Technical Contents

Engineering Guide: Pronto Parts

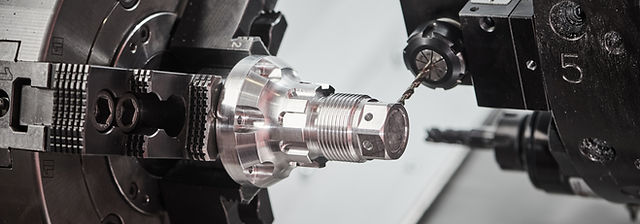

Engineering Insight Precision as the Non-Negotiable Foundation for Pronto Parts

In high-stakes custom metal manufacturing, the term precision transcends mere specification; it is the absolute bedrock of functional integrity, operational safety, and long-term economic viability. Pronto parts, demanded for rapid deployment in critical applications, cannot afford the luxury of tolerance stacking, dimensional drift, or surface imperfections. A deviation measured in microns can cascade into catastrophic system failure, unplanned downtime costing thousands per minute, or compromised safety margins. Precision engineering ensures that every component interfaces flawlessly within complex assemblies, withstands extreme operational stresses, and delivers the predicted performance lifecycle. It is not a value-add; it is the fundamental prerequisite for parts operating in aerospace, defense, medical, and advanced industrial systems where failure is not an option. Compromising on precision for speed is a false economy, inevitably leading to costly rework, scrap, delayed projects, and reputational damage far exceeding any initial time savings.

Wuxi Lead Precision Machinery operates at this uncompromising standard daily. Our engineering heritage is forged in environments where precision is measured against the most rigorous global benchmarks. We have successfully delivered mission-critical components for Olympic Games infrastructure projects, where flawless performance under intense public scrutiny and tight deadlines was paramount. Equally significant is our proven track record supplying precision parts for demanding military applications, adhering to stringent national and international defense specifications where zero defects and absolute reliability are non-negotiable requirements. This dual experience – serving the pinnacle of global sporting events and the exacting demands of defense – provides unparalleled validation of our capability to consistently achieve micron-level accuracy under pressure, ensuring your pronto parts perform exactly as engineered, precisely when needed.

Achieving this level of precision for rapid-turnaround parts demands more than advanced machinery; it requires integrated engineering rigor from design through final inspection. At Lead Precision, we embed precision into every process stage. Our experienced engineering team collaborates early to optimize designs for manufacturability without sacrificing critical tolerances. We leverage a modern fleet of multi-axis CNC machining centers, grinding systems, and coordinate measuring machines (CMMs), all maintained to the highest calibration standards. Statistical process control (SPC) is applied rigorously, ensuring consistency batch after batch. The result is pronto parts that arrive not just quickly, but with documented, guaranteed precision, eliminating the hidden costs and risks of dimensional uncertainty.

Our core precision machining capabilities consistently deliver for demanding applications as shown below.

| Capability | Specification Range | Typical Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | Ensures perfect fit in high-precision assemblies |

| Surface Roughness (Ra) | 0.1 µm to 0.8 µm | Critical for sealing surfaces, fatigue life, fluid dynamics |

| Geometric Accuracy | ±0.002 mm per 100 mm | Maintains functional alignment under load |

| Material Versatility | Aerospace Alloys, Titanium, Inconel, Stainless Steels, Tool Steels | Meets extreme environment requirements |

| Process Control | Full SPC, 100% CMM inspection on critical features | Guarantees zero-defect delivery |

Precision is the silent guarantor of performance for your pronto parts. Wuxi Lead Precision Machinery combines proven experience in the world’s most demanding sectors with rigorous process discipline to deliver components where accuracy is absolute, not approximate. Trust us to manufacture your critical metal parts with the speed you require and the precision your application demands.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for high-performance industries including aerospace, medical, energy, and automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex, high-precision components with exceptional accuracy and repeatability. Our machining centers operate with simultaneous multi-axis motion, allowing for intricate geometries, tight tolerance features, and reduced setup cycles—critical for prototyping and low-to-mid volume production runs.

Our 5-axis CNC systems are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to ensure consistent part quality and process stability. This technology supports a wide range of engineering-grade metals such as aluminum alloys, stainless steels, titanium, Inconel, and tool steels. By leveraging advanced CAM programming and adaptive machining strategies, we minimize material waste, reduce lead times, and maintain tight control over surface finishes and dimensional accuracy.

Quality assurance is embedded throughout our manufacturing workflow. Every critical component undergoes comprehensive inspection using a Zeiss Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. The CMM system provides traceable, high-resolution 3D measurement data, allowing for first-article inspection reports (FAIR), production lot validation, and full dimensional certification. Our quality management system is ISO 9001:2015 certified, and we adhere to AS9100 standards for aerospace-grade work.

We maintain strict environmental and operational controls within our CNC and inspection zones to minimize thermal drift and mechanical vibration—factors that can influence measurement accuracy and part consistency. All inspection data is documented and archived for full production traceability, supporting regulatory compliance and customer audit requirements.

