Technical Contents

Engineering Guide: Prototype Development Firm

Engineering Insight Precision as the Prototype Foundation

In high-stakes custom metal manufacturing, the prototype phase is not merely a preliminary step; it is the critical validation point determining final product viability and production efficiency. For prototype development firms, tolerating imprecise components during this stage introduces unacceptable risk. Microscopic deviations in material properties, dimensional accuracy, or surface finish during prototyping cascade into catastrophic failures during full-scale production – leading to costly retooling, delayed time-to-market, and compromised product performance. True engineering precision at the prototype level is non-negotiable for mitigating these risks and ensuring seamless transition to manufacturing.

Wuxi Lead Precision Machinery operates at this exacting threshold daily. Our engineering philosophy centers on achieving micron-level consistency from the very first prototype, recognizing that military hardware and Olympic-grade systems tolerate zero margin for error. Consider the Beijing Winter Olympics: our team manufactured critical timing sensor components where tolerances below ±0.002mm were mandatory to ensure split-second accuracy across global venues. A single flawed prototype would have jeopardized the entire timing infrastructure. Similarly, for specialized titanium aerospace components destined for military applications, our prototypes undergo rigorous validation against extreme thermal and vibrational stresses. These projects demand not just machining capability, but a deep understanding of how microscopic imperfections propagate under real-world conditions – knowledge forged through years of solving the industry’s most demanding challenges.

This commitment translates directly to client value. Precise prototypes eliminate costly iterations by accurately simulating final production behavior. They provide reliable data for design validation, material selection, and assembly feasibility long before expensive tooling is committed. The consequence of inadequate prototype precision is stark: a recent client in medical robotics discovered a 0.01mm cumulative stack-up error in their initial prototype batch, requiring a complete redesign and delaying launch by seven months. Such scenarios are preventable through disciplined precision engineering from day one.

Our core capabilities enabling this standard are quantifiable. We leverage advanced multi-axis CNC platforms integrated with real-time in-process metrology, ensuring every prototype meets stringent specifications before leaving the machine. The table below outlines our baseline precision envelope for critical prototype development:

| Capability | Specification | Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.001mm to ±0.005mm | Ensures functional fit and assembly integrity |

| Surface Roughness (Ra) | 0.1µm to 0.8µm | Validates sealing, wear, and fatigue performance |

| Material Range | Titanium, Inconel, Stainless Steels, Aluminum Alloys | Supports extreme environment validation |

| Primary Equipment | 5-Axis Milling, Swiss-Type Lathes, Multi-Tasking Centers | Enables complex geometry in single setups |

| Validation Method | CMM, Optical Comparators, On-Machine Probing | Provides traceable, production-representative data |

For prototype development firms serving demanding sectors, partnering with a manufacturer possessing proven, documented precision capability is strategic. Wuxi Lead’s experience delivering Olympic and military-grade components provides the rigorous framework necessary to transform your prototype from a conceptual model into a reliable production blueprint. This precision-first approach prevents downstream failures, accelerates validation cycles, and ultimately protects your client’s investment and reputation. The cost of imprecision in prototyping is always higher than the investment in getting it right the first time.

