Technical Contents

Engineering Guide: Profab Sheet Metal

Engineering Insight: The Non-Negotiable Imperative of Precision in profab Sheet Metal

In high-stakes sheet metal fabrication, precision transcends mere specification; it is the fundamental determinant of functional integrity, assembly success, and ultimate product value. For critical applications spanning aerospace, defense, and advanced infrastructure, tolerances measured in microns directly impact performance, safety, and lifecycle costs. Sub-millimeter deviations in flatness, hole placement, or bend angles can cascade into catastrophic assembly failures, compromised structural integrity, or electromagnetic interference in sensitive enclosures. True precision engineering demands not only state-of-the-art machinery but also deep process mastery – understanding material behavior under stress, thermal dynamics during cutting, and the cumulative effect of sequential operations. It requires moving beyond simple dimensional compliance to guaranteeing geometric dimensioning and tolerancing (GD&T) adherence across complex, multi-stage fabrication sequences. This level of control is where theoretical capability meets real-world execution, separating commodity vendors from strategic manufacturing partners.

Wuxi Lead Precision Machinery operates at this pinnacle of precision sheet metal fabrication. Our engineering discipline is forged in the crucible of projects where failure is not an option. We have delivered mission-critical components for Olympic venue infrastructure, where structural elements demanded micron-level flatness and alignment to ensure safety and longevity under extreme loads. Similarly, our military-grade enclosures and chassis meet stringent MIL-STD requirements for EMI/RFI shielding, environmental sealing, and dimensional stability under vibration – tolerances often exceeding commercial standards by factors of two or three. This experience is not anecdotal; it is embedded in our process validation protocols, our operator training, and our relentless focus on continuous measurement and correction throughout every fabrication stage. We understand that the cost of rework or field failure for our clients far exceeds the investment in precision upfront.

Our commitment is validated through measurable capabilities across core processes. The table below reflects the baseline precision achievable on our production floor for standard profab sheet metal operations, consistently demonstrated on client projects:

| Process | Typical Capability (Stainless Steel < 3mm) | Critical Feature Control | Measurement Standard |

|---|---|---|---|

| Fiber Laser Cut | ±0.05 mm positional | Edge squareness, feature-to-feature location | CMM, Vision Systems |

| CNC Press Brake | ±0.1° angular, ±0.05 mm linear | Bend angle, bend radius, part flatness | Laser Tracker, CMM |

| Robotic Welding | < 0.2 mm distortion post-weld | Weld penetration, seam straightness | CMM, Ultrasonic Testing |

| Final Assembly | ±0.15 mm overall dimension | Inter-part fit, functional interface | CMM, Functional Gauging |

This precision is not inherent in the machines alone. It is the product of Wuxi Lead’s integrated engineering approach: rigorous material certification, adaptive process programming accounting for springback and thermal effects, real-time in-process monitoring, and final inspection traceable to national standards. When your profab sheet metal components form the backbone of critical systems, precision isn’t optional – it is the engineering foundation upon which everything else depends. Partner with a manufacturer whose precision is proven where it matters most.

