Technical Contents

Engineering Guide: Protective Edge For Sheet Metal

Engineering Insight: The Critical Role of Precision in Protective Edges for Sheet Metal

In high-performance sheet metal fabrication, the protective edge is far more than a finishing detail—it is a critical engineering component that ensures durability, safety, and long-term structural integrity. Whether deployed in aerospace enclosures, military-grade housings, or precision equipment used in Olympic-certified facilities, the protective edge serves as the first line of defense against mechanical impact, environmental exposure, and operator injury. At Wuxi Lead Precision Machinery, we recognize that the efficacy of a protective edge is directly tied to the precision of its design and execution.

A poorly formed edge can lead to stress concentration, material fatigue, and premature failure. In contrast, a precisely engineered edge distributes load evenly, resists deformation, and maintains functional performance under extreme conditions. This level of consistency is only achievable through advanced CNC forming technologies, tight tolerance control, and deep metallurgical understanding—capabilities that define our manufacturing philosophy.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in sheet metal solutions for mission-critical industries. Our work has contributed to equipment enclosures used in Olympic training facilities, where reliability and safety are non-negotiable. Additionally, we have supplied components for defense applications requiring MIL-STD compliance, where edges must withstand shock, vibration, and corrosive environments without compromise. These projects demand more than standard fabrication—they require a mastery of edge geometry, material behavior, and finishing integrity.

Our engineers employ finite element analysis (FEA) during the design phase to simulate stress distribution along protective edges, optimizing radius, angle, and material thickness before any metal is cut. This proactive approach eliminates guesswork and ensures that every edge performs as intended in real-world conditions. Furthermore, our in-house quality control lab conducts edge hardness testing, dimensional verification, and accelerated corrosion testing to validate performance against international standards.

Below are key specifications that define our protective edge fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | Stainless Steel (304, 316), Aluminum (5052, 6061), Cold-Rolled Steel, Galvanized Steel |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance | ±0.1 mm (forming), ±0.05 mm (edge radius) |

| Minimum Bending Radius | 1.0 x material thickness (depending on grain direction and alloy) |

| Edge Finishing Options | Deburred, Tumble-polished, Electropolished, Powder-coated |

| Compliance Standards | ISO 9001:2015, MIL-STD-167, GB/T 1804-m |

| Testing Protocols | Salt Spray Test (96–500 hrs), Rockwell Hardness, Dimensional CMM Inspection |

Precision in protective edge formation is not an incremental advantage—it is a foundational requirement for high-reliability manufacturing. At Wuxi Lead Precision Machinery, we combine advanced technology with proven expertise to deliver edges that protect not only the component, but the people and systems that depend on them.

Precision Specs & Tolerances

Technical Capabilities: Precision Fabrication of Protective Edges for Sheet Metal

Wuxi Lead Precision Machinery delivers uncompromising quality in protective edge fabrication for critical sheet metal applications. Our specialized focus ensures edges meet stringent functional and safety requirements, preventing cuts, abrasion, and component damage while maintaining aesthetic integrity. Achieving this demands advanced manufacturing technology and rigorous quality control, capabilities we have engineered into every stage of production at our Wuxi facility.

