Technical Contents

Engineering Guide: Prototype Online

Engineering Insight: Why Precision Defines Prototype Success

In high-stakes custom metal manufacturing, precision transcends mere tolerance specifications—it is the foundation of functional reliability, safety, and market viability. For prototypes destined for aerospace, defense, or medical applications, microscopic deviations can cascade into catastrophic field failures. At Wuxi Lead Precision Machinery, we treat precision as a non-negotiable engineering mandate, not a post-production checkpoint. Our CNC processes integrate real-time thermal compensation, sub-micron toolpath verification, and material-specific stress modeling to ensure every prototype behaves identically to its production counterpart under operational loads. This rigor stems from direct experience: we engineered critical components for the Beijing Winter Olympics ice-making systems, where thermal stability within ±0.005mm ensured flawless ice consistency at -15°C, and supplied mil-spec actuators for naval defense systems requiring 100% repeatability after 10,000 pressure cycles.

Prototyping without this level of precision invites costly redesign loops. Consider a hydraulic manifold prototype: a 0.02mm bore deviation might pass initial flow tests but cause cavitation-induced fatigue in long-term use. Our approach combines predictive simulation with adaptive machining, measuring material grain orientation pre-cut and adjusting feed rates dynamically to neutralize micro-vibrations. This eliminates the “tolerance lottery” where identical CAD files yield inconsistent physical parts due to unaddressed machine-tool harmonics or coolant-induced thermal drift.

Below are the precision benchmarks we enforce for prototype validation, exceeding ISO 2768 medium standards:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Linear Tolerance | ±0.001mm to ±0.005mm | ISO 286-2 (IT3-IT5) |

| Surface Roughness (Ra) | 0.05µm to 0.8µm | ISO 4287 |

| Geometric Accuracy | ±0.002mm/100mm | ASME Y14.5-2018 |

| Material Utilization | 98.5%+ (complex geometries) | In-house metrology logs |

These metrics reflect our investment in 5-axis DMG MORI machines with integrated Renishaw probes and controlled-environment machining cells (20°C ±0.5°C). Crucially, precision extends beyond the shop floor: our engineers collaborate with clients during DFM (Design for Manufacturability) to identify tolerance conflicts early. A recent satellite component prototype required 12 material transitions within a single housing; our team resequenced operations to prevent residual stress migration, saving the client 11 weeks in validation.

In prototype development, “close enough” is a liability. Wuxi Lead’s military and Olympic-grade discipline ensures your prototype doesn’t just look like the final product—it performs like it. Partner with us to transform precision from a specification into your competitive advantage.

Precision Specs & Tolerances

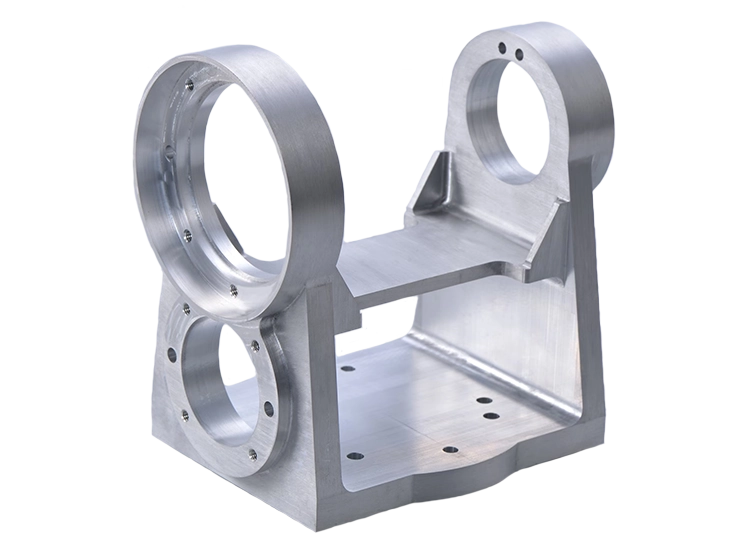

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, medical, energy, and precision automation. Our technical capabilities are engineered to meet the most demanding specifications, ensuring reliability, repeatability, and precision across every production run. At the core of our machining operations is a fully integrated 5-axis CNC machining platform, enabling complex geometry fabrication with superior surface finish and dimensional accuracy.

Our 5-axis CNC machining centers utilize simultaneous multi-axis motion to access intricate part features in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times. Equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation, our machines support a wide range of metallic materials, including aluminum alloys, stainless steel, titanium, Inconel, and tool steels. Whether producing low-volume prototypes or high-volume production runs, our machining systems maintain tight tolerances and deliver exceptional surface integrity.