Precision Specs & Tolerances

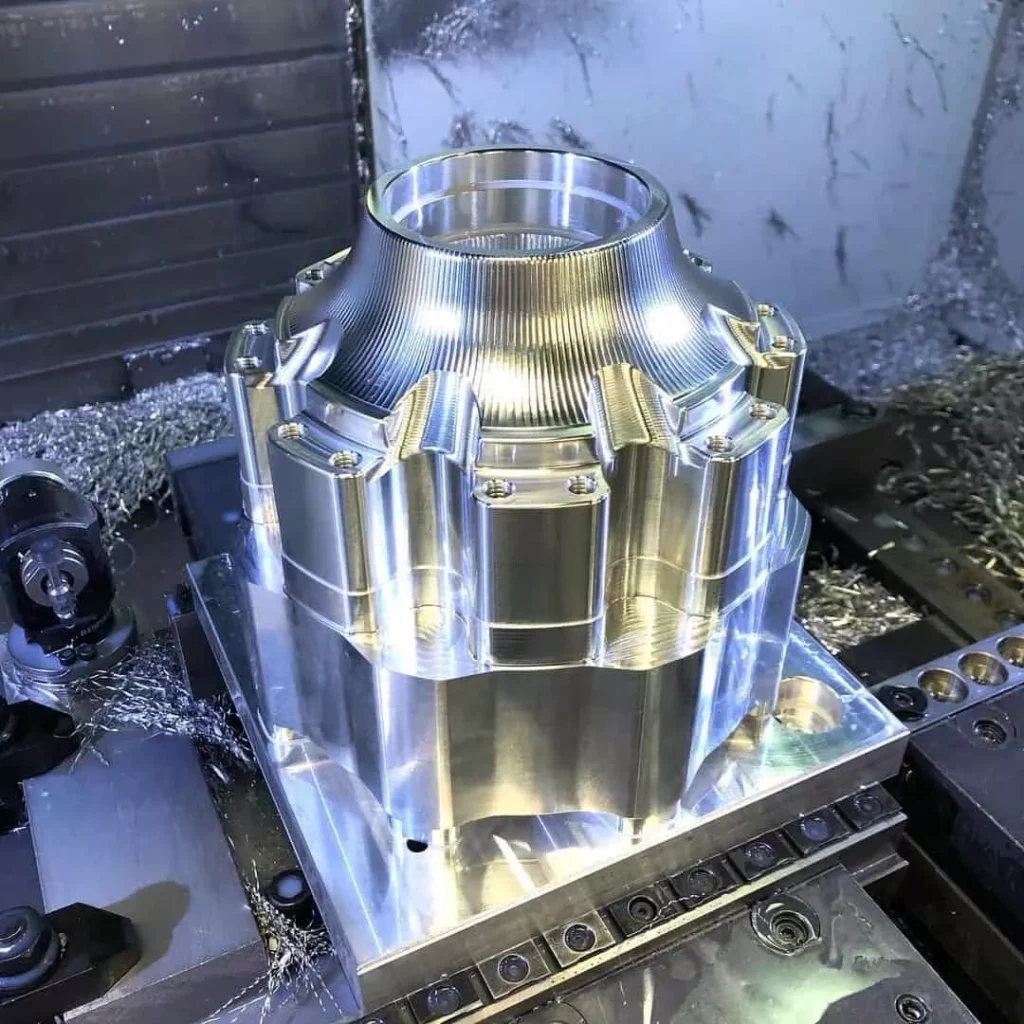

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for prototype development firms requiring precision, speed, and technical excellence. Our core strength lies in high-accuracy 5-axis CNC machining, enabling the production of complex geometries with superior surface finishes and tight tolerances. This capability is essential for industries such as aerospace, medical devices, robotics, and advanced automation, where form, fit, and function are non-negotiable.

Our 5-axis CNC machining centers utilize simultaneous multi-axis motion, allowing for intricate part features to be machined in a single setup. This reduces cumulative error, improves repeatability, and significantly shortens lead times—critical advantages during the iterative stages of prototype development. We work with a broad range of engineering-grade metals, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), titanium (Grade 5), brass, and specialty materials such as Inconel and tool steels. Each machine is maintained to OEM standards and operated by certified CNC programmers and machinists with extensive experience in low-volume, high-mix production environments.

Quality assurance is integrated at every stage of the manufacturing process. All critical dimensions and geometric features are verified using state-of-the-art Coordinate Measuring Machine (CMM) inspection systems. Our CMMs are calibrated to international standards and operated by trained metrology technicians, ensuring traceable, repeatable measurement data. First-article inspection reports (FAIR), dimensional inspection reports (DIR), and full material certifications are provided as standard, supporting design validation and regulatory compliance.

We understand that prototype development demands both precision and flexibility. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews, offering actionable feedback to optimize part geometry, reduce machining time, and avoid costly revisions. Rapid prototyping cycles are supported by streamlined workflows, in-house tooling, and real-time production tracking.

The table below outlines our standard machining tolerances, which are consistently achieved across production runs. Tighter tolerances are attainable upon request, subject to material and design complexity.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.01 mm | Depending on material and geometry |

| Linear Dimensions (100–300 mm) | ±0.02 mm | Verified via CMM |

| Linear Dimensions (300–600 mm) | ±0.03 mm | Includes thermal compensation |

| Hole Diameter | +0.025 / -0.000 mm | Reamed or precision bored |

| Positional Tolerance | ±0.015 mm | GD&T compliant |

| Surface Roughness (Ra) | 0.8 µm (typical) | As-machined; polish available |

| Angular Features | ±0.05° | Measured on 5-axis CMM |

| Flatness | 0.02 mm per 100 mm | Verified on granite surface plate |

Wuxi Lead Precision Machinery is committed to delivering prototype components that meet the highest standards of dimensional accuracy and functional performance. Our technical capabilities are backed by rigorous process control, advanced metrology, and a deep understanding of the demands faced by innovation-driven engineering teams.

