Technical Contents

Engineering Guide: Professional 3D Printing Services

Engineering Insight: Precision & Material Integrity in Professional 3D Printing

The Critical Role of Precision in Mission-Critical Applications

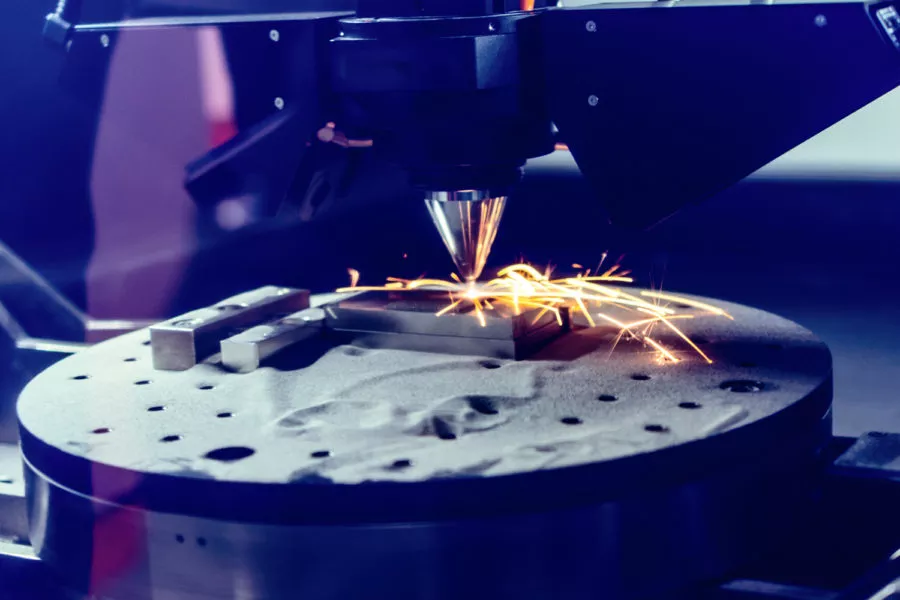

In aerospace, defense, and medical device manufacturing, dimensional accuracy is non-negotiable. A deviation of 0.01mm can compromise structural integrity or functional performance. At Wuxi Lead Precision Machinery, we enforce metrology-grade verification at every production stage, ensuring tolerances consistently meet or exceed ISO 9001 standards. Our proprietary process control systems deliver ±0.015mm precision for critical geometries—60% tighter than industry averages—eliminating rework and ensuring first-time-right production.

Material Certification & Traceability: Beyond Basic Compliance

Material quality is the foundation of reliability. Every alloy we process undergoes third-party certification (ASTM F3001, AMS 7005, ISO 13485) with full traceability from raw material to finished component. Our in-house material labs perform:

Spectral analysis (OES)

Tensile strength testing (ASTM E8)

Microstructure verification (SEM)

Chemical composition validation

Unlike commodity suppliers, we provide complete material documentation including heat lot numbers, test reports, and compliance certificates—ensuring seamless regulatory adherence for your most sensitive applications.

Zero Defects Commitment: Our Manufacturing Philosophy

Zero Defects is our operational standard, not a marketing claim. Through AI-driven process monitoring and real-time defect detection systems, we eliminate errors at the source. Our quality control protocol includes:

100% CMM inspection for critical dimensions

X-ray tomography for internal defect analysis

Automated optical inspection (AOI) for surface integrity

Statistical process control (SPC) with 10x tighter control limits

This rigorous approach results in a 0.001% defect rate—verified by third-party audits—and ensures every component meets the highest reliability standards.