The following table outlines our standard machining tolerances and achievable specifications under controlled conditions:

| Specification | Typical Capability | Notes |

|---|---|---|

| Positional Tolerance | ±0.005 mm | Meets ISO 2768-mK |

| Linear Dimensional Tolerance | ±0.01 mm | Up to 500 mm length |

| Angular Tolerance | ±0.05° | Verified via CMM |

| Surface Roughness (Ra) | 0.8 µm (typical), down to 0.4 µm | As machined; polishing available |

| Feature Size (Minimum) | 0.5 mm diameter | For milled features and holes |

| Geometric Tolerance (Flatness, Roundness) | 0.01 mm | Per ASME Y14.5 |

| Maximum Work Envelope | 1200 x 800 x 600 mm | For 5-axis machining |

Our technical team collaborates directly with engineering partners to review design for manufacturability (DFM), recommend material and tolerance optimizations, and ensure seamless transition from CAD model to certified component. With 5-axis CNC precision and CMM-backed quality control, Wuxi Lead Precision Machinery provides a reliable, high-integrity manufacturing solution for demanding applications.

Material & Finish Options

Material Selection for Precision Pronto Parts: Aluminum, Steel, Titanium & Anodizing

Material selection is a critical engineering decision in rapid precision manufacturing, directly impacting part performance, lead time, and total cost. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your application’s mechanical, environmental, and functional demands to ensure optimal “pronto” delivery without compromising integrity. Understanding core characteristics prevents costly redesigns and delays in urgent projects.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and consumer electronics for their exceptional strength-to-weight ratio and machinability. These grades offer good fatigue resistance, thermal conductivity, and inherent corrosion resistance in many environments. Aluminum’s lower density reduces inertia in moving parts and lowers shipping costs. Its extrusion-friendly nature also supports complex geometries often required in rapid prototyping and production. However, pure aluminum lacks the wear resistance needed for high-friction interfaces without surface treatment.

Carbon and alloy steels (e.g., 4140, 1018) provide superior hardness, wear resistance, and structural strength for heavy-duty applications like tooling, shafts, and load-bearing components. Stainless steels (304, 316) add essential corrosion resistance for medical, marine, and chemical processing environments. Steel’s higher density and machining complexity compared to aluminum can influence machining time and cost, but its durability in high-stress or abrasive conditions is unmatched. Selecting the correct steel grade ensures longevity under significant mechanical loads.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable for extreme-performance sectors like aerospace and biomedical implants. They offer an unparalleled strength-to-weight ratio exceeding steel, exceptional corrosion resistance across harsh media (including seawater and acids), and biocompatibility. While titanium machining demands specialized tooling and processes due to its low thermal conductivity and tendency to gall, its performance in weight-critical, high-temperature, or highly corrosive applications justifies the investment for mission-critical pronto parts.

Anodizing is the premier surface finish for aluminum components, transforming the surface into a durable, corrosion-resistant aluminum oxide layer. Type II (sulfuric acid) anodizing provides standard protection and excellent dye receptivity for identification, while Type III (hardcoat) anodizing delivers superior abrasion resistance at thicknesses typically ranging from 25 to 70 μm. Anodizing enhances part longevity without dimensional compromise when controlled precisely – a capability central to our CNC processes. Note that anodizing is exclusive to aluminum; steel and titanium require alternative finishes like passivation, plating, or喷涂 for corrosion management.

Key Material Properties Comparison

| Material Family | Common Grades | Density (g/cm³) | Tensile Strength (MPa) | Key Advantages | Typical Pronto Application Focus |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310-570 | Lightweight, high machinability, good thermal conductivity | Enclosures, brackets, drone components, heat sinks |

| Steel | 1018, 4140, 304, 316 | 7.8-8.0 | 400-1200+ | High strength, wear resistance, structural integrity | Shafts, tooling, fasteners, hydraulic components |

| Titanium | Ti-6Al-4V (Gr5) | 4.4 | 900-1100 | Highest strength-to-weight ratio, extreme corrosion resistance | Aerospace fittings, medical implants, marine hardware |

Selecting the right material and finish upfront accelerates your pronto project timeline. Wuxi Lead’s engineering team collaborates closely with clients to validate material suitability against functional requirements, ensuring rapid delivery of precision parts that perform reliably in service. Contact us for a technical consultation on optimizing your next urgent manufacturing project.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process is engineered for excellence, ensuring every custom metal component meets the highest standards of precision, consistency, and reliability. Our systematic approach—spanning Design, Prototyping, and Mass Production—is built around a Zero Defects philosophy, guaranteeing that every part delivered performs exactly as intended in your application.

The journey begins with Design, where our engineering team collaborates closely with clients to transform concepts into manufacturable, high-performance solutions. Utilizing advanced CAD/CAM software and DFMA (Design for Manufacturability and Assembly) principles, we optimize geometry, material selection, and tolerances early in the process. This phase includes comprehensive feasibility analysis, stress simulation, and thermal modeling where applicable, ensuring the design is not only functional but also cost-effective and scalable for production.

