Technical Contents

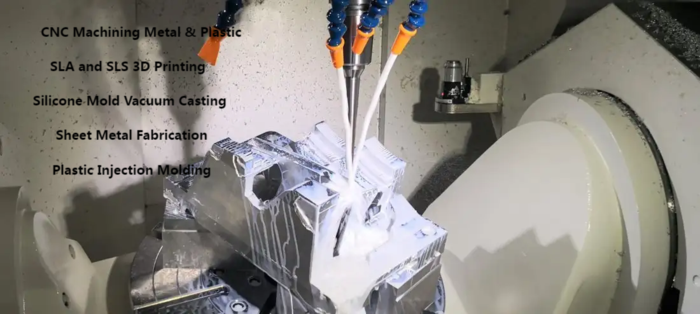

Engineering Guide: Protomold Injection Molding

Engineering Insight: Precision as the Non-Negotiable Core of Protomold Injection Molding

In high-stakes custom metal manufacturing, protomold injection molding transcends simple rapid prototyping. It serves as the critical validation phase where theoretical designs confront the unforgiving physics of molten material flow, cooling dynamics, and ejection forces. At Wuxi Lead Precision Machinery, we understand that the precision achieved during this protomold stage directly dictates the viability, performance, and cost-effectiveness of the final production tooling and parts. Tolerance stacks determining flight safety in aerospace components or micro-movement accuracy in medical devices cannot be compromised at the prototype level. A deviation of mere microns in the protomold cavity translates to catastrophic functional failure or unsustainable scrap rates in volume production. This is where true engineering rigor separates capable partners from commodity suppliers.

Our approach integrates decades of CNC machining excellence directly into protomold development. We treat the protomold cavity and core inserts not as disposable patterns, but as miniature production tools demanding the same metrology-grade precision applied to final steel molds. This philosophy stems from our proven experience delivering mission-critical components under the most stringent requirements. We engineered and manufactured precision elements for Beijing 2022 Winter Olympic infrastructure, where environmental resilience and dimensional stability under extreme conditions were paramount. Similarly, our work supporting advanced Chinese military programs demanded absolute adherence to tolerance specifications where failure was not an option. This heritage instills a culture where every micrometer matters, and process validation is non-negotiable.

The foundation of this precision lies in meticulous process control and material science understanding. We leverage advanced simulation not merely for feasibility checks, but to predict and preemptively correct micro-shrinkage, weld line weaknesses, and residual stress points before the first shot. Our protomold cavities, machined on sub-micron capable 5-axis centers, undergo the same rigorous CMM validation as production tooling. Surface finishes critical for optical clarity or biocompatibility are achieved through specialized polishing techniques honed in demanding sectors. This eliminates costly design iterations later and provides clients with prototype parts that accurately reflect final production capability, de-risking the entire development timeline.

The following table outlines key precision parameters we consistently achieve and validate within our protomold injection molding process:

| Parameter | Typical Capability | Measurement Standard | Critical Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ISO 2768-mK / ASME Y14.5 | Ensures assembly fit and functional performance |

| Cavity Pressure Control | ±1.5% | Real-time cavity sensors | Prevents flash, short shots, and internal stresses |

| Thermal Stability | ±0.5°C | Mold thermocouples | Controls crystallization, shrinkage, and warpage |

| Shot Repeatability (Weight) | ±0.15% | Statistical process control | Guarantees consistent material density and properties |

| Surface Finish (Cavity) | Ra 0.05 µm (2 µin) | Profilometer | Critical for optics, seals, and biocompatibility |

Wuxi Lead Precision Machinery delivers more than protomolds; we deliver precision-certified validation. Our Olympic and military-grade engineering discipline ensures your prototype isn’t just a concept model, but a true predictor of production success, accelerating time-to-market while eliminating costly late-stage surprises inherent in less rigorous approaches. Precision isn’t our goal – it’s our baseline requirement.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for high-performance industrial applications. At the core of our technical capabilities is our 5-axis CNC machining platform, which enables us to produce complex, precision-engineered components with exceptional accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC technology allows simultaneous movement across five axes, minimizing setup cycles and enabling the machining of intricate geometries in a single operation. This capability is particularly critical for industries such as aerospace, medical, and automotive, where component complexity and repeatability are paramount.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems to ensure consistent performance and minimal thermal drift. The integration of advanced CAM software ensures optimized toolpaths, reduced cycle times, and enhanced material utilization. We work with a wide range of metals, including aluminum alloys, stainless steel, titanium, tool steels, and exotic alloys, supporting both prototype and high-volume production runs.

Quality assurance is embedded into every stage of our manufacturing process. All components undergo comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). These high-precision metrology systems provide full 3D measurement validation, ensuring that every part conforms to the specified geometric dimensioning and tolerancing (GD&T) requirements. Our CMM inspection process is compliant with ISO 10360 standards and supports first-article inspection reports (FAIR), production part approval processes (PPAP), and full traceability documentation.

