Technical Contents

Engineering Guide: Prototype To Cad Comparison

Engineering Insight: Prototype to CAD Comparison in High-End Metal Manufacturing

In the world of custom metal manufacturing, the transition from digital design to physical prototype is a critical juncture where precision defines performance. At Wuxi Lead Precision Machinery, we specialize in bridging the gap between CAD models and real-world prototypes with uncompromising accuracy. The prototype to CAD comparison is not merely a validation step—it is a foundational engineering process that ensures dimensional integrity, functional reliability, and compliance with exacting industry standards.

Every component we manufacture begins as a high-fidelity CAD model, engineered to meet specific mechanical, thermal, and load-bearing requirements. Once the prototype is produced through advanced CNC machining, multi-axis milling, or precision turning, it undergoes rigorous metrological analysis. Using coordinate measuring machines (CMM), laser scanning, and optical comparators, we perform a full geometric dimensioning and tolerancing (GD&T) evaluation, comparing physical measurements directly against the original CAD file. This process identifies even micron-level deviations, enabling immediate corrective actions before full-scale production begins.

Precision is non-negotiable in sectors such as aerospace, defense, and high-performance sports equipment—industries where Wuxi Lead has demonstrated proven expertise. Our involvement in manufacturing components for Olympic-grade athletic systems and mission-critical military hardware underscores our commitment to zero-defect outcomes. In these applications, a deviation of even 0.01 mm can compromise structural integrity or aerodynamic efficiency. Our prototype-to-CAD verification protocols are designed to prevent such risks, ensuring that every part performs exactly as simulated.

Beyond dimensional accuracy, the comparison process validates material behavior, surface finish, and assembly compatibility. We analyze how real-world manufacturing variables—such as tool wear, thermal expansion, and material anisotropy—affect the final product. This data is fed back into the design loop, enabling iterative refinement that aligns the physical prototype with virtual intent.

At Wuxi Lead, we treat the prototype not as a standalone model but as the first iteration of a production-ready component. Our engineering team works in close collaboration with clients to interpret comparison reports, recommend design for manufacturing (DFM) improvements, and ensure seamless scalability from prototype to volume production.

The following table outlines key specifications and capabilities that support our prototype-to-CAD comparison process:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.005 mm |

| Surface Finish | Ra 0.2 – 3.2 μm (adjustable) |

| Materials Supported | Aluminum alloys, Stainless steel, Titanium, Inconel, Brass, Tool steels |

| CAD Compatibility | STEP, IGES, Parasolid, SolidWorks, CATIA, Siemens NX |

| Inspection Equipment | Zeiss CMM, 3D Laser Scanners, Optical Comparators, Vision Systems |

| Reporting | Full GD&T Analysis, Deviation Color Maps, First Article Inspection (FAI) Reports |

By integrating precision engineering with advanced metrology, Wuxi Lead ensures that every prototype not only matches the CAD model—but exceeds expectations in performance and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Realized from CAD to Physical Prototype

At Wuxi Lead Precision Machinery, we bridge the critical gap between digital design intent and physical reality with uncompromising accuracy. Our core strength lies in transforming complex CAD models into high-fidelity metal prototypes and production components, where dimensional integrity is non-negotiable. This capability is fundamental for industries like aerospace, medical device development, and advanced robotics, where a prototype’s deviation from its CAD model directly impacts functionality, safety, and time-to-market. We achieve this through the strategic integration of advanced multi-axis machining and rigorous, traceable metrology.

