Technical Contents

Engineering Guide: Prototypen Hersteller

Engineering Insight: The Critical Role of Precision in Prototyping for High-Performance Applications

In the realm of advanced manufacturing, the transition from concept to physical prototype defines the success of innovation. For industries where failure is not an option—such as aerospace, defense, and high-performance sports—the role of precision in prototyping cannot be overstated. At Wuxi Lead Precision Machinery, we understand that a prototype is not merely a preliminary model; it is the first true validation of engineering intent, material behavior, and functional performance under real-world conditions.

Precision in prototyping ensures dimensional accuracy, repeatability, and consistency across components, all of which are vital when developing systems that operate under extreme stress, temperature, or load. Even a deviation of a few microns can compromise structural integrity, affect assembly fit, or degrade performance. This is particularly critical in applications such as military-grade equipment or Olympic-level sports technology, where every element must perform at its peak.

Our experience at Wuxi Lead has been shaped by decades of delivering mission-critical components for defense systems and precision parts used in Olympic athletic equipment. These projects demand more than advanced machinery—they require a culture of exactness, rigorous quality control, and deep material science expertise. For instance, a prototype developed for a high-speed reconnaissance drone must maintain aerodynamic integrity while withstanding vibration and thermal expansion. Similarly, a custom titanium component for a competitive bobsled must balance minimal weight with maximum strength, requiring sub-5-micron tolerances and flawless surface finishes.

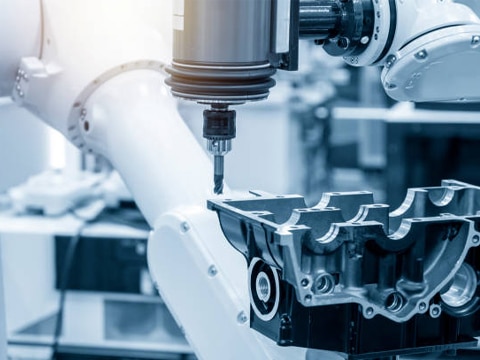

We achieve this level of precision through a combination of state-of-the-art CNC machining centers, in-house metrology labs, and a team of engineers trained in failure mode analysis and geometric dimensioning and tolerancing (GD&T). Every prototype undergoes a multi-stage inspection process, including CMM (Coordinate Measuring Machine) verification and first-article reporting, ensuring compliance with ISO 9001 and AS9100 standards.

Our clients rely on us not only for technical capability but also for engineering partnership. We engage early in the design phase to identify potential manufacturability issues, recommend material substitutions, and optimize part geometry for both performance and cost-efficiency. This proactive collaboration reduces iteration cycles and accelerates time to market—critical advantages in competitive industries.

Below are key technical capabilities that define our prototyping precision:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.001 mm to ±0.005 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (adjustable) |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Magnesium |

| Maximum Work Envelope | 2000 mm × 1200 mm × 800 mm |

| Machining Centers | 3-axis, 4-axis, 5-axis CNC |

| Inspection Equipment | CMM, Optical Comparator, Laser Scanning |

| Certifications | ISO 9001:2015, AS9100D |

At Wuxi Lead Precision Machinery, we treat every prototype as a gateway to production excellence. Our proven track record in military and Olympic applications underscores our ability to deliver precision when it matters most. For manufacturers demanding reliability, accuracy, and performance, we provide not just parts—but engineered confidence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Prototype Excellence

Wuxi Lead Precision Machinery delivers the advanced manufacturing capabilities essential for demanding prototype development. Our core strength lies in integrating cutting-edge multi-axis CNC technology with rigorous quality control protocols, ensuring your complex metal prototypes meet exacting functional and dimensional requirements from the first iteration. We specialize in transforming intricate CAD models into high-fidelity physical components, accelerating your design validation and testing phases while minimizing costly redesign cycles. Our facility is purpose-built for the unique challenges of low-volume, high-complexity prototype production, where precision, material versatility, and rapid turnaround are non-negotiable.

