Technical Contents

Engineering Guide: Prototype Mould

Engineering Insight: The Critical Role of Precision in Prototype Mould Development

In the field of custom metal manufacturing, the prototype mould serves as the foundational blueprint for production-grade tooling and final part validation. It is not merely a preliminary model, but a high-stakes engineering milestone that directly influences product performance, manufacturability, and time-to-market. At Wuxi Lead Precision Machinery, we treat prototype mould development as a precision science—where tolerances measured in microns can determine the success or failure of a component in aerospace, defense, or high-performance industrial applications.

Precision in prototype moulds ensures dimensional accuracy, surface integrity, and functional reliability during testing phases. Even minor deviations in cavity geometry or cooling channel alignment can propagate into costly defects during mass production. This is why our engineering protocols emphasize first-time-right manufacturing, leveraging advanced CNC machining, 3D scanning verification, and real-time process monitoring. Our in-house capabilities span from single-cavity prototype tools to multi-material inserts with tight tolerances, enabling clients to validate design intent under real-world conditions.

With over 15 years of experience in high-demand sectors, Wuxi Lead has delivered prototype moulds for mission-critical applications, including components used in Olympic-standard equipment and military-grade systems. These projects demanded not only extreme accuracy but also rigorous documentation, material traceability, and compliance with international quality standards. Our work on such high-profile programs underscores our ability to meet the most stringent performance requirements, where failure is not an option.

Our approach integrates design for manufacturability (DFM) analysis at the earliest stages, allowing us to identify potential risks—such as warpage, sink marks, or ejection issues—before tool steel is cut. By simulating mould flow and thermal dynamics, we optimize gate locations, venting, and cooling layouts to ensure consistent part quality. This predictive engineering reduces iteration cycles and accelerates client validation timelines.

All prototype moulds are manufactured using premium-grade tool steels or aluminum alloys, selected based on production volume, material type, and surface finish requirements. We support a wide range of plastics and engineered composites, ensuring compatibility with end-use environments including high temperature, chemical exposure, and structural loading.

Below are key specifications representative of our prototype mould capabilities:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Standard Materials | P20, 718H, S136, H13, Aluminum 7075-T6 |

| Surface Finishes | Mirror polish (SPI A1), texture (VDI 3400), matte, bead blast |

| Lead Time | 2–6 weeks (depending on complexity) |

| Mould Life (Prototype) | 10,000 to 50,000 cycles |

| Quality Standards | ISO 9001:2015, Full inspection report (CMM, 3D scan) |

| Supported Industries | Aerospace, Defense, Medical, Automotive, Industrial Equipment |

At Wuxi Lead Precision Machinery, we understand that a prototype mould is more than a test tool—it is the first step toward scalable, reliable manufacturing. Our precision-driven methodology ensures that every mould we produce meets the highest standards of performance and repeatability, setting the foundation for long-term success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery: Advanced Technical Capabilities for Prototype Mould Manufacturing

