Technical Contents

Engineering Guide: Prototype Maker 3D

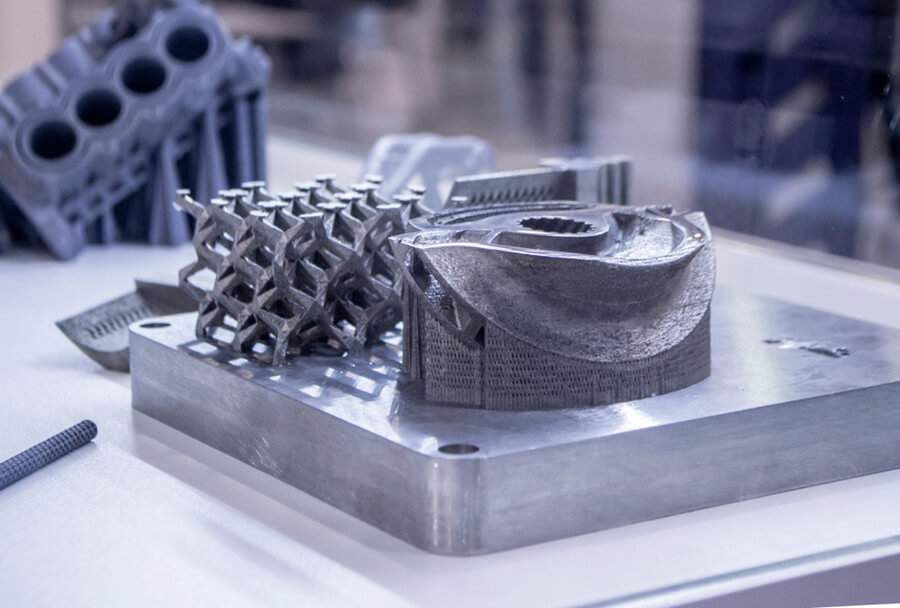

Engineering Insight: The Critical Role of Precision in 3D Prototype Manufacturing

In the realm of advanced manufacturing, the transition from concept to physical reality hinges on one non-negotiable factor—precision. When it comes to 3D prototype development, especially in custom metal fabrication, even micron-level deviations can compromise functionality, safety, and scalability. At Wuxi Lead Precision Machinery, we understand that a prototype is not merely a model; it is the foundational blueprint for mass production, integration into complex systems, and ultimately, market success.

Precision in 3D prototyping transcends dimensional accuracy. It encompasses material integrity, surface finish consistency, geometric conformity, and repeatability across iterations. These parameters are especially critical in high-stakes industries such as aerospace, defense, and high-performance sports equipment—sectors where our engineering team has delivered mission-critical components. Our involvement in Olympic-grade equipment manufacturing and military-grade subsystems underscores our commitment to tolerances that meet or exceed international standards. In these applications, failure is not an option, and our prototyping process reflects that imperative.

Utilizing state-of-the-art 3D modeling software, multi-axis CNC machining, and advanced metrology systems, we ensure that every prototype aligns with the client’s engineering intent. Our in-house capabilities allow for rapid iteration without sacrificing accuracy, enabling clients to validate designs, conduct functional testing, and accelerate time-to-market. Whether producing a single titanium aerospace bracket or a series of stainless steel hydraulic manifolds, our process maintains a consistent tolerance envelope, verified through CMM (Coordinate Measuring Machine) and laser scanning technologies.

What sets Wuxi Lead apart is not just technology, but experience. Our engineers bring over a decade of specialization in high-precision metal prototyping, having supported projects where performance under extreme conditions is mandatory. This depth of expertise allows us to anticipate challenges in manufacturability, suggest design optimizations, and deliver prototypes that perform as final-use parts.

The following table outlines our standard precision capabilities for metal 3D prototypes:

| Specification | Performance Level |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | 0.4 – 1.6 μm (adjustable) |

| Material Compatibility | Aluminum 6061/7075, Stainless Steel 316L/17-4PH, Titanium Grade 5, Inconel 718, Brass |

| Maximum Build Volume | 500 × 400 × 300 mm |

| Layer Resolution (for hybrid processes) | 20 – 50 μm |

| Positional Accuracy | ±0.01 mm/m |

| Post-Processing Options | CNC finishing, heat treatment, anodizing, passivation, polishing |

At Wuxi Lead Precision Machinery, we treat every prototype as a commitment to excellence. Our integration of precision engineering, rigorous quality control, and real-world application experience ensures that your 3D prototype is not just a model—but a reliable, high-performance representation of your innovation.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Prototyping

Wuxi Lead Precision Machinery delivers exceptional technical execution for demanding metal prototype projects, leveraging state-of-the-art infrastructure and rigorous process control. Our core competency centers on high-precision 5-axis CNC machining, enabling the production of complex, near-net-shape components in a single setup. This eliminates cumulative error from multiple fixtures and significantly reduces lead times compared to conventional 3-axis methods or multi-operation workflows. Our fleet includes industry-leading DMG MORI and Makino 5-axis vertical machining centers, featuring simultaneous 5-axis interpolation, high-speed spindles (up to 24,000 RPM), and integrated probing systems. These machines achieve sub-micron level positioning accuracy (ISO 230-2 verified) and maintain thermal stability critical for micron-tolerance work on challenging geometries. We routinely machine a comprehensive range of engineering alloys including aerospace-grade titanium (Ti-6Al-4V), Inconel 718, 17-4 PH stainless steel, aluminum 7075-T6, and beryllium copper, handling part envelopes up to 1000 x 800 x 600 mm with optimal surface finishes down to Ra 0.4 µm.

