surface finishes and tight tolerances. These systems allow simultaneous multi-axis movement, significantly reducing setup times and part handling while improving accuracy. This is particularly critical for prototyping and low-to-mid volume production runs where design fidelity and functional performance are non-negotiable.

Our 5-axis CNC centers are equipped with high-speed spindles, automatic tool changers, and integrated coolant systems, supporting a wide range of materials including aluminum alloys, stainless steel, titanium, brass, and high-performance engineering metals. This versatility ensures compatibility with aerospace, medical, automotive, and industrial automation applications. Each machine is operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, minimize cycle times, and ensure material integrity throughout the machining process.

Quality control is embedded at every stage of production. We employ a comprehensive inspection protocol led by Coordinate Measuring Machine (CMM) technology, ensuring dimensional accuracy across all critical features. Our CMM systems are calibrated to international standards and operated by trained metrology technicians who generate detailed inspection reports for full traceability. In addition to CMM, we utilize optical comparators, surface finish testers, and micrometric verification tools to validate conformance to customer specifications.

All prototyping and production workflows follow strict process controls aligned with ISO 9001 standards. From initial CAD review to final packaging, our integrated quality management system ensures consistency, reliability, and compliance. This disciplined approach enables Wuxi Lead to serve as a trusted extension of engineering teams worldwide, particularly those seeking high-integrity components for validation, testing, or limited deployment.

The following table outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Linear Tolerance | ±0.01 mm |

| Angular Tolerance | ±0.1° |

| Surface Roughness (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Minimum Feature Size | 0.5 mm diameter |

| Material Thickness Range | 0.8 mm to 150 mm |

| CMM Measurement Accuracy | ±0.003 mm |

| Lead Time (Prototyping) | 7–15 business days |

Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality assurance, and deep technical expertise to deliver prototype components that meet the exacting demands of advanced manufacturing sectors. Our 5-axis CNC and CMM-driven inspection systems ensure that every part shipped from our facility in China meets the highest standards of precision—regardless of complexity.

Material & Finish Options

Strategic Material Selection for Precision Prototyping in Georgia

Material choice fundamentally dictates prototype performance, manufacturability, and cost-effectiveness for Georgia-based engineering teams. Selecting the optimal alloy requires balancing mechanical properties, environmental resistance, weight constraints, and finish requirements against project specifications. At Wuxi Lead Precision Machinery, we guide clients through this critical decision using decades of CNC machining expertise and rigorous material science understanding. Our ISO 9001 and IATF 16949 certified processes ensure consistent quality whether producing single validation units or pre-production batches for Atlanta aerospace firms or Savannah industrial equipment developers.

Aluminum alloys dominate prototyping due to their excellent strength-to-weight ratio, superior machinability, and cost efficiency. Grade 6061-T6 offers robust corrosion resistance and weldability, ideal for structural frames and fluid handling components. For high-stress applications like drone chassis or robotics arms, 7075-T6 delivers near-steel strength while maintaining light weight, though at a higher material cost. Aluminum’s high thermal conductivity also benefits heat-sensitive prototypes.

Carbon and alloy steels provide unmatched strength and wear resistance for demanding mechanical prototypes. 4140 chrome-moly steel withstands high impact loads in tooling and automotive suspension components, responding well to heat treatment. Stainless steel 304 offers essential corrosion resistance for medical or marine prototypes without the expense of higher grades. Steel prototypes often require post-machining stress relief to maintain dimensional stability during testing.

Titanium Grade 5 (Ti-6Al-4V) is the premium solution for weight-critical, high-temperature applications such as aerospace brackets or medical implants. Its exceptional strength-to-density ratio and biocompatibility justify the significant cost and challenging machinability for mission-critical Georgia prototypes where failure is not an option. We employ specialized toolpaths and coolant strategies to machine titanium efficiently.

Critical mechanical properties guide final selection as shown below:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Key Corrosion Resistance | Typical Prototype Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Good (atmospheric) | Enclosures, brackets, heat sinks |

| Steel 4140 | 7.85 | 655 | Fair (requires coating) | Shafts, tooling, high-load fixtures |

| Stainless 304 | 8.0 | 515 | Excellent (general) | Medical devices, food processing |

| Titanium Ti-6Al-4V | 4.43 | 900 | Outstanding | Aerospace components, implants |

Anodizing transforms aluminum prototypes by enhancing surface durability and enabling precise cosmetic control. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dye color options for identification. For Georgia clients requiring military or aerospace validation, we implement Type III (hardcoat) anodizing, producing a thick, integral oxide layer exceeding 50 HRC hardness for extreme abrasion resistance in landing gear or hydraulic components. All anodizing processes are NADCAP-accredited and include rigorous thickness and seal quality verification.

Wuxi Lead Precision Machinery partners with Georgia engineering teams to navigate these material complexities. We provide metallurgical data, DFM analysis, and finish recommendations specific to your prototype’s functional requirements and testing environment. Contact our technical sales team for a material selection consultation backed by 15 years of high-mix, low-volume production excellence serving global innovators.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to deliver precision metal components with zero defects for clients seeking prototyping services in Georgia and beyond. Our methodology integrates engineering rigor with advanced manufacturing technology, ensuring seamless transition from concept to volume production.