Our primary machining platform centers on state-of-the-art 5-axis CNC milling and turning centers. This technology enables simultaneous movement across all five axes, allowing us to machine complex geometries, deep cavities, and compound angles in a single setup. The elimination of multiple fixturing operations is critical for prototype integrity, significantly reducing cumulative error potential and ensuring superior part accuracy and surface finish consistency. We routinely handle challenging materials including aerospace-grade aluminum alloys (7075-T6, 6061), stainless steels (303, 304, 316, 17-4PH), titanium (Grade 5), and engineering plastics. Our programming expertise leverages advanced CAM software for optimized toolpaths, maximizing efficiency and surface quality even on the most intricate organic shapes or thin-walled features common in prototypes.

Quality assurance is embedded into every stage of our process, not merely a final checkpoint. All critical prototype components undergo comprehensive inspection using calibrated Zeiss and Hexagon CMM systems. This provides full geometric dimensioning and tolerancing (GD&T) verification against your master CAD model, generating detailed inspection reports with traceable data points. Beyond dimensional accuracy, we perform rigorous material verification, surface roughness analysis (Ra values), and visual inspection for surface defects. This systematic approach guarantees that the prototype you receive is a true representation of your design intent, providing reliable data for your engineering evaluations and reducing the risk of downstream failures during testing.

The achievable tolerances for your prototype depend on the specific geometry, material, and feature size. The following table outlines our standard and tight tolerance capabilities for common prototype materials under controlled conditions. Achieving tighter tolerances may influence lead time and cost; our engineering team will collaborate with you to define the optimal specification for your application.

| Feature Type | Material Group | Standard Tolerance (mm) | Tight Tolerance Capability (mm) | Notes |

|---|---|---|---|---|

| Linear Dimensions | Aluminum Alloys | ±0.025 | ±0.005 – ±0.010 | Up to 300mm; tighter on small features |

| Stainless Steel | ±0.025 | ±0.008 – ±0.015 | ||

| Titanium Alloys | ±0.030 | ±0.010 – ±0.020 | ||

| Hole Diameter | All Metals | H7 / h7 | H6 / h6 | Reamed/bored; depth dependent |

| Positional Tolerance | All Metals | ±0.025 | ±0.010 | Relative to primary datums |

| Profile of Surface | All Metals | ±0.050 | ±0.025 | Complex contours |

| Surface Roughness | Machined Finish | Ra 1.6 μm | Ra 0.4 μm | As-machined; polished finishes available |

Partnering with Wuxi Lead means accessing manufacturing precision that supports confident engineering decisions. Our technical team provides proactive feedback during the manufacturability review stage, identifying potential issues early to optimize your design for successful prototyping. We understand that your prototype is the foundation for production; we deliver the dimensional certainty and material integrity you require to move forward with confidence. Contact our engineering team to discuss the specific requirements of your next complex metal prototype project.

Material & Finish Options

Material selection is a foundational decision in custom metal manufacturing, directly influencing the performance, durability, and cost-efficiency of prototypes and end-use components. At Wuxi Lead Precision Machinery, we specialize in precision machining of aluminum, steel, and titanium—three of the most widely used metals in high-performance industrial applications. Each material offers distinct mechanical and thermal properties, making them suitable for different operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly well-suited for aerospace, automotive, and consumer electronics applications where weight reduction is critical. Among the most commonly used grades are 6061-T6 and 7075-T6, with the latter offering higher strength for demanding structural roles. Aluminum’s natural oxide layer provides inherent protection against environmental degradation, but additional surface treatment such as anodizing can significantly enhance wear and corrosion resistance.

Steel, particularly in its stainless and alloy forms, delivers superior strength, hardness, and temperature resistance. Grades like 304 and 316 stainless steel are widely used in medical devices, food processing, and marine environments due to their exceptional corrosion resistance and compliance with stringent hygiene standards. For industrial tooling and high-stress mechanical components, alloy steels such as 4140 and 4340 provide excellent toughness and fatigue resistance. While heavier than aluminum, steel’s durability and cost-effectiveness make it a preferred choice for long-life parts.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high temperatures and corrosive media make it ideal for aerospace, defense, and medical implant applications. Though more challenging and costly to machine, titanium’s performance advantages in critical systems justify its use where failure is not an option.

