Technical Contents

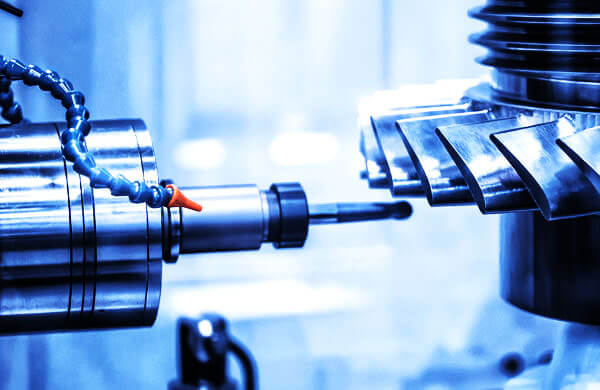

Engineering Guide: Production Cnc Machining

Engineering Insight: The Foundational Role of Precision in Production CNC Machining

Precision in CNC machining transcends mere dimensional accuracy; it is the cornerstone of functional reliability, assembly integrity, and ultimate product performance within complex manufacturing ecosystems. In high-volume production environments, even micron-level deviations compound rapidly, leading to catastrophic downstream consequences: increased scrap rates, costly assembly line stoppages, compromised product lifespan, and significant warranty liabilities. True precision engineering encompasses not only the machine tool’s inherent capabilities but also the holistic integration of thermal stability, vibration control, advanced toolpath strategies, rigorous process validation, and continuous in-process monitoring. It demands a systems approach where every element – from raw material consistency to coolant management and operator expertise – is calibrated to sustain repeatability over thousands of cycles. This unwavering consistency is non-negotiable for industries where component failure is not an option, directly impacting safety, regulatory compliance, and brand reputation.

At Wuxi Lead Precision Machinery, we engineer production CNC machining processes for this exact reality. Our operational philosophy is forged in the crucible of mission-critical applications. We have successfully delivered components meeting the extreme tolerances required for aerospace subsystems and defense platforms, where failure is unacceptable. Similarly, our contribution to Olympic-grade equipment manufacturing demanded not only micron-level precision but also the ability to replicate it flawlessly across production runs under intense time constraints. This experience validates our capability to manage the full spectrum of production challenges – from initial material validation and fixture design to real-time process adjustment and final inspection – ensuring every part conforms to the most stringent specifications, batch after batch. It is this proven ability to translate theoretical precision into sustained, high-yield production that defines our value proposition.

The table below outlines key technical specifications inherent to our production machining platforms, demonstrating the engineered foundation for sustained precision:

| Parameter | Specification | Relevance to Production Precision |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.002 mm | Ensures consistent feature location across all parts |

| Repeatability (X/Y/Z) | ±0.001 mm | Guarantees part-to-part uniformity in high-volume runs |

| Spindle Runout (TIR) | ≤ 0.0005 mm | Critical for fine surface finishes and tight tolerances |

| Thermal Compensation | Active, Multi-Zone System | Maintains accuracy during extended production cycles |

| 5-Axis Simultaneous Machining | Yes (B/T, Trunnion) | Enables complex geometries in single setups, reducing error accumulation |

Sustained precision in production is not an accident; it is the direct result of deliberate engineering choices, disciplined process control, and deep operational experience. Wuxi Lead Precision Machinery leverages its proven track record in the most demanding sectors to deliver production CNC machining solutions where accuracy, reliability, and efficiency are inseparably linked. We transform precision from a specification into a measurable, repeatable manufacturing outcome.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced production CNC machining services engineered for high-complexity components across aerospace, medical, energy, and industrial automation sectors. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling the precise fabrication of intricate geometries with superior surface finishes and minimal setup transitions. This multi-axis capability allows simultaneous cutting from five different angles, significantly enhancing part accuracy and reducing lead times compared to traditional 3-axis systems. By eliminating the need for multiple fixtures and manual repositioning, our 5-axis platforms ensure consistency, reduce human error, and support the production of highly integrated components in a single machining cycle.

Our facility operates a fleet of high-rigidity, thermally stable 5-axis CNC machines equipped with high-speed spindles, real-time tool monitoring, and automated tool changers. These systems are programmed using advanced CAM software, enabling optimized toolpaths, adaptive machining strategies, and efficient material removal rates. All programs undergo rigorous simulation and collision detection prior to execution, ensuring operational safety and dimensional fidelity. Materials routinely processed include aerospace-grade aluminum alloys, titanium, Inconel, stainless steel, and engineering plastics, all machined under tightly controlled environmental conditions to maintain precision.