In addition to CMM, we utilize optical comparators, surface roughness testers, and digital micrometry to verify dimensional integrity and surface quality. Our quality control team is certified to ISO 9001 standards, and all inspection data is digitally archived for full auditability and long-term process stability analysis.

The following table outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Angular Tolerance | ±0.1° |

| Surface Roughness (Ra) | 0.8 µm (typical), down to 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Minimum Wall Thickness (Metal) | 0.5 mm (aluminum), 0.8 mm (steel) |

| Hole Diameter Tolerance | H7 (ISO 286-1) |

| Geometric Tolerances (Flatness, Roundness) | ±0.01 mm per 100 mm |

By combining 5-axis CNC precision with rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures that every component meets the most demanding technical specifications. Our technical capabilities are designed to support protomold injection molding applications, where tight tolerances, material consistency, and surface fidelity are essential for mold performance and part replication.

Material & Finish Options

Material Selection for Precision Protomold Injection Molding

Selecting the optimal material for protomold injection molding cores, cavities, and critical inserts is fundamental to achieving part quality, mold longevity, and production efficiency. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific production volume, part geometry, resin characteristics, and surface finish requirements. Aluminum, tool steel, and titanium each offer distinct advantages for demanding prototyping and low-to-medium volume production scenarios. The choice directly impacts thermal management, wear resistance, and the achievable surface finish, particularly when combined with processes like anodizing.

Aluminum alloys, such as 7075-T6 or 6061-T6, provide exceptional thermal conductivity and machinability. This makes them ideal for rapid prototyping and initial production runs where quick cycle times and efficient heat dissipation are critical. Aluminum molds significantly reduce lead times compared to steel, accelerating your product development cycle. While suitable for thousands of shots with engineering resins, aluminum’s lower hardness necessitates protective surface treatments like hard anodizing for extended life in abrasive applications. It remains the premier choice for fast-turnaround validation and bridge tooling.

For higher volume production demands exceeding 50,000 shots or when processing highly abrasive or glass-filled resins, premium tool steels like H13, S7, or P20 are essential. These materials deliver superior hardness, wear resistance, and thermal stability under sustained high pressure and temperature cycles. Properly heat-treated and polished steel molds ensure consistent part dimensions and surface quality over extended runs. While initial machining is more complex and costly than aluminum, the longevity and dimensional stability of steel provide the best long-term value for significant production quantities.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are reserved for highly specialized applications demanding extreme corrosion resistance combined with high strength-to-weight ratio, such as medical or chemical processing molds. Its biocompatibility and resistance to harsh environments are unmatched, though cost and machining complexity are significantly higher. Titanium excels where conventional steels would rapidly degrade, justifying its use in niche, high-value scenarios.

Anodizing is a critical surface enhancement, particularly for aluminum molds. Type II (sulfuric acid) anodizing provides good corrosion resistance and a base for dyeing, while Type III (hard coat) anodizing dramatically increases surface hardness and wear resistance, extending aluminum mold life substantially. The anodized layer must be precisely controlled to avoid dimensional changes affecting critical mold features.

Key material properties for protomold applications are summarized below:

| Material | Density (g/cm³) | Typical Hardness (HRC) | Corrosion Resistance | Best Applications |

|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 15-20 (Base) | Moderate | Rapid prototyping, bridge tooling, low-volume production (up to 10k shots), heatsinks |

| H13 Tool Steel | 7.80 | 48-52 (Heat Treated) | Good | Medium-to-high volume production (>50k shots), abrasive resins, high-precision cores/cavities |

| Titanium Ti-6Al-4V | 4.43 | 32-36 (Base) | Excellent | Extreme corrosion environments, medical implants, specialized aerospace components |

Material selection is not merely a technical specification; it is a strategic decision impacting your time-to-market, unit cost, and final part performance. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and metallurgical knowledge to recommend and fabricate molds using the optimal material and finish combination for your unique protomold injection molding challenge, ensuring precision, durability, and cost-effectiveness from prototype to production.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless injection molding begins with precision engineering in the design phase. Our team of senior CNC engineers collaborates closely with clients to transform conceptual sketches into detailed 3D CAD models. Utilizing advanced simulation software, we conduct mold flow analysis to predict material behavior, optimize gate locations, and minimize warpage or sink marks. This digital validation ensures that every geometric complexity, tolerance requirement, and surface finish is accounted for before any metal is cut. Design for manufacturability (DFM) reviews are conducted rigorously to eliminate potential defects at the source, aligning the part geometry with the capabilities of protomold injection molding systems. All designs adhere to ISO 9001 and IATF 16949 standards, ensuring compliance with global automotive, medical, and industrial requirements.

