Technical Contents

Engineering Guide: Prototype Maker Online Free

Engineering Insight: The Role of Precision in Online Prototype Development

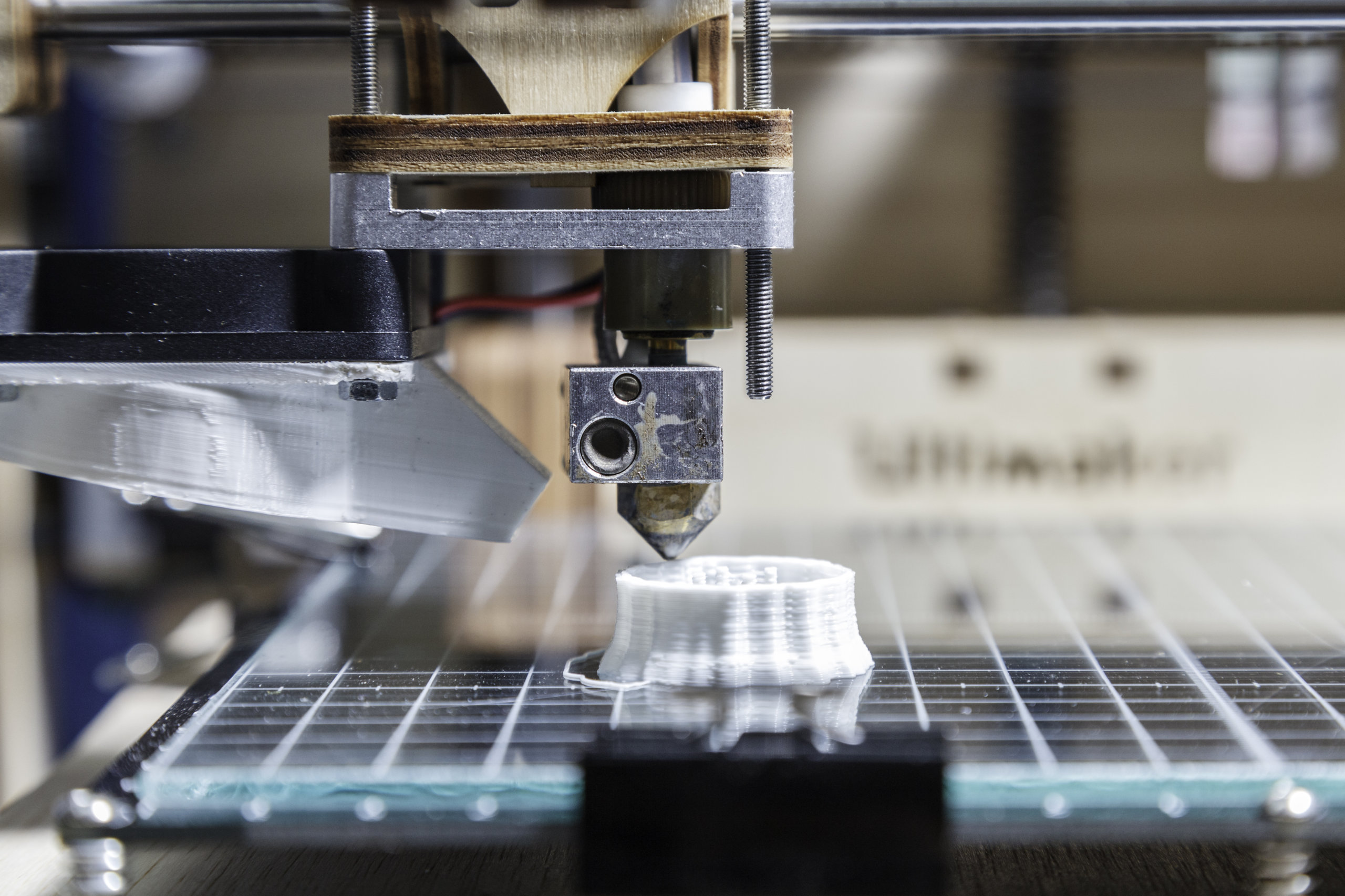

In the rapidly evolving landscape of custom metal manufacturing, the ability to generate a prototype maker online free service has become a pivotal tool for innovation. However, while accessibility and cost-efficiency are compelling advantages, the true measure of a prototype lies not in its speed of creation, but in its dimensional accuracy, material integrity, and functional reliability. At Wuxi Lead Precision Machinery, we understand that precision engineering is the foundation upon which successful prototyping is built—especially when serving high-stakes industries such as aerospace, defense, and advanced industrial automation.