Quality assurance is intrinsically woven into our manufacturing process, not merely a final checkpoint. Every critical prototype undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using our Zeiss CONTURA and Hexagon GLOBAL S systems. These high-accuracy CMMs, calibrated to ISO 17025 standards, perform full geometric dimensioning and tolerancing (GD&T) verification against the client’s native 3D CAD model. Our inspection protocol includes first-article inspection reports (FAIR) with detailed deviation mapping, material certification traceability, and real-time in-process probing for critical feature validation during machining. This integrated approach ensures dimensional integrity and functional performance from the very first prototype, mitigating risk and accelerating design validation cycles for our clients in aerospace, medical device, and advanced robotics sectors.

The following table details our standard and achievable tolerance capabilities for precision metal prototypes, validated through our CMM-driven quality system:

| Feature Type | Standard Capability | Tight Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM / High-Precision Micrometer |

| Angular Dimensions | ±0.05° | ±0.02° | CMM / Optical Comparator |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM (GD&T Analysis) |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Profilometer |

| Concentricity | Ø0.025 mm | Ø0.010 mm | CMM / Dial Indicator |

Our technical capability extends beyond machine specs to deep engineering collaboration. Our applications engineering team works directly with client design teams during the DFMA phase, identifying potential manufacturability improvements for complex prototypes while ensuring critical functional requirements are met. This proactive partnership, combined with our 5-axis machining mastery and uncompromising CMM-backed quality control, ensures your metal prototype functions as intended, accelerates time-to-test, and provides reliable data for production scaling. Wuxi Lead transforms intricate design concepts into dimensionally perfect, functionally validated metal prototypes with the precision required for next-generation product development.

Material & Finish Options

Material selection is a critical step in precision prototype development, directly influencing performance, durability, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-performance industries such as aerospace, automotive, and medical devices. Our expertise in CNC machining enables us to work with a range of advanced materials, with aluminum, steel, and titanium being the most commonly specified for prototype applications. Each material offers distinct mechanical and thermal properties, making them suitable for different operational environments.

Aluminum is widely favored for prototyping due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is particularly popular for structural and non-critical load-bearing components, offering good weldability and dimensional stability. For applications requiring higher strength, 7075-T6 provides superior tensile properties, though with reduced corrosion resistance compared to 6061. Aluminum’s low density makes it ideal for aerospace and portable equipment prototypes where weight savings are crucial.

Steel remains the material of choice when high strength, wear resistance, and structural integrity are paramount. We commonly machine 304 and 316 stainless steel for their excellent corrosion resistance and suitability in sterile or harsh environments—common in medical and marine applications. For mechanical components requiring hardness and fatigue resistance, we utilize alloy steels such as 4140 and tool steels, which can be heat-treated to meet stringent performance standards. While heavier than aluminum, steel offers unmatched durability and predictability under load.

Titanium, particularly Grade 5 (Ti-6Al-4V), is selected for mission-critical prototypes where extreme strength-to-density ratio, biocompatibility, and resistance to high-temperature environments are required. Commonly used in aerospace and medical implant development, titanium is challenging to machine due to its low thermal conductivity and tendency to gall. However, with optimized CNC parameters and tooling, Wuxi Lead ensures tight tolerances and excellent surface integrity.

Surface finishing enhances both functionality and appearance. Anodizing is a key post-processing option for aluminum prototypes. This electrochemical process increases surface hardness and corrosion resistance while allowing for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) delivers a thicker, wear-resistant layer suitable for industrial environments.

The following table summarizes key material properties and applications:

| Material | Grade | Tensile Strength (MPa) | Density (g/cm³) | Key Properties | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Lightweight, corrosion-resistant | Enclosures, brackets, prototypes |

| Aluminum | 7075-T6 | 570 | 2.8 | High strength, good fatigue resistance | Aerospace components |

| Stainless Steel | 316 | 580 | 8.0 | Excellent corrosion resistance | Medical, marine, food processing |

| Alloy Steel | 4140 | 655 | 7.85 | High toughness, heat-treatable | Shafts, gears, tooling |

| Titanium | Ti-6Al-4V | 900 | 4.43 | High strength-to-weight, biocompatible | Aerospace, medical implants |

Selecting the right material and finish ensures that your prototype not only meets design intent but also performs reliably in real-world conditions. At Wuxi Lead, we support material certification, mechanical testing, and finish validation to deliver prototypes that bridge the gap between concept and production.