Quality assurance is integral to our production workflow. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing micron-level verification of critical dimensions, geometric tolerances, and surface profiles. Our CMM inspection routines are fully programmable and aligned with customer-specific GD&T requirements, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Data from inspections are documented in detailed First Article Inspection (FAI) and Production Part Approval Process (PPAP) reports, providing full traceability for each batch.

The following table outlines the standard and precision tolerance capabilities achievable across common machining operations:

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | CMM, Micrometers |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Pin Gauges, CMM |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | CMM, Optical Comparator |

| Flatness | 0.05 mm | 0.01 mm | CMM, Surface Plate & Dial |

| Perpendicularity | 0.05 mm | 0.02 mm | CMM, Height Gauge |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | Surface Roughness Tester |

All tolerances are achievable on parts up to 800 x 600 x 500 mm in size, depending on material and geometry. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to ensure optimal machinability, cost efficiency, and adherence to functional requirements. With a focus on precision, repeatability, and full-process control, Wuxi Lead Precision Machinery sets the benchmark for high-end production CNC machining in global advanced manufacturing.

Material & Finish Options

Material Selection for Precision CNC Machining

Selecting the optimal material is critical for balancing performance, cost, and manufacturability in CNC machining. At Wuxi Lead Precision Machinery, we prioritize materials that align with your functional requirements while leveraging our advanced 5-axis CNC capabilities. Aluminum, steel, and titanium dominate high-end applications, each offering distinct advantages. Understanding their properties ensures your components meet stringent tolerances and operational demands without unnecessary expenditure.

Aluminum alloys like 6061 and 7075 deliver an exceptional strength-to-weight ratio and superior thermal conductivity. They machine efficiently at high speeds, reducing cycle times and tool wear. 6061 excels in structural applications requiring weldability, while 7075’s higher strength suits aerospace and defense components. Both accept anodizing well, enhancing corrosion resistance and surface durability. Steel variants such as 4140 and 17-4PH provide high tensile strength and wear resistance. 4140 is ideal for shafts and tooling under heavy loads, whereas 17-4PH’s precipitation-hardening properties make it indispensable for medical and aerospace parts needing post-machining heat treatment. Titanium Ti-6Al-4V, though challenging to machine due to low thermal conductivity and high reactivity, is unmatched for extreme environments. Its corrosion resistance and strength at elevated temperatures justify its use in critical aerospace and biomedical implants, despite slower machining parameters and specialized tooling requirements.

Anodizing remains the premier finish for aluminum, transforming the surface into a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing offers cost-effective corrosion and wear resistance for general industrial use, typically in 8–25μm thickness. For mission-critical applications, Type III (hardcoat) anodizing achieves 25–50μm thickness, providing exceptional abrasion resistance and electrical insulation—essential for hydraulic components or military hardware. Note that anodizing dimensional impact must be accounted for in tight-tolerance features, as the process grows the oxide layer inward and outward from the base material.

Our engineering team evaluates material grain structure, hardness, and thermal behavior to optimize CNC programs. Below is a comparative overview of key properties:

| Material | Key Grades | Machinability (Relative) | Typical Applications | Critical Notes |

|---|---|---|---|---|

| Aluminum | 6061, 7075 | Excellent (90-100%) | Aerospace frames, heat sinks | Low density; anodizing essential |

| Steel | 4140, 17-4PH | Good (60-75%) | Tooling, shafts, valves | Requires post-machining heat treatment |

| Titanium | Ti-6Al-4V | Moderate (25-40%) | Aircraft fittings, medical implants | Slow feed rates; strict coolant control |

Material choice directly impacts lead time, tooling costs, and final part integrity. Wuxi Lead’s expertise ensures your selection aligns with both performance goals and production efficiency. We collaborate early in the design phase to mitigate risks like chatter in titanium or warpage in thin-walled aluminum. Contact our engineering team to validate your material strategy against real-world CNC constraints.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes in high-volume CNC machining. Rooted in advanced manufacturing principles and strict quality assurance, our workflow seamlessly transitions from design to prototyping and into mass production, ensuring every component meets exacting international standards.