Our experience as a certified precision manufacturer for Olympic-standard equipment and military-grade components has instilled a rigorous discipline in every phase of production. These projects demanded tolerances within ±0.002 mm, full traceability of materials, and adherence to ISO 9001 and AS9100 quality standards. When applied to prototype development, this level of precision ensures that early-stage components are not merely visual models, but functional representations capable of withstanding real-world testing and validation.

Free online prototype makers often prioritize convenience over accuracy, relying on automated quoting systems that may overlook critical factors such as material anisotropy, thermal deformation, or tool deflection. At Lead Precision, our digital platform integrates advanced CNC simulation and DFM (Design for Manufacturability) analysis to preemptively identify potential flaws. This ensures that the prototype delivered matches both the geometric intent and the performance expectations of the original design.

Furthermore, our in-house 5-axis milling, Swiss turning, and laser cutting capabilities allow us to maintain tight control over production variables. Whether fabricating a single titanium aerospace bracket or a batch of stainless steel hydraulic manifolds, our equipment is calibrated daily and operated by engineers with over 15 years of average experience.

We offer a free online prototype quoting system not as a replacement for engineering rigor, but as an entry point into a process where precision is non-negotiable. Our clients benefit from instant access to manufacturability feedback, lead time estimates, and material optimization suggestions—all powered by real-time machine data.

Below are key specifications that define our prototype manufacturing capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm to ±0.01 mm (depending on material and geometry) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (5-axis milling) |

| Minimum Feature Size | 0.3 mm internal radii, 0.1 mm wall thickness |

| Materials Supported | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5, Brass, Copper, Inconel |

| Lead Time (Prototype) | 5–10 business days (including inspection and reporting) |

| Quality Documentation | Full CMM reports, material certs, FAI available |

Precision is not an optional upgrade—it is the standard. At Wuxi Lead Precision Machinery, we combine advanced technology with deep engineering expertise to ensure that every prototype functions as the first true iteration of a production-ready component.

Precision Specs & Tolerances

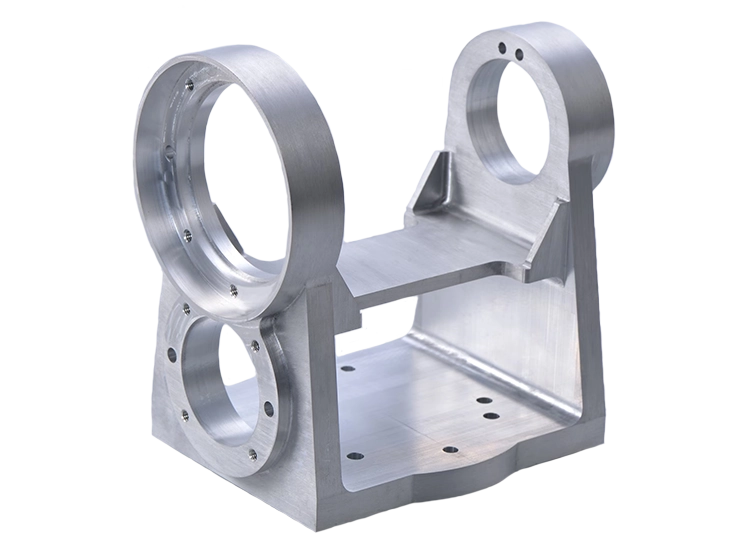

Technical Capabilities: Precision Metal Prototyping Beyond Basic Online Services

Wuxi Lead Precision Machinery delivers engineered metal prototypes where standard “free online prototype maker” services reach their limits. We specialize in complex, high-integrity metal components requiring true industrial precision, not just conceptual models. Our foundation is a modern, tightly controlled manufacturing ecosystem designed specifically for demanding prototyping and low-volume production in aerospace, medical, and advanced industrial sectors. Forget the compromises of automated quotation systems for simple geometries; we engage engineering expertise from your initial sketch to final inspection.

Our core capability centers on advanced 5-axis CNC machining. We operate a dedicated cell featuring DMG MORI CTX beta 1250 and Hermle C 800 U milling centers, providing simultaneous multi-axis movement for intricate geometries, compound angles, and complex organic shapes impossible with 3-axis systems. This eliminates multiple setups, drastically improving positional accuracy and surface finish while reducing lead times. Material versatility is critical for functional prototypes; we routinely machine titanium alloys (including Ti-6Al-4V), high-strength aluminum (7075-T6), stainless steels (17-4PH, 316L), Inconel 718, and specialized engineering plastics like PEEK. Our machines maintain sub-micron repeatability, ensuring the first part meets specification and every subsequent piece is identical.

Precision is meaningless without rigorous verification. Every critical prototype undergoes comprehensive dimensional validation using our Zeiss CONTURA G2 Coordinate Measuring Machine (CMM). This isn’t a spot-check; we execute full GD&T analysis against your CAD model, generating detailed inspection reports with traceable NIST-certified measurements. Our CMM process validates complex contours, true position tolerances, profile accuracy, and surface relationships that basic calipers or optical comparators cannot assess. This level of scrutiny is non-negotiable for prototypes destined for performance testing or regulatory submission. We integrate inspection data directly with machining processes for immediate corrective action, ensuring zero-defect delivery.