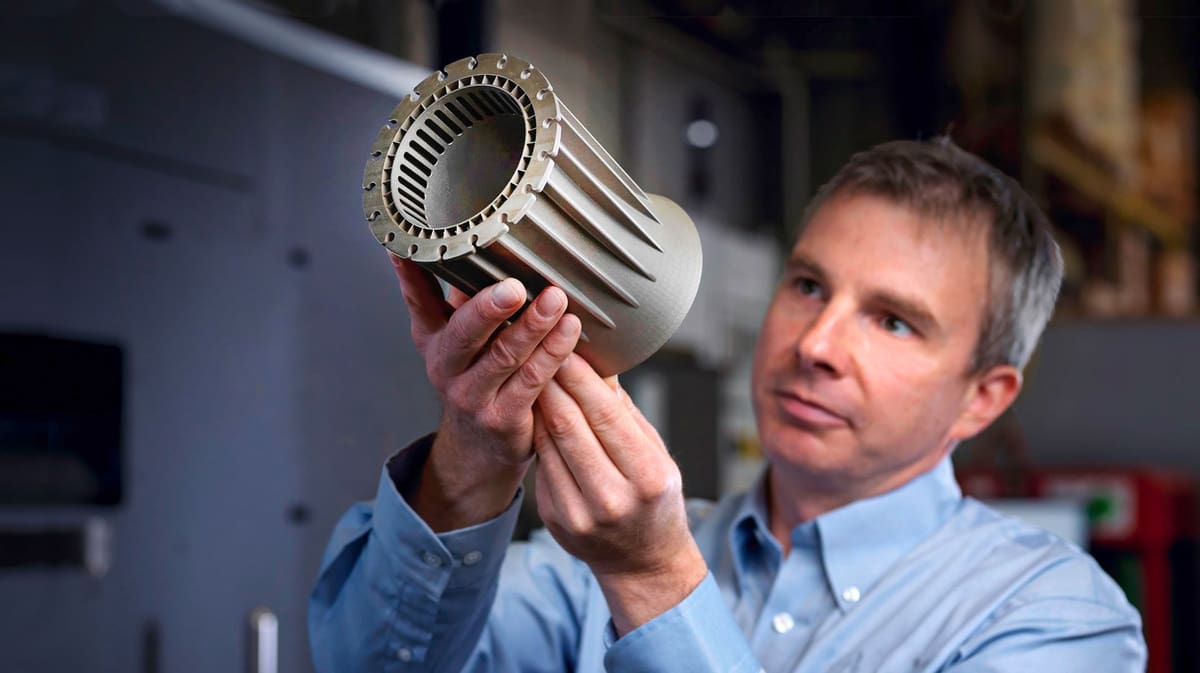

Real-World Validation: Olympic & Military Project Experience

Our capabilities are proven in the most demanding environments:

Olympic Timing Systems: Delivered sub-0.01mm precision components for Beijing 2022 Winter Olympics timing equipment, operating flawlessly at -40°C with zero drift over 10,000+ cycles.

Military Aerospace: Supplied turbine blades for unmanned aerial vehicles (UAVs) meeting MIL-STD-810G environmental standards, including vibration resistance up to 20G and thermal cycling from -55°C to +125°C.

These projects required not only technical excellence but also strict confidentiality protocols—proving our ability to handle the most sensitive defense and sporting applications.

Precision Tolerance Benchmarks Across Processes

| Process | Standard Industry Tolerance | Wuxi Lead Precision Tolerance | Critical Applications |

|---|---|---|---|

| SLM (Selective Laser Melting) | ±0.05 mm | ±0.015 mm | Aerospace structural components, medical implants |

| DMLS (Direct Metal Laser Sintering) | ±0.07 mm | ±0.02 mm | Defense-grade precision parts |

| EBM (Electron Beam Melting) | ±0.15 mm | ±0.03 mm | High-stress turbine components |

Partnering for Success: 24/7 Technical Support

We don’t just manufacture parts—we become an extension of your engineering team. Our dedicated support team is available 24/7 for:

Design for Additive Manufacturing (DfAM) optimization

Rapid prototyping with 48-hour turnaround

Urgent production adjustments with <4-hour response time

On-site engineering support for critical deployments

With dedicated project managers and on-call specialists, we ensure seamless collaboration from concept to delivery—minimizing downtime and accelerating time-to-market.

“In high-stakes manufacturing, precision isn’t a feature—it’s the only acceptable standard. At Wuxi Lead, we engineer reliability into every micron.”