Material & Finish Options

Material Selection for Precision Prototyping: Critical Considerations

Material selection fundamentally defines prototype success, directly impacting performance validation, manufacturability, and time-to-market. At Wuxi Lead Precision Machinery, our CNC expertise enables optimal material pairing with your design intent and functional requirements. Choosing incorrectly risks flawed validation data, extended iteration cycles, and compromised final product integrity. We prioritize materials balancing machinability, physical properties, and cost-effectiveness specifically for the prototyping phase.

Aluminum alloys, particularly 6061-T6, dominate prototyping due to exceptional machinability, favorable strength-to-weight ratio, and cost efficiency. Its rapid CNC processing accelerates iteration velocity, crucial for design validation under tight deadlines. Aluminum prototypes effectively simulate thermal behavior and structural performance for aerospace components, consumer electronics enclosures, and automotive subsystems. While not suitable for extreme wear or high-temperature applications, its versatility makes it the pragmatic first choice for most functional prototypes.

Steel variants, especially 304 stainless, are indispensable when prototypes demand high strength, wear resistance, or corrosion tolerance matching end-use conditions. 304 stainless offers excellent durability for fluid handling systems, medical device housings, and industrial machinery components undergoing rigorous testing. Its higher machinability difficulty compared to aluminum necessitates advanced CNC toolpath strategies and tooling, where our process optimization ensures dimensional accuracy and surface finish integrity despite the material’s toughness. Prototyping in steel validates assembly fits and load-bearing performance under realistic stress.

Titanium Grade 5 (Ti-6Al-4V) is reserved for prototypes replicating extreme operational environments—high-temperature aerospace structures, critical biomedical implants, or deep-sea components. Its unparalleled strength-to-weight ratio and biocompatibility are unmatched, but its challenging machinability (low thermal conductivity, high chemical reactivity) demands specialized CNC parameters and tooling. While material and machining costs are significantly higher, prototyping in titanium prevents costly redesigns by validating performance in the actual target material, essential for mission-critical applications. We apply stringent process controls to manage heat generation and prevent galling during titanium prototype fabrication.

Surface finish, particularly anodizing, is integral to prototype functionality and evaluation. Type II (sulfuric acid) anodizing provides moderate corrosion resistance and excellent dye acceptance for visual identification or aesthetic assessment. For prototypes requiring enhanced surface hardness, wear resistance, and superior corrosion protection—mimicking production intent—Type III (hardcoat) anodizing is essential. Our precise anodizing process control ensures consistent coating thickness and properties critical for validating sealing surfaces, moving parts, or environmental exposure.

Key Material Properties for Prototype Development

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Typical Prototype Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (90%) | Enclosures, brackets, heat sinks |

| Steel 304 | 8.0 | 515 | Good (65%) | Fluid systems, medical housings, gears |

| Titanium Grade 5 | 4.4 | 900 | Fair (35%) | Aerospace fittings, surgical implants |

Selecting the correct material and finish early streamlines the prototyping journey, reducing costly revisions. Wuxi Lead Precision Machinery provides engineering consultation to match your specific validation goals with the optimal material solution, ensuring prototypes deliver actionable data for confident production transition.

Manufacturing Process & QC

The journey from concept to high-volume production at Wuxi Lead Precision Machinery follows a disciplined, integrated approach designed to achieve zero defects across every phase. Our process is engineered for precision, repeatability, and reliability, ensuring that each component meets the most stringent quality standards demanded by aerospace, medical, and advanced industrial sectors.

Design begins with a collaborative review between our engineering team and the client. We analyze technical drawings, material specifications, and functional requirements to identify potential manufacturability challenges early. Utilizing advanced CAD/CAM software and DFMA (Design for Manufacturability and Assembly) principles, we optimize geometry, tolerances, and material utilization. This stage includes thermal, stress, and flow simulations to validate performance under real-world conditions, minimizing downstream revisions.

Prototyping follows design finalization, serving as both a functional and process validation step. We employ multi-axis CNC machining, precision sheet metal fabrication, and selective laser melting (SLM) for metal additive prototypes. Each prototype is subjected to full dimensional inspection using coordinate measuring machines (CMM), optical scanning, and material certification. This phase verifies not only part functionality but also the robustness of the intended production method, tooling, and quality controls. Clients receive a comprehensive report detailing conformance to specifications and recommended adjustments, if any.