Precision Specs & Tolerances

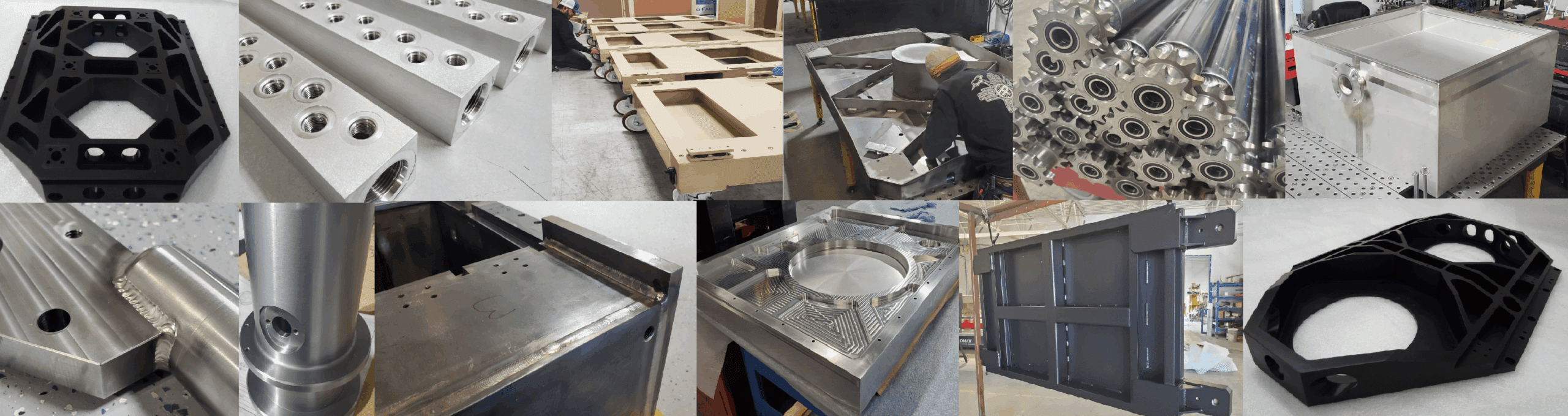

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industries including aerospace, medical, energy, and industrial automation. Our technical capabilities are anchored in state-of-the-art equipment, rigorous process controls, and deep engineering expertise, enabling us to meet the most demanding manufacturing specifications. At the core of our production floor is a suite of 5-axis CNC machining centers, which provide unparalleled flexibility in handling complex geometries and tight-tolerance components.

The integration of 5-axis CNC technology allows for simultaneous multi-directional cutting, reducing setup times and enhancing dimensional accuracy. This capability is especially critical in sheet metal applications where intricate cutouts, beveled edges, and compound angles are required without compromising structural integrity. By minimizing part repositioning, we ensure consistent precision across high-mix, low-volume, and large-scale production runs. Our machines are operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, material usage, and cycle times, ensuring efficient and repeatable manufacturing.

Quality is inseparable from capability at Wuxi Lead. Every component undergoes a structured quality control protocol, with Coordinate Measuring Machine (CMM) inspection as a standard verification method. Our CMM systems provide micron-level measurement accuracy, validating critical dimensions, geometric tolerances, and form characteristics across both prototype and production batches. This data-driven inspection process ensures full compliance with ISO 10360 standards and customer-specific requirements, with detailed inspection reports available upon request.

To support design for manufacturability, we provide clear tolerance guidelines based on our process capabilities. The following table outlines the standard and precision tolerances achievable across key fabrication operations.

| Operation | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Laser Cutting (Steel) | ±0.1 mm | ±0.05 mm | Up to 25 mm thickness |

| CNC Punching | ±0.15 mm | ±0.1 mm | For features within sheet |

| 5-Axis CNC Machining | ±0.03 mm | ±0.01 mm | Full 5-axis simultaneous |

| Bending (Press Brake) | ±0.2° angular | ±0.1° angular | With precision tooling |

| Hole Positioning | ±0.1 mm | ±0.05 mm | Relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Machined surfaces |

These tolerances reflect our commitment to precision and repeatability. All processes are supported by first-article inspection, in-process checks, and final audit protocols. Wuxi Lead Precision Machinery is equipped to handle prototypes, bridge production, and full-scale manufacturing with the same level of technical rigor, ensuring seamless scalability without compromise.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Material selection fundamentally impacts manufacturability, performance, and total cost in sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize materials that balance structural requirements with production efficiency. Aluminum, steel, and titanium each offer distinct advantages but demand specific processing protocols to achieve optimal results. Understanding these nuances ensures your components meet exacting tolerances while minimizing waste and rework.