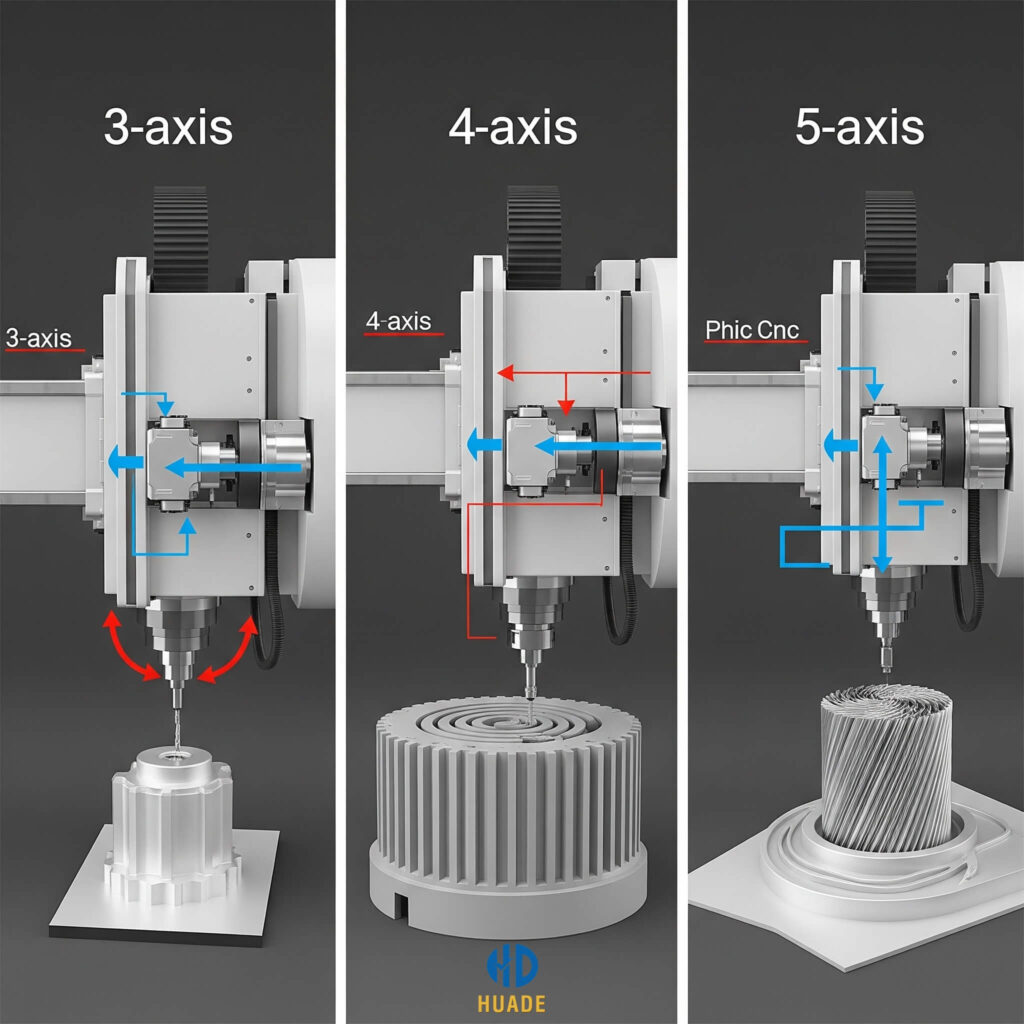

Our foundation is a modern fleet of high-precision 5-axis CNC machining centers. Unlike conventional 3-axis systems, 5-axis technology allows simultaneous movement across all critical planes, enabling the machining of intricate geometries—organic contours, deep cavities, undercuts, and compound angles—in a single setup. This eliminates cumulative errors from multiple fixturing operations, a common source of deviation between CAD and physical parts. Our machines feature rigid structures, thermal compensation systems, and high-resolution feedback loops, ensuring exceptional stability and repeatability during extended machining cycles. This capability is essential for producing prototypes that faithfully replicate the designer’s vision, allowing for accurate form, fit, and functional testing before committing to expensive production tooling.

Verification is not an afterthought; it is embedded within our process. Every critical prototype undergoes comprehensive Coordinate Measuring Machine (CMM) inspection against the original 3D CAD model. Our state-of-the-art CMMs, calibrated to international standards (ISO 17025), perform full geometric dimensioning and tolerancing (GD&T) analysis. This generates detailed deviation maps, highlighting any discrepancies between the manufactured part and the digital blueprint with micron-level precision. This data-driven validation provides objective evidence of conformance, instilling confidence that the prototype meets all specified requirements. It also offers invaluable feedback to the design and engineering teams, enabling rapid iteration and refinement early in the development cycle, significantly reducing the risk of downstream failures.