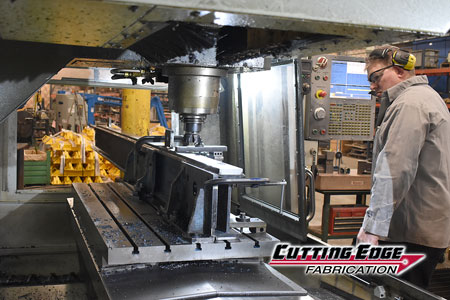

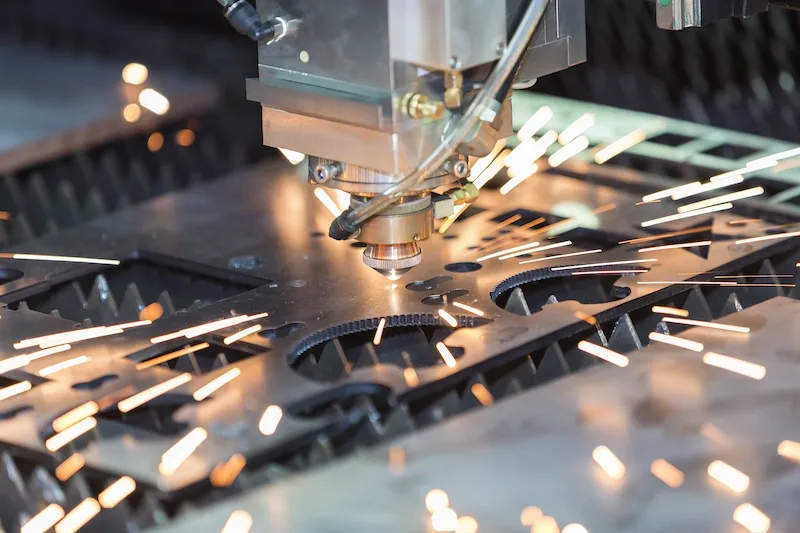

Central to our protective edge expertise is our fleet of state-of-the-art 5-axis CNC machining centers, including models from DMG MORI and MAZAK. These systems provide the simultaneous multi-directional movement essential for forming complex, consistent protective geometries—such as rolled hems, folded flanges, and precision-mitered corners—on diverse sheet metal substrates including stainless steel, aluminum, and galvanized steel. The 5-axis capability eliminates the need for multiple setups, significantly reducing cumulative error and ensuring geometric continuity along the entire edge profile. This precision is critical for edges requiring seamless transitions, tight internal radii, or integration with sealing surfaces, directly impacting the final product’s durability and user safety. Our programming leverages advanced CAM software to optimize toolpaths, minimizing stress on the material and preventing micro-cracking or distortion during edge formation.

Quality verification is non-negotiable. Every protective edge component undergoes comprehensive inspection using our coordinate measuring machines (CMM), specifically Zeiss CONTURA and GLOBAL platforms. These systems provide micron-level accuracy in validating critical dimensions, edge radius consistency, angular tolerances, and overall form. CMM inspection data is meticulously documented against customer drawings and internal standards, providing full traceability. This data-driven approach ensures not only compliance with specified tolerances but also identifies any process drift before it impacts subsequent parts, guaranteeing batch-to-batch consistency essential for high-volume or safety-critical applications.

The following table details the typical dimensional and geometric tolerances achievable across our protective edge fabrication processes, validated through our CMM inspection protocols. These represent our standard production capability; tighter tolerances are attainable for specific project requirements through dedicated process refinement.

| Process | Dimensional Tolerance | Angular Tolerance | Edge Radius Consistency |

|---|---|---|---|

| Precision Rolling | ±0.08 mm | ±0.5° | ±0.10 mm |

| CNC Forming (5-Axis) | ±0.05 mm | ±0.3° | ±0.05 mm |

| Laser Cutting Prep | ±0.03 mm | ±0.2° | N/A |

| Final Deburring/Finishing | ±0.10 mm | ±0.8° | ±0.15 mm |

Our integrated 5-axis CNC manufacturing and Zeiss CMM validation infrastructure forms the bedrock of reliable protective edge production. This combination ensures edges consistently meet demanding functional specifications, enhancing product lifespan and end-user safety. For complex edge geometries requiring the highest precision, our engineering team collaborates directly with clients to optimize designs for manufacturability and validate performance against application-specific criteria. Contact Wuxi Lead Precision Machinery to discuss your exact protective edge requirements and receive a detailed capability assessment.

Material & Finish Options

Material selection plays a critical role in the performance, durability, and cost-efficiency of protective edges used in sheet metal fabrication. At Wuxi Lead Precision Machinery, we emphasize matching material properties with application requirements to ensure optimal function in demanding industrial environments. The three primary materials used for protective edges—aluminum, steel, and titanium—each offer distinct advantages depending on load, environment, and longevity expectations.