Surface finishing plays a vital role in optimizing material performance. Anodizing, a process primarily applied to aluminum, electrochemically thickens the natural oxide layer, enhancing surface hardness and wear resistance. Type II (sulfuric acid) anodizing provides a decorative and protective finish, while Type III (hardcoat) anodizing delivers a dense, abrasion-resistant surface suitable for functional components. Anodized layers are also electrically insulating and can be dyed in a range of colors for identification or aesthetic purposes.

Below is a comparative overview of key material properties and anodizing specifications.

| Material | Typical Grades | Tensile Strength (MPa) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 2.7 | Aerospace, Electronics, Automotive |

| Steel | 304, 316, 4140 | 500–1000 | 7.8–7.9 | Medical, Industrial, Marine |

| Titanium | Ti-6Al-4V (Grade 5) | 900–950 | 4.4 | Aerospace, Defense, Medical |

| Finish Type | Material Compatibility | Thickness Range (µm) | Hardness (HV) | Key Benefits |

|---|---|---|---|---|

| Type II Anodizing | Aluminum | 5–25 | 200–300 | Corrosion resistance, dyeable finish |

| Type III Anodizing | Aluminum | 25–100 | 400–600 | High wear resistance, durable coating |

Selecting the right material and finish requires a balance of functional requirements, environmental exposure, and production constraints. Wuxi Lead Precision Machinery supports clients in making informed decisions through engineering consultation and prototyping expertise, ensuring optimal performance from concept to production.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Precision Metal Manufacturing Process for Prototypen Hersteller

At Wuxi Lead Precision Machinery, we engineer seamless transitions from concept to volume production for high-stakes metal components. Our integrated process—Design, Prototyping, Mass Production—is engineered for Zero Defects compliance, ensuring German-engineered quality meets global supply chain demands. We eliminate costly iterations by embedding precision at every phase, leveraging 15 years of aerospace and medical manufacturing expertise.

Design Phase: Precision by Intent

Our process begins with rigorous Design for Manufacturing (DFM) collaboration. Clients submit CAD models; our engineers conduct tolerance stack-up analysis and material suitability reviews within 72 hours. We identify potential machining conflicts early—such as thin-wall instability or suboptimal tool access—reducing prototyping cycles by 40%. All designs undergo thermal and stress simulation using Siemens NX, ensuring geometries align with CNC capabilities. This phase culminates in a signed-off manufacturing blueprint, locking critical dimensions and surface finishes to ISO 2768-mK standards.

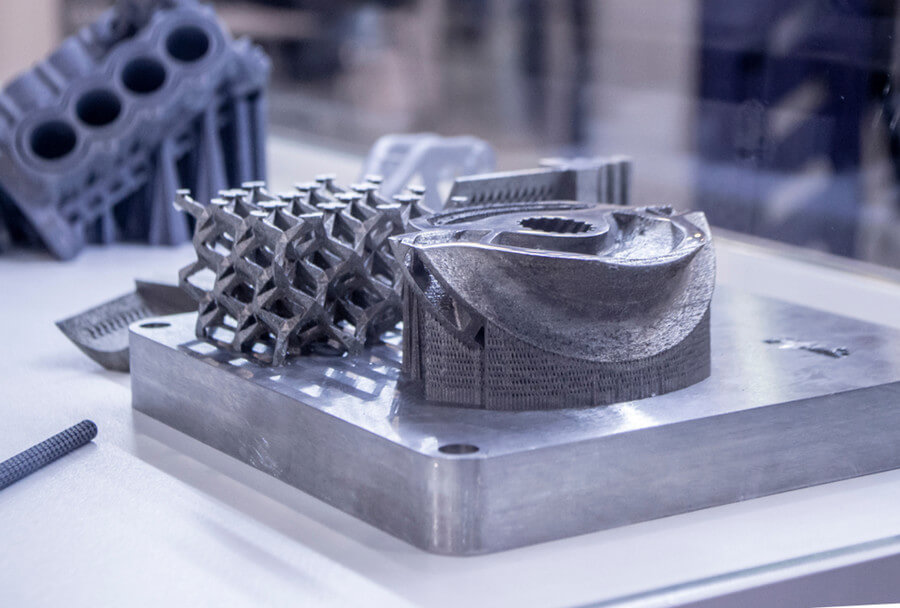

Prototyping Phase: Validation Without Compromise

Prototypes are machined on the same HAAS UMC-750 5-axis centers used in volume production, eliminating process variability. We produce 2–5 functional units per design iteration, employing in-process probing for real-time dimensional verification. Each prototype undergoes first-article inspection per AS9102 standards, with CMM reports validating ±0.005 mm tolerances. Clients receive annotated deviation maps highlighting any non-conformities against CAD models. This closed-loop validation ensures only geometrically perfect designs advance to mass production, slashing time-to-market by 30%.