Understanding achievable tolerances is fundamental to successful prototyping. While online calculators offer generic ranges, real-world capability depends on geometry, material, and process control. Our proven machining tolerances for critical features are consistently maintained as follows:

| Feature Type | Typical Tolerance (Metric) | Typical Tolerance (Imperial) | Process Notes |

|---|---|---|---|

| Linear Dimensions | ± 0.005 mm | ± 0.0002 in | Standard for critical mating surfaces |

| Hole Diameter (Reamed) | ± 0.003 mm | ± 0.0001 in | H7/g6 fits achievable |

| Positional Tolerance | ± 0.010 mm | ± 0.0004 in | Verified via CMM full GD&T analysis |

| Surface Roughness (Ra) | 0.8 µm | 32 µin | As-machined; finer with polishing |

| Profile of Surface | 0.015 mm | 0.0006 in | Complex contours per ISO 1101 |

These specifications represent our standard production capability for well-defined features in stable materials. We achieve tighter tolerances (±0.001 mm / ±0.00004 in) for specific features through specialized fixturing, process refinement, and environmental controls – discuss your critical requirements during engineering review. Our value lies not just in hitting numbers, but in providing the documented evidence and engineering partnership to ensure your prototype performs as intended in the real world. Request a free DFM analysis to understand how our capabilities solve your specific prototyping challenge; there is no substitute for engineered precision.

Material & Finish Options

Material selection is a critical step in precision prototype manufacturing, directly influencing performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC machining for custom metal prototypes, offering expert guidance in choosing the optimal material and finish for your application. Among the most widely used metals in industrial prototyping are aluminum, steel, and titanium—each offering distinct mechanical properties and compatibility with finishing processes such as anodizing.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and consumer electronics prototypes where lightweight performance is essential. The most common grade used in precision machining is 6061-T6, which provides good weldability and moderate strength. When enhanced with anodizing, aluminum gains improved surface hardness, wear resistance, and aesthetic versatility. Anodizing creates a durable oxide layer that can be dyed in various colors, making it suitable for both functional and appearance-critical prototypes.

Steel, particularly stainless steel grades such as 304 and 17-4 PH, is chosen for applications demanding high strength, thermal stability, and resistance to wear and corrosion. Stainless steel is frequently used in medical devices, fluid systems, and industrial tooling. While it is denser and more challenging to machine than aluminum, its structural integrity under load and temperature makes it indispensable for rigorous environments. Unlike aluminum, steel cannot be anodized but benefits from alternative surface treatments such as passivation, electropolishing, or powder coating.

Titanium, specifically Grade 5 (Ti-6Al-4V), offers an exceptional combination of high tensile strength, low density, and outstanding resistance to extreme temperatures and corrosive environments. It is the material of choice for aerospace components, biomedical implants, and high-performance automotive systems. However, its high cost and difficulty in machining require advanced CNC capabilities and tooling strategies. Titanium does support specialized surface treatments, but anodizing is primarily used for color coding or minor surface enhancement rather than wear protection.

Below is a comparative overview of key material properties relevant to prototype development.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Grades | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 | 6061-T6, 7075-T6 | Yes | Aerospace, electronics, enclosures |

| Stainless Steel | 7.9 | 515–1300 | 304, 17-4 PH | No | Medical, food processing, tooling |

| Titanium | 4.5 | 950–1170 | Ti-6Al-4V (Gr 5) | Limited (decorative) | Aerospace, defense, implants |

Selecting the right material involves balancing mechanical requirements, environmental exposure, and budget constraints. At Wuxi Lead, our engineering team collaborates with clients to match material properties with functional goals, ensuring prototypes meet both design intent and real-world performance. Combined with precision CNC machining and advanced finishing options like anodizing, we deliver prototypes that transition seamlessly from concept to production.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Flawless Production

At Wuxi Lead Precision Machinery, transforming your design into flawless metal components follows a rigorously controlled sequence: Design Validation, Precision Prototyping, and Zero-Defect Mass Production. This integrated workflow eliminates costly errors and ensures manufacturability from the outset, directly addressing the limitations of purely automated “free online prototype maker” tools which lack critical engineering oversight. True precision begins long before metal meets cutter.

The process commences with exhaustive Design for Manufacturability (DFM) analysis. Our engineering team scrutinizes your CAD data, identifying potential weaknesses in geometry, material selection, or tolerance stack-ups that could compromise quality or yield. We collaborate closely with your designers, providing actionable feedback to optimize the part for CNC machining, sheet metal fabrication, or additive processes. This proactive step prevents 85% of potential production defects before a single chip is produced, converting theoretical designs into robust, manufacturable realities. Skipping this phase, as generic online tools often do, risks inherent flaws carried into prototyping and production.