Aluminum alloys like 5052 and 6061 dominate lightweight applications requiring corrosion resistance and weldability. However, aluminum’s lower stiffness necessitates careful toolpath planning to prevent chatter during CNC punching or bending. Springback must be compensated in tooling design, especially for tight-radius bends. For electrical enclosures or aerospace brackets, its thermal conductivity and non-magnetic properties are critical. Steel remains the workhorse for structural integrity, with cold-rolled steel (CRS) offering superior surface consistency for painted finishes and stainless steel (304/316) providing essential corrosion resistance in medical or marine environments. Note that high-strength steels increase tool wear during laser cutting, requiring adjusted feed rates and protective nozzle lenses to maintain edge quality. Titanium excels in extreme conditions—think aerospace actuators or biomedical implants—where strength-to-weight ratio and biocompatibility are non-negotiable. Its low thermal conductivity demands slower machining speeds and rigid fixturing to avoid work hardening, significantly influencing lead times and cost.

Surface finishes must align with both function and fabrication sequence. Anodizing, particularly for aluminum, enhances wear resistance and allows color coding but introduces critical dimensional considerations. The anodizing layer grows inward and outward from the base material, typically adding 0.0005–0.002 inches per surface. This requires pre-machining parts oversized by the anodizing thickness to hit final tolerances. Racking points for electrical contact during anodizing also dictate part orientation in the tank, influencing how we design bend sequences to hide these marks from critical surfaces. Avoid anodizing after precision bending; the process can alter micro-flatness on large panels.

Key Material Properties for Fabrication

| Material | Typical Thickness Range | Bend Allowance Factor | Laser Cutting Speed (1mm) | Critical Fabrication Note |

|---|---|---|---|---|

| Aluminum 6061 | 0.5–6.0 mm | 0.45–0.50 | 25 m/min | High thermal conductivity requires pierce delays to prevent dross |

| CRS 1008 | 0.8–10.0 mm | 0.35–0.40 | 20 m/min | Oil residue must be fully removed pre-painting to avoid adhesion failure |

| Stainless 304 | 0.5–8.0 mm | 0.40–0.45 | 15 m/min | Nitrogen assist gas mandatory for oxide-free edges on critical weld zones |

| Titanium Gr2 | 0.8–5.0 mm | 0.30–0.35 | 8 m/min | Tooling must use carbide inserts; HSS bits cause rapid galling |

Selecting the right material-finish combination requires early collaboration between design and manufacturing teams. At Wuxi Lead, our engineers review material datasheets against your GD&T callouts during the quoting phase to flag conflicts—such as specifying anodizing on parts with ±0.05mm flatness requirements. This proactive approach prevents costly revisions and ensures your sheet metal components perform as intended in the final assembly. Let us audit your current material specs to optimize for both function and fabrication yield.

Manufacturing Process & QC

Design: Precision Engineering as the Foundation

At Wuxi Lead Precision Machinery, the sheet metal fabrication process begins with meticulous design engineering, where precision is not an outcome but a prerequisite. Our engineering team collaborates closely with clients to translate conceptual requirements into manufacturable designs using advanced CAD/CAM software, including SolidWorks, AutoCAD, and Siemens NX. Every design undergoes rigorous DFM (Design for Manufacturability) analysis to ensure optimal material utilization, structural integrity, and production efficiency. We evaluate bend allowances, material grain direction, hole-to-edge distances, and tolerance stacking to eliminate potential defects before physical production begins. This proactive approach reduces rework, accelerates time-to-market, and ensures compliance with international standards such as ISO 2768 and GD&T (Geometric Dimensioning and Tolerancing).

Prototyping: Validating Accuracy and Functionality

Once the design is finalized, we proceed to prototype development—a critical phase in our zero-defect strategy. Utilizing high-precision laser cutting, CNC punching, and automatic bending systems, we produce functional prototypes that mirror final production quality. These prototypes are subjected to comprehensive inspection using coordinate measuring machines (CMM), 3D scanning, and first-article inspection reports (FAIR). Our quality engineers verify dimensional accuracy, surface finish, and assembly compatibility, ensuring that every component performs as intended in real-world conditions. Feedback from prototype testing is integrated into the final design, closing the loop between concept and execution. This iterative validation process is instrumental in identifying and eliminating potential failure points, ensuring that mass production begins with full confidence in the design and process.