Design is the foundation of every successful production cycle. Our engineering team collaborates closely with clients to analyze CAD/CAM models, perform Design for Manufacturability (DFM) reviews, and optimize geometries for precision and cost efficiency. Material selection, tolerances, surface finishes, and critical dimensions are evaluated at this stage to prevent downstream issues. Finite Element Analysis (FEA) and tolerance stack-up simulations are employed where necessary to validate structural integrity and fit.

Once the design is finalized, we proceed to prototyping. This phase allows for physical validation of form, fit, and function. Using 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes in the intended production material—ensuring accurate representation of final part performance. These prototypes undergo rigorous inspection using Coordinate Measuring Machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage is integrated into the manufacturing program, minimizing risk during scale-up.

Mass production is executed on automated, high-speed CNC machining lines with real-time process monitoring. Each machine is calibrated daily, and tool wear is continuously tracked using in-process probing systems. Statistical Process Control (SPC) is implemented to detect deviations before they affect output quality. Our production cells operate under ISO 9001-certified protocols, with full traceability from raw material to finished component. Every batch is subjected to first-article inspection and ongoing sampling checks to maintain zero-defect objectives.

Our commitment to precision is demonstrated in the capabilities of our equipment and the rigor of our processes. The table below outlines key specifications achieved across our production floor.

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Surface Finish (Ra) | As low as 0.4 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Tolerance Range | ±0.01 mm to ±0.001 mm |

| Spindle Speed | Up to 24,000 rpm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Brass, Engineering Plastics |

| Production Volume Range | 1 – 500,000+ units annually |

From initial concept to final delivery, Wuxi Lead Precision Machinery ensures that every stage of the production process is controlled, documented, and optimized. By integrating advanced technology with disciplined quality management, we deliver high-precision CNC machined components at scale—on time and defect-free.

Why Choose Wuxi Lead Precision

Your Next Precision Partner for Mission-Critical Components

Wuxi Lead Precision Machinery stands ready to resolve your most demanding production CNC machining challenges. Global manufacturers trust our ISO 9001:2015-certified facility for complex, high-tolerance components where failure is not an option. We eliminate supply chain vulnerabilities through vertically integrated processes—from raw material sourcing to final inspection—ensuring absolute control over quality and delivery timelines. Our 15,000m² facility in Wuxi operates 24/7 with 85+ CNC systems, including 5-axis milling, multi-axis turning, and Swiss-type machines, all maintained to sub-micron accuracy standards. When your project requires tolerances down to ±0.005mm across aerospace alloys, medical-grade titanium, or hardened steels, our engineering team collaborates from DFM through first-article validation to de-risk production.

Technical Capabilities at a Glance

| Capability | Lead Precision Standard | Industry Typical |

|---|---|---|

| Positional Tolerance | ±0.005 mm | ±0.012 mm |

| Material Range | Titanium, Inconel, PEEK, 440C | Standard steels only |

| Max Work Envelope | 1,200 x 800 x 650 mm | 800 x 500 x 400 mm |

| Surface Finish (Ra) | 0.4 µm | 1.6 µm |

| Quality Certification | ISO 9001, AS9100, NADCAP | ISO 9001 only |

Unlike conventional machine shops, we deploy proprietary in-process gauging systems that reduce scrap rates by 37% and accelerate time-to-shipment. Our engineers utilize Mastercam and Siemens NX for seamless CAD/CAM integration, preventing costly design-to-manufacturing gaps. For regulated industries, we provide full material traceability with PMI reports and first-article inspection packages compliant with AS9102 or PPAP Level 3 requirements. This operational rigor translates to 99.2% on-time delivery for clients across aerospace, energy, and medical device sectors—proven through 12 consecutive years of zero critical non-conformances.

Partnering with Lead Precision means accessing engineering expertise that anticipates problems before they reach your production line. We invest in predictive maintenance analytics and staff cross-training to ensure machine uptime exceeds 95%, directly protecting your program schedules. When your project faces tight deadlines or evolving specifications, our agile workflow accommodates rapid design iterations without compromising precision.

Initiate your precision manufacturing partnership today. Email [email protected] with your component drawings and target volumes. Our applications engineers will respond within 24 hours with a detailed capability assessment and actionable timeline. For urgent RFQs, include “Priority Review” in the subject line to trigger expedited evaluation. Trust Lead Precision to transform your most complex CNC machining requirements into certified, on-specification reality—where engineering excellence meets uncompromised delivery. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.