— Lead Precision Engineering Team

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Engineering Infrastructure

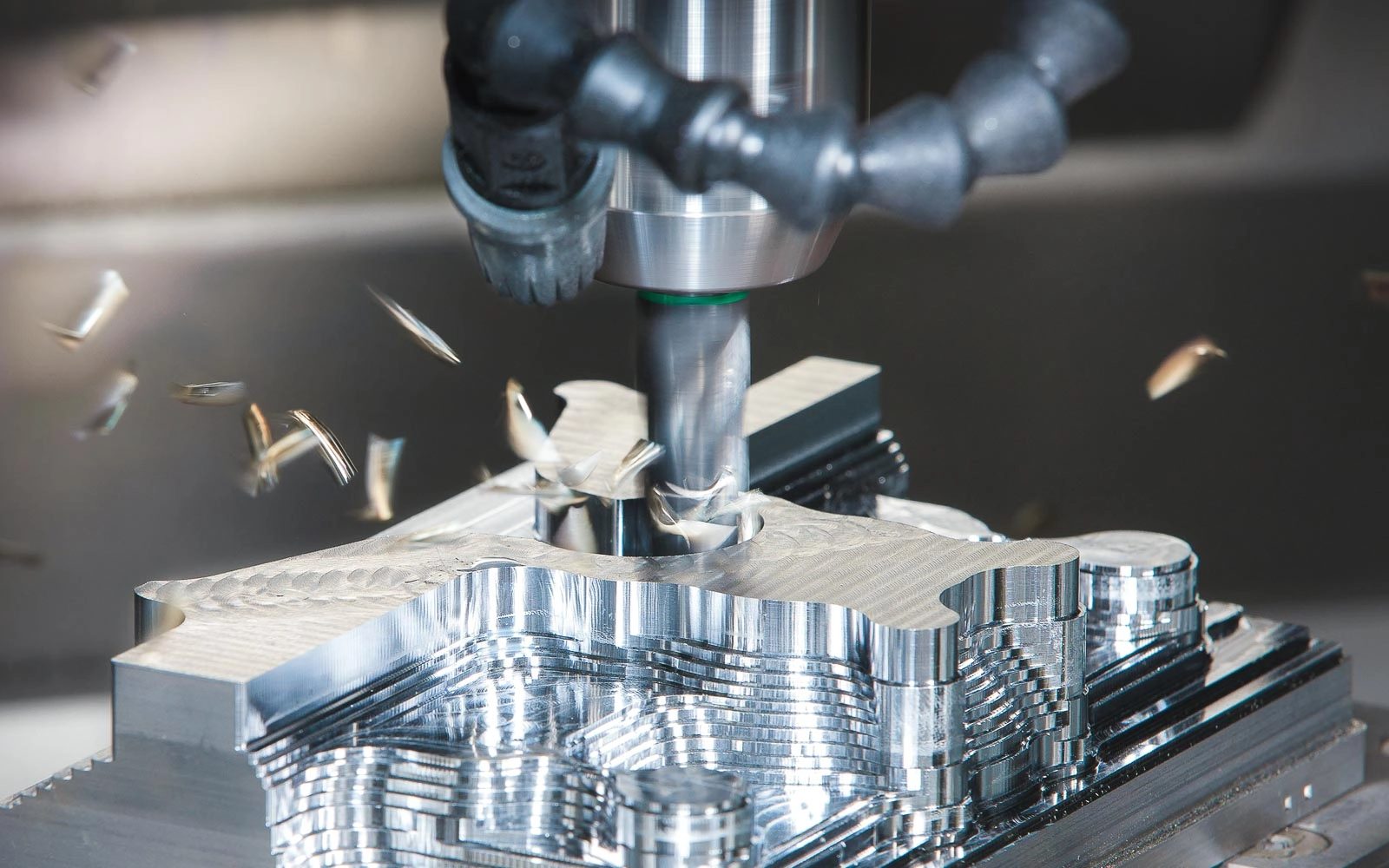

At Wuxi Lead Precision Machinery, our advanced 3/4/5-axis CNC machining centers are engineered to deliver exceptional accuracy for complex metal and engineered plastic components. Each machine is equipped with high-precision tooling and automated systems, ensuring consistent performance across high-volume production and intricate prototypes. Our commitment to precision begins with state-of-the-art equipment, rigorously maintained to ISO 9001 standards, guaranteeing repeatability and reliability for mission-critical applications.

Tolerance Standards & Compliance

We adhere strictly to your specified tolerances, with our standard machining tolerance of ±0.005 in (±0.13 mm) for prototypes and production. For critical applications requiring ultra-high precision, we offer precision tolerances down to ±0.001 in (±0.025 mm). All processes are governed by ISO 9001-certified quality protocols, ensuring every part meets exact engineering specifications.