The result is a seamless, reliable transition from virtual design to tangible component. Our integrated approach minimizes the “prototype surprise,” where physical parts fail to match expectations, accelerating development cycles and reducing costly rework. We deliver not just a part, but a verified representation of your CAD data, ready for critical evaluation.

Key Dimensional Capability Specifications

| Feature Category | Typical Capability Range | Measurement Standard | Notes |

|---|---|---|---|

| Linear Dimensional Tolerance | ±0.005 mm to ±0.025 mm | Per ISO 2768-mK | Depends on feature size & geometry |

| Geometric Tolerance (GD&T) | ±0.003 mm to ±0.015 mm | Per ASME Y14.5 / ISO 1101 | Position, Profile, Runout achievable |

| Surface Roughness (Ra) | 0.4 µm to 1.6 µm | Per ISO 1302 | Machining parameters & material dependent |

| Maximum Part Size (5-Axis) | Ø 800 mm x 650 mm H | Machine envelope | Specific machine model dependent |

| CMM Measurement Uncertainty | U = 1.9 + L/300 µm (k=2) | ISO 10360-2 | For length measurement up to 1000 mm |

This commitment to precision engineering and metrological validation ensures your prototypes are true digital twins, providing the reliable data needed for confident engineering decisions and successful product launches.

Material & Finish Options

Material Selection for Prototype to CAD Comparison in Precision Manufacturing

When transitioning from prototype to final CAD-based production, material selection plays a pivotal role in ensuring dimensional accuracy, mechanical performance, and long-term reliability. At Wuxi Lead Precision Machinery, we emphasize aligning material properties with design intent, environmental exposure, and functional requirements. The most widely used metals in custom manufacturing—aluminum, steel, and titanium—each offer distinct advantages depending on the application.