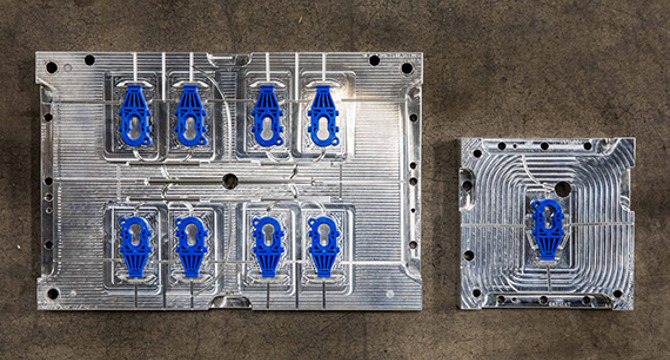

Prototyping: Validating Functionality and Fit

Once the design is finalized, we transition into rapid prototyping using high-precision CNC machining and soft tooling methods. This stage is critical for physical validation of form, fit, and function. Prototypes are produced using production-grade materials and tested under real-world conditions to verify dimensional accuracy, mechanical performance, and assembly compatibility. Our metrology lab employs coordinate measuring machines (CMM), optical comparators, and laser scanning to ensure prototype conformity within ±0.005 mm. Feedback from this phase is integrated into final tooling adjustments, closing the loop on design imperfections. This iterative validation process drastically reduces risk during mass production and ensures alignment with the zero-defect mandate.

Mass Production: Consistency at Scale

With design and prototype approval, Wuxi Lead initiates full-scale production using hardened steel molds and fully automated protomold injection molding cells. Each production run is governed by strict process parameters monitored in real time through integrated sensors and statistical process control (SPC) systems. We maintain tight control over melt temperature, injection pressure, cooling cycles, and part ejection to ensure uniformity across batches. In-line vision systems and automated sorting reject non-conforming parts instantly, maintaining a defect rate below 10 PPM (parts per million). All finished components undergo 100% visual inspection and batch-level destructive testing to validate mechanical integrity.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Compatibility | ABS, PC, POM, PA6, PBT, PP, PE, PPS, LCP |

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on size) |

| Surface Finish Options | SPI A1, A2, B1, B2, VDI 3400, textured, polished |

| Part Weight Range | 0.1 g – 1,200 g |

| Mold Life | 100,000 – 1,000,000 cycles (hardened steel) |

| Production Capacity | Up to 500,000 units per month |

| Quality Standards | ISO 9001, IATF 16949, RoHS, REACH |

Through integrated design, prototyping, and production, Wuxi Lead Precision Machinery delivers zero-defect injection molded components with unmatched repeatability and quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Integrated Metal Manufacturing Excellence

In the complex landscape of precision manufacturing, seamless integration between plastic and metal components defines product success. While ProtoMold excels in rapid plastic injection molding, Wuxi Lead Precision Machinery delivers the critical metal counterpart your projects demand. We specialize in custom CNC-machined metal parts that meet the exacting tolerances and material integrity required for aerospace, medical, and industrial applications. Partnering with us ensures your entire assembly—from polymer housings to load-bearing metal fixtures—achieves unified performance and reliability.

Our ISO 9001-certified facility in Wuxi, China, combines advanced multi-axis CNC milling, turning, and grinding capabilities with rigorous quality control. Unlike generic suppliers, we engineer solutions for challenging alloys including titanium, Inconel, and hardened stainless steels, where dimensional stability under thermal or mechanical stress is non-negotiable. Our process eliminates the supply chain fragmentation that delays time-to-market, providing end-to-end traceability from raw material certification to final inspection.

Technical Capabilities at a Glance

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Material Expertise | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, Stainless 17-4PH |

| Max Part Dimensions | 1,200 mm × 800 mm × 600 mm |

| Volume Flexibility | Prototypes to 50,000+ units annually |

| Surface Finishes | Anodizing, Passivation, Micro-blasting, Precision Grinding |

| Quality Assurance | CMM, Optical Comparator, 100% First-Article Inspection |

We understand that precision metal manufacturing transcends mere part production. It requires anticipating how your metal components interact with ProtoMold’s plastic elements in final assembly—addressing thermal expansion differentials, load distribution, and corrosion resistance at the interface. Our engineering team collaborates early in your design phase, offering DFM feedback that prevents costly iterations and ensures manufacturability without compromising functionality. This proactive partnership reduces NRE costs by up to 30% while accelerating validation cycles.

When your project demands metals that perform under extreme conditions, generic machining won’t suffice. Wuxi Lead Precision Machinery provides the metallurgical expertise, process control, and scalability that global OEMs rely on for mission-critical components. We don’t just meet specifications; we validate performance through real-world testing protocols tailored to your application.

Initiate your project with a partner who bridges the gap between plastic and metal manufacturing ecosystems. Contact our engineering team directly at Contact [email protected] to discuss material selection, tolerance strategies, or production scaling. Include your ProtoMold project reference for seamless cross-platform coordination. Let us deliver the metal precision that completes your vision—on time, to spec, and ready for integration. Your next breakthrough in manufacturing synergy starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.