It begins with Design Engineering, where our technical team collaborates closely with the client to analyze CAD models, material specifications, and functional requirements. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to identify potential risks and optimize geometry, tolerances, and surface finishes. This stage ensures that the design is not only functionally sound but also manufacturable with high repeatability and minimal waste.

Once the design is finalized, we proceed to the Prototyping phase. Using state-of-the-art CNC machining centers, multi-axis lathes, and precision sheet metal fabrication tools, we produce initial prototypes in the exact material specified for final production. This allows for accurate mechanical testing, fit checks, and performance validation. Every prototype is subjected to full dimensional inspection using coordinate measuring machines (CMM) and optical comparators to verify conformance to print. Clients receive a detailed First Article Inspection (FAI) report, including material certifications and traceability documentation. Feedback from this stage is incorporated swiftly, enabling rapid design iterations if necessary.

Upon client approval, the project transitions to Mass Production. Our facility in Wuxi operates under strict ISO 9001-certified quality management protocols. Production lines are set up with standardized work instructions, tooling validation, and real-time process monitoring. We employ Statistical Process Control (SPC) to track critical dimensions and detect variation trends before they affect output quality. Each batch undergoes in-process and final inspections, with full lot traceability maintained throughout. Our lean manufacturing principles minimize cycle times while maximizing throughput and consistency.

Wuxi Lead’s commitment to zero defects is reinforced through automation, operator training, and a closed-loop corrective action system. Any non-conformance triggers immediate root cause analysis and process adjustment, ensuring continuous improvement.

Below are key technical capabilities supporting our production process:

| Specification | Detail |

|---|---|

| CNC Machining Tolerance | ±0.005 mm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Brass, Carbon Steel, Inconel |

| Surface Finishes | As-machined, Anodizing, Plating, Powder Coating, Passivation |

| Quality Standards | ISO 9001:2015, AS9100D (aerospace), PPAP, FAI |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Prototype) | 7–15 days |

| Lead Time (Mass Production) | 20–35 days, scalable |

By integrating precision engineering with scalable manufacturing, Wuxi Lead delivers reliable, high-quality metal components to global clients, including those in Georgia seeking advanced prototyping and production solutions.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Strategic Prototyping Solution for Georgia Manufacturing Excellence

Georgia’s advanced manufacturing sector demands prototyping partners who deliver precision, speed, and unwavering reliability. At Wuxi Lead Precision Machinery, we bridge the gap between your design intent and production-ready metal components through a seamless China-to-Georgia workflow engineered for U.S. industrial standards. Our ISO 9001-certified facility combines German-engineered CNC technology with veteran engineering oversight to eliminate the cost and timeline risks inherent in domestic prototyping. We understand Georgia manufacturers face compressed development cycles and stringent quality gates; our turnkey service ensures your prototypes meet aerospace, medical, and industrial specifications on time, every time.

Unlike regional shops constrained by legacy equipment, Lead Precision leverages a 24/7 production ecosystem with 85+ CNC centers—including 5-axis milling, Swiss turning, and multi-spindle systems—to compress lead times by 30–50% without sacrificing micron-level accuracy. Our engineers collaborate directly with your team via encrypted digital workspaces, providing real-time DFM feedback and material optimization to prevent costly redesigns. Every prototype undergoes rigorous first-article inspection with CMM reports traceable to NIST standards, ensuring compliance with AS9100, ISO 13485, and MIL-STD requirements critical for Georgia’s defense and medical device clusters.

Below summarizes our core prototyping capabilities for Georgia clients:

| Specification | Capability Detail |

|---|---|

| Materials | Aluminum 7075-T6, 6061; Stainless 303/304/316; Titanium Gr5; Inconel 718; Brass C360 |

| Tolerances | ±0.005mm (standard); ±0.001mm (micromachining) |

| Max Work Envelope | 1,200 x 800 x 650mm (5-axis milling); Ø42mm (Swiss turning) |

| Lead Time | 7–12 days (complex geometries); 3–5 days (rush service) |

| Certifications | ISO 9001:2015, ISO 14001, AS9100D, ITAR registered |

Your prototype is the foundation of production scalability. We eliminate the “valley of death” between concept and volume manufacturing by validating designs against real-world production constraints from day one. Our Georgia clients—from Savannah aerospace innovators to Atlanta medical startups—leverage our in-house anodizing, passivation, and precision welding to receive fully finished, test-ready units that accelerate FAA or FDA validation. With dedicated project managers fluent in English and EST-hour support, communication barriers dissolve.

Do not let geographical distance compromise your innovation timeline. Contact Lead Precision Machinery today to receive a guaranteed prototype quote within 4 business hours. Email [email protected] with your CAD files and requirements. Our engineering team will respond with a detailed production plan, material sourcing strategy, and timeline analysis—no obligation. For Georgia manufacturers demanding uncompromised quality and speed, the global standard in precision prototyping starts here. Act now to secure your Q4 development schedule.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.