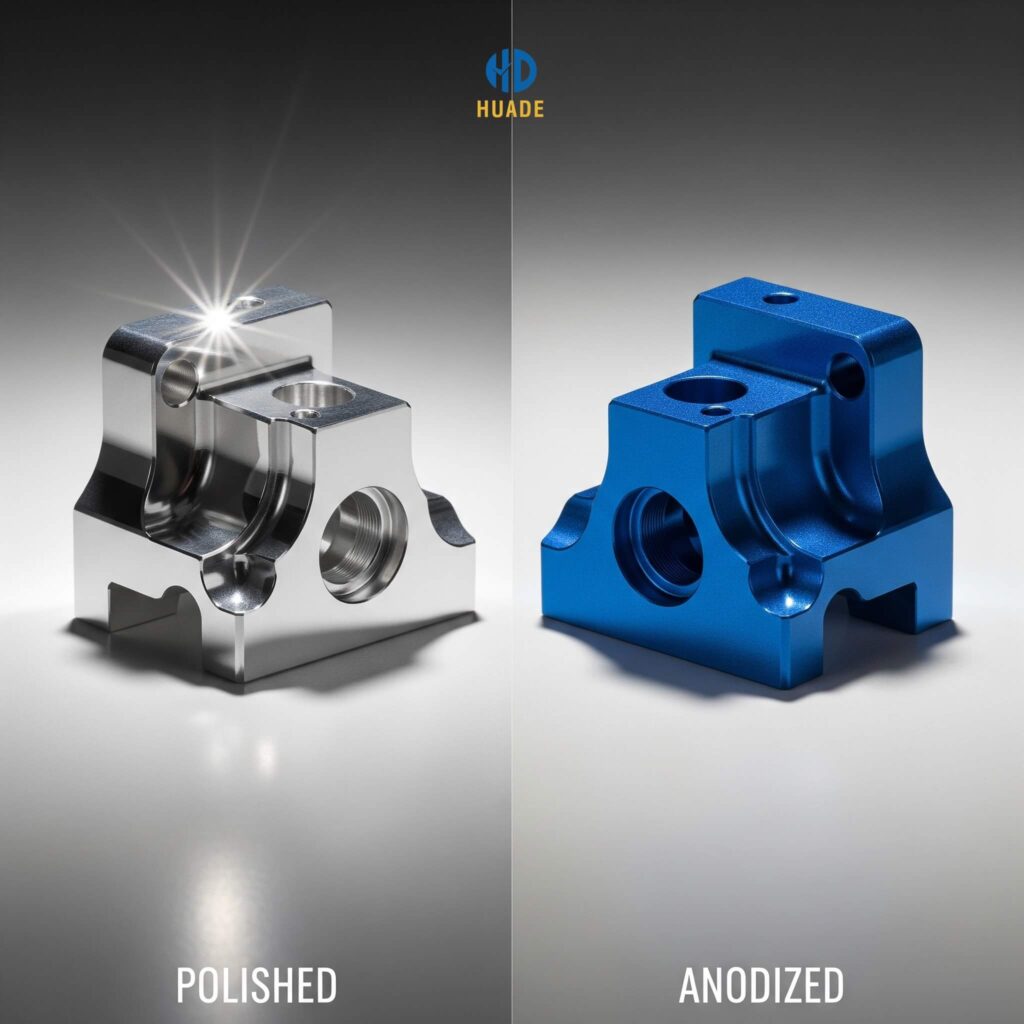

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for prototypes and end-use parts in aerospace, electronics, and automotive sectors where weight reduction is critical. 6061-T6 and 7075-T6 are common grades, with the latter offering higher strength for demanding structural applications. Aluminum readily accepts surface treatments such as anodizing, which enhances wear resistance and provides aesthetic consistency across production batches.

Steel, particularly stainless steel grades like 304 and 17-4 PH, delivers superior strength, durability, and resistance to high temperatures and corrosive environments. It is the preferred choice for medical devices, industrial tooling, and components requiring high fatigue resistance. While heavier than aluminum, steel’s dimensional stability under load makes it suitable for precision parts where deflection must be minimized. Machining steel requires advanced tooling and process control, which Wuxi Lead implements through our high-tolerance CNC systems.

Titanium, specifically Grade 5 (Ti-6Al-4V), offers an exceptional combination of high strength, low density, and outstanding corrosion resistance, particularly in saline or acidic environments. It is widely used in aerospace, defense, and biomedical applications. However, its low thermal conductivity and high chemical reactivity demand specialized machining techniques. When scaling from prototype to production, maintaining consistent tool paths and cooling strategies is essential to avoid material distortion.

Surface finishing, particularly anodizing for aluminum, bridges the gap between prototype and production by ensuring uniform appearance and enhanced surface hardness. Type II (sulfuric acid) anodizing provides decorative and moderate protection, while Type III (hardcoat anodizing) delivers a thick, wear-resistant layer suitable for industrial components. Anodizing also improves paint and adhesive bonding, critical for assemblies requiring secondary processing.

Understanding these material behaviors ensures that the transition from prototype to CAD-validated production maintains integrity across form, fit, and function.

| Material | Common Grades | Density (g/cm³) | Tensile Strength (MPa) | Key Applications | Typical Finish Options |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310–570 | Aerospace, Electronics | Anodizing (Type II/III), Powder Coat |

| Stainless Steel | 304, 17-4 PH | 7.9 | 505–1300 | Medical, Industrial | Passivation, Electropolishing |

| Titanium | Ti-6Al-4V (Grade 5) | 4.4 | 900–1100 | Aerospace, Biomedical | Anodizing, Bead Blasting |

