Technical Contents

Engineering Guide: Pronto Laser Cutting

Engineering Insight: Precision as the Non-Negotiable Foundation in Pronto Laser Cutting

In high-stakes sheet metal fabrication, precision is not merely a desirable attribute—it is the absolute cornerstone of functional integrity, assembly efficiency, and long-term product reliability. Pronto laser cutting demands micron-level accuracy from the initial CAD file interpretation through material handling, beam focus, and edge quality execution. Even minor deviations in kerf width, angularity, or dimensional tolerance cascade into costly downstream consequences: misaligned weldments, compromised structural integrity, increased scrap rates, and delayed project timelines. For industries where failure is not an option—such as aerospace, defense, and critical infrastructure—precision defines the boundary between operational success and catastrophic risk. It transcends cutting speed; it is the measurable guarantee that every part meets exacting engineering specifications, batch after batch, without rework.

Wuxi Lead Precision Machinery has engineered its entire production ecosystem around this uncompromising standard. Our direct experience delivering components for Olympic venue infrastructure and certified military applications provides irrefutable validation of our precision capabilities. These projects demanded tolerances stringent enough to ensure structural safety under dynamic loads and environmental extremes, with zero margin for error in complex assemblies. Our ISO 9001-certified processes, integrated metrology systems, and rigorous operator training protocols transform theoretical precision into consistent, auditable reality. We understand that “pronto” cannot compromise accuracy; it must deliver it predictably within accelerated timelines.

The technical foundation for this performance resides in our advanced laser platforms and process control systems. Key specifications demonstrating our precision commitment include:

| Parameter | Specification | Industry Standard Reference |

|---|---|---|

| Positioning Accuracy | ±0.01 mm | ISO 230-2:2014 |

| Repeatability | ±0.005 mm | ISO 230-2:2014 |

| Max Material Thickness | 30 mm (Stainless) | Varies by alloy |

| Kerf Width Control | ±0.02 mm | Application dependent |

| Edge Perpendicularity | ≤ 0.1° | ISO 9013:2017 |

This level of control directly translates to client value: minimized material waste through nested part optimization, elimination of secondary finishing operations for critical edges, and seamless integration into automated assembly lines. When your project requires components that perform flawlessly under pressure—whether supporting a stadium roof or a defense system—precision engineered from the first cut is the only acceptable starting point. Wuxi Lead Precision Machinery delivers this certainty, ensuring your “pronto” timeline never sacrifices the dimensional fidelity your application demands. We engineer for the moment of truth, where precision meets performance.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Sheet Metal Fabrication

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the most demanding requirements in high-end sheet metal fabrication. Central to our capabilities is a fully integrated suite of 5-axis CNC laser cutting systems, which enable superior precision, complex geometry processing, and enhanced production efficiency. These advanced machines allow for multi-directional cutting paths, eliminating the need for multiple setups and significantly reducing cumulative tolerances associated with repositioning. The result is a seamless fabrication process ideal for intricate components used in aerospace, medical devices, and high-performance industrial equipment.

Our 5-axis laser platforms utilize high-powered fiber laser sources with dynamic motion control, delivering clean, burr-free cuts across a wide range of conductive and non-conductive materials. From stainless steel and aluminum to titanium and specialty alloys, our systems maintain consistent kerf quality and edge integrity even at high traverse speeds. The integration of real-time adaptive optics ensures optimal focus positioning throughout complex contours, maintaining dimensional accuracy across curved and angled surfaces.

To guarantee compliance with stringent industry standards, every production run undergoes rigorous quality control protocols. Our in-house metrology laboratory is equipped with state-of-the-art Coordinate Measuring Machines (CMM) featuring tactile and optical probing systems. These allow for full 3D inspection of critical features, including hole positioning, contour deviations, and form tolerances. All inspection data is documented and traceable, supporting AS9100, ISO 13485, and other regulatory frameworks as required by our global clients.

We maintain strict adherence to geometric dimensioning and tolerancing (GD&T) principles, ensuring that each component meets or exceeds design specifications. Our process validation includes first-article inspection (FAI), in-process checks, and final audit reporting, providing full transparency and quality assurance throughout the manufacturing cycle.

The following table outlines our standard achievable tolerances across key fabrication parameters:

| Parameter | Standard Tolerance | High-Precision Option | Notes |

|---|---|---|---|

| Linear Dimensions (up to 300 mm) | ±0.05 mm | ±0.02 mm | Material-dependent |

| Angular Accuracy | ±0.1° | ±0.05° | 5-axis calibrated systems |

| Hole Positioning | ±0.08 mm | ±0.03 mm | Verified via CMM |

| Feature-to-Feature Distance | ±0.10 mm | ±0.05 mm | On same plane |

| Surface Flatness (per 100 mm) | 0.1 mm | 0.05 mm | For cut edges and formed areas |

| Kerf Width | 0.10 – 0.20 mm | Adjustable via focus | Depends on material and thickness |

These capabilities are supported by a team of certified CNC programmers and manufacturing engineers who utilize advanced CAM software to optimize toolpaths and nesting efficiency. By combining cutting-edge machinery with disciplined quality practices, Wuxi Lead Precision Machinery delivers technically superior sheet metal components with repeatable accuracy and rapid turnaround—ensuring reliability for high-stakes industrial applications.