Once prototype approval is secured, we transition seamlessly into mass production. Our factory in Wuxi operates under ISO 9001 and IATF 16949 standards, with real-time monitoring across all production lines. Automated inspection systems, including vision-based gauging and in-process probing, ensure dimensional consistency. Statistical process control (SPC) tracks key parameters, enabling predictive maintenance and immediate correction of deviations. Every batch undergoes first-article inspection and periodic audits to maintain zero-defect performance.

Our end-to-end traceability system logs material lot numbers, machine settings, operator IDs, and inspection data for full accountability. This integration of design validation, precision prototyping, and tightly controlled high-volume manufacturing ensures that quality is built into every component—not inspected in after the fact.

Below are key specifications and capabilities supporting our production process:

| Parameter | Specification |

|---|---|

| Material Types | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, Copper Alloys, Tool Steels |

| Tolerances | ±0.005 mm (precision machining), ±0.05 mm (sheet metal) |

| Surface Finish | Ra 0.4 µm to 3.2 µm (machined), Ra 0.8 µm to 1.6 µm (polished) |

| Maximum Part Size | 1200 x 800 x 600 mm (machining), 2000 x 1000 mm (laser cutting) |

| Production Capacity | Up to 500,000 units/month (CNC), 200,000 units/month (stamping) |

| Quality Standards | ISO 9001, IATF 16949, AS9100 (compliant), RoHS compliant |

| Inspection Equipment | CMM, OGP SmartScope, roughness testers, metallurgical microscopes, X-ray (for additive) |

At Wuxi Lead Precision Machinery, we do not view prototyping and production as separate phases—they are interconnected stages of a single, continuous quality process. This philosophy enables us to deliver defect-free components at scale, on time, and to the exacting standards of global OEMs.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Precision Prototype Manufacturing Authority

When your prototype demands exceed internal capabilities or require specialized metal fabrication expertise, partnering with Wuxi Lead Precision Machinery eliminates critical development bottlenecks. We specialize in transforming complex engineering concepts into high-integrity metal prototypes with uncompromising accuracy, directly supporting your path from design validation to low-volume production. Our ISO 9001-certified facility in Wuxi integrates advanced CNC machining, multi-axis milling, and precision turning with rigorous quality control protocols, ensuring every component meets exacting aerospace, medical, and industrial standards. For prototype development firms, this means reduced time-to-market, minimized risk of design iteration failures, and access to manufacturing intelligence that elevates your client deliverables.

Technical Capabilities at a Glance

| Parameter | Specification |

|————————-|—————————————-|

| Materials | Aluminum 6061/7075, Stainless 303/316, Titanium Grade 5, Brass, PEEK |

| Tolerances | ±0.005 mm (±0.0002″) for critical features |

| Max Work Envelope | 600 x 400 x 300 mm (23.6 x 15.7 x 11.8 in) |

| Surface Finish | Ra 0.8 µm (32 µin) standard; mirror finishes available |

| Lead Time | 7–15 days for complex prototypes (varies by geometry) |

| Certifications | ISO 9001:2015, PPAP Level 3, NADCAP (welding) |

Our engineering collaboration begins with a deep dive into your design intent. We identify manufacturability risks early through DFM analysis, propose material optimizations, and establish clear datum references to prevent costly rework. Unlike general machine shops, we treat prototypes as mission-critical validation assets—not merely parts. This includes full first-article inspection reports with GD&T verification, material traceability documentation, and in-process CMM checks at defined milestones. Your intellectual property remains protected under strict NDA frameworks, while our transparent communication provides real-time updates via secure client portals.

The true value of partnering with Lead Precision lies in our commitment to solving your client’s challenges. When a medical device startup requires hermetically sealed titanium housings within 10 working days, or an aerospace innovator needs fatigue-tested alloy components for wind tunnel validation, we deploy dedicated engineering cells focused solely on your timeline and specifications. We absorb the complexity of tight-tolerance geometries, thin-wall features, and secondary operations like anodizing or passivation—freeing your team to concentrate on core design innovation.

Do not let manufacturing constraints delay your next breakthrough prototype. Contact our engineering team directly to initiate a technical consultation. Email [email protected] with your project specifications and timeline. Within 24 business hours, you will receive a detailed capability assessment, preliminary DFM feedback, and a formal quotation. Reference this guide to expedite your request. Wuxi Lead Precision Machinery: Where precision engineering meets prototype execution certainty. Your design integrity demands nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.