Aluminum is widely favored for protective edges due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for applications where weight reduction is essential, such as in aerospace, transportation, and cleanroom equipment. The natural oxide layer provides inherent protection against environmental degradation, but when enhanced with surface treatments like anodizing, aluminum achieves superior wear and abrasion resistance. 6061-T6 and 7075-T6 are among the most commonly used aluminum alloys in our production, offering balanced mechanical properties and weldability.

Steel, particularly stainless steel grades such as 304 and 316, delivers high tensile strength and impact resistance, making it ideal for heavy-duty industrial enclosures, machinery guards, and outdoor installations. While heavier than aluminum, steel provides exceptional durability under mechanical stress and elevated temperatures. 316 stainless steel adds molybdenum for enhanced resistance to chlorides and marine environments, making it suitable for coastal or chemical processing applications. Carbon steel variants are also used when post-coating or painting is planned, though they require protective finishes to prevent rust.

Titanium stands at the premium end of material options, offering an outstanding strength-to-density ratio and exceptional resistance to corrosion, even in highly aggressive environments. It maintains structural integrity at elevated temperatures and is commonly used in aerospace, defense, and high-performance automotive sectors. While titanium has higher raw material and machining costs, its longevity and reliability in extreme conditions justify its use where failure is not an option.

Surface finishing significantly influences the functional lifespan of protective edges. Anodizing, particularly Type II and Type III (hard coat), is a key process for aluminum components. It increases surface hardness, improves wear resistance, and allows for color coding for safety or branding. Hard anodized layers can reach 50–75 µm in thickness, providing excellent protection in high-abrasion environments.

Below is a comparative overview of key material properties for protective edge applications.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | High (with anodizing) | Anodizing, powder coating | Enclosures, transport frames |

| Stainless 304 | 515 | 8.0 | Very High | Passivation, polishing | Food processing, outdoor guards |

| Stainless 316 | 570 | 8.0 | Excellent (chloride) | Electropolishing | Marine, chemical handling |

| Titanium Gr5 | 895 | 4.5 | Exceptional | Bead blasting, anodizing | Aerospace, defense systems |

Selecting the right material and finish requires a detailed understanding of operational conditions. Wuxi Lead Precision Machinery supports clients in making informed decisions by combining material science expertise with precision manufacturing capabilities.

Manufacturing Process & QC

Protective Edge Manufacturing: Zero Defects Through Process Rigor

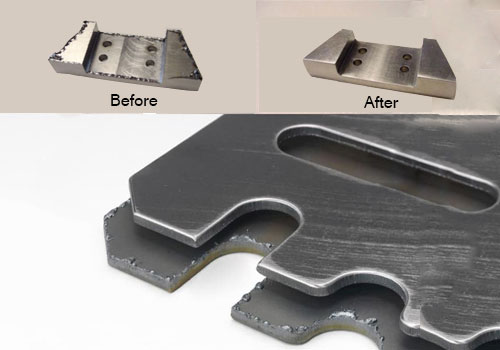

Achieving flawless protective edges for sheet metal components demands an integrated production methodology where design precision, prototyping validation, and controlled mass production converge. At Wuxi Lead Precision Machinery, we execute this sequence with uncompromising discipline to eliminate defects before they reach the customer. Protective edges are critical safety and functional elements; dimensional inaccuracies or surface imperfections directly compromise part integrity and end-product performance. Our process ensures every edge meets stringent specifications consistently.

The foundation is our advanced digital design phase. Engineers utilize 3D CAD software to model the protective edge geometry, incorporating precise bend radii, material thickness, and stress distribution analysis. Finite Element Analysis (FEA) simulates real-world forces to validate structural resilience under load. Concurrently, CAM programming optimizes toolpaths for CNC press brakes and secondary finishing equipment, minimizing springback and ensuring consistent forming forces. This phase establishes the exact dimensional and geometric targets that subsequent stages must achieve, with tolerances defined to the micron level where critical.

Prototyping transitions digital intent into physical validation. We produce initial samples using the finalized CAM programs on production-grade CNC press brakes and deburring systems. Each prototype undergoes rigorous metrology: Coordinate Measuring Machines (CMM) verify critical dimensions like edge radius consistency and angular accuracy, while surface profilometers measure roughness against Ra 0.8 µm specifications. Functional testing simulates installation and load conditions. Any deviation triggers immediate root cause analysis and program/tooling adjustment. This step is non-negotiable; it confirms process capability and material behavior before committing to volume.