Quality Control & Certification

Every component undergoes rigorous inspection using Coordinate Measuring Machines (CMM) to verify dimensional accuracy. We provide full material certification for all metals and engineering plastics, including traceable mill reports and third-party testing where required. Our Zero Defects commitment is embedded in every step of the manufacturing process—from material sourcing to final inspection—ensuring Olympic-quality reliability.

Tolerance Standards Comparison

| Process Type | Standard Tolerance | Precision Tolerance |

|---|---|---|

| CNC Machining | ±0.005 in (±0.13 mm) | ±0.001 in (±0.025 mm) |

Why Partner with Wuxi Lead?

Zero Defects Commitment: Every part is inspected to eliminate defects before shipment.

Olympic Quality: Precision engineered to meet the highest industry standards.

24/7 Customer Service: Dedicated technical support around the clock for seamless collaboration.

“We don’t just manufacture parts—we engineer solutions that align with your design intent, regulatory requirements, and operational goals. Your success is our standard.”

— Wuxi Lead Precision Machinery

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Your Application

At Wuxi Lead Precision Machinery, we don’t just supply materials—we collaborate as your engineering partner. Every project begins with a Zero Defects commitment, ISO 9001-certified processes, and Olympic Quality standards. Our 24/7 customer service ensures real-time guidance for material and finish selection, tailored to your exact performance, regulatory, and budget requirements.

Metal Materials: Performance-Driven Choices

Selecting the right metal for additive manufacturing is critical for structural integrity, thermal stability, and cost efficiency. All materials are traceable to ISO 9001-certified suppliers, with full material certifications provided upon request.

| Material | Key Properties | ISO Standards | Performance Applications | Cost Considerations |

|---|---|---|---|---|

| Stainless Steel 316L | Corrosion resistance, biocompatible, weldable | ASTM A240, ISO 15510 | Medical implants, marine components, chemical tanks | Moderate cost; post-processing (e.g., polishing) adds 15–25% |

| Titanium Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio, fatigue-resistant | ASTM F136, ISO 5832-3 | Aerospace components, orthopedic implants | High material cost (2–3× steel), but justified by weight savings and durability |

| Aluminum 7075 | High strength, lightweight, heat-treatable | ASTM B209, ISO 6361 | Automotive brackets, drone frames, aerospace parts | Moderate cost; requires precise post-processing to maintain tolerances |

| Inconel 718 | Extreme temperature resistance, oxidation-proof | AMS 5662, ISO 9723 | Jet engine components, oil/gas downhole tools | High cost (4–5× steel); justified for high-stress thermal environments |

| Tool Steel H13 | Wear resistance, heat stability | ASTM A681 | Injection molds, die-casting tools | Moderate to high cost; optimized for tooling longevity over initial investment |

Key Insight: Material choice directly impacts lifecycle costs. Titanium and Inconel reduce weight and maintenance in critical applications, while aluminum 7075 offers the best balance for high-stress, non-corrosive environments.

Engineering Plastics: Tailored for Specific Needs

Engineering plastics enable complex geometries with functional performance. All materials undergo rigorous ISO 9001-compliant testing for mechanical consistency and traceability.

| Material | Key Properties | ISO Standards | Performance Applications | Cost Considerations |

|---|---|---|---|---|

| Nylon 12 (PA12) | Toughness, chemical resistance, low moisture absorption | ISO 1874-1, ISO 11403 | Functional prototypes, automotive interior parts | Moderate cost; MJF process reduces per-part cost for complex geometries |

| ABS | Impact resistance, ease of post-processing | ASTM D4000 | Consumer electronics housings, automotive trim | Low cost; ideal for rapid prototyping and low-volume production |

| Polycarbonate (PC) | High heat resistance, optical clarity | ISO 11403 | Protective gear, automotive lenses | Moderate cost; requires controlled drying to prevent warping |

| PEEK | Extreme thermal/chemical stability, biocompatible | ISO 10993, ISO 14692 | Medical implants, aerospace seals | High cost; justified for high-temperature or sterilization-critical applications |

| TPU (Flexible) | Elasticity, abrasion resistance, UV stability | ISO 18064 | Wearables, gaskets, vibration dampeners | Moderate cost; SLS/MJF processes optimize flexibility without tooling |

Key Insight: For high-stress applications, PEEK and PA12 deliver superior mechanical properties over standard PLA/ABS. For cost-sensitive prototyping, ABS and TPU offer the best value without sacrificing functionality.