Manufacturing Process & QC

Precision Manufacturing Process: From Design to Zero-Defect Production

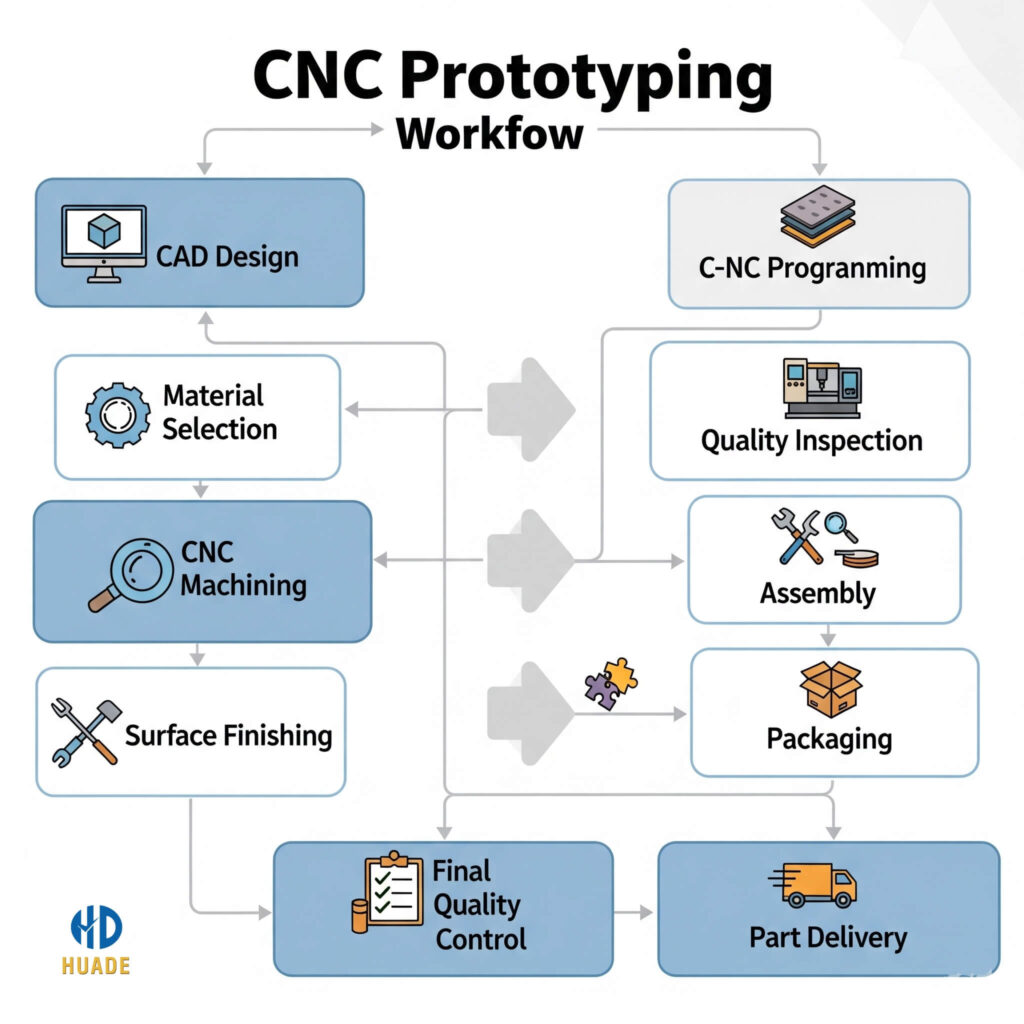

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality, transforming client concepts into flawless metal components through a rigorously controlled sequence. This begins with meticulous Design validation. Our engineering team conducts exhaustive CAD model analysis, verifying geometric integrity, manufacturability, and adherence to client specifications before any material is cut. This foundational step ensures the digital blueprint is optimized for both function and precision machining, eliminating theoretical errors early.

The critical bridge between design intent and mass production is Prototyping. We fabricate physical prototypes using the exact CNC processes and materials designated for series production. This is not merely a form check; it is a comprehensive metrology-grade verification against the original CAD model. Every critical dimension, surface finish, and feature is measured using calibrated CMMs and optical comparators. The prototype serves as the physical benchmark, validating that the digital design translates perfectly into reality under actual production conditions. This phase is where potential deviations are identified and resolved, preventing costly errors downstream.