Once the design is finalized, we move to Prototyping. This critical stage allows for real-world validation of form, fit, and function. Using CNC machining, sheet metal fabrication, or precision stamping—depending on the component—we produce low-volume prototypes with the same materials and process parameters as full-scale production. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Any deviations are addressed immediately, and design or process adjustments are implemented before progression. This iterative verification ensures that the final product will meet exact specifications under operational conditions.

With prototype approval, we transition seamlessly into Mass Production. Our state-of-the-art facility in Wuxi integrates automated CNC machining centers, robotic material handling, and in-process gauging systems to maintain micron-level accuracy across high volumes. Every production run is governed by a documented quality plan, including First Article Inspection (FAI), Statistical Process Control (SPC), and 100% critical dimension checks where required. Our ISO 9001-certified quality management system ensures traceability, from raw material batch numbers to final inspection reports.

Throughout all phases, the Zero Defects mindset is enforced through continuous monitoring, predictive maintenance, and real-time data analytics. Operator training, process standardization, and root cause analysis of any non-conformance eliminate recurrence and uphold yield integrity.

The following table outlines key capabilities across our production stages:

| Process Phase | Key Technologies Used | Tolerances Achieved | Lead Time (Typical) | Quality Verification Methods |

|---|---|---|---|---|

| Design | CAD/CAM, DFMA, FEA, CFD | N/A | 3–7 days | Design Review, Simulation Reports |

| Prototyping | 5-Axis CNC, Laser Cutting, Stamping | ±0.005 mm | 7–14 days | CMM, Optical Comparator, RA Measurement |

| Mass Production | Automated CNC, Press Brakes, CMMs | ±0.01 mm (repeatability) | 15–30 days | SPC, FAI, 100% Critical Dimension Checks |

By integrating precision engineering with disciplined process control, Wuxi Lead ensures that every “pronto part” is manufactured right the first time—every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Metal Manufacturing Excellence

In the demanding landscape of industrial production, sourcing precision metal components that meet exacting specifications without derailing project timelines remains a critical challenge. Generic suppliers often lack the engineering depth or process control required for mission-critical applications, leading to costly rework, supply chain vulnerabilities, and delayed time-to-market. Wuxi Lead Precision Machinery exists to eliminate these pain points. As your dedicated engineering partner, we integrate advanced manufacturing capabilities with proactive technical collaboration, transforming complex design requirements into flawless, on-specification metal parts delivered with exceptional reliability. We don’t just fulfill orders; we solve your specific manufacturing challenges.

Our foundation is built upon rigorously controlled processes and state-of-the-art infrastructure. We operate a comprehensive suite of multi-axis CNC machining centers, Swiss-type lathes, and precision grinding equipment, all maintained to stringent international standards. This technological backbone, combined with our AS9100 and ISO 9001:2015 certified quality management system, ensures consistent output meeting the most demanding aerospace, medical, and industrial automation tolerances. The table below summarizes our core production capabilities for rapid, high-integrity metal component manufacturing.

| Capability Category | Specification Detail |

|---|---|

| Materials Expertise | Aluminum Alloys (6061, 7075), Stainless Steel (303, 304, 316, 17-4PH), Titanium (Gr2, Gr5), Brass, Copper, Inconel, Tool Steels |

| Geometric Precision | Tight Tolerances: ±0.0002″ (5μm); Surface Finishes: Ra 0.4μm to 3.2μm achievable |

| Part Complexity | Multi-axis Milling (5-Axis), Swiss Turning (Up to 32mm), Complex Mill-Turn, Precision Grinding |

| Volume Flexibility | Rapid Prototyping (72-hour lead time typical), Low to High-Volume Production Runs |

| Quality Assurance | Full CMM Inspection, GD&T Reporting, Material Certification, In-Process SPC, First Article Inspection (FAI) per AS9102 |

What truly differentiates Lead Precision is our embedded engineering approach. Our team of senior CNC programmers and manufacturing engineers engages early in your project lifecycle. We conduct thorough Design for Manufacturability (DFM) reviews, identifying potential production hurdles and cost-saving opportunities before metal is cut. This collaborative partnership minimizes iterations, accelerates validation, and guarantees the final part performs exactly as intended within your assembly. We manage the entire process – from raw material sourcing with full traceability to final packaging and logistics coordination – providing a single point of accountability for your supply chain.

Stop navigating the risks of inconsistent quality or communication gaps with distant suppliers. Partner with a manufacturer that prioritizes your engineering success as much as your delivery schedule. Contact our technical sales team directly at [email protected] to initiate a confidential consultation. Provide your project specifications, and we will respond within one business day with a detailed capability assessment, realistic lead time projection, and a clear path to achieving your production goals. Experience the Lead Precision difference: where engineering rigor meets manufacturing excellence for your most critical metal components. Let us become your trusted partner for precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.