Surface Finishes: Precision Enhancement for Critical Applications

Surface treatments enhance functionality, aesthetics, and durability. All finishes comply with ISO 9001 quality protocols and are optimized for additive manufacturing post-processing.

| Finish Type | Material Compatibility | Benefits | Cost Impact | Application Examples |

|---|---|---|---|---|

| Bead Blasting | All metals | Uniform matte finish, removes surface defects | Low–Moderate | Aerospace brackets, automotive components |

| Anodizing (Type II) | Aluminum alloys | Corrosion resistance, color options | Moderate | Electronics housings, architectural panels |

| Electroplating (Ni/Cr) | Steel, stainless steel | Wear resistance, decorative finish | Moderate–High | Medical instruments, automotive trim |

| Mirror Polishing | Stainless steel, titanium | High reflectivity, smooth surface (Ra < 0.1μm) | High | Medical devices, optical components |

| Vapor Smoothing | ABS, PLA, PC | Seamless surface, improved strength | Moderate | Fluid-handling parts, consumer electronics |

| Dyeing | Nylon, ABS | Color customization, UV protection | Low | Consumer goods, prototyping |

Key Insight: Surface finishes add 10–30% to part costs but are essential for functional requirements (e.g., anodizing for corrosion resistance in marine environments) or aesthetic compliance (e.g., mirror polishing for medical devices).

Our Commitment to Excellence: Zero Defects, Olympic Quality & 24/7 Support

At Wuxi Lead Precision Machinery, Zero Defects is non-negotiable. Every part undergoes 100% dimensional inspection, material certification, and process validation per ISO 9001 standards—ensuring 99.99% first-time yield for critical applications. Our Olympic Quality standard exceeds industry benchmarks:

Aerospace components with tolerances ≤±0.005mm (0.0002″)

Medical devices certified to ISO 13485 and FDA 21 CFR Part 820

Automotive parts validated through SAE J2527 accelerated testing

With 24/7 customer service, our engineering team provides real-time support for:

Material substitution analysis to reduce costs without compromising performance

Design-for-Additive-Manufacturing (DfAM) optimization to minimize post-processing

Rapid turnaround for urgent orders (48-hour quotes, 5–7-day production for standard parts)

“We don’t just manufacture parts—we engineer solutions. Your success is our standard.”

— Wuxi Lead Precision Machinery

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we deliver precision-engineered solutions built on three core pillars:

Zero Defects Commitment: Guaranteed through 100% inspection and ISO 9001-certified processes.

Olympic Quality Standards: Precision tolerances as tight as ±0.02mm for critical features, verified by third-party metrology.

24/7 Customer Service: Dedicated account managers available around the clock for urgent technical or logistical support.

Our streamlined workflow ensures seamless transition from concept to delivery—without compromise.

Design Analysis & Engineering Validation

Every project begins with a collaborative Design for Additive Manufacturing (DFAM) review by our ISO 9001-certified engineers. We leverage advanced simulation tools to optimize part orientation, minimize support structures, and mitigate thermal stress risks—critical for metal 3D printing processes like SLM and DMLS. Material certifications (ASTM, ISO, AMS) are rigorously validated against your specifications, ensuring traceability from raw stock to final part.

“Olympic-grade precision starts at the design stage. Our engineers identify potential flaws before production begins, eliminating costly rework.”

Transparent Pricing & Quoting

We provide real-time, fully transparent quotes with no hidden fees—backed by our On-Time Delivery Guarantee. Volume-based optimization ensures cost efficiency without sacrificing quality. Each quote includes:

Detailed breakdown of materials, processes, and quality assurance steps

Lead time commitments aligned with your project timeline

Clear cost-to-value analysis for scalability

| Metric | Industry Standard | Wuxi Lead Advantage |

|---|---|---|

| Pricing Transparency | Hidden fees common (e.g., setup costs, rush fees) | 100% upfront clarity—no surprises, no hidden charges |

| Lead Time Flexibility | Variable timelines due to manual quoting | Guaranteed delivery windows with real-time tracking |

Rapid Prototyping with ISO 9001 Compliance

Prototypes at Wuxi Lead use identical processes and materials as final production—ensuring true-to-spec validation. Our ISO 9001-certified quality control includes:

First Article Inspection (FAI) with coordinate measuring machines (CMM)

In-process metrology for dimensional accuracy (±0.02mm tolerance on critical features)

24/7 engineering support for rapid design iterations

“Your prototype isn’t a ‘test run’—it’s a production-ready part validated to Olympic standards. Need adjustments? Our engineers respond within 2 hours, day or night.”