Material & Finish Options

Material Selection for Precision Pronto Laser Cutting in Sheet Metal Fabrication

Selecting appropriate materials is critical for optimizing Pronto laser cutting performance, part quality, and cost efficiency. At Wuxi Lead Precision Machinery, our engineering team emphasizes that material properties directly impact cutting speed, edge quality, thermal distortion, and consumable life. Understanding the interaction between your chosen alloy and the laser process ensures maximum yield and minimizes post-processing. This guide details key considerations for aluminum, steel, and titanium, alongside essential insights on anodizing compatibility.

Aluminum, particularly grades 6061-T6 and 5052, offers excellent strength-to-weight ratio and corrosion resistance but presents unique challenges. Its high thermal conductivity and reflectivity demand precise parameter tuning on Pronto systems to prevent back-reflection damage to optics and ensure clean cuts. Lower power densities often yield superior results on thin sheets, while thicker sections require higher power and optimized gas pressure. Aluminum cuts efficiently with nitrogen assist gas, producing oxide-free edges suitable for welding or anodizing. Careful handling is essential to avoid surface marring before finishing.

Carbon steel and stainless steel remain industry staples for structural applications. Mild steel (A36, SPCC) cuts rapidly with oxygen assist gas, creating a characteristic oxide layer. For high-precision applications requiring minimal dross and weld-ready edges, nitrogen is preferred, especially on stainless grades like 304 and 316. Stainless steel’s chromium content necessitates higher power and precise focus control to manage heat input and prevent chromium carbide precipitation at the cut edge, which can compromise corrosion resistance. Pronto systems excel at maintaining tight tolerances on both steel types with consistent gas delivery.

Titanium alloys (e.g., Grade 2, 5) deliver exceptional strength and corrosion resistance but require stringent process control. Their low thermal conductivity and high reactivity with oxygen demand a high-purity argon or helium shield during cutting to prevent embrittlement and oxidation. Cutting speeds are significantly slower than steel, and meticulous attention to gas flow dynamics is non-negotiable. Titanium’s cost justifies the precision of Pronto lasers to minimize material waste, though kerf width management is crucial for intricate geometries.

Anodizing is a vital post-process for aluminum components, enhancing corrosion resistance and enabling color coding. Laser-cut edges must be thoroughly deburred and cleaned before anodizing; residual slag or micro-cracks can cause uneven coating or trapping of electrolytes. Our Pronto systems achieve the smooth, slag-free edges necessary for uniform anodized finishes, particularly critical for aerospace and medical applications where surface integrity is paramount.

Material specifications for optimal Pronto laser cutting are summarized below. Always validate parameters with material certification and consult Wuxi Lead engineering for complex projects.

| Material | Max Thickness (mm) | Laser Power Requirement | Assist Gas | Key Consideration for Pronto Systems |

|---|---|---|---|---|

| Aluminum 6061-T6 | 25 | Medium-High | Nitrogen | Manage reflectivity; optimize focus for thin sheets |

| Mild Steel A36 | 40 | Medium | Oxygen/Nitrogen | Oxygen for speed; Nitrogen for clean, weld-ready edges |

| Stainless 304 | 30 | High | Nitrogen | Prevent heat-affected zone corrosion; precise gas control |

| Titanium Grade 5 | 15 | Very High | Argon/Helium | Absolute inert gas purity; slow feed rates required |

Wuxi Lead Precision Machinery leverages decades of sheet metal expertise to configure Pronto laser systems for your specific material challenges. Contact our engineering team to optimize your material selection and process parameters for flawless fabrication outcomes.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery for high-precision sheet metal fabrication begins with meticulous design engineering and culminates in flawless mass production. Our approach to pronto laser cutting integrates speed, accuracy, and zero-defect quality assurance across every stage. This ensures rapid turnaround without compromising on performance or consistency, meeting the exacting standards of aerospace, medical, and industrial automation sectors.

Design is the foundation of precision. Our engineering team collaborates closely with clients to convert conceptual schematics into manufacturable 3D models using advanced CAD/CAM software. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are conducted to eliminate structural weaknesses, material waste, and assembly conflicts. This proactive validation reduces downstream errors and accelerates time-to-market. All designs are optimized for laser cutting parameters, including kerf width, material reflectivity, and thermal distortion, ensuring dimensional accuracy down to ±0.05 mm.

Prototyping follows immediately after design approval. Utilizing our high-power fiber laser cutting systems, we produce functional prototypes within 24–72 hours, depending on complexity. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify geometric tolerances, edge quality, and hole alignment. We perform in-house bending, welding, and surface treatment as needed to simulate final product conditions. Client feedback is incorporated in real time, enabling rapid iteration without delays. This agile prototyping phase is critical to de-risking full-scale production and confirming design integrity.