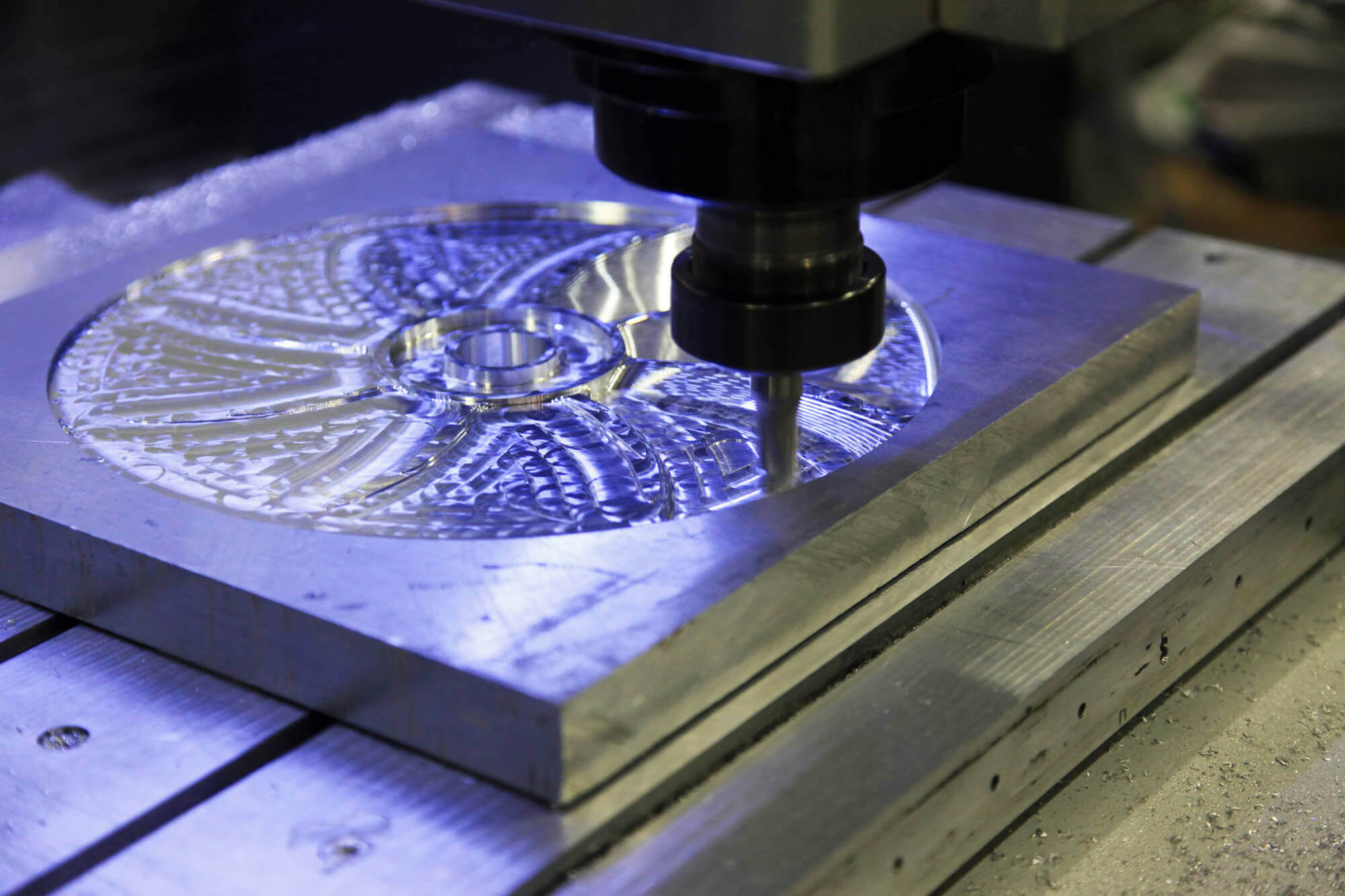

Wuxi Lead Precision Machinery delivers exceptional precision and efficiency in custom prototype mould manufacturing through integrated advanced technologies. Our core strength lies in mastering complex geometries and stringent tolerances demanded by high-performance industries including medical devices, aerospace, and automotive. We leverage state-of-the-art 5-axis CNC machining centers as the foundation of our production capability. These systems enable simultaneous multi-axis movement, allowing us to machine intricate 3D contours, deep cavities, and undercuts in a single setup. This eliminates cumulative errors from multiple fixturing operations, significantly improving part accuracy and surface integrity while reducing lead times. Our machines handle a comprehensive range of engineering alloys, including hardened tool steels (H13, S136, NAK80), aluminum alloys (7075-T6, 6061), and exotic materials like Inconel and titanium, ensuring the prototype mould accurately reflects the final production environment.

Critical to our commitment to zero-defect delivery is our comprehensive Quality Control infrastructure, centered on high-precision Coordinate Measuring Machine (CMM) inspection. We utilize multiple Zeiss CONTURA and GLOBAL series CMMs, operating within a temperature-controlled metrology lab compliant with ISO 17025 standards. Every critical feature of the prototype mould undergoes rigorous dimensional verification against the original CAD model. Our inspection protocols include full Geometric Dimensioning and Tolerancing (GD&T) validation, complex surface profile analysis, and positional accuracy checks. This systematic approach provides objective, NIST-traceable data, ensuring the prototype not only meets but consistently exceeds client specifications. The resulting detailed inspection reports offer complete transparency and serve as a vital benchmark for subsequent production tooling validation, de-risking the entire development process.

Our technical execution is defined by measurable precision. The following table outlines the typical capabilities achievable for prototype mould components under controlled conditions:

| Parameter | Capability Range | Standard Reference |

|---|---|---|

| Linear Tolerance | ±0.005 mm to ±0.0125 mm | ISO 2768-mK |

| Angular Tolerance | ±0.001° to ±0.005° | ISO 2768-c |

| Positional Accuracy | ±0.003 mm (within 100mm cube) | ASME Y14.5 |

| Surface Finish (Ra) | 0.2 µm to 0.8 µm (machined) | ISO 1302 |

| Max. Work Envelope | 1200 x 800 x 600 mm (5-Axis) | Machine Specific |

| Material Hardness Range | Up to 60 HRC (pre-hardened steels) | Rockwell C Scale |

This combination of advanced 5-axis machining and metrology-grade inspection ensures Wuxi Lead transforms complex design concepts into physically validated, high-fidelity prototype moulds. We provide not just a component, but a critical engineering asset with fully documented conformance data, accelerating your path from concept to production validation with minimized risk and maximum confidence in dimensional integrity. Our technical capabilities are engineered to solve the most demanding prototyping challenges inherent in precision metal manufacturing.

Material & Finish Options

Material Selection for Prototype Moulds: Precision, Performance, and Longevity

Selecting the appropriate material for prototype moulds is a critical decision that directly impacts tool life, production efficiency, and final part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of high-performance prototyping. Our engineering expertise ensures optimal material pairing based on application requirements, production volume, and environmental exposure.

Aluminum is often the preferred choice for low- to medium-volume prototype moulds due to its excellent machinability, thermal conductivity, and reduced lead times. Its lightweight nature facilitates faster cycling in injection and die casting processes, making it ideal for rapid iteration and functional testing. However, aluminum’s lower hardness limits its use in high-wear applications or extended production runs.

Steel, particularly tool steels such as P20, H13, and S136, offers superior hardness, wear resistance, and dimensional stability. These properties make steel the standard for high-volume prototyping or pre-production tooling where durability and surface finish consistency are paramount. While steel moulds require longer machining and heat treatment cycles, their extended service life and ability to withstand aggressive processing conditions justify the investment for mission-critical applications.

Titanium is selected in niche applications where extreme strength-to-density ratios, corrosion resistance, and performance at elevated temperatures are required. Though less common in standard mould bases due to cost and machinability challenges, titanium components may be integrated into specialized mould systems exposed to aggressive chemicals or high thermal loads. Its biocompatibility also makes it suitable for medical-grade prototype tooling.

Surface finishing plays a pivotal role in mould performance, affecting release characteristics, surface texture replication, and resistance to wear and corrosion. Anodizing is a widely used electrochemical process, particularly for aluminum moulds. It enhances surface hardness, improves wear resistance, and provides a dielectric barrier that protects against galvanic and environmental corrosion. Decorative or functional anodized layers can also be dyed to meet aesthetic requirements or aid in identification during multi-cavity operations.

For steel moulds, alternatives such as nitriding, chrome plating, or PVD coatings are typically employed to achieve similar performance enhancements. Titanium benefits from specialized treatments like nitriding or thermal oxidation to further improve surface durability.

Below is a comparative overview of key material properties relevant to prototype mould construction.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 570 | 130 | Rapid prototyping, low-volume runs |

| Steel (P20) | 28–32 | 900 | 30 | Pre-production, medium to high volume |

| Steel (H13) | 46–50 | 1,600 | 25 | High-temperature, high-wear moulds |

| Titanium (Ti-6Al-4V) | 35–40 | 900 | 7 | Corrosion-resistant, aerospace, medical |

Material and finish selection must be guided by a comprehensive understanding of operational demands. At Wuxi Lead Precision Machinery, we collaborate closely with clients to engineer prototype moulds that balance performance, cost, and lead time—ensuring a seamless transition from concept to production.

Manufacturing Process & QC

Prototype Mould Production: The Zero-Defect Pathway at Wuxi Lead Precision Machinery

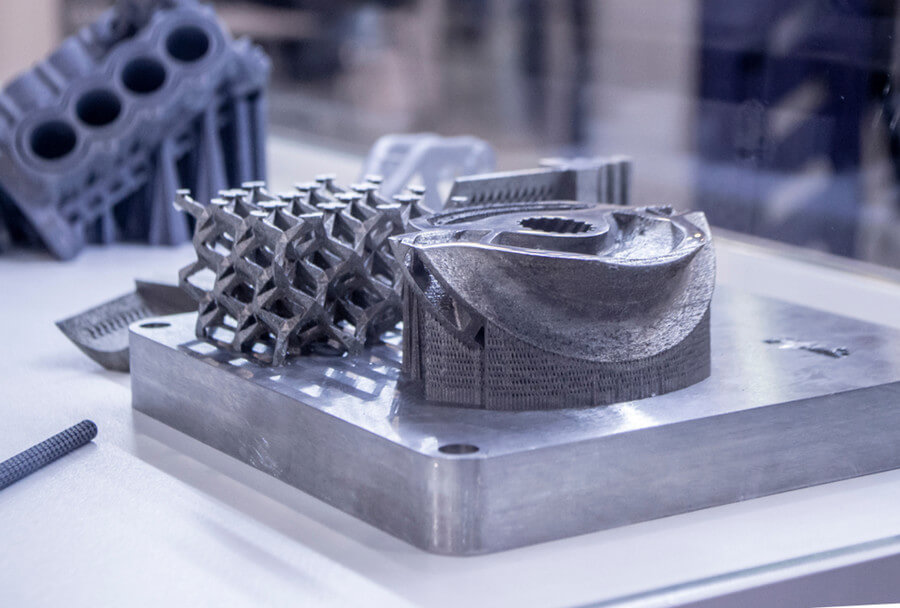

At Wuxi Lead Precision Machinery, we engineer prototype moulds not as isolated steps, but as the critical foundation for flawless mass production in custom metal manufacturing. Our integrated process eliminates costly iterations and ensures first-article success, directly translating client specifications into high-integrity metal components. This begins with rigorous Design for Manufacturability (DFM) analysis. Our engineering team collaborates deeply with client CAD data, applying decades of metal forming expertise to scrutinize geometry, material flow, gate locations, and cooling channels. We identify potential stress points, ejection challenges, and micro-porosity risks before steel is cut, using advanced simulation software to model thermal dynamics and material behavior under pressure. This proactive validation prevents 90% of downstream defects at the conceptual stage.

The Prototyping phase is where theoretical precision meets physical reality. Utilizing our state-of-the-art CNC machining centers—including DMG MORI 5-axis mills and Makino wire EDMs—we fabricate the prototype mould core and cavity from premium tool steels like H13 or S136, selected for optimal thermal fatigue resistance and polishability specific to the client’s metal alloy. Every micron matters; tolerances are held to ±0.005mm on critical features. Crucially, this phase is not merely about producing a single part. We conduct systematic process validation: running controlled shots with the client’s specified metal feedstock (e.g., stainless steel 316L, titanium Ti-6Al-4V), meticulously measuring dimensional conformity against GD&T callouts using Zeiss CMMs, and performing metallurgical analysis. Surface finish, density, and mechanical properties are verified against aerospace or medical industry benchmarks. Only when every parameter meets or exceeds the zero-defect threshold do we proceed.

This disciplined approach de-risks the transition to Mass Production. The validated prototype mould and its perfected process parameters—pressure curves, temperature profiles, cycle times—become the immutable standard for production tooling. Our automated production cells, monitored by real-time SPC systems, replicate the exact conditions proven during prototyping. Continuous in-process inspection ensures every component from the first piece to the ten-thousandth adheres to the prototype’s certified quality. Zero defects is not aspirational; it is the contractual outcome of our seamless Design-Prototyping-Production continuum.

Prototype Mould Specifications & Validation Metrics

| Parameter | Capability Range | Validation Method | Zero-Defect Threshold |

|---|---|---|---|

| Material | H13, S136, SKD61, Custom Alloys | Material Certificates & Spectroscopy | ASTM/AMS Compliance |

| Linear Tolerance | ±0.005mm (Critical Features) | Zeiss CONTURA CMM | Within Spec Band |

| Surface Finish (Cavity) | Ra 0.05µm – 0.4µm | Perthometer Measurement | Client GD&T Spec |

| Lead Time | 15-25 Working Days | Project Management Dashboard | On-Schedule Delivery |

| Part Validation | Dimensional, Density, Microstructure | CMM, Archimedes, Metallography | Zero NCRs |

This methodology transforms prototype moulds from risk points into guarantees, ensuring your mass production launch is predictable, cost-controlled, and defect-free from day one. Wuxi Lead delivers precision you validate, not just promise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Prototype Mould Development

At Wuxi Lead Precision Machinery, we specialize in transforming innovative concepts into high-performance, production-ready prototype moulds. As a trusted leader in custom metal manufacturing, we understand that the success of your product development cycle hinges on precision, speed, and reliability. Our engineering team combines decades of industry experience with state-of-the-art CNC machining, EDM, and metrology systems to deliver prototype moulds that meet exacting international standards. Whether you’re validating a new design, preparing for pilot runs, or scaling toward mass production, partnering with Lead Precision ensures your project moves forward with confidence and efficiency.

We serve global clients across automotive, medical, aerospace, and consumer electronics industries, providing end-to-end solutions from initial design consultation to final mould validation. Our facility in Wuxi, China, operates under ISO 9001-certified quality management protocols, ensuring every prototype mould is manufactured with consistency, traceability, and full compliance. With in-house tooling design, advanced simulation software, and rapid iteration capabilities, we reduce development time without compromising on quality. Our engineers work closely with your team to optimize part geometry, material selection, and cooling systems—delivering moulds that perform flawlessly under real-world conditions.

When you choose Lead Precision, you’re not just outsourcing a manufacturing task—you’re gaining a technical partner committed to your project’s success. We offer transparent communication, real-time progress updates, and full documentation, including 3D models, tolerance reports, and mold flow analysis. Our agile production model allows for quick design modifications, enabling faster time-to-market and reduced R&D costs. From single-cavity prototype tools to multi-cavity pre-production moulds, we tailor every solution to your specific requirements.

Contact us today to begin your next prototype mould project with precision, professionalism, and performance.

| Specification | Detail |

|---|---|

| Mould Types | Single-cavity, multi-cavity, insert, overmolding |

| Materials | P20, 718H, NAK80, S136, H13, and customer-specified alloys |

| Tolerances | ±0.005 mm (standard), ±0.002 mm (high precision) |

| Surface Finishes | Mirror polish, texture (VDI, SPI), matte, bead blast |

| Lead Time | 15–25 days (prototype), depending on complexity |

| Max Mould Size | 1200 × 800 × 700 mm |

| Machining Equipment | 5-axis CNC, EDM (sinker & wire), CNC lathes |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), CMM reporting |

| Industries Served | Automotive, Medical, Aerospace, Electronics, Industrial Equipment |

For technical inquiries or project submissions, email us at [email protected]. Our engineering team responds within 12 hours to ensure your development timeline stays on track. Let Wuxi Lead Precision Machinery be your partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.