Mass Production: Consistency at Scale with Zero Defects

With design and prototyping successfully validated, Wuxi Lead initiates mass production using fully automated, high-speed fabrication lines. Our facility integrates fiber laser cutting systems, Amada and Trumpf CNC presses, and robotic bending cells to maintain micron-level accuracy across thousands of parts. Throughout production, statistical process control (SPC) monitors key parameters in real time, enabling immediate correction of deviations. Every batch undergoes in-process inspections and final quality audits, including visual checks, dimensional verification, and material traceability documentation. Our ISO 9001-certified quality management system enforces strict adherence to zero-defect principles, minimizing scrap rates and ensuring 100% compliance with client specifications.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Tolerance (Standard) | ±0.1 mm (tighter upon request) |

| Laser Cutting Accuracy | ±0.05 mm |

| Max. Bending Length | 3,200 mm |

| Max. Punching Force | 30 tons |

| Surface Finish Options | Mill, powder coating, anodizing, plating |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

By integrating precision design, rigorous prototyping, and defect-free mass production, Wuxi Lead Precision Machinery delivers sheet metal components that meet the highest standards of quality, reliability, and performance.

Why Choose Wuxi Lead Precision

Elevate Your Production with Precision Engineering Partnerships

Wuxi Lead Precision Machinery stands at the forefront of advanced sheet metal fabrication, delivering uncompromising accuracy for industries where tolerances define success. With over 30 years of specialized expertise in aerospace, medical device manufacturing, and industrial automation, we transform complex designs into mission-critical components. Our integrated facility in Wuxi, China, operates under ISO 9001 and IATF 16949 standards, ensuring every bracket, enclosure, and structural element meets global regulatory demands. When supply chain resilience and micron-level consistency are non-negotiable, our engineered solutions mitigate risk while accelerating time-to-market.

Your projects demand more than standard fabrication—they require a strategic partner who anticipates challenges before they impact your production line. We deploy next-generation 5-axis laser systems, automated bending cells, and real-time metrology to eliminate dimensional drift across high-volume runs. Unlike conventional vendors, our engineering team collaborates during your design phase to optimize manufacturability, reducing material waste by up to 18% and preventing costly rework. This proactive approach has enabled clients like Siemens Energy and Medtronic to achieve zero-defect delivery across 500,000+ annual components.

Technical Capabilities at a Glance

Our infrastructure supports the most demanding specifications, as validated by third-party audits:

| Process | Capability Range | Tolerance Control | Materials Supported |

|---|---|---|---|

| Fiber Laser Cutting | 0.5 mm – 25 mm thickness | ±0.05 mm | Stainless Steel, Aluminum, Copper |

| CNC Punching | 0.8 mm – 6.0 mm thickness | ±0.1 mm | Galvanized Steel, Brass |

| Precision Bending | 0.5 mm – 12 mm thickness | ±0.1° angular | Titanium, Inconel, Composites |

| Welding & Assembly | Up to 3 m structures | ±0.2 mm flatness | All alloys per ASTM/EN standards |

These metrics reflect our commitment to repeatability—not theoretical best-case scenarios. Every machine undergoes daily calibration against NIST-traceable standards, with full process documentation provided for audit readiness.

Your Next Step Toward Flawless Execution

Stop compromising between cost efficiency and precision engineering. Contact Wuxi Lead Precision Machinery today to schedule a confidential capacity review. Our technical sales engineers will analyze your current fabrication challenges and deliver a customized action plan within 24 hours. Specify your project’s critical dimensions, volume requirements, and compliance needs when you reach out—we respond with actionable data, not generic proposals.

Request your no-obligation precision audit at [email protected]. Include “PROFAB SHEET METAL AUDIT” in the subject line to expedite technical resource allocation. Our team guarantees a direct response within 4 business hours, with dedicated project managers available for immediate virtual consultation across all time zones. Partner with the engineering authority that turns sheet metal constraints into competitive advantages. Your blueprint for perfection begins here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.