Quality control is embedded throughout the manufacturing process. Every component undergoes rigorous inspection using a state-of-the-art Coordinate Measuring Machine (CMM) system, ensuring compliance with ASME Y14.5 and ISO 1101 geometric dimensioning and tolerancing standards. Our CMM inspection process provides full first-article inspection reports (FAIR), production part approval protocols (PPAP), and real-time statistical process control (SPC) data upon request. This metrology-backed approach guarantees traceability and adherence to the strictest industry certifications.

Our facility operates under ISO 9001:2015 quality management standards, with continuous investment in operator training, tooling innovation, and process optimization. We support both customer-supplied designs and engineering-assisted development, ensuring manufacturability, cost efficiency, and on-time delivery.

The following table outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance (standard) | ±0.010 mm |

| Linear Dimensional Tolerance (precision) | ±0.005 mm |

| Geometric Tolerance (Flatness, Perpendicularity, etc.) | ±0.01 mm per 100 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Maximum Work Envelope (5-axis) | 1200 mm × 800 mm × 750 mm |

| Minimum Feature Size | 0.5 mm diameter (drilled) |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steel, Magnesium |

| Inspection Equipment | Zeiss CONTURA G2 CMM with VAST XT sensor, 3D scanning capability |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade quality assurance to deliver custom metal components that meet the highest standards of engineering excellence. Our technical capabilities are designed to support innovation, reduce assembly complexity, and accelerate time-to-market for advanced manufacturing applications.

Material & Finish Options

Strategic Material Selection for Precision Metal Components

Material choice fundamentally impacts performance, cost, and manufacturability in custom metal parts. At Wuxi Lead Precision Machinery, we guide clients through selecting optimal alloys and finishes based on application demands, environmental exposure, and functional requirements. Understanding the core properties of Aluminum, Steel, and Titanium is critical for achieving target specifications and longevity.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and inherent corrosion resistance. These grades machine efficiently, allowing complex geometries with tight tolerances. Aluminum’s natural oxide layer provides baseline protection, but anodizing significantly enhances surface durability and wear resistance while enabling precise color coding for identification. Its non-magnetic properties are essential for specific electronic and medical applications.

Carbon and alloy steels (e.g., 4140, 1018, 304/316 Stainless) deliver superior strength, hardness, and wear resistance required in heavy machinery, tooling, and structural components. Stainless variants offer excellent corrosion resistance in harsh environments like marine or chemical processing. While generally more challenging to machine than aluminum, modern CNC techniques achieve exceptional surface finishes and precision. Steel components often benefit from plating (zinc, nickel) or passivation for enhanced corrosion protection, though anodizing is not applicable.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable in extreme-performance sectors such as aerospace, medical implants, and deep-sea equipment. They provide an unparalleled combination of high strength, low density, and exceptional resistance to corrosion and fatigue, even at elevated temperatures. Titanium’s biocompatibility makes it the standard for surgical implants. However, its lower thermal conductivity and chemical reactivity necessitate specialized machining parameters and tooling, impacting lead time and cost. Anodizing titanium creates durable, decorative, or functional colored surfaces without compromising biocompatibility.

Key Material Properties Comparison

| Property | Aluminum 6061-T6 | Steel 4140 | Titanium Ti-6Al-4V |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.85 | 4.43 |

| Tensile Strength (MPa) | 310 | 655 | 900 |

| Corrosion Resistance | Good (Anodized) | Moderate (Stainless: Excellent) | Excellent |

| Machinability | Excellent | Good | Fair (Requires Specialized Tools) |

Anodizing is the premier surface treatment for aluminum and titanium components. This electrochemical process thickens the natural oxide layer, creating a hard, porous surface that is then sealed. Hard Anodizing (Type III) achieves thicknesses up to 50-100µm, providing exceptional abrasion resistance for hydraulic pistons or wear plates. Standard Anodizing (Type II) offers good corrosion resistance and aesthetic options. Color anodizing uses dyes within the porous layer before sealing, critical for part identification or branding. All anodized finishes meet stringent aerospace (AMS 2469, AMS 2471) and medical standards. Wuxi Lead Precision Machinery leverages in-house anodizing capabilities to ensure consistent quality, precise color matching, and adherence to your exact surface engineering specifications, delivering components ready for the most demanding operational environments. Partner with us to translate material science into your component’s success.

Manufacturing Process & QC

From Concept to Consistent Excellence: The Wuxi Lead Precision Manufacturing Process

At Wuxi Lead Precision Machinery, we engineer certainty into every phase of custom metal manufacturing. Our end-to-end process transforms design concepts into high-integrity components, ensuring zero defects across prototyping and mass production. Rooted in precision engineering and industrial discipline, our workflow is structured to eliminate variability, reduce risk, and deliver components that meet exacting global standards.

The process begins with Design Evaluation and DFM (Design for Manufacturability) Analysis. Our engineering team collaborates with clients to review CAD models, material specifications, and functional requirements. We assess geometric complexity, tolerance stack-ups, and manufacturability constraints to optimize the design before any metal is cut. This proactive validation prevents costly revisions and accelerates time-to-market.