Mass production leverages Statistical Process Control (SPC) to sustain zero defects. Every production run begins with first-article inspection against the approved prototype. During manufacturing, automated in-process checks occur at defined intervals: laser micrometers monitor edge radius, vision systems detect surface flaws, and torque sensors verify consistent forming pressure. Real-time SPC charts track key parameters, triggering automatic machine halts if trends approach tolerance limits. All finished parts undergo 100% visual inspection under controlled lighting and random CMM spot checks. Material traceability and full documentation accompany every batch, providing auditable proof of conformance.

This integrated approach transforms quality from an inspection outcome into an engineered result. By validating design through prototyping and embedding control within mass production, Wuxi Lead ensures protective edges deliver absolute reliability, eliminating field failures and costly rework for our clients. The specifications below define our standard for excellence.

| Parameter | Specification | Verification Method |

|---|---|---|

| Edge Radius | ±0.02 mm | CMM / Optical Comparator |

| Bend Angle | ±0.5° | Angle Gauge / CMM |

| Surface Roughness | Ra ≤ 0.8 µm | Surface Profilometer |

| Dimensional Tolerance | ±0.05 mm (critical) | CMM / Precision Micrometer |

| Burr Height | ≤ 0.01 mm | Optical Microscope |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Protective Edge Solutions in Sheet Metal Fabrication

In the high-stakes world of industrial manufacturing, the integrity of sheet metal components is only as strong as their weakest point—the edge. Exposed or unfinished edges pose risks ranging from operator injury to part failure under stress. At Wuxi Lead Precision Machinery, we specialize in engineered protective edge solutions that enhance safety, durability, and performance across your fabricated metal products. As a trusted partner in precision sheet metal fabrication, we combine advanced forming technology with rigorous quality control to deliver protective edge profiles tailored to your exact specifications.

Our expertise lies in transforming standard sheet metal components into finished, safe, and structurally reinforced products through precision rolling, hemming, folding, and edge crimping techniques. Whether you are fabricating enclosures, chassis, HVAC components, or industrial panels, our protective edge solutions prevent fraying, reduce sharpness, and improve resistance to impact and corrosion. Each process is optimized using state-of-the-art CNC press brakes, robotic handling systems, and custom tooling designed in-house—ensuring repeatability, accuracy, and compliance with international safety standards.

We understand that every client operates within unique production constraints and performance requirements. That’s why our engineering team works closely with yours to analyze material type, thickness, bend radius, and end-use environment before recommending a protective edge strategy. From low-volume prototypes to high-volume production runs, we offer scalable solutions that integrate seamlessly into your supply chain—without compromising on precision or lead time.

Our facility in Wuxi is equipped with ISO 9001-certified quality systems, real-time process monitoring, and material traceability protocols to ensure every component meets the highest benchmarks. We process a wide range of materials, including cold-rolled steel, stainless steel, aluminum, and galvanized sheets, with thicknesses ranging from 0.5 mm to 3.0 mm. All protective edge treatments are tested for edge smoothness, dimensional accuracy, and structural integrity before shipment.

Below are the key technical specifications for our protective edge fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 3.0 mm |

| Minimum Bend Radius | 0.8 x material thickness |

| Edge Finish Options | Rolled, Hemmed, Folded, Crimped |

| Tolerance (Edge Profile) | ±0.1 mm |

| Maximum Part Length | 3000 mm |

| Materials Supported | CR, SS304/316, Al5052/6061, Galvanized Steel |

| Production Capacity | Up to 50,000 pcs/month |

| Quality Standards | ISO 9001:2015, ISO 13849 (safety compliance) |

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision engineering collaborator committed to elevating the safety and performance of your sheet metal products. Our global client base relies on us for consistent quality, technical agility, and responsive support from design through delivery.

For expert consultation and customized protective edge solutions, contact us today at [email protected]. Let us help you build safer, stronger, and more reliable metal components—edge by edge.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.