Following successful prototype approval, we transition seamlessly into Mass Production. Crucially, the validated prototype and its metrology data become the reference for establishing and monitoring the production process. Our Zero Defects Protocol is activated, embedding quality control at every stage. Real-time in-process gauging, statistical process control (SPC) with defined capability indices (Cp/Cpk > 1.67), and 100% critical feature inspection ensure consistent output. The initial prototype-CAD comparison data directly informs the control limits and inspection criteria for the production run, guaranteeing every part meets the exact specification without variation.

This integrated approach—Design validation, Prototype as physical CAD twin, and Production governed by prototype-verified standards—is the core of our Zero Defects commitment. It systematically eliminates guesswork, ensuring first-article approval rates exceed 98% and production PPM defect rates remain consistently below 10. The rigor applied during the prototype-CAD comparison phase is the decisive factor in achieving predictable, high-yield manufacturing.

The following table details key parameters verified during the prototype-to-CAD comparison phase, forming the baseline for mass production control:

| Parameter | CAD Specification | Prototype Measurement | Acceptance Criteria |

|---|---|---|---|

| Dimensional Tolerance | ±0.010 mm | ±0.008 mm | Within spec, Cpk ≥ 1.67 |

| Critical Surface Roughness | Ra 0.8 µm | Ra 0.75 µm | Ra ≤ 0.8 µm |

| Geometric Accuracy (GD&T) | Position Ø0.025 mm | Position Ø0.020 mm | Within tolerance zone |

| Material Hardness | 45-48 HRC | 46.5 HRC | Within specified range |

This disciplined progression—from validated design through metrologically confirmed prototyping to tightly controlled mass production—delivers the dimensional certainty and process reliability demanded by aerospace, medical, and advanced industrial clients. It transforms the prototype from a simple model into the definitive standard for zero-defect manufacturing execution.

Why Choose Wuxi Lead Precision

When transitioning from prototype to final production, precision, consistency, and engineering integrity are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in high-end custom metal manufacturing that bridges the gap between concept and scalable production. Our advanced CNC machining, sheet metal fabrication, and precision engineering capabilities ensure your prototype design is not only replicated with exacting accuracy but optimized for real-world performance, durability, and cost-efficiency.

Partnering with Lead Precision means aligning with a manufacturer that treats your design as a strategic asset. We go beyond replication—we validate. Every prototype-to-CAD comparison is conducted using industry-leading 3D scanning technology and metrology-grade software to detect deviations at the micron level. This rigorous verification process ensures that the final manufactured part conforms precisely to your digital model, maintaining geometric fidelity, dimensional accuracy, and functional integrity.

Our engineering team collaborates directly with your design and R&D departments to analyze discrepancies, recommend material and tolerance adjustments, and refine manufacturability without compromising design intent. Whether you’re producing aerospace components, medical devices, or industrial automation systems, we deliver a seamless transition from prototype validation to full-scale production—all under ISO 9001-certified quality management systems.

We understand that in high-stakes industries, even a 0.01 mm deviation can lead to system failure. That’s why our prototype-to-CAD comparison service includes comprehensive reporting with color-mapped deviation analysis, cross-sectional comparisons, and GD&T verification. This level of transparency empowers your team to make informed decisions, accelerate time-to-market, and reduce costly rework.

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we build trusted partnerships grounded in technical excellence, responsiveness, and long-term value.

| Specification | Capability |

|---|---|

| Dimensional Accuracy | Up to ±0.005 mm |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Brass, Tool Steels, Exotic Alloys |

| Max Workpiece Size | 2000 mm × 1200 mm × 800 mm |

| 3D Scanning Resolution | 0.01 mm point accuracy |

| CAD Comparison Output | Deviation maps, PDF reports, STEP/IGES annotations |

| Industries Served | Aerospace, Medical, Robotics, Semiconductor, Automotive |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) Reports |

We invite you to experience the precision and reliability that global engineering leaders trust. For a detailed prototype-to-CAD evaluation, technical consultation, or quotation, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your partner in turning innovation into precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.