Mass Production: Zero Defects Execution

Volume runs deploy automated SPC (Statistical Process Control) systems monitoring 15+ parameters per machine cycle. Our facility implements error-proofing via Renishaw tool setting probes and laser micrometers, triggering automatic shutdowns if tolerances drift beyond ±0.003 mm. Every 50th part undergoes 100% CMM re-inspection, while batch-level certifications include material traceability (MTR) and surface roughness reports (Ra ≤ 0.8 µm). This multi-layered approach achieves <50 PPM defect rates, validated by third-party audits from TÜV Rheinland.

Process Specifications Across Production Stages

| Phase | Key Parameters | Tolerance Range | Quality Control Method |

|---|---|---|---|

| Design | Material Grade, Geometry Complexity | ±0.02 mm (initial) | DFM Simulation, GD&T Validation |

| Prototyping | Surface Finish, Feature Criticality | ±0.005 mm | CMM First-Article Inspection (AS9102) |

| Mass Production | Dimensional Stability, Batch Consistency | ±0.003 mm | SPC Charts, 100% Batch Certification |

Wuxi Lead’s end-to-end control transforms prototypen hersteller workflows into defect-proof production pipelines. By unifying engineering rigor with real-time quality analytics, we deliver components that exceed DIN and ISO benchmarks while optimizing total cost of ownership. Contact our engineering team to discuss DFM analysis for your next precision metal project—where every prototype is a blueprint for perfection.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we don’t just manufacture metal components—we engineer precision solutions tailored to the exact demands of high-performance industries. As a leading prototypen hersteller in China, we specialize in delivering custom metal parts with tight tolerances, superior surface finishes, and rapid turnaround times. Whether you’re developing a single prototype or scaling to low-volume production, our advanced CNC machining, multi-axis milling, and turning capabilities ensure your designs are transformed into reality with uncompromising quality.

Our facility in Wuxi is equipped with state-of-the-art machinery and staffed by certified engineers who bring decades of experience in aerospace, medical, automation, and industrial equipment manufacturing. We understand that precision is not a feature—it’s a requirement. That’s why every component we produce undergoes rigorous in-process inspections and final quality verification using calibrated CMMs and optical measurement systems. Our ISO 9001:2015 certification reflects our commitment to consistency, traceability, and continuous improvement.

We recognize that your project demands more than just machining. It requires a partner who listens, adapts, and delivers. From initial design consultation to material selection, DFM analysis, and post-processing services such as anodizing, plating, or laser engraving, we provide end-to-end support. Our engineering team collaborates closely with your design staff to identify potential improvements, reduce lead times, and optimize manufacturability—saving you time and cost without sacrificing performance.

Our technical capabilities are built to handle the most demanding specifications. Below is an overview of our core manufacturing parameters:

| Specification | Capability |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis milling; turning with live tooling |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Tolerance | ±0.005 mm (±0.0002 in) typical |

| Surface Finish | As fine as Ra 0.4 μm (16 μin) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Copper, Tool Steels, and engineered alloys |

| Lead Time | Prototypes: 5–7 days; Production: 10–15 days (varies by complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP documentation available |

Choosing the right manufacturing partner is critical to your product’s success. At Wuxi Lead Precision Machinery, we combine German-level precision with the agility and cost-efficiency of Chinese manufacturing—offering you the best of both worlds. Our mission is to become a seamless extension of your engineering team, enabling faster innovation and reliable delivery.

Start your next project with confidence. Contact us today at [email protected] to discuss your requirements, request a quote, or receive a DFM feedback report. Let Lead Precision be your trusted prototypen hersteller for precision, performance, and partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.