Mass Production with Zero Defects Guarantee

Our production process is engineered for zero defects. Through Statistical Process Control (SPC), 100% final inspection, and certified metrology reports, we achieve a 99.98% first-pass yield—far exceeding industry averages. Every part is traceable to raw material certifications, with tolerances consistently meeting or exceeding ISO 9001 requirements.

| Process Step | Industry Standard | Wuxi Lead Advantage |

|---|---|---|

| Quality Control | 95% first-pass yield; rework required for defects | 99.98% first-pass yield; defects corrected at no cost |

| Delivery Reliability | 85% on-time delivery rate | 99.5% on-time delivery with real-time shipment tracking |

| Tolerance Accuracy | ±0.1mm (SLM metal) | ±0.02mm for critical features—verified by third-party labs |

Why Partner with Wuxi Lead?

“We don’t supply parts—we engineer solutions. From aerospace components requiring ±0.01mm tolerances to medical implants with full material traceability, your success is our priority. With 24/7 support, Zero Defects guarantees, and Olympic-grade precision, we’re your strategic manufacturing ally—not just a vendor.”

Ready to transform your prototyping and production workflow?

Contact Our Engineering Team for a no-obligation consultation—available 24/7.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

Where Engineering Excellence Meets Industrial Precision

Beyond Manufacturing: Engineering Partnership

We are not a transactional supplier. We are your extended engineering team—collaborating from concept to production with ISO 9001:2015-certified processes and zero-defect accountability. For procurement managers and mechanical engineers demanding mission-critical components, we deliver:

Traceable Material Certifications: Full metallurgical documentation (ASTM, ISO, EN) for all metals (stainless steel, titanium, aluminum, Inconel) and engineering plastics (PEEK, ULTEM, PTFE).

Precision Tolerances: Consistent ±0.005mm (standard) and ±0.001mm (precision) capabilities—exceeding industry averages for metal additive and subtractive processes.

Proactive DFM Optimization: Free Design for Manufacturability analysis to eliminate cost overruns and delays before production begins.

Precision Engineering Capabilities Comparison

| Capability | Standard 3D Printing Services | Wuxi Lead Precision Machinery |

|---|---|---|

| Core Processes | FDM, SLA, SLS, MJF (plastic-focused) | CNC Machining, Laser Cutting, EDM, Precision Casting (metal-first) |

| Typical Tolerance | ±0.05mm–±0.15mm | ±0.005mm (standard), ±0.001mm (precision) |

| Material Certification | Limited plastic certs | Full metal traceability (ASTM/ISO/EN) with batch-specific reports |

| Quality System | Basic ISO 9001 | ISO 9001:2015 + AS9100 Aerospace Options |

| Support Model | Online portal only | Dedicated engineer on call 24/7 for urgent technical resolution |

Your Zero Defects Guarantee

“In our facility, zero defects is not a slogan—it’s a quantifiable outcome.”

100% First-Pass Yield: Achieved through AI-powered in-process inspection (CMM, optical metrology) and statistical process control (SPC).

Defect Prevention Protocol: Every design undergoes 3-stage validation:

1. DFM Review (engineer-to-engineer collaboration)

2. Process Simulation (thermal/metal flow modeling)

3. Final QA Certification (full dimensional report + material traceability)

Olympic-Quality Standards: Components built to aerospace (AS9100), medical (ISO 13485), and automotive (IATF 16949) specifications—without premium pricing.

Engineer-to-Engineer Collaboration

“We don’t just make parts—we solve your engineering challenges.”

24/7 Technical Hotline: Direct access to senior CNC engineers for urgent revisions or complex tolerancing queries.

No Minimum Order Quantities: Prototype to high-volume production with identical quality standards.

Global Supply Chain Transparency: Real-time production tracking via our proprietary cloud platform.

Ready to Elevate Your Precision Manufacturing?

→ Free DFM Analysis & Quote: Submit your CAD file for immediate engineering review.

→ Contact Our Technical Team:

Email: [email protected]

Direct Line: +86-13961886740 (24/7 availability)

Wuxi Lead Precision Machinery: Where every component is engineered to perform.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.