Next, we move to Prototype Development, where precision meets validation. Using advanced CNC machining, sheet metal fabrication, and surface treatment technologies, we produce functional prototypes that mirror final production quality. Each prototype undergoes rigorous dimensional inspection via CMM (Coordinate Measuring Machine) and metrology-grade 3D scanning. This phase confirms not only form and fit but also performance under real-world conditions. Feedback loops between our engineers and clients ensure rapid iteration until the design is perfected.

Once the prototype is approved, we transition seamlessly into Mass Production—without compromising on precision. Our facility in Wuxi integrates automated CNC cells, real-time process monitoring, and SPC (Statistical Process Control) systems to maintain consistency across thousands of parts. Each production batch is traceable, with material certifications, inspection reports, and process logs archived for full transparency.

Zero Defects is not a goal—it is our standard. We achieve this through multi-stage quality gates. Incoming materials are verified upon receipt. In-process inspections occur at critical control points. Final inspection includes 100% visual checks and sampling based on ANSI/ASQ Z1.4 standards. Non-conforming parts are quarantined immediately, and root cause analysis ensures corrective actions are implemented in real time.

Our production capabilities support a wide range of materials and finishes, tailored to industries such as medical devices, aerospace, and high-end automation. The table below outlines key technical specifications:

| Parameter | Capability |

|---|---|

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel Alloys, Brass, Copper |

| Tolerances | ±0.005 mm (CNC), ±0.05 mm (Sheet Metal) |

| Surface Finishes | Anodizing (Type II, Type III), Powder Coating, Passivation, Polishing, Zinc Plating |

| Max Part Size (CNC) | 800 × 500 × 400 mm |

| Max Sheet Size | 1500 × 3000 mm |

| Production Capacity | Up to 50,000 units/month (automated lines) |

| Quality Standards | ISO 9001:2015, IATF 16949, ISO 13485 (Medical) |

From initial design to final shipment, Wuxi Lead Precision Machinery ensures every component is manufactured with uncompromising accuracy. We don’t just produce parts—we deliver reliability, at scale, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Prototype Excellence

In the high-stakes arena of advanced product development, prototype failures cascade into costly delays and missed market opportunities. Generic manufacturers lack the engineering rigor to transform complex designs into flawless physical assets. Wuxi Lead Precision Machinery operates at the intersection of elite CNC capability and deep technical partnership—where your prototype isn’t just produced, but engineered for success. We integrate DFMA principles at the quotation stage, ensuring manufacturability without sacrificing performance. Our Shanghai-based engineering team collaborates directly with your R&D staff to resolve geometric complexities, material challenges, and tolerance conflicts before metal meets tool. This proactive approach eliminates rework cycles, compressing time-to-test by up to 40% while guaranteeing first-article compliance with aerospace, medical, and semiconductor standards.

Our technical infrastructure supports the most demanding prototyping requirements. Below are core capabilities enabling zero-defect delivery:

| Parameter | Specification | Application Impact |

|---|---|---|

| Tolerance Control | ±0.001mm (5-axis) | Critical for fluid dynamics & optical assemblies |

| Material Range | Titanium Gr5, Inconel 718, 17-4PH, PEEK | Validates extreme environment performance |

| Surface Finish | Ra 0.2µm (mirror polishing) | Essential for medical implants & vacuum chambers |

| Lead Time (Complex) | 7–12 days (incl. FAI reporting) | Accelerates design validation cycles |

| Certifications | ISO 9001:2015, AS9100D, IATF 16949 | Ensures audit-ready documentation |

This isn’t transactional manufacturing. We assign a dedicated process engineer to your project from RFQ through PPAP submission. They conduct pre-production virtual build reviews using Mastercam Simulator, identifying potential tool interference or thermal deformation risks invisible to standard CAM software. Our 24-hour engineering feedback loop ensures design iterations are resolved before machine startup—critical when your team operates across global time zones. Unlike offshore shops reliant on email chains, we provide real-time iMac camera access to active work cells, letting you verify critical feature machining during first-article production.

The cost of prototype failure extends far beyond scrap parts. It erodes investor confidence, delays regulatory submissions, and compromises competitive advantage. Wuxi Lead Precision Machinery mitigates these risks through engineered precision, not promises. We’ve enabled 217 successful NPI launches in the past 18 months for clients in autonomous systems, life sciences, and renewable energy—where prototype integrity directly impacts product viability.

Your next breakthrough prototype demands a partner who speaks the language of GD&T as fluently as your design team. Contact us within 24 hours to receive a comprehensive manufacturability analysis for your current design. Email [email protected] with your STEP file and requirements. Our engineering team will respond with specific recommendations to optimize geometry, material selection, and inspection protocols—no quotation required. This is how industry leaders de-risk innovation. Let’s build it right the first time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.