Manufacturing Process & QC

Precision Manufacturing Workflow: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production process engineered for mission-critical metal components. Our methodology eliminates costly errors by integrating Design, Prototyping, and Mass Production into a closed-loop system where Zero Defects is non-negotiable. This approach is essential for aerospace, medical, and semiconductor clients where failure is unacceptable.

The process begins with collaborative Design engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis, scrutinizing geometry, material selection, and tolerance stacks against ISO 2768 and client-specific standards. We leverage advanced simulation software to predict thermal deformation, stress points, and toolpath efficiency, ensuring the design is inherently producible. Material certification is verified at this stage, with options spanning titanium alloys, Inconel, aluminum 7075, and hardened steel. Any potential flaw is resolved digitally before physical work commences, preventing downstream rework.

Prototyping transitions the validated design into tangible form using high-precision CNC milling and turning centers. Unlike additive-only prototyping services, we replicate final production methodologies to expose hidden risks. Each prototype undergoes comprehensive metrology: CMM inspection, surface roughness testing, and first-article reports per AS9102. This phase validates not just form and fit, but also process stability. Critical data—tool wear rates, cycle times, and thermal behavior—is captured to calibrate mass production parameters. A single prototype iteration often prevents six-figure scrap costs in full-scale runs.

Mass Production deploys our zero-defect framework through statistical process control and real-time monitoring. Every component is traceable via laser-etched serial numbers linked to machine logs, material certs, and inspection records. In-process checks occur at predefined intervals using automated vision systems and touch-probe inspections on Haas and DMG MORI equipment. Final inspection includes 100% critical dimension verification and batch-level material testing. Our ISO 9001-certified workflow ensures deviations trigger immediate root-cause analysis and corrective action, not merely part rejection.

This seamless integration guarantees that lessons from prototyping directly harden production protocols. Clients receive components meeting exacting specifications without compromise—on time, every time.

Wuxi Lead Precision Production Capabilities

| Parameter | Specification Range | Equipment Used | Quality Standard |

|---|---|---|---|

| Tolerance | ±0.005 mm to ±0.001 mm | 5-Axis CNC Milling/Turning | ISO 2768 mK |

| Materials | Titanium, Inconel, Aluminum, Steel, Brass | Haas, DMG MORI, Okuma | AMS, ASTM, EN Certified |

| Max Work Envelope | 1200 x 800 x 600 mm | 5-Axis Vertical Machining | AS9100 Rev D Compliant |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm | Precision Grinding Centers | ISO 1302 |

| Lead Time (Proto) | 7-15 days | Coordinate Measuring Machines | PPAP Level 3 |

Our process delivers certainty: prototypes that mirror production reality, and mass production that achieves zero escapes. Partner with us to convert design intent into flawless metal components.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched 3D Prototype Manufacturing Excellence

At Wuxi Lead Precision Machinery, we understand that in high-performance industries such as aerospace, medical technology, automotive engineering, and advanced robotics, the transition from concept to physical reality demands precision, speed, and technical mastery. As a leading custom metal manufacturing partner in China, we specialize in transforming digital designs into high-integrity 3D prototypes with exacting tolerances and superior surface finishes. Our advanced CNC machining, multi-axis milling, and precision turning capabilities are engineered to meet the rigorous demands of next-generation product development.

When you choose to partner with Lead Precision, you are not just outsourcing production—you are aligning with a team of engineering professionals committed to your innovation timeline. Our end-to-end prototyping solutions integrate design for manufacturability (DFM) analysis, rapid material sourcing, and real-time project tracking to ensure your prototype is delivered on schedule, every time. We work with a broad spectrum of engineering-grade metals, including aluminum 6061 and 7075, stainless steel 303 and 316, titanium Ti-6Al-4V, and specialty alloys such as Inconel 718 and brass C3604. Whether you require a single functional prototype or low-volume bridge production, our scalable processes support your development cycle with consistency and precision.

Our facility in Wuxi is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machines, coordinate measuring machines (CMM), and automated inspection systems to guarantee dimensional accuracy down to ±0.005 mm. Every prototype undergoes rigorous quality control, including first-article inspection reports (FAIR), material certification, and surface finish validation, ensuring compliance with international standards such as ISO 9001:2015 and AS9100 for aerospace applications.

Below are key technical specifications that define our 3D prototype manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| Lead Time (Prototype) | 5–12 business days, depending on complexity |

| Certifications | ISO 9001:2015, ISO 14001, RoHS compliant |

We invite engineering teams, R&D departments, and product designers to initiate a collaboration that accelerates innovation. Contact us today at [email protected] to submit your 3D model, receive a competitive quote, and begin the process with a manufacturing partner built for precision. At Lead Precision, we don’t just make prototypes—we enable breakthroughs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.