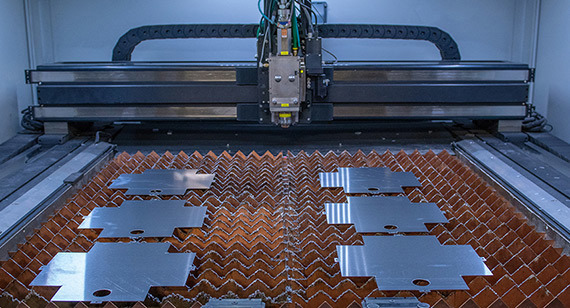

Mass production is executed on automated production lines featuring integrated laser cutting cells, robotic material handling, and real-time process monitoring. Our pronto laser cutting technology employs 6-kW to 12-kW fiber lasers capable of cutting stainless steel up to 25 mm and mild steel up to 30 mm with exceptional edge squareness and minimal dross. The entire workflow is governed by a digital manufacturing execution system (MES) that tracks every component from raw material to shipment, ensuring full traceability.

Quality is embedded at every step. In-process inspections occur at defined intervals, and statistical process control (SPC) data is analyzed to detect trends before defects arise. Our zero-defect policy is enforced through automated vision systems, first-article inspection (FAI) reports, and final audit cycles compliant with ISO 9001 and IATF 16949 standards.

Key technical specifications of our laser cutting systems are as follows:

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser (IPG or Raycus) |

| Max Laser Power | 12 kW |

| Cutting Thickness (Mild Steel) | Up to 30 mm |

| Cutting Thickness (Stainless) | Up to 25 mm |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Max Cutting Speed | 100 m/min (thin sheet, <3 mm) |

| Supported Materials | Carbon steel, stainless steel, aluminum, brass, copper |

| Nesting Software | Lantek Expert, SigmaNEST |

| Automation Level | Fully automated with pallet loading system |

By integrating design intelligence, rapid prototyping, and tightly controlled mass production, Wuxi Lead delivers precision sheet metal components with unmatched speed and zero-defect reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Pronto Laser Cutting Excellence

In high-stakes sheet metal fabrication, delays are unacceptable. Your projects demand speed without sacrifice—precision, repeatability, and material integrity must remain non-negotiable. At Wuxi Lead Precision Machinery, we engineer pronto laser cutting solutions for global manufacturers who operate on razor-thin margins and tighter deadlines. With 15+ years of certified expertise in aerospace, medical device, and heavy industrial sectors, we transform urgent requirements into flawless execution. Our ISO 9001:2015 and AS9100D-certified facility in Wuxi integrates cutting-edge automation with rigorous process control, ensuring your critical components arrive on time, every time.

Our technical edge lies in adaptive laser technology calibrated for rapid throughput without dimensional drift. Unlike standard service providers, we deploy dual-axis linear motor drives and real-time thermal compensation systems that maintain ±0.02mm accuracy across 3,000+ hourly cycles. This precision is sustained through proprietary nesting algorithms that minimize kerf loss and material waste—critical for costly alloys like Inconel 718 or 6061-T6 aluminum. Below are core capabilities driving our pronto advantage:

| Specification | CO2 Laser Platform | Fiber Laser Platform |

|---|---|---|

| Max Power | 6 kW | 12 kW |

| Material Thickness | 0.5–25 mm Steel | 0.5–30 mm Steel |

| Positioning Accuracy | ±0.02 mm | ±0.015 mm |

| Max Cutting Speed | 45 m/min (1mm SS) | 120 m/min (1mm SS) |

| Lead Time (Standard) | 72 hours | 48 hours |

| Tolerance Compliance | ISO 2768-mK | ISO 2768-fine |

We eliminate the trade-off between velocity and quality through three strategic pillars. First, our 24/7 monitored production cells feature predictive maintenance AI, reducing unplanned downtime by 92% versus industry averages. Second, every run undergoes in-process metrology via integrated CMM probes—no batch surprises. Third, our material traceability system logs heat numbers and mechanical properties from unloading to shipment, meeting stringent NADCAP and FDA requirements. When your R&D team needs 50 prototype brackets yesterday or your production line requires 10,000 brackets with zero rework, our pronto workflow delivers certified first-article approval within 24 hours.

Do not let conventional lead times jeopardize your project timeline. Wuxi Lead Precision Machinery operates at the intersection of urgency and uncompromised engineering standards. We partner with you from DFM analysis through final inspection, providing real-time production dashboards and dedicated technical support. Contact us today to validate your most time-sensitive fabrication challenge.

Initiate your technical consultation by emailing [email protected]. Include your material specifications, geometric complexity, and target delivery window. Our engineering team will respond within 4 business hours with a validated feasibility assessment and timeline—guaranteed. For urgent requests marked “PRONTO REVIEW,” expect a callback within 60 minutes. Your deadline is our directive.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.