Prototyping is not merely a sample creation stage; it is a critical verification checkpoint within our Zero Defects framework. Using the exact production-grade materials and processes intended for volume manufacturing, we produce functional prototypes under controlled conditions. Each prototype undergoes comprehensive metrology against the validated design, including CMM inspection, surface roughness testing, and material property verification. This phase validates not only the part geometry but also the efficiency and stability of the proposed manufacturing process itself. Any deviation triggers immediate root cause analysis and process refinement, ensuring the prototype is a true predictor of mass production capability.

Mass production leverages the perfected process parameters and tooling validated during prototyping. Our automated CNC cells, operated by certified technicians, execute machining with micron-level consistency. Real-time in-process gauging and SPC (Statistical Process Control) monitor critical dimensions continuously. Every component batch undergoes 100% visual inspection and rigorous sampling per AQL standards, with full traceability from raw material to finished part. This closed-loop system, built upon the foundation of DFM and prototyping, guarantees Zero Defects delivery at scale. The initial engineering investment eliminates scrap, rework, and supply chain disruption inherent in reactive manufacturing approaches.

Key Process Metrics & Zero Defects Integration

| Process Phase | Key Activities | Precision Metrics | Zero Defects Safeguards |

|---|---|---|---|

| Design Validation | DFM Analysis, Material Selection, Tolerance Stack-up Review | ±0.01mm Feasibility Assessment | Preventative Error Elimination, Design Lock |

| Precision Prototyping | Functional Sample Production, Full Metrology, Process Validation | ±0.005mm CMM Certification | Prototype Sign-off, Process FMEA |

| Mass Production | High-Volume CNC Machining, In-Process Gauging, Final QA | ±0.002mm SPC Control Limits | 100% Visual Inspection, AQL Sampling, Traceability |

This disciplined progression – where Design informs Prototyping, and Prototyping certifies Production – is the cornerstone of reliable, high-integrity metal component supply. Relying solely on automated online quoting without this engineering integration risks costly quality failures. Wuxi Lead embeds precision at every tier, ensuring your first prototype and your ten-thousandth part meet identical, uncompromising standards. Contact our engineering team to initiate a process built for zero defects, not just online convenience.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that precision, speed, and reliability are non-negotiable in high-end manufacturing. As a global leader in custom metal fabrication, we specialize in transforming complex design concepts into fully functional, high-tolerance prototypes and production parts—fast, accurately, and cost-effectively. Whether you are developing aerospace components, medical devices, or industrial automation systems, our engineering-driven approach ensures your project meets the highest standards of quality and performance.

Our state-of-the-art CNC machining centers, combined with decades of metallurgical expertise, allow us to deliver prototype parts with micron-level precision and rapid turnaround. We support a wide range of materials including aluminum, stainless steel, titanium, brass, and specialty alloys, ensuring compatibility with your engineering requirements. From 3-axis to 5-axis milling, precision turning, and multi-spindle machining, our capabilities are designed to handle even the most intricate geometries with ease.

What sets Wuxi Lead Precision Machinery apart is our end-to-end service model. We don’t just manufacture parts—we partner with engineers, designers, and procurement teams to optimize designs for manufacturability, reduce lead times, and lower total production costs. Our team provides expert DFM feedback within hours, not days, enabling faster iterations and accelerating your time to market. With ISO 9001:2015 certification and rigorous in-process quality inspections, every component we produce meets international standards for dimensional accuracy and surface finish.

We support global clients with seamless digital workflows. Upload your CAD files directly through our online platform for instant quoting and design analysis. No minimum order quantities. No hidden fees. Just precision manufacturing, on demand.

For high-integrity applications where performance cannot be compromised, trust a partner with a proven track record across Europe, North America, and Asia. At Wuxi Lead Precision Machinery, we don’t just meet expectations—we redefine them.

Contact us today to begin your next project. Email [email protected] and connect with our engineering team for personalized support, technical consultation, and fast turnaround on your prototype requests.

| Specification | Detail |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, 5-Axis CNC Milling, CNC Turning, Multi-Spindle Machining |

| Tolerances | As tight as ±0.005 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Copper, Inconel, Tool Steels |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Passivation, Polishing |

| Lead Time | Prototypes: 5–7 days; Production: 10–15 days (standard) |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI) Reports, PPAP Support |

| File Formats Accepted | STEP, IGES, DWG, DXF, PDF, SolidWorks, X_T |

Begin your collaboration with a manufacturer that values precision as much as you do. Email [email protected